Professional Documents

Culture Documents

CU Triaxial Tests Using ELE DS7 Software

Uploaded by

Juan Daniel Garcia VargasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CU Triaxial Tests Using ELE DS7 Software

Uploaded by

Juan Daniel Garcia VargasCopyright:

Available Formats

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

SECTION I: SYSTEM PREPARATION

A. POWER AND MAIN SUPPLY SETTINGS (See Figure A for Master Control Panel)

1. Press the “Power Display” power button to the “ON” position. After Stabilization (approx. 15

min.), push the “Tare” button to zero the display.

2. Turn on the laboratory compressed air supply. Viewing the “Pressure Supply” gauge, adjust the

“Master Regulator” until the desired maximum supply pressure is reached. The displayed pressure

should be about 10 psi more than the required cell pressure. Do not exceed 150 psi (1034 kPa)

pressure.

3. Turn on the laboratory water supply.

B. FILLING OF THE DE-AIRED WATER TANK SYSTEM

1. Turn the “De-Airing Water Control” valve to the “Fill” position (Figure 1).

2. When the tank water level is about 1” from the top (Figure 2), turn the “De-Airing Water Control”

valve to the “vent” position (Very Slowly to allow water to drain).

Figure 1: De-Airing Water Control Valve Figure 2: De-airing Water Tank

C. DE-AIRING THE WATER TANK

1. Turn on the laboratory vacuum supply. The associated amount of vacuum available to your system

will be displayed on the “Vacuum Supply Gauge”.

E. Steward 1 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

2. Turn the “De-Airing Water Control” valve to the “Vacuum” position (Figure 1).

3. Apply vacuum to the De-Airing Water Tank for 30-45 minutes and, at the same time, gently shake

the tank occasionally to enhance the removal of air from water. Some air bubbles may remain and

will be removed by pressure during the test.

4. Turn the “De-Airing Water Control” valve to the “vent” position and equalize the pressure within

the de-airing chamber using the pressure relief valve at the top.

D. FILLING THE BURETTE CHANNELS

1. Set all valves on the test cell to the closed position.

2. Set the “De-Airing Water Control” valve to the “Pressure” position.

3. Set the “Burette/Annulus Input Control” valve to the “vent” position.

4. Set the “Annulus Control Switch” to the “open” position (Normal).

5. Slowly turn the “Burette/Annulus Flow Control” valve to the “Fill” position. Be careful not to fill

the burette too rapidly to cause turbulence and create air bubbles within the water.

6. When the water reaches the desired level (up to the 2 mL measurement), turn the

“Burette/Annulus Flow Control” valve to the “Cell Operate” position. Do not overfill. Water

should not be allowed to flow into the pressure tube at the top.

7. Repeat the above steps until all burette channels being used are filled to the desired level.

8. Set De-aired Water Control valve to “VENT” position and equalize the pressure within the de-

airing chamber using the pressure relief valve at the top.

Note: If the water level in the “De-Aired Water Tank System” drops to about 2” from the bottom, repeat

the filling and de-airing procedures described in section B and C.

E. DE-AIRING THE BURETTE CHANNELS

1. Remove the tube with the quick-disconnect from the panel below the burette that will be de-aired.

2. Turn on the laboratory vacuum supply. The associated amount of vacuum available to your system

will be displayed on the “Vacuum Supply Gauge”.

3. Set the “Burette/Annulus Input Control” valve for each channel to the “vacuum” position. Under

normal operating conditions, the de-airing process should be completed in about 10-20 minutes.

4. After completion, set all “Input Control” valves back to the “vent” position very slowly.

SECTION II: SAMPLE PREPARATION

This section will offer three different methods of sample preparation (See Figure 3 for final prepared

Sample).

- Undisturbed sample from sample tubes

- Remolded made from a bulk sample, typically utilized for demonstration or research purposes.

- Loose sand samples, typically utilized for demonstration or research purposes.

E. Steward 2 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

Figure 3: Prepared Undisturbed or Remolded Samples

F. UNDISTRUBED SAMPLE PREPARATION

1. Trim the sample to be tested using a Miter Box.

2. Use the trimmings to obtain the Moisture Content of the sample before test.

3. Measure the height and diameter of the sample at various locations to get an average value.

4. Measure the weight of the trimmed sample before installing the membrane.

5. Install a membrane onto the suction membrane device and apply a vacuum to the tube to pull the

membrane to the walls of the device.

6. Place the membrane over the sample and remove the suction device.

G. REMOLDED SAMPLE PREPARATION

1. Obtain a soil sample that has been passed through a sieve to break up clumps (#40?)

2. Moisture condition the sample to near optimum moisture content for a few hours

3. Lubricate and clamp a mold of the appropriate size

4. Tamp the sample into the mold using the appropriate energy and amount of lifts as prescribed by

the requirements.

5. Carefully remove the sample from the mold and trim the top and bottom using a miter box

6. Measure the height and diameter of the sample at various locations to get average values.

7. Measure the weight of the trimmed sample before installing the membrane.

H. LOOSE SAND SAMPLE PREPARATION

The steps in this section may be more advanced and require experience with the equipment

prior to attempting.

1. Place the loose sand into a container and obtain the weight of the container with the sand

E. Steward 3 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

2. Bleed air from all lines and then close all valves on the test cell.

3. Install a membrane to the base pedestal of the test cell using 2 o-rings on the grooves. Be careful

to install the membrane with no wrinkles or folds

4. Place a saturated filter paper atop a saturated porous stone and install inside the membrane atop

the base pedestal with the filter paper up.

5. Place grease along the o-rings around the base pedestal and lubricate the edges of the split mold

former to help create a seal.

6. Install the split mold former around the membrane and tighten with a clamp.

7. Fold the top of the membrane around the top of the mold former and place 2 o-rings around the

folded-over membrane. Be careful to arrange the membrane with no folds.

8. Install the tube from the split former nipple to the auxiliary vacuum supply on the Master Control

Panel to create a suction of the membrane to the walls of the mold. Remove any wrinkles and

arrange the membrane to be smooth against the wall.

9. Measure the inside height of from the top of the filter paper to the top of the mold

10. With about 3-5 psi on the back pressure line, use the rear bottom bleed valve to fill the inside of

the membrane with de-aired water about one-third full (~ 2 in)

11. Using a spoon or small scoop, pour the sand into the water in the membrane up to about a half

inch form the top of the mold. Be careful not to lose any sand that does not fall into the

membrane.

12. Open the rear bottom valve to install additional water for all sand to be saturated. Avoid standing

water at the top. Gently tapping the sides of the mold can help the sand and water migrate

together

13. Continue to pour sand and water until the saturate sand reaches just below the top of the mold

(about the same distance as the thickness of the porous stone)

14. Measure the estimated average height of the top of the sand to the top of the mold and subract that

value from the measurement obtained in #H-8 to be the sample height.

15. Place a saturated filter paper atop a saturated porous stone and install atop the sand with the filter

paper down.

16. Remove the 2 o-rings from the membrane at the top of the mold. The vacuum suction will likely

be lost at this time and now remove the tube form the auxiliary vacuum connection on the Master

Control Panel.

17. Install the top cap on top of the porous stone and fold the membrane over the sides of the top cap.

Install 2 o-rings around the membrane into the grooves of the top cap.

18. Connect the tube from the extra valve (make sure the valve is closed) at the top of the Back

Pressure transducer box to the auxiliary vacuum connection on the Master Control Panel (Figure

4).

Figure 4: Vacuum valve and tube on Back Pressure Box

19. Slowly open the top BP valve with the vacuum and watch the water come from the top cap

through the drainage line and into the tube from the valve. Once water is about 3-4 inches into the

E. Steward 4 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

tube from the valve, close the valve with the vacuum. Note the value on the software screen of the

negative pressure on the BP transducer.

20. Remove the clamp and the split mold from the sample, careful not to damage the membrane or the

sample.

21. Place the test cell chamber over the sample and tighten the locking rods.

22. Place the piston slightly above the top cap and lock the piston into place.

23. Open the bleed screw at the top of the cylinder and attach the tube marked “CP” to the connection

marked “water” located at the bottom left of the panel. Open the valve on the triaxial cell marked

“Cell Pressure”. This will gradually fill the cell. Control the flow using the valve marked CP on

the Triaxial cell.

24. Once all the air is removed from the chamber, close the CP valve and relieve the pressure from the

tube and place back into the CP connection on the panel.

25. Close and tighten the top bleed screw on the Triaxial cell

26. From the negative pressure observed in #H-18, apply a similar positive pressure to the cell

pressure transducer and open the cell pressure valve (typically 12-14 psi).

27. Slowly open the back pressure line to relieve the internal negative pressure within the sample to

equalize the pressure back to atmospheric pressure.

28. Start the Cell pressure increment Saturation stage with the current pressure on the sample and go

up from that pressure.

29. Continue testing with step I.

SECTION III: SOFTWARE AND TEST SAMPLE SETUP

I. CU TRIAXIAL TEST SOFTWARE START

1. Double click on the software icon “DS7” on the desktop.

2. Click on the button “New Test”.

3. Select the machine that will be used for the test “ --Triaxial Consolidated Undrained/Drained

Tests-AS”.

4. Click on the button “Select a Machine for the Test”.

5. Fill in the spaces in this window and click on the button “OK” to the right side of the screen. The

fields marked * by their side can not be left blank and the characters \ / *. , : ; @ # ~ ? can not be

used while filling up the spaces (Note for “B” and “C” specimens, use “Load Existing Sample”

button for specimen combining).

6. In the window “Tests in Progress” make sure that you select the machine that you want to run and

then click on the button “OK” at the bottom of the screen.

J. TEST INITIALIZATION - SOFTWARE

1. In the “Test Monitoring” window, make sure that all the test data shown in the upper left box is

correct.

2. Click on the button “Start Test Stage” located to the upper right side of the screen.

3. In the next window select “Test Initialization” and click on button “OK”.

4. In the “Test Initialization” window, enter the previously measured sample Diameter, weight, and

height.

5. The bulk density of the sample will be calculated automatically by the software.

6. The information regarding the Membrane Thickness and Young’s Modulus are default values and

may not be changed, unless using a different kind of membrane around the sample. Enter paper

side drains information if used (Perimeter).

7. Enter “Cell Pressure Increments Steps”, which is the increased pressure used during each B-value

check (Normally 50 kPa unless directed by client differently).

8. Enter “Back pressure Differential”, which is the pressure differential between the cell pressure and

the back pressure during back pressure saturation (Normally 5 kPa unless directed by client

differently).

E. Steward 5 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

9. Enter the “Required Effective Stress” which is the pressure difference during the consolidation

stage between the cell pressure (σ3) and the back pressure (u) after the saturation of the sample

(This figure will change with specimen A, B & C) Normally this figure is doubled e.g. 100 (A),

200 (B), 400 (C) or what is required by client.

10. After entering all data click on the green button “Confirm Setup Data”.

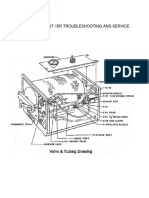

K. TEST INITIALIZATION – SAMPLE AND TEST CELL (see Figure B for more detail

regarding cell)

1. Using a small pressure on the back pressure lines from the Master Control Panel, flush the rear

bottom valve, Back Pressure line, and Pore water pressure to the sample on the cell

Note: No air must be present in the Back Pressure pipe lines.

2. At this time, make sure the piston within the VCU water chamber is near the middle. To move the

piston, move the left switch in the direction (UP or DOWN) the piston needs to move and open the

Back Pressure valve on the test cell to allow water to flow through the top cap into a container

until the piston is at the appropriate location. Once this is completed move the switches to Bypass

(horizontal) on the left switch and “Off” (or down) on the right switch)

3. Remove the pressure and open the bleed screws on the transducer boxes on the CP, BP & PWP

pressure transducers to atmosphere and press the red button to zero readings to correct zero

datum.

Note: the PWP and the flushing valve opposite will now be closed and not be opened again until

the test is over.

4. Important Note! No leaks are tolerated with the CU test so check the membrane carefully for

damage before fitting (replace membranes if suspect).

5. Carefully place the sample on the Triaxial cell base pedestal including upper and lower porous

discs (with filter paper on the discs) and fit side drains if required.

Note: Porous stones should be de-aired by boiling in water or vacuum

6. Place the top pressure pad and use black O-rings to secure the membrane around the base pedestal

and top pressure pad.

7. Ensure the o-ring around the cell is clean and greased to help seal the chamber (Figure 5).Place

the test cell chamber over the sample and tighten the locking rods.

Clean and grease Chamber

O-ring

Figure 5: Cell Bottom with Chamber O-ring

8. Lower the piston slightly above the top cap and lock the piston into place.

9. Open the bleed screw at the top of the cylinder and attach the Cell Pressure tube to the connection

marked “water” located at the bottom left of the panel. Open the valve on the triaxial cell marked

“Cell Pressure”. This will gradually fill the cell. Control the flow using the Cell Pressure valve on

the Triaxial cell.

E. Steward 6 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

10. Once all the air is removed from the chamber, close the CP valve and relieve the pressure from the

tube and place back into the CP connection on the panel.

11. Close and tighten the top bleed screw on the Triaxial cell

12. Again, click on the green button “Confirm Machine Setup”.

13. This will bring you back to the “Test Monitoring” window.

SECTION IV: CU TRIAXIAL TESTING

L. SATURATION STAGES

1. Cell Pressure Increment (B-Value determination)

a. Click on button “Start Test Stage” located to the upper right side of the screen.

b. Select “Saturation (Cell Pressure Increment)” and press OK.

c. Make sure that initial pressures are correct. First time through the CP should be at

approx. zero or just above (If CP is above 5 kPa then remove excess and resample).

d. All valves should be closed on the Triaxial cell, except the valve between the sample and

the Pore Water Pressure transducer should be open. The VCU should have the left switch

on Bypass (horizontal) and the right switch on OFF (down)

e. Adjust cell pressure (shown at bottom of screen) to required target pressure using the air

regulator valve on the Triflex panel. Do this by increasing the regulator for the burette to

the pressure required and moving the switch to “Pressure” on the Master Control Panel.

f. Press “Continue” and then press “start countdown” to begin the countdown. After zero,

immediately open the cell pressure valve on the Triaxial Cell.

g. Watch for the B-value and pore pressure graph to stabilize

i. IF B-value is less than 0.95 then press “End Test Stage” button and go to step

“2. Back Pressure Increment”

NOTE: Repeat steps L-1 and L-2 until B-value reaches 0.95 or larger

ii. IF B-value is 0.95 or above then press “End Test Stage” button and go to “M

CONSOLIDATION STAGE”

2. Back Pressure Increment (Back Pressure saturation)

a. Click on button “Start Test Stage” located to the upper right side of the screen.

b. Select “Saturation (Back Pressure Increment)” and press OK.

c. The Volume Change Unit transducer must be turned “online”. To do this, move the left

switch in the direction of positive polarity (Most are UP for positive and marked

“Saturate”) and move the right switch to horizontal (Most marked “Online”) (See Figure

C for details on VCU)

d. Using the BP air regulator on the Triflex panel adjust the BP (shown at bottom of screen)

to Back Pressure Target required.

h. Press “Continue” and start count down immediately open the BP pressure valve on the

Triaxial Cell. (Note! The cell pressure valve must be open and the required difference

between the CP and BP maintained with the CP always higher of the two).

e. Carefully study the Volume change graph on the left side of the screen as the reading

should be increasing in value positively, yet the plot should have a negative slope. When

the volume measurement graph has a zero slope and the pore pressure is stabilized the

stage can be stopped by pressing “End Test Stage” button.

NOTE: The Pore water pressure will eventually equal (or be very close to) the Back

Pressure. The sample can continue to accept water (increase in volume) well after the

stabilization of the pore water pressure.

f. Return to section 1. Cell Pressure Increment of the Saturation Stage to recheck the B-

value. (It might take 2, 3 or more back pressure stages to arrive at a suitable B-value of

.95 or above.

E. Steward 7 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

Important Note: Never go directly to the CONSOLIDATION STAGE from this Back

Pressure Saturation stage. Always check the B-value first!

M. CONSOLIDATION STAGE

1. Click on button “Start Test Stage” located to the upper right side of the screen.

2. Select “Consolidation” and press OK.

3. The Back Pressure valve should already be closed. Adjust Cell Pressure air regulator to bring the

Cell Pressure to the required target which should then give the required Effective Stress.

4. Open the cell pressure valve slowly to dissipate excess PWP. Wait for the PWP reading at the

bottom of the screen to stabilize. (This should take around 5 to 30 mins depending on the type of

soil being tested).

5. Change the piston direction on the VCU to the opposite of the Saturation stage (typically DOWN)

and the right switch should be Horizontal (marked “on-line")

6. Press the “Continue” button and start the countdown. After the Countdown, immediately open the

Back Pressure valve on the Triaxial cell.

7. The volume change readings should have a positive value, yet the plot should have a negative

slope (This will be a conventional 1-dimensional consolidation curve). Wait for the volume

change reading to stabilize with a zero slope to complete the consolidation stage

8. Then press the “End Test Stage” button to officially end the consolidation stage.

N. COMPRESSION STAGE

1. Make sure Tritest Load frame is switched on at the back of the frame.

2. Click on the button “Start Test Stage” located to the upper right side of the screen and select the

“Compression” option and press OK.

3. As the test is Undrained the Back Pressure valve must be closed. For Drained test, leave this

valve open.

4. Confirm consolidated length (the figure shown is calculated based on the volume change during

saturation and consolidation).

5. Follow screen instructions how to calculate correct platen speed for shearing based on the time

factors indicated from the consolidation plots during the consolidation stage.

6. Enter the required platen speed into the load frame speed entry option by entering the value and

pressing the left facing arrow button at the bottom right of the keypad.

7. The logging rates shown are as required by ASTM. They can be changed by the user if required.

The figures shown are the rate at what the system will be logging transducer readings throughout

the compression stage as the LVDT attached to the test frame is moved. The results will be taken

at 0.1% up to 1% and then at every 1 % there after. (ELE recommend 0.3% after 1% mark)

8. With the load measuring device not touching the sample press the red button to RESET FORCE

reading at the bottom of the screen and then press the fast up arrow on loading frame so the top

cap on the sample comes in to contact with the load measuring device. (20 to 30 Newton’s are

recommended).

9. Set up the axial strain transducer onto the flat plate on the top of the cell chamber, with the LVDT

piston pushed in slightly and then press the red button to RESET the displacement reading at the

bottom of the screen.

10. Make sure the PWP is stabilized and press “Continue” and start the countdown. At zero after the

countdown press the “RUN” button on the load frame.

11. Monitor the stress vs. strain graph and see when the sample fails which can be 1 to 3 days,

depending the type of soil.

Note: Do not allow PWP to rise to fast. If the PWP does start race up then slow the loading frame

platen speed down accordingly. Speed can be changed on the fly.

12. Once sample failure has been determined or the axial strain has reached the appropriate

percentage, press “End Test Stage” and “Stop” button on the Tritest Load Frame.

E. Steward 8 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

O COMPLETING THE TEST ON THE SOFTWARE

1. On the VCU, move the left piston switch to horizontal position labeled "Bypass" and the right

switch to vertical position marked "off".

2. Click on “Start Test Stage” button.

3. Select “Final Measurements” and click on OK.

4. Enter all parameters that are available at this time. These values can be left blank until Analysis

occurs.

5. Click on green button “Confirm Data”.

6. Click “OK” on the window stating “FINAL STAGE IS NOW COMPLETE. PRESS OK TO

STORE THE TEST DATA READY FOR ANALYSIS OR PRESS "CANCEL" TO PERFORM

FURTHER STAGES”.

7. Save the Raw data obtained from the test to the directory of your choice. The software will prompt

to an organized default directory which is the best option.

8. If required press “Exit” to return to Windows.

P REMOVING THE SAMPLE AFTER TESTING

1. Use the button on the keypad of the load frame to lower the sample away from the load piston

and return the platen to the start position, ready for the next test.

2. Open the Back pressure valve. Turn the CP and BP “Set Pressure Control” knobs on the Master

Control Panel counter counterclockwise to reduce both pressure supplies. Be sure to reduce the

pressures in a way that the cell pressure is always a higher value than the back pressure to ensure

the sample does not deteriorate further.

3. Close the back pressure valve on the cell and move the Back Pressure and Cell Pressure

Burette/Annulus Input Control valve to "Vent" position.

4. Remove the quick disconnect tube from the Cell Pressure location on the Master Control panel

and place in a drain or bucket (if the disconnect fitting is a locking fitting, attach the female

locking disconnect fitting to allow flow)

5. Open the top bleed screw on the cylinder in the load cell assembly.

6. Open the valve on the test cell marked “Cell Pressure”. This will drain the water from the cylinder.

7. Unscrew the three rods from the sides of the cylinder and take off the cell cover.

8. Carefully remove the top O-rings, top cap, and porous stones from the sample. Fold the

membrane down and take a picture of the failed sample, if desired.

9. Carefully remove the sample from the base pedestal and membrane and place in a container

appropriate for moisture content in an oven. Be sure to remove the filter paper material from both

ends of the sample.

10. Obtain a wet weight with the sample and the empty container weight. Place sample in oven

according to ASTM Moisture Content standards.

11. Close the Cell Pressure valve on the cell and place the Cell Pressure tube connection back into the

Cell pressure location on the Master Control panel.

12. Thoroughly clean all residue and water from the test around the cell. Store the test cylinder with

the bleed screw open and the bottom able to allow air to flow and the cell to dry.

13. Clean the membrane with water and pat dry, inside and out. Once dry, the membrane can be

stored in a sealed bag with baby powder to preserve the material until the next use. Discard

membranes with any distortion or holes.

Q ANALYSIS AND REPORT PREPARATION

E. Steward 9 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

1. Select “Analysis & Reports” and press the Browse Directories button to identify the data to be

processed (i.e. the raw test data has a .ini suffix). Press the "Select Cur Dir" button to identify the

test folder.

Note: the Open button is not valid in this dialog box

2. In the Raw Data Files window, select the raw data file to be analyzed.

3. Now the same data cells as the Final Measurements stage regarding wet and dry weights as well as

initial moisture content, lab temperature, specific gravity, must be filled.

4. Press the "Analyse Test" button and follow any instructions on the screen. The result will be a

processed data file (.dat file) and it will be listed in the Processed Data Files window. This file

contains all the raw test data plus the processed data and is used by DS7 as the data source for

writing reports.

5. Unlike the data acquisition procedure, data analysis may be carried out sometime after the

physical test and may be performed on a different PC from that used for the data acquisition. This

allows analysis and reporting to proceed on an office PC, perhaps in a different location from the

lab, so that lab PC’s may be used for continuous testing and not occupied with the post testing

operations such as data manipulation and generating reports. This facility is especially convenient

if the lab and office PC’s are networked. To analyze the data remotely, transfer the raw data (.ini)

file to a PC with DS7 software installed and perform the analysis and report generation in the

usual way.

6. Raw data files (.ini files) may be re-analyzed at any time. For example if the raw data contains an

erroneous value, it can be corrected in the “Edit Raw Data” section in the “Monitor Test” section

of the software and the file re-analyzed, as long as this is consistent with the test house’s policy on

data integrity and trace-ability. Clearly, it is valid to correct some values, such as an incorrectly

entered lab temperature etc. The final responsibility for the accuracy of results, however, must

always rest with the test house.

7. After successfully analyzing your raw data files, you are ready to produce a report. You should be

seeing the raw data files (.ini files) listed in the box entitled Raw Tests Analysis and a list of the

analyzed data files in the “Processed Data Files” box.

8. Select the .dat file you would like to analyze and select the "Write Test Report" button. You will

now be offered a choice of report file name and location, but ELE recommends that you use the

default name supplied by DS7, as this will keep the file names consistent and all files associated

with the job in one place. Click Save to continue and DS7 will load MS Word and fill in the report

template with the test results. If the report already exists, you will be offered the choice of over-

writing the file or choosing a new name.

Note: Do not attempt to operate MS Word manually whilst the report is being compiled.

9. The DS7 Test Analysis screen will show again after the report has been completed. At this stage,

you may make any changes to the format of the report using MS Word in the normal way.

10. Triaxial tests require the results from more than one specimen from the same sample in order to

produce cohesion and friction angle (c' and ϕ). After 2, 3, or 4 test specimens are tested, the Mohr

Circle plot must be generated.

11. After all tests have been analyzed and a Word document has been generated for each test

specimen, click the "Write Group Report" button. The software will list the analyzed tests. Using

the SHIFT key, click on all tests that should be grouped to generate the Mohr circle plot. Press

OK. This will show the Mohr's circle plot. Manually adjust the tangent line to acquire the c and

ϕ values. Then press OK and a Group report will be generated. This group report is a combined

report of the original individual tests along with the final page with the failure criteria summarized

and plotted. Save the file as suggested.

E. Steward 10 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

Pressure Display Switches

Pressure Control Regulators

Burette/Annulus Input Control

Valves

Inner Burette/Outer Annulus

Burette/Annulus Flow Control

Valves

Tube connections out to cell.

Quick Disconnect fittings

Figure A: Tri-Flex 2 Master Control Panel

E. Steward 11 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

Rear Air Bleed Valve

(Closed During Testing)

In From VCU

Cell Pressure Valve,

Transducer Box With

Bleed Screw

Back Pressure Valve,

Transducer Box With

Bleed Screw

PP Valve Open

During Testing

In From CP burette

on Master Control Pore Pressure Valve,

Panel Transducer Box With

Bleed Screw

PP Bleed Valve Closed

During Testing

Figure B: Standard Setup Triaxial Cell

E. Steward 12 Updated: June 30, 2011

CU (CONSOLIDATED UNDRAINED) TRIAXIAL TESTS USING ELE DS7

SOFTWARE AND TRIFLEX 2 PRESSURE PANEL

Piston Flow Directional Valve

(Up During Saturation and

positive polarity, Down during

Consolidation, Bypass in Electronics switch (Online is

Horizontal position) horizontal, Off is Vertical down)

In From BP Burette

Out to cell

on Master Control

Panel

VCU water chamber (start test

with piston at center of chamber,

ensure no air bubbles visible)

Figure C: Volume Change Unit (VCU)

E. Steward 13 Updated: June 30, 2011

You might also like

- Triaxial TestDocument18 pagesTriaxial TestTiong V YenNo ratings yet

- Drilling Fluid Test Procedure: Filtration TestsDocument5 pagesDrilling Fluid Test Procedure: Filtration TestsInam Ali AwanNo ratings yet

- Determination of Coefficient of Permeability Using Constant-Head Test and Falling Head TestDocument7 pagesDetermination of Coefficient of Permeability Using Constant-Head Test and Falling Head TestVerra Myza AratNo ratings yet

- Mud Lab Manual - NewDocument32 pagesMud Lab Manual - Newfisco4ril67% (6)

- Falling Head PermeabilityDocument7 pagesFalling Head PermeabilityArjun Kumar100% (1)

- 11 Biology Notes Ch10 Cell Cycle and Cell DevisionDocument7 pages11 Biology Notes Ch10 Cell Cycle and Cell DevisionRohit ThakranNo ratings yet

- Advantage Mud Manual PDFDocument408 pagesAdvantage Mud Manual PDFEduardo Guajardo100% (2)

- Unconsolidated UndrainedDocument9 pagesUnconsolidated UndrainedMohd Syafiq Akmal100% (2)

- Mp1 Type 1 ManualDocument69 pagesMp1 Type 1 ManualJerryNo ratings yet

- Shell Marine Pocketbook For International MarineDocument60 pagesShell Marine Pocketbook For International MarineGage Cendk HNo ratings yet

- Power Grid Corporation of India Limited Construction ManagementDocument8 pagesPower Grid Corporation of India Limited Construction ManagementRahul RanjanNo ratings yet

- MethodStatement CUTriaxial SaturationDocument2 pagesMethodStatement CUTriaxial SaturationDr Wong Kim YuenNo ratings yet

- Permeability of Soil Using The Falling Head MeathodDocument4 pagesPermeability of Soil Using The Falling Head MeathodSreekala Prabhasankar100% (3)

- Triaxial Test: Consolidated UndrainedDocument9 pagesTriaxial Test: Consolidated UndrainedNguyễn Hòa100% (1)

- Iso 4309 2017Document10 pagesIso 4309 2017C. de JongNo ratings yet

- Armstrong Series L Bladder Expansion Tank Installation Instructions PDFDocument2 pagesArmstrong Series L Bladder Expansion Tank Installation Instructions PDFAngel CastNo ratings yet

- Measuring the Density of Air at Sea Level (STPDocument2 pagesMeasuring the Density of Air at Sea Level (STPHarry SmithNo ratings yet

- Orifice Jet Flow Experiment GuideDocument3 pagesOrifice Jet Flow Experiment GuideshaneshaneshaneshaneNo ratings yet

- Permeometro - 1Document6 pagesPermeometro - 1Hassan RodriguezNo ratings yet

- Instruction Manual Vacuum CondenserDocument12 pagesInstruction Manual Vacuum CondenserGarry BernzNo ratings yet

- CVG3109 - Lab - Consolidated Drained Tests For Sand - 2014Document11 pagesCVG3109 - Lab - Consolidated Drained Tests For Sand - 2014Rhedo.AbdNo ratings yet

- Hydrogen Sampling InstructionsDocument8 pagesHydrogen Sampling Instructionstruongthaihung2510No ratings yet

- OFITE MODEL 230: Single Cell Cement Analyzer ManualDocument7 pagesOFITE MODEL 230: Single Cell Cement Analyzer ManualJadeja GirirajsinhNo ratings yet

- Midterm - Unit OpsDocument19 pagesMidterm - Unit OpsKrizzia Anne ShengNo ratings yet

- Instructions: For Chilled Water Buffer Tank Maintenance MODELS: CVU/CVL 120 - 1000Document2 pagesInstructions: For Chilled Water Buffer Tank Maintenance MODELS: CVU/CVL 120 - 1000Vũ Đình QuangNo ratings yet

- Lab Expt 04 - Investigation of Forced VorticesDocument5 pagesLab Expt 04 - Investigation of Forced VorticesGIANNE MARIE AZURINNo ratings yet

- Permeability Tests: Geotechnical Engineering, Laboratory 7Document5 pagesPermeability Tests: Geotechnical Engineering, Laboratory 7Portia ShilengeNo ratings yet

- Blowout Simulator BOPDocument3 pagesBlowout Simulator BOPSunil KumarNo ratings yet

- Determining Liquid Limits of Soils: Test Procedure ForDocument12 pagesDetermining Liquid Limits of Soils: Test Procedure ForBega MarcilooNo ratings yet

- Lab Manual Separation Tech Jan 2021Document43 pagesLab Manual Separation Tech Jan 2021Abdul QayyumNo ratings yet

- ENGN 311/311L Fluid Mechanics Experiment #1 Hydrostatic Force on an Inclined PlaneDocument3 pagesENGN 311/311L Fluid Mechanics Experiment #1 Hydrostatic Force on an Inclined PlanenidhalsaadaNo ratings yet

- Cover Page For Uche NwokoroDocument6 pagesCover Page For Uche NwokoroShammah ChidiNo ratings yet

- Hydropneumatic TestDocument2 pagesHydropneumatic Testremaya KCNo ratings yet

- Bioreactor Procedures for Startup, Operation and ShutdownDocument3 pagesBioreactor Procedures for Startup, Operation and ShutdownAjgaj1No ratings yet

- Enpe460 LabDocument12 pagesEnpe460 LabPraise KoobeeNo ratings yet

- Prosedur Dry Sieve AnalysisDocument2 pagesProsedur Dry Sieve AnalysisxianqianhuiNo ratings yet

- Membrane Filter Tester Instruction Manual: Part No. 396460 Rev. BDocument23 pagesMembrane Filter Tester Instruction Manual: Part No. 396460 Rev. BWajid NizamiNo ratings yet

- Determining Soil Permeability Constant Head MethodDocument5 pagesDetermining Soil Permeability Constant Head MethodTutor_KLNo ratings yet

- Lab Manual Separation Tech Jan 2020Document48 pagesLab Manual Separation Tech Jan 2020nisasoberi0% (1)

- Lab Manual Soil MechanicsDocument14 pagesLab Manual Soil Mechanicsabhay9911No ratings yet

- Experiment 5 - Spray ChamberDocument5 pagesExperiment 5 - Spray ChamberAhmad DanialNo ratings yet

- Materials and MethodologyDocument12 pagesMaterials and MethodologyEvan SmithNo ratings yet

- Determining Permeability of Sands Using Constant Head TestDocument12 pagesDetermining Permeability of Sands Using Constant Head TestArisan Iqma100% (2)

- Infant Incubators: Penlon B e Llo W S UnitDocument3 pagesInfant Incubators: Penlon B e Llo W S Unitjose_mario1128No ratings yet

- Transpiration and Evapotranspiration Measuring InstrumentsDocument9 pagesTranspiration and Evapotranspiration Measuring InstrumentsI Gede Eka Agastya PutraNo ratings yet

- 401 TestingDocument8 pages401 TestingMark Still DelarnaNo ratings yet

- Oedometer and Direct ShearDocument58 pagesOedometer and Direct ShearGloria AtwebembeireNo ratings yet

- Oil Well Blowout Simulator: BackgroundDocument3 pagesOil Well Blowout Simulator: Backgroundhesam abbaszadehNo ratings yet

- California Test 112 Settlement MonitoringDocument22 pagesCalifornia Test 112 Settlement MonitoringarslanpasaNo ratings yet

- Lab Manual Separation Tech February 2023Document41 pagesLab Manual Separation Tech February 2023Nurhanis DayanaNo ratings yet

- 1.103 Civil Engineering Materials Laboratory (1-2-3)Document5 pages1.103 Civil Engineering Materials Laboratory (1-2-3)prieten20006936No ratings yet

- Transpiration ExperimentDocument5 pagesTranspiration ExperimentNg Shu ZhenNo ratings yet

- Constant Head Apparatus ISOP #08Document6 pagesConstant Head Apparatus ISOP #08Julia Montelin PowersNo ratings yet

- Fila 121 Autoclave Quadrant (M)Document14 pagesFila 121 Autoclave Quadrant (M)Cap. de Per. 4-14 Maat 1No ratings yet

- Constant Head Permeability TestDocument12 pagesConstant Head Permeability Testanis098No ratings yet

- test-09(1)Document6 pagestest-09(1)Ateafac Anastasia NjuafacNo ratings yet

- Instructions - Lab 3.2 Falling Head Test PDFDocument2 pagesInstructions - Lab 3.2 Falling Head Test PDFTai TaNo ratings yet

- Constant Falling Head Permeability Test PDFDocument14 pagesConstant Falling Head Permeability Test PDFvinoNo ratings yet

- SOP Gas AbsorptionDocument19 pagesSOP Gas AbsorptionKevin EsmunaldoNo ratings yet

- Triaxial ProcedureDocument6 pagesTriaxial ProcedureUduebor MichealNo ratings yet

- Liflus: Operating ManualDocument41 pagesLiflus: Operating ManualausfliegeNo ratings yet

- Determine Soil Shear Parameters with Triaxial TestDocument8 pagesDetermine Soil Shear Parameters with Triaxial TestTenzinKesangNo ratings yet

- Standard Test Procedures Manual: 1. Scope 1.1. Description of TestDocument5 pagesStandard Test Procedures Manual: 1. Scope 1.1. Description of TestTemur LomidzeNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Chapter 11: The EyesDocument26 pagesChapter 11: The Eyesriley2021No ratings yet

- MR Skin Prick TestingDocument9 pagesMR Skin Prick TestingAyuAnatrieraNo ratings yet

- 特变电工画册(英文定稿)Document52 pages特变电工画册(英文定稿)Diego MantillaNo ratings yet

- SG PB Imds1350Document103 pagesSG PB Imds1350zky0108No ratings yet

- Seismic Design Coefficients and Factors TableDocument3 pagesSeismic Design Coefficients and Factors TableJonathan ColeNo ratings yet

- Schutz - Subnotes PDFDocument47 pagesSchutz - Subnotes PDFJarryd RastiNo ratings yet

- Different Project Topics of BSNLDocument3 pagesDifferent Project Topics of BSNLAbhijit Tripathy0% (1)

- Home Automation Chapter 1Document7 pagesHome Automation Chapter 1Nishant Sawant100% (1)

- Book Review - Water, Ecosystems and Society A Confluence of Disciplines. by Jayanta BandyopadhyayDocument2 pagesBook Review - Water, Ecosystems and Society A Confluence of Disciplines. by Jayanta BandyopadhyayPDNo ratings yet

- Grundfos CR 5 4 A A A e HqqeDocument10 pagesGrundfos CR 5 4 A A A e HqqePrejit RadhakrishnaNo ratings yet

- Providence Anadime Chorus Adc3Document1 pageProvidence Anadime Chorus Adc3wplaisNo ratings yet

- Towards Sustainable Water Management in SoharDocument48 pagesTowards Sustainable Water Management in SoharMiss Preyashi kumarNo ratings yet

- The Pros and Cons of Reductive Matte Smelting For PGMsDocument4 pagesThe Pros and Cons of Reductive Matte Smelting For PGMsCristian Andres Florez VergaraNo ratings yet

- La Consolacion College - Caloocan: Module in General Physics 1 Module 5: Kinematic QuantitiesDocument6 pagesLa Consolacion College - Caloocan: Module in General Physics 1 Module 5: Kinematic QuantitiesJhon Christian ManzoNo ratings yet

- Des 415 Research 01Document29 pagesDes 415 Research 01Just scribble me For funNo ratings yet

- The Efficient Way To Prevent Water Carryover and Keep Your Indoor Air HealthierDocument1 pageThe Efficient Way To Prevent Water Carryover and Keep Your Indoor Air HealthierAzrinshah Abu BakarNo ratings yet

- Soal UAS Bahasa Inggris Kelas 2 SD Semester 1 (Ganjil) : A. Choose The Correct Answer by Crossing (X) A, B or C!Document7 pagesSoal UAS Bahasa Inggris Kelas 2 SD Semester 1 (Ganjil) : A. Choose The Correct Answer by Crossing (X) A, B or C!Hamizan ShopNo ratings yet

- Aisladores Polimericos vs. Aisladores Ceramicos Unmsm PDFDocument22 pagesAisladores Polimericos vs. Aisladores Ceramicos Unmsm PDFvgcasasNo ratings yet

- Beira Port MozambiqueDocument4 pagesBeira Port Mozambiqueripper_oopsNo ratings yet

- All ProblemsDocument107 pagesAll ProblemsjoshiabhijeetNo ratings yet

- NEDO's Role in International Technical Cooperation ProjectsDocument45 pagesNEDO's Role in International Technical Cooperation Projectsamitsh20072458No ratings yet

- Algebra II PreAP SimplificationDocument4 pagesAlgebra II PreAP SimplificationSummer SharmaNo ratings yet

- Footing BiaxialDocument33 pagesFooting BiaxialSanthoshkumar RayavarapuNo ratings yet

- Panasonic DMP BDT230PDocument87 pagesPanasonic DMP BDT230PaldoNo ratings yet

- Declaration Letter - Vetagro To GSDocument3 pagesDeclaration Letter - Vetagro To GSVíctor RodríguezNo ratings yet