Professional Documents

Culture Documents

Molykote G-1056, G-1057 and G-1067 Greases: Greases With Low-Temperature and Noise-Damping Properties

Molykote G-1056, G-1057 and G-1067 Greases: Greases With Low-Temperature and Noise-Damping Properties

Uploaded by

shyam sundarOriginal Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMolykote G-1056, G-1057 and G-1067 Greases: Greases With Low-Temperature and Noise-Damping Properties

Molykote G-1056, G-1057 and G-1067 Greases: Greases With Low-Temperature and Noise-Damping Properties

Uploaded by

shyam sundarTransportation & Industrial

MOLYKOTE® G-1056, G-1057

and G-1067 Greases

Greases with low-temperature and noise-damping properties

These noise-damping Outstanding noise reduction property

greases offer: Conventional noise-damping greases increase operational resistance at low temperature

• Excellent noise reduction and low- as they use high-viscosity oil to reduce noise. New base oil and additive technology

temperature performance enables these new greases to have lower friction at low temperature and better noise-

• Less stringiness and easy handling for damping properties at room temperature.

a cleaner manufacturing environment

• Controlled oil separation and bleed

for cleaner parts and less staining Noise reduction Good low-temperature

over time property comparison property under -40°C

• Good water washout resistance for 1,000

1,000

Starting

Starting

Lower value indicates

Lower value indicates

extended life in wet applications MOLYKOTE

MOLYKOTE ® ®

G-1067

G-1067 Grease

Grease

better friction

better friction

680

680

Torque, mN-m

Torque, mN-m

Running

Running

Conventional

Conventional noise

noise reduction

reduction grease

grease 500500

Starting

Starting

Running

Running

260260

No No grease

grease

Applications

46 46 22 22

0 0 15 15 30 30 45 45 60 60 75 75 90 90 0 0

Conventional noise MOLYKOTE® G-1067 Grease

Lower

Lower value

value indicates

indicates better

better noise

noise reduction

reduction property

property (db)(db) reduction grease

Automotive body parts

Test method: Low-temperature torque test

Slides and guides, actuators, cables (JIS K 2220).

Controlled oil separation and bleed

Before test

Home appliances Conventional noise MOLYKOTE®

Moving parts in refrigerators, washing reduction grease G-1067 Grease

machines, air conditioners

Office equipment moving parts

Test method: Oil bleed (JIS K 2220

100°C x 24 hours) – grease is colored for

After test (100°C x 24 hours) testing.

Conventional noise MOLYKOTE®

reduction grease G-1067 Grease

6% oil bleed 0% oil bleed

Typical properties

MOLYKOTE® G-1056 MOLYKOTE® G-1057 MOLYKOTE® G-1067

Test and condition Unit Test method

Grease Grease Grease

Visual

Appearance (60 worked, 25°C) –

observation

Yellow Semi-transparent White

Penetration – JIS K 2220 352 348 342

Bleed (100°C x 24 hrs) % JIS K 2220 0.0 0.0 0.0

Evaporation (99°C x 22 hrs) % JIS K 2220 0.1 0.1 0.1

Dropping point °C JIS K 2220 229 234 210

Copper corrosion test (100°C x 24 hrs) – JIS K 2220 1a 1a 1a

Water washout (38°C x 1 hr) % JIS K 2220 0.4 0.1 2.5

Low- Starting torque mN•m JIS K 2220 70 83 46

temperature

torque Running torque mN•m JIS K 2220 61 55 22

4 ball wear test mm ASTM D2266 0.54 0.83 0.67

Bleed test (frosted glass surface, 60°C x 24 hrs) mm Internal test 18 20 20

Specification Writers: These values are not intended for use in preparing specifications. Please contact your local MOLYKOTE sales representative prior to writing specifications on these products.

®

Learn more: Contact us

To learn more about using MOLYKOTE® G-1056 Grease, MOLYKOTE® G-1057

Grease and MOLYKOTE® G-1067 Grease with low-temperature and noise-

damping properties, contact your MOLYKOTE® technical representative or

visit molykote.com.

DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, SM

or ® are owned by affiliates of DuPont de Nemours, Inc.

unless otherwise noted.

© 2019 DuPont.

The information set forth herein is furnished free of charge and is based on technical data that DuPont believes to be reliable and falls within the normal range of

properties. It is intended for use by persons having technical skill, at their own discretion and risk. This data should not be used to establish specification limits nor

used alone as the basis of design. Handling precaution information is given with the understanding that those using it will satisfy themselves that their particular

conditions of use present no health or safety hazards. Since conditions of product use and disposal are outside our control, we make no warranties, express or implied,

and assume no liability in connection with any use of this information. As with any product, evaluation under end use conditions prior to specification is essential.

Nothing herein is to be taken as a license to operate or a recommendation to infringe on patents.

Form No. 001-20413-AGP0820 #16086

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ink Problem Solving Guide OffsetDocument11 pagesInk Problem Solving Guide OffsetTapaskumar ChakrabortyNo ratings yet

- Catalog Mud Pump 25864Document24 pagesCatalog Mud Pump 25864agus100% (1)

- Technical Information Course: Ethsmfb12 10th of Octobre 2011 Gas Natural Fenosa Office HV-Test Set WRV1.5/680Document8 pagesTechnical Information Course: Ethsmfb12 10th of Octobre 2011 Gas Natural Fenosa Office HV-Test Set WRV1.5/680Freddy Escorza100% (1)

- 0.3 - HV TestingDocument9 pages0.3 - HV TestingFreddy EscorzaNo ratings yet

- Lower Secondary Science 9 English Language Workbook AnswersDocument14 pagesLower Secondary Science 9 English Language Workbook AnswersD.Hoolash50% (2)

- Asme 16.9Document58 pagesAsme 16.9kampit100% (2)

- Humates and Humic Acids. by Dr. Boris LevinskyDocument24 pagesHumates and Humic Acids. by Dr. Boris LevinskyLucianaNo ratings yet

- A Study On Low Magnetic PermeabilityDocument28 pagesA Study On Low Magnetic PermeabilitymishikhanNo ratings yet

- Template-Free Synthesis of Uniform Hollow Silica Nanoparticles ForDocument6 pagesTemplate-Free Synthesis of Uniform Hollow Silica Nanoparticles ForPradipto Sankar MaitiNo ratings yet

- BEST Transformer Test Procedures en PDFDocument50 pagesBEST Transformer Test Procedures en PDFFreddy Escorza67% (3)

- Tanks BOQ FinalDocument19 pagesTanks BOQ Finalmustafe50% (2)

- Thermo Drain 52 Pages - CatalogueDocument52 pagesThermo Drain 52 Pages - CatalogueSandeep Nair100% (1)

- Gamesa Electric StatcomDocument4 pagesGamesa Electric StatcomFreddy EscorzaNo ratings yet

- This Is Molykote: Specialty LubricantsDocument2 pagesThis Is Molykote: Specialty LubricantsFreddy EscorzaNo ratings yet

- Manual Abb Switchsync f236 2pdfDocument121 pagesManual Abb Switchsync f236 2pdfFreddy EscorzaNo ratings yet

- Manual Hypack 123-125Document6 pagesManual Hypack 123-125Freddy EscorzaNo ratings yet

- CIGRE Sensitivity Verification "UHF Equivalent To 5 PC"Document3 pagesCIGRE Sensitivity Verification "UHF Equivalent To 5 PC"Freddy EscorzaNo ratings yet

- 5.3 - DMS PDM SoftwareDocument95 pages5.3 - DMS PDM SoftwareFreddy EscorzaNo ratings yet

- ABB IndustrialTransformer PDFDocument10 pagesABB IndustrialTransformer PDFFreddy EscorzaNo ratings yet

- Friction Stir Spot WeldingDocument12 pagesFriction Stir Spot WeldingManish MNo ratings yet

- Curriculum Vitae - Vy Minh Loc PDFDocument9 pagesCurriculum Vitae - Vy Minh Loc PDFKolusu SivakumarNo ratings yet

- Coaxial Cables For Railway ApplicationDocument18 pagesCoaxial Cables For Railway Applicationrose chenNo ratings yet

- Test Report: M/s Felix Generics Pvt. LTDDocument2 pagesTest Report: M/s Felix Generics Pvt. LTDShreya Test HouseNo ratings yet

- Full Syllabus Test-01 - Xef-Polymer-GateDocument14 pagesFull Syllabus Test-01 - Xef-Polymer-GateArjun Satheesh KumarNo ratings yet

- FREE ONLINE PRE BOARD EXAM Design and ConstructionDocument33 pagesFREE ONLINE PRE BOARD EXAM Design and ConstructionWilliam Jude Kristian CondeNo ratings yet

- Wollastonite IJSRET - Paper TemplateDocument4 pagesWollastonite IJSRET - Paper TemplateChidananda GNo ratings yet

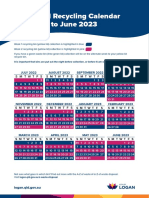

- Waste and Recycling Calendar 2022 23 JULY UPDATE AccessibleDocument1 pageWaste and Recycling Calendar 2022 23 JULY UPDATE Accessiblegedi routeNo ratings yet

- WINTER INTERN REPORT by VARSHINIDocument36 pagesWINTER INTERN REPORT by VARSHINIMadhavi LathaNo ratings yet

- 7721 CarpentryDocument2 pages7721 CarpentrywarrencareertechNo ratings yet

- Aero PromotersDocument2 pagesAero PromotersNataniel LinaresNo ratings yet

- Experiment No: 02 Experiment Name:: Identification of Dyestuff From Unknown Dyed Sample (Direct Dye)Document3 pagesExperiment No: 02 Experiment Name:: Identification of Dyestuff From Unknown Dyed Sample (Direct Dye)Md. Sazzadul IslamNo ratings yet

- Natural Gas Hydrates A Guide For Engineers 4Th Edition John Carroll Download PDF ChapterDocument51 pagesNatural Gas Hydrates A Guide For Engineers 4Th Edition John Carroll Download PDF Chapterscott.street885100% (3)

- Measurement Systems: Application and Design by Ernest O. DoebelinDocument20 pagesMeasurement Systems: Application and Design by Ernest O. DoebelinAlhji AhmedNo ratings yet

- Technical Specification: ITEM 00252 In-Place Full Depth Cold Flexible Pavement RecyclingDocument6 pagesTechnical Specification: ITEM 00252 In-Place Full Depth Cold Flexible Pavement RecyclingV Venkata NarayanaNo ratings yet

- 1.2 The Mole ConceptDocument6 pages1.2 The Mole ConceptCicy IrnaNo ratings yet

- BASF ShortDocument13 pagesBASF ShortCancerian Ag50% (2)

- Wiremax Products On Connectronics Corp.Document2 pagesWiremax Products On Connectronics Corp.zakariiNo ratings yet

- SABIC®-PP QR6731K Global Technical Data SheetDocument2 pagesSABIC®-PP QR6731K Global Technical Data SheetPhahad HasimNo ratings yet

- Conduction and Breakdown in Liquid DielectricsDocument6 pagesConduction and Breakdown in Liquid DielectricsSanjid ElahiNo ratings yet

- Thin-Walled Structures: Guanbo Bian, Kara D. Peterman, Shahabeddin Torabian, Benjamin W. SchaferDocument13 pagesThin-Walled Structures: Guanbo Bian, Kara D. Peterman, Shahabeddin Torabian, Benjamin W. SchaferJoseAngelFernandezOrtegaNo ratings yet