Professional Documents

Culture Documents

Mounted Engine Dynamometer Evaluation of High Octane Retail Fuels

Mounted Engine Dynamometer Evaluation of High Octane Retail Fuels

Uploaded by

wagnerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mounted Engine Dynamometer Evaluation of High Octane Retail Fuels

Mounted Engine Dynamometer Evaluation of High Octane Retail Fuels

Uploaded by

wagnerCopyright:

Available Formats

Mounted Engine Dynamometer Evaluation

of High Octane Retail Fuels

Executive Summary

Fuel comparison tests were performed on three leading brand high octane fuels,

Shell V-Power Racing and two Premium 98 Octane fuels (brands X and Y),

under strictly controlled conditions. Tests were performed using a current model

Mitsubishi Evo IX 2ltr turbocharged engine* mounted to a purpose built engine

dynamometer cell. Tests were conducted using the standard Mitsubishi ECU and

a MoTeC Plug In M800 ECU. No modifications were made to the engine.

The results of the testing clearly indicated that:

1) Tuning of engines is required to obtain the maximum benefit from any fuel.

2) There can be significant performance benefits to the fitting of a MoTeC

Engine Control Unit (ECU), even without engine modifications.

3) Shell V-Power Racing 100 Octane fuel consistently delivered significantly

more torque (up to 10.7%) and engine horsepower (up to 4.6%) than other

commercially available high octane fuels in the retail market.

In addition, based on limited testing, Aviation Fuel (Av Gas) was also tested.

Initial results showed that V-Power Racing was superior in its detonation

resistance and able to make more power than the tested Av Gas.

*Mitsubishi Lancer, Evolution IX, 4G63 2ltr, 16 valve DOHC MIVEC intercooled, turbocharged engine

© May 2007 MoTeC P/L www.motec.com.au Page 1 of 13

Introduction

Controlled testing and monitoring of engine performance has always revealed

clear evidence that while some fuels have inherent capabilities to deliver higher

levels of engine performance, the magnitude of improvement in performance is

related to two factors:

1) The level of engine tuning specific to the particular fuel

2) The quality of the fuel itself.

The aim of the following study was to map engine performance against relatively

minor tuning of a standard high performance engine, the Mitsubishi EVO IX 2Ltr,

and fuel quality. The fuels chosen were available at and sourced from major

brand retail service stations and as such are readily available to the general

public.

Fuels chosen for comparison - Shell 100 Octane V-Power Racing and two

Premium 98 Octane brands (X and Y) - were considered to be representative of

the premium and super premium fuels available in the retail market place.

Trial Setup

The EVO IX engine was ramped on the engine dyno with test fuel at a rate of 300

rpm/sec to emulate maximum acceleration similar to 4th gear. Fuel was pumped

from storage by an electric fuel pump, which was also used to flush fuel through

the system when fuel changeover occurred.

Trial data represented in the report is the average of 10 runs. Fuels were tested

under identical and reproducible controlled conditions.

Engine Tuning - Timing Advance Results

While running on the MoTeC ECU, the EVO IX engine timing was adjusted in all

runs to maximise torque curves for all fuels tested. Engine ignition timing was

advanced incrementally until ping / detonation was detected by the independent

detonation detection device, then retarded sufficiently to prevent detonation

during ramp runs.

Premium 98 Octane fuels X and Y were both found to exhibit detonation at the

same level of ignition timing advancement.

In all cases, including a trial with Aviation Gasoline (Av Gas), 100 Octane V-

Power Racing was found to accept greater levels of timing advancement than the

other trial fuels.

The elevated octane of V-Power Racing was found to allow an extra 3.5 degrees

of timing advancement when utilizing the MoTeC M800 Plug in ECU at standard

boost levels.

© May 2007 MoTeC P/L www.motec.com.au Page 2 of 13

With boost raised to 20 PSI via reprogramming through the MoTeC ECU, an

extra 7.0 degrees of timing advancement was made once V Power was

introduced. This was substantially more than expected and the torque curves say

it all. (Fig 2)

Fuel Timing Advance (Deg) Torque

Premium X 98 Octane 0 302.9

Premium Y 98 Octane 0 305.5

100 Octane V-Power Racing 3.5 316.9

Table 1. Engine timing adjustment comparison, MoTeC M800 Plug in ECU

standard boost.

Fuel Timing Advance (Deg) Torque

Premium X 98 Octane 0 328.1

Premium Y 98 Octane 0 328.1

100 Octane V-Power Racing 7 363.5

Table 2. Engine timing adjustment comparison, MoTeC M800 Plug in ECU,

20psi boost.

Engine Dynamometer Torque Curve Results

Torque curves derived from the average result of ten runs for each fuel, under

comparable conditions, were represented graphically (see Figures 1 and 2). For

ease of interpretation, differences between fuels under similar trial conditions

have been highlighted in colour. Key data, turbocharger boost pressure, ECU

type, peak torque and % difference between fuels tested are reported in Tables 3

and 4.

Figure 1 represents three trials applying increasing levels of engine tuning to the

fuels involved:

Trial 1: ‘Standard ECU’

Using the Mitsubishi ECU as if fitted to the standard vehicle with standard

Turbocharger boost (14psi). This resulted in close to 1% variation in peak torque

between Premium X 98 Octane and V-Power racing 100 Octane.

© May 2007 MoTeC P/L www.motec.com.au Page 3 of 13

Trial 2: ‘MoTeC ECU boost matched to Std ECU’

The Mitsubishi ECU was replaced with a MoTeC M800 Plug in ECU. The

turbocharger boost profile was tuned to match the standard ECU and ignition

timing maximised to suit the engine. This combination resulted in a significant

increase in torque for both fuels, 16.5% for V-Power Racing and 13.5% for

Premium X 98 Octane.

Comparing both fuels together, there was

a 3.4% increase in torque for V-Power

Racing relative to Premium X 98 Octane.

Trial 3: ‘MoTeC ECU 20psi boost’

A final refinement in tuning via an

increase in turbocharger boost pressure to 20psi resulted in a further increase in

torque relative to Trial 1 of 36.0% for V-Power Racing and a 24.0 % for Premium

X 98 Octane.

These results indicate that dramatic increases in torque can be achieved via

engine tuning and sophisticated engine management systems, and that 100

Octane V-Power Racing delivered measurable and significantly better boosts to

performance than Premium X 98 Octane fuel.

© May 2007 MoTeC P/L www.motec.com.au Page 4 of 13

Engine Dynamometer Results

Figure 1: Torque comparison of VPR and Premium X 98 Octane.

Turbo Torque % Max

Fuel ECU Pressure @ 3950 Torque

(PSI) rpm Diff.

Premium 98 Octane Mitsubishi 14 265.0

100 Octane V-Power Racing Mitsubishi 14 267.5 +0.9%

Premium 98 Octane MoTeC 14 300.8

100 Octane V-Power Racing MoTeC 14 311.0 +3.4%

Premium 98 Octane MoTeC 20 328.5

100 Octane V-Power Racing MoTeC 20 363.7 +10.7%

Table 3: Torque Curves

© May 2007 MoTeC P/L www.motec.com.au Page 5 of 13

Figure 1a: Progressive torque comparison.

Turbo Torque % Max

Fuel ECU Pressure @ 3950 Torque

(PSI) rpm Gain

Premium 98 Octane Mitsubishi 14 265.0

100 Octane V-Power Racing Mitsubishi 14 267.5 +0.9%

Premium 98 Octane MoTeC 14 300.8 +13.5%

100 Octane V-Power Racing MoTeC 14 311.0 +17.4%

Premium 98 Octane MoTeC 20 328.5 +24.0%

100 Octane V-Power Racing MoTeC 20 363.7 +37.2%

Table 3a: Progressive Torque advantage relative to standard Mitsubishi ECU on

Premium 98 Octane

© May 2007 MoTeC P/L www.motec.com.au Page 6 of 13

Figure 2: Comparison of VPR and Premium 98 Octane X and Y under optimum

engine conditions.

Turbo Torque % Max

Fuel ECU Pressure @ 3900 Torque

(PSI) rpm Difference

Premium X 98 Octane MoTeC 20 328.1

Premium Y 98 Octane MoTeC 20 328.1 0%

100 Octane V-Power Racing MoTeC 20 363.5 +10.8%

Table 4: V-Power Racing and Premium 98 Octane Fuel Torque

© May 2007 MoTeC P/L www.motec.com.au Page 7 of 13

Figure 3: Horse Power Comparison of VPR and Premium 98 Octane.

Turbo Horse % Max

Fuel ECU Pressure Power @ HP Diff.

(PSI) 6750rpm

Premium 98 Octane Mitsubishi 14 302.5

100 Octane V-Power Racing Mitsubishi 14 308.5 +2.0%

Premium 98 Octane MoTeC 14 339.6

100 Octane V-Power Racing MoTeC 14 352.6 +3.8%

Premium 98 Octane MoTeC 20 343.8

100 Octane V-Power Racing MoTeC 20 359.6 +4.6%

Table 5: V-Power Racing and Premium X 98 Octane Horse Power Results

© May 2007 MoTeC P/L www.motec.com.au Page 8 of 13

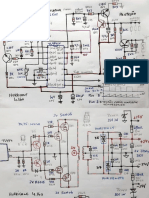

MoTeC PROCEDURES

EQUIPMENT USED

MoTeC Research Centre engine dynamometer cell

Cell includes:

Dynamic Test Systems water brake engine dynamometer with Dyno

Log electronic control software.

Dyno Log software features full ambient condition compensation.

Engine and dyno monitored by MoTeC Advanced Dash Logger (ADL)

EQUIPMENT SET UP

DATA LOGGING

MoTeC Advanced Dash Logger was set up to:

A. Record the following parameters

1. RPM

2. Boost

3. Air temp after intercooler

4. Ambient Air Temp

5. Water Temp

6. Exhaust Temp

7. Oil Temp

8. Fuel Pressure

9. Engine Torque

10. Oil Pressure

© May 2007 MoTeC P/L www.motec.com.au Page 9 of 13

B. Alarm against breach of limits on the following parameters

1. Ambient Air Temperature +/- 6 Deg C

2. Boost level +/- 7 kPa

3. Oil Temperature +/- 15 Deg C

4. Inlet Air Temperature +/- 6 Deg C

5. Oil Pressure +/- 100 kPa

6. Water Temperature +/- 10 Deg C

7. Exhaust Temperature +/- 75 Deg C

FUEL

60 L Batch Controlled Premium X 98 Octane fuel

60L Batch Controlled Premium Y 98 Octane fuel

60L Batch controlled 100 Octane Fuel VPR – Shell V-Power Racing

All fuel was laboratory tested by Intertek Testing Services P/L 218

Lorimer St North Melbourne.

Testing was against key fuel parameters [density (ASTM D4052),

Distillation (ASTM D86), Reid Vapour pressure (ASTM D323),

Research Octane (ASTM D2699) and Motor Octane (ASTM D2700)] to

ensure homogeneity and determine quality.

Fuel was obtained by direct purchase from local service station retail

outlets.

Plumb in 4 separate fuel cells.

The 4 cells enabled quick and efficient changing of fuel types:

1. Premium X 98 Octane

2. Premium Y 98 Octane

3. V-Power Racing 100 Octane

4. Waste fuel from draining lines between fuel changes.

The fuel system was flushed through after each fuel change over and

engine run for 1 minute to remove traces of previous fuel.

© May 2007 MoTeC P/L www.motec.com.au Page 10 of 13

TEST ENGINE

Standard Mitsubishi Lancer Evolution IX 2ltr 4G63 2ltr 16 valve DOHC

MIVEC intercooled turbocharged engine

Set up in Dyno cell as near as possible to installation in vehicle.

Use standard air induction and exhaust front pipe including catalytic

converter.

Fit up extra sensors external of engine sensors to meet

requirements for measurements into the MoTeC dash Logger.

Fit up external detonation listening device also.

TESTING

Conditions

All testing was done under stable atmospheric conditions and final

results recorded on the same day

Procedure

After a suitable warm up, a series of ramp tests were conducted

whereby the average of 10 runs were recorded as the standard for

the relevant fuel.

Ramp Test Procedure

Position engine throttle to 100%

Engine was held by Dyno at a pre start speed of 2000 RPM off

boost.

© May 2007 MoTeC P/L www.motec.com.au Page 11 of 13

The engine was then accelerated at a controlled rate of 300RPM

per second (similar to maximum acceleration of the vehicle in a

higher gear)

Ramp run was completed at 6750 rpm and torque was logged and

displayed on Dyno Log software. The entire test was computer

controlled, promoting repeatable results.

Repeat ramp tests for different fuels to be tested.

TEST COMBINATIONS

1. Standard ECU and wiring harness as fitted in the factory car.

Measures were taken to ensure the factory ECU was running

in its normal condition and not in any limp home mode.

2. Remove standard ECU and fit MoTeC M800 Plug in ECU and

modify boost curve to match that of the standard Mitsubishi ECU.

Then tune to MoTeC ECU to make max Torque on each relevant

fuel. Utilise on-board knock monitoring to determine no detonation

throughout tuning procedure.

3. Modify boost curve in MoTeC plug in ECU to increase average

boost of 14 to 20 PSI. Then tune to MoTeC ECU to make max

Torque on each relevant fuel.

TEST RESULTS

Test results were represented graphically for direct comparison. Individual data

points such as torque at specific engine speeds was determined by the operator

via the assessment software.

© May 2007 MoTeC P/L www.motec.com.au Page 12 of 13

Appendix 1

FUEL QUALITY TEST RESULTS

Test Test Unit VPR X Y

Method

Density ASTM g/cm3 0.7714 0.7575 0.7554

@15oC D4052

o

Distillation ASTM C IBP 40.3 33.4 32.7

D86

10% 54.3 54.6 52.7

Evap

50% 109.3 107.6 105.7

Evap

90% 141.3 153.7 163.1

Evap

FBP 173.9 184.5 190.2

Residue 1.0 1.2 0.9

%v/v

Research ASTM RON 101.1 98.2 98.4

Octane D2699

Motor ASTM MON 87.8 86.7 86.5

Octane D2700

Reid ASTM kPa 59.00 64.00 57.25

Vapour D323

Pressure

Table 6: Fuel batch control results.

© May 2007 MoTeC P/L www.motec.com.au Page 13 of 13

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- LS Swaps: How to Swap GM LS Engines into Almost AnythingFrom EverandLS Swaps: How to Swap GM LS Engines into Almost AnythingRating: 3.5 out of 5 stars3.5/5 (2)

- How to Use and Upgrade to GM Gen III LS-Series Powertrain Control SystemsFrom EverandHow to Use and Upgrade to GM Gen III LS-Series Powertrain Control SystemsRating: 3.5 out of 5 stars3.5/5 (4)

- Catalogo Ford RacingDocument244 pagesCatalogo Ford RacingwagnerNo ratings yet

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Troubleshooting and Repair of Diesel EnginesFrom EverandTroubleshooting and Repair of Diesel EnginesRating: 1.5 out of 5 stars1.5/5 (2)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume I: the Twin CamFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume I: the Twin CamNo ratings yet

- Designing and Tuning High-Performance Fuel Injection SystemsFrom EverandDesigning and Tuning High-Performance Fuel Injection SystemsRating: 3.5 out of 5 stars3.5/5 (7)

- Seminar Report On I-VtecDocument31 pagesSeminar Report On I-Vtecmaheshkawade1360% (5)

- Catalogo GM PerformanceDocument167 pagesCatalogo GM PerformancewagnerNo ratings yet

- Outboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairFrom EverandOutboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairRating: 3 out of 5 stars3/5 (1)

- Engine TuningDocument7 pagesEngine TuningJOSE100% (1)

- Caterpillar 3406 B C Peec Repair ManualDocument8 pagesCaterpillar 3406 B C Peec Repair Manualchristopher100% (54)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Sae 2020-01-1286 Benchmark 2018 Toyota Camry Ub80e Eight Speed Auto TransDocument13 pagesSae 2020-01-1286 Benchmark 2018 Toyota Camry Ub80e Eight Speed Auto TransPeterNo ratings yet

- 1.8l Turbo ATC AWP PDFDocument270 pages1.8l Turbo ATC AWP PDFred eagle winsNo ratings yet

- Hybrid Transmission For FWD VehiclesDocument9 pagesHybrid Transmission For FWD VehiclesMatheus RodriguesNo ratings yet

- Development of The Next-Generation Half-Toroidal CVT With Geared Neutral and Power-Split Systems For 450 N-M EnginesDocument9 pagesDevelopment of The Next-Generation Half-Toroidal CVT With Geared Neutral and Power-Split Systems For 450 N-M EnginesAbhishekJadhav100% (1)

- Torque Converter SystemDocument32 pagesTorque Converter SystembederinadmlNo ratings yet

- Audi 01J Multitronic CVTDocument99 pagesAudi 01J Multitronic CVTenes_br95% (21)

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972From EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (3)

- Samsung UE32 5000QW Service ManualDocument68 pagesSamsung UE32 5000QW Service ManualDoru Razvan50% (2)

- DK-26 Instruction Manual (Maintenance) PDFDocument191 pagesDK-26 Instruction Manual (Maintenance) PDFFernando César Carbone86% (7)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- 2002 01 0378v001 PDFDocument12 pages2002 01 0378v001 PDFwinter1998100% (1)

- Numerical RelayDocument19 pagesNumerical RelayRajesh Naik Dharavath100% (1)

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Variable Compression Ratio EnginesDocument24 pagesVariable Compression Ratio EnginesAzher UddinNo ratings yet

- 1.8l ENGINEDocument304 pages1.8l ENGINEjoao xavierNo ratings yet

- Multitronic 01JDocument100 pagesMultitronic 01JAlex Dosoftei100% (1)

- Am CircuitsDocument14 pagesAm CircuitsIngkz JeraeNo ratings yet

- CAT 789C BrochureDocument28 pagesCAT 789C Brochurezaneswing100% (1)

- Traction, Transmission and Brakes SystemDocument9 pagesTraction, Transmission and Brakes SystemTrường NguyenNo ratings yet

- Development of An Engine Variable Geometry Intake System For A Formula SAE ApplicationDocument12 pagesDevelopment of An Engine Variable Geometry Intake System For A Formula SAE ApplicationerfwefedfNo ratings yet

- Laminar Burning Velocity As A FuelDocument8 pagesLaminar Burning Velocity As A FuelFeliks SutrisnoNo ratings yet

- Performace Test On Otto Engine With Premium and Pertamax FuelDocument12 pagesPerformace Test On Otto Engine With Premium and Pertamax FuelRifanni JuliantiNo ratings yet

- Specifications: 2008 Ford Edge SE 2008 Ford Edge SEDocument6 pagesSpecifications: 2008 Ford Edge SE 2008 Ford Edge SECarlos VelázquezNo ratings yet

- 1zzfe Technical DataDocument13 pages1zzfe Technical Datacris5001100% (1)

- In Uence of Fuel Injector Position of Port-Fuel Injection Retrofit-Kit To The Performances of Small Gasoline En..Document9 pagesIn Uence of Fuel Injector Position of Port-Fuel Injection Retrofit-Kit To The Performances of Small Gasoline En..Aasif SheikhNo ratings yet

- Dynamometer Testing of Caterpillar Engines (0781, 1000) : Shutdown SISDocument72 pagesDynamometer Testing of Caterpillar Engines (0781, 1000) : Shutdown SISMOHD NAJMAN BIN MUDANo ratings yet

- Methanol Mix Diesel - Yusaf - Hamawand - Baker - Najafi - PVDocument11 pagesMethanol Mix Diesel - Yusaf - Hamawand - Baker - Najafi - PVasep saefullohNo ratings yet

- TT 2006 1.8LDocument255 pagesTT 2006 1.8LCarlos CarvajalNo ratings yet

- Zeroshift Automated Manual Transmission SAE2007!26!061Document4 pagesZeroshift Automated Manual Transmission SAE2007!26!061José Antonio GutiérrezNo ratings yet

- 2010-01-0310 - Advanced Development and Dynamometer Tuning of A Suzuki GSXR 600cc Engine For An FSAE® VehicleDocument9 pages2010-01-0310 - Advanced Development and Dynamometer Tuning of A Suzuki GSXR 600cc Engine For An FSAE® VehicleCaio PaimNo ratings yet

- Vtec and Ivtec ComparisionDocument12 pagesVtec and Ivtec ComparisionAjithNo ratings yet

- Maintenance TT 2002Document100 pagesMaintenance TT 2002andy gronemanNo ratings yet

- EMD 710ECO Repower SolutionsDocument2 pagesEMD 710ECO Repower Solutionsriza_azhariNo ratings yet

- Project Report TE LabDocument7 pagesProject Report TE LabRadhika GurjarNo ratings yet

- SAE - 2007 01 1311ToyotaAA80EDocument10 pagesSAE - 2007 01 1311ToyotaAA80Evipper king2012No ratings yet

- Formation of Driving Torque of Engine Inthe Technological Transport Machine With Multiphase Injection of FuelDocument10 pagesFormation of Driving Torque of Engine Inthe Technological Transport Machine With Multiphase Injection of FuelTJPRC PublicationsNo ratings yet

- Ahorro de EnergiaDocument4 pagesAhorro de Energiaclide_050793No ratings yet

- 06A 407 - 407GX - 407GXi B2 M250-C47E4 Dual EECS 2023MAY24Document86 pages06A 407 - 407GX - 407GXi B2 M250-C47E4 Dual EECS 2023MAY24echaletintaNo ratings yet

- Honda Variable Cam ControlDocument24 pagesHonda Variable Cam ControlJameel Khan100% (1)

- A Study of Maximum Power Operation For Engine in Continuously Variable Transmission PowertrainDocument4 pagesA Study of Maximum Power Operation For Engine in Continuously Variable Transmission PowertrainSanjeev RanjanNo ratings yet

- CVT Simulation On The Dynamic Engine Test BedDocument3 pagesCVT Simulation On The Dynamic Engine Test BedCiprian SerdinNo ratings yet

- Designing Optimizing and Fabrication of PDFDocument10 pagesDesigning Optimizing and Fabrication of PDFBharat SinghNo ratings yet

- Ijaiem 2014 09 07 8Document12 pagesIjaiem 2014 09 07 8International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- High Octane FuelDocument9 pagesHigh Octane FuelPurna Satria NugrahaNo ratings yet

- Kurosawa 1999Document7 pagesKurosawa 1999shubham3singhal-2No ratings yet

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemFrom EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNo ratings yet

- D153 Display: DatasheetDocument4 pagesD153 Display: DatasheetwagnerNo ratings yet

- Power Distribution Module 15Document3 pagesPower Distribution Module 15wagnerNo ratings yet

- Esquema Fonte Hurricane 4.160Document3 pagesEsquema Fonte Hurricane 4.160wagnerNo ratings yet

- CH 06 ArtilleryDocument64 pagesCH 06 ArtilleryPGNo ratings yet

- GL 107 MV Outdoor Cicuit Breaker BrucherDocument6 pagesGL 107 MV Outdoor Cicuit Breaker BrucherNguyễn Tiến Dũng100% (2)

- Bascula Ypc 100 enDocument18 pagesBascula Ypc 100 enOctavio RomeroNo ratings yet

- Lenovo E43Document42 pagesLenovo E43Ramdas KambleNo ratings yet

- Model Type Fabricante TypeDocument22 pagesModel Type Fabricante TypeNadja LimaNo ratings yet

- Catalog RACKDocument332 pagesCatalog RACKnike03No ratings yet

- AHU Loads OldDocument12 pagesAHU Loads OldMohsin KaziNo ratings yet

- Pneumatic Modulevel ControllersDocument60 pagesPneumatic Modulevel Controllersjcheese83No ratings yet

- Avid Technical Manual: (English)Document27 pagesAvid Technical Manual: (English)mcallaNo ratings yet

- C17 C28D5 X2.5Document4 pagesC17 C28D5 X2.5Pritesh Kumar100% (1)

- LY HR6000 ManualDocument6 pagesLY HR6000 ManualAdam RzymskiNo ratings yet

- Fast Door PDFDocument132 pagesFast Door PDFGo MocNo ratings yet

- C2020 I & O and STD Wiring For C and A ProbesDocument2 pagesC2020 I & O and STD Wiring For C and A ProbesDave PotterNo ratings yet

- Sipeed Maix-BIT Specifications EN V2.0Document6 pagesSipeed Maix-BIT Specifications EN V2.0Vlad TimisoaraNo ratings yet

- 85018v2 Manual Vol 2 Rev CDocument150 pages85018v2 Manual Vol 2 Rev CyavuzovackNo ratings yet

- Manual Es8 Nueva Generacion.Document52 pagesManual Es8 Nueva Generacion.darwinNo ratings yet

- Heritage Institute of Technology: Department of Mechanical EngineeringDocument8 pagesHeritage Institute of Technology: Department of Mechanical EngineeringSwapnil DeyNo ratings yet

- Two Reaction TheoryDocument57 pagesTwo Reaction TheorySumathi AmbunathanNo ratings yet

- Operation & Maintenance Manual: Models TL1055, TL1255Document144 pagesOperation & Maintenance Manual: Models TL1055, TL1255Tristan Manuel100% (1)

- Häggloader 10HR-B 3A - MaintenanceDocument116 pagesHäggloader 10HR-B 3A - MaintenanceEmrah Mertyürek100% (1)

- Powertronic Installation Manual-Yamaha Fz25/Fazer25 (2018-2019)Document28 pagesPowertronic Installation Manual-Yamaha Fz25/Fazer25 (2018-2019)Vignesh B.RNo ratings yet

- Solar CarDocument22 pagesSolar CaranilNo ratings yet

- Basic of 4-20ma Current LoopDocument1 pageBasic of 4-20ma Current Loopzakarianoui35No ratings yet

- Aro PumpDocument8 pagesAro PumpRizalino BrazilNo ratings yet

- 4X4 RangeDocument2 pages4X4 RangeAmit YadavNo ratings yet

- Power Supply EmersonDocument20 pagesPower Supply Emersonindra gunawanNo ratings yet