Professional Documents

Culture Documents

Biofloc Technology (BFT) in Shrimp Farming: Past and Present Shaping The Future

Uploaded by

Michael LeirvagOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biofloc Technology (BFT) in Shrimp Farming: Past and Present Shaping The Future

Uploaded by

Michael LeirvagCopyright:

Available Formats

OPINION

published: 20 December 2021

doi: 10.3389/fmars.2021.813091

Biofloc Technology (BFT) in Shrimp

Farming: Past and Present Shaping

the Future

Maurício G. C. Emerenciano 1*, Anselmo Miranda-Baeza 2 , Marcel Martínez-Porchas 3 ,

Moisés A. Poli 4 and Felipe do Nascimento Vieira 5

1

Commonwealth Scientific and Industrial Research Organisation (CSIRO), Livestock and Aquaculture Program, Bribie Island

Research Centre, Woorim, QLD, Australia, 2 Universidad Estatal de Sonora (UES) Unidad Navojoa, Navojoa, Mexico, 3 Centro

de Investigación en Alimentación y Desarrollo, A.C. Biología de Organismos Acuáticos. Hermosillo, Mexico, 4 Nicovita-Vitapro

SA, Lima, Peru, 5 Laboratório de Camarões Marinhos, Universidade Federal de Santa Catarina, Florianópolis, Brazil

Keywords: Litopenaeus vannamei, water quality, production costs, hybrid system, circular economy, microbial

approaches, intensification, sustainability

INTRODUCTION

Shrimp farming is growing worldwide, with a key driving factor being its high value in global

seafood markets. In 2018, the first-sale value of farmed crustaceans was 69,300 million USD, in

which Penaeus (Litopenaeus) vannamei was the most cultivated species with an annual growth

rate of 8.78% (FAO, 2020). As a result, the importance of farmed shrimp as a source of food,

Edited by: employment, and economic development is indisputable. The increasing demand and shortage of

Hüseyin Sevgili, resources, such as land and water, have pushed the industry toward intensifying shrimp farming (Xu

Isparta University of Applied et al., 2021). However, conventional intensive farming practices with high water exchange rates can

Sciences, Turkey

lead to disease outbreaks and crop losses (Thitamadee et al., 2016). In this sense, the current trend

Reviewed by: suggests an increased demand for more “controlled intensive systems” with increased efficiency

Jia-Song Zhang,

and biosecurity.

Chinese Academy of Fishery Sciences

(CAFS), China

In large production areas (e.g., Asia and some Latin American countries), Biofloc Technology

(BFT) became an alternative to overcome these issues, providing increased predictability and

*Correspondence:

consistency (El-Sayed, 2021). The BFT contributes to nutrient optimization as studies reported that

Maurício G. C. Emerenciano

mauricio.emerenciano@csiro.au

bioflocs could contribute to ∼20% of the protein required by shrimp (Avnimelech, 2012). Burford

et al. (2004) suggested that up to 29% of daily nitrogen retention of the shrimp was sourced by the

Specialty section:

natural biota (bioflocs). These microbial aggregates also provide vitamins, bioactive compounds,

This article was submitted to and beneficial bacteria (probiotics) (Yu et al., 2021). Under suitable conditions, BFT improves feed

Marine Fisheries, Aquaculture and efficiency, stimulates growth, enhances the immune system (Hostins et al., 2019), and promotes a

Living Resources, better physiological status compared to shrimp farmed in traditional systems (Cardona et al., 2016).

a section of the journal Nowadays, after ∼20 years of evolution, BFT has been adapted and adjusted to different regions,

Frontiers in Marine Science

locations, salinities, applied to one single-phase (nursery) or multiple phases, outdoor and indoor

Received: 11 November 2021 conditions, and according to different farm infrastructure, operational and resources limitations.

Accepted: 23 November 2021 The accumulated BFT knowledge has provided a baseline for the development of other related

Published: 20 December 2021

microbial-based (e.g., Aquamimicry, synbiotics, and semi-biofloc; Zeng et al., 2020; El-Sayed, 2021;

Citation: Hussain et al., 2021), hybrid (e.g., BioRAS; Xu et al., 2020), and integrated (e.g., shrimp + fish)

Emerenciano MGC, Miranda-Baeza A, systems (Wright, 2015), with at least nine different variations. However, regardless of the system

Martínez-Porchas M, Poli MA and

chosen and adopted, it is crucial to consider the local specificities (e.g., technological, social,

Vieira FdN (2021) Biofloc Technology

(BFT) in Shrimp Farming: Past and

financial, and environmental), tailoring day-to-day management practices and ongoing production

Present Shaping the Future. strategies accordingly. In addition, considering the higher production costs compared to traditional

Front. Mar. Sci. 8:813091. low-input systems, the commercialization and post-harvest aspects are crucial to guarantee the

doi: 10.3389/fmars.2021.813091 resilience and competitiveness of BFT-based shrimp farms. In this opinion manuscript, we describe

Frontiers in Marine Science | www.frontiersin.org 1 December 2021 | Volume 8 | Article 813091

Emerenciano et al. Biofloc Technology in Shrimp Farming

some key BFT characteristics regarding its past and present, growth and uniformity. Similarly, water probiotics (Hostins

while highlighting future challenges and opportunities aiming to et al., 2019), and feed additives such as organic acids (Da Silva

contribute to the sustainability of intensive shrimp farming. et al., 2016), probiotics (Kesselring et al., 2019), prebiotics, and

immunostimulants (Zhou et al., 2020) have been contributing to

the improvement of shrimp health and diseases resistance.

BFT IN SHRIMP FARMING: PAST Regarding water quality, new aeration systems are emerging

(Susanti et al., 2021) but still need validation at a larger

The BFT system originated in the 1970s at the French Research

scale. Although vastly improved, issues with N-compounds and

Institute for Exploitation of the Sea (IFREMER) located in

management of suspended solids persist in some farms leading

Tahiti, French Polynesia. It was later expanded to commercial

to poor growth, low DO levels, pathogenic vibrio outbreaks,

shrimp farms in partnership with private sector companies

and eventually mortalities. In terms of solids, some strategies

from the U.S. In the 1990s and early-2000s, R&D efforts and

have been adopted in small operations, e.g., clarifiers (Ray et al.,

commercial adoption began in the U.S. and Central America

2010), RAS filtration systems and skimmers (Fleckenstein et al.,

enabling further development of commercial large-scale shrimp

2020); and in large-scale farms, the solids are concentrated and

operations, including Asia and Latin America (Burford et al.,

removed through “shrimp toilets” by limited water exchanges

2004; Ulloa-Walker et al., 2020).

(Afroz and Alam, 2013). Regardless of the strategy, proper

However, by that time, the lack of understanding of

waste management is a current challenge. Additionally, other

the different components (e.g., engineering, production

production strategies have been implemented and led to an

management, and aquatic microbiology) led to poor system

increase in actual production rates; for example, the maintenance

control. As a result, imbalance of the microbial population

of alkalinity within optimal levels (Furtado et al., 2015), adoption

and toxic N-compounds issues were commonly observed, as

of partial harvests (Da Silveira et al., 2022), artificial substrates

well as the excessive concentration of suspended solids (Ray

(Legarda et al., 2018) and “bacterial-rich” inoculums from a

et al., 2010), poor alkalinity (Furtado et al., 2015), and C:N

mature tank or pond (Ferreira et al., 2020). These processes

ratio management (Panigrahi et al., 2019). During the evolution

can optimize the use of resources, speed up and maintain the

process, a wide variety of designs, conditions, strategies, and

nitrification process and improve the water quality parameters.

equipment have been evaluated, including aeration systems (Lara

Unfortunately, not all these practices have been fully adopted at a

et al., 2017); clarification methods (Ray et al., 2010); water depths

commercial level, mostly due to the lack of knowledge or logistics

(Krummenauer et al., 2016), indoor and outdoor conditions (Xu

issues scaling them up into large operations.

et al., 2021), and stocking densities (Krummenauer et al., 2011;

From an educational perspective, the farm technicians are

Da Silveira et al., 2020). Several training courses were carried

usually receptive to adopting new practices, but ongoing training

out, and the trained human resources from the 1990s and more

and incorporation of specialized personnel are often required.

recently from the 2000s, now spread globally, supported the

An example of a lack of training was the “brown water”

BFT expansion and the implementation of various commercial

nursery system in Ecuador. The “brown water” refers to BFT

operations worldwide (Ulloa-Walker et al., 2020).

heterotrophic-based (mostly using molasses and commercial

probiotics to control ammonia) operated in small indoor lined

BFT IN SHRIMP FARMING: PRESENT concrete tanks. Stoichiometric calculations were poorly applied

in some cases, leading to N-compounds issues, and therefore

In the past, BFT was mostly restricted to universities and research high water exchange rates were frequently observed. As a

centres. Nowadays, it has become consolidated as a production result, several nursery facilities were abandoned, unsatisfactory

system in many countries. Locations once considered unsuitable growth performance was observed, and most farmers switched to

for shrimp farming are now starting to produce in indoor “green water” earthen pond-based nurseries (Ching et al., 2020).

closed systems (e.g., Germany and Canada), mainly due to the On the other hand, higher rates of BFT adoption (or similar

advances in technology over previous years in genetics, nutrition, microbial-based approaches) have been observed in Brazil, Peru,

engineering, and management in particular (El-Sayed, 2021). Guatemala, and Mexico, particularly during the nursery phase.

Currently, BFT has been applied in the nursery (especially in In Asia, Vietnamese intensive farms seem to be very adaptable to

the Americas and, more recently, Asia) and grow-out phases. new microbial-based protocols applied to nursery and grow-out

Stocking densities impact the shrimp harvest size (Krummenauer phases (Arnold et al., 2020; Boaventura et al., 2020).

et al., 2011) and may influence the operational risks (e.g., disease

outbreaks) and production costs. Large commercial operations

normally adopt conservative stocking densities, whereas small DISCUSSION: FUTURE CHALLENGES AND

indoor “boutique farms” tend to stock with higher densities OPPORTUNITIES

aiming to optimize resources/infrastructure (Figure 1). In terms

of shrimp performance, water quality parameters in optimal Past and present are supporting the BFT future development.

levels, proper feed management, and desirable microbial profile Although such technique was conceived to close the gap toward

of the water are key points in BFT. Moreover, the use of sustainable aquatic production, constraints such as high energy

high-quality diets associated with automatic feeders (promoting costs and proper management of the residual solids remain

better spatial and temporal feed distribution) has improved unsolved (Ray et al., 2010). For that, alternative processes

Frontiers in Marine Science | www.frontiersin.org 2 December 2021 | Volume 8 | Article 813091

Emerenciano et al. Biofloc Technology in Shrimp Farming

FIGURE 1 | Different scales currently utilized in commercial biofloc-based shrimp farming: large-scale farm in Vietnam, Asia (left); and small-scale “boutique close to

market” farm in Brazil, Latin America (right).

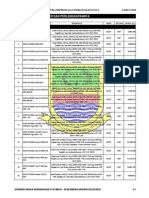

TABLE 1 | Summary of BFT evolution over time with key characteristics by period.

Past Present Future/Opinion

Lack of understanding of different areas of Better understanding of the technology Refined economic modellings and

knowledge (e.g., engineering, production Improved design and engineering improved system efficiency

management, and aquatic microbiology) Higher control of water quality parameters Precision farming tools and automation

Poor system design (e.g., aeration Better manipulation over the microbial Circular economy

systems, drain system, etc.) community Applied “Omics”

Poor control of water quality parameters Adequate C:N ratio management Tailored feeds and breeding programs

(e.g., levels of suspended solids, Improved predictability, consistency,

N-compounds, alkalinity) performance, and economics

Poor C:N ratio management

Imbalance of the microbial population

Poor predictability and consistency

Sub-optimal performance and economics

and energy sources (Badiola et al., 2018), Integrated Multi- interaction between the microbes, the quorum sensing, and

trophic Aquaculture (IMTA) (Poli et al., 2019; Holanda et al., other communications processes are practical examples that

2020; Legarda et al., 2021), and new recycling options for the must be better understood (Dobretsov et al., 2009). Indeed,

wastes generated (solid and liquid fractions) could enhance the the screening of microbial profiles could be connected

circularity of BFT (Bauer et al., 2012), ultimately generating with management decision support tools and apps, and

“green-labelable” products and promoting the creation of help to control better and manipulate these communities

startups focused on sustainable solutions (Subasinghe et al., to achieve improved biofloc nutritional quality, pathogen

2009). Likewise, new sensor technologies and data management control, and production outcomes. In addition, information

& cloud systems coupled with machine learning, smart feeding about the effect of bioflocs on shrimp quality is still scarce.

technologies (e.g., hydroacoustic), and management decision Initial studies documented that biofloc consumption did

support tools are examples of precision farming solutions that not impact the post-harvest sensorial attributes (Martinez-

could contribute to a more functional BFT system (Rahman Porchas et al., 2020). Moreover, tailored feeds, broader

et al., 2021; Reis et al., 2022). Nevertheless, adoption at scale access to postlarvae from BFT-tailored breeding programs

and economics analysis will likely determine the feasibility of and BFT applied to other penaeid species are also expected.

such technologies. An extensive review done by Ulloa-Walker et al. (2020)

Efficient microbial management is mandatory in BFT. In described and highlighted promising results with non-L.

this sense, biotechnology tools and particularly the “omics” vannamei species in nursery, grow-out, and broodstock

sciences will be required to identify and understand the conditions. However, few initiatives have been reported at

microbial properties forming bioflocs, including the microbiota, larger scales, and future adoptions are foreseen, especially in the

mycobiota, and phytobiota. The biofouling process, the nursery phase.

Frontiers in Marine Science | www.frontiersin.org 3 December 2021 | Volume 8 | Article 813091

Emerenciano et al. Biofloc Technology in Shrimp Farming

CONCLUSIONS/OPINION medium-large operations, the adoption of economic modellings

and sensitivity analysis, precision farming technologies, holistic

Biofloc technology (hybrid and other microbial-based systems) health monitoring, and improved biosecurity protocols will help

can widely contribute to the sustainable intensification of identify opportunities to reduce costs and production-associated

shrimp production. The technique evolved from an experimental risks, improving the system predictability, competitiveness,

system to become a large-scale production system applied and resilience.

in many countries, particularly in the nursery phase. During

this journey, a better understanding of the system, including AUTHOR CONTRIBUTIONS

engineering, roles of microbial communities, water quality, and

feed management, has allowed for a more comprehensive and ME: article conceptualization, writing, and review. AM-B,

predictable environment (Table 1). In the future, scalability MM-P, MP, and FV: writing and review. All authors contributed

and incorporating circular economy concepts might help to the article and approved the submitted version.

overcome some existing issues, reducing the carbon footprint and

environmental impacts. In addition, more examples of industry- ACKNOWLEDGMENTS

academia collaborations are needed and expected.

The COVID 19 pandemic forced shrimp farmers globally We gratefully acknowledge the work of our numerous students,

to be much more efficient in managing production costs. technical staff, industry collaborators, and colleagues who have

Biofloc technology still has a high production cost when contributed to the body of knowledge related to the biofloc

compared to traditional (earthen pond) systems. Especially in technology in shrimp farming.

REFERENCES Dobretsov, S., Teplitski, M., and Paul, V. (2009). Mini-review: quorum sensing

in the marine environment and its relationship to biofouling. Biofouling 25,

Afroz, T., and Alam, S. (2013). Sustainable shrimp farming in Bangladesh: a 413–427. doi: 10.1080/08927010902853516

quest for an Integrated Coastal Zone Management. Ocean Coastal Manage. 71, El-Sayed, A. F. M. (2021). Use of biofloc technology in shrimp aquaculture: a

275–283. doi: 10.1016/j.ocecoaman.2012.10.006 comprehensive review, with emphasis on the last decade. Rev. Aquacult. 13,

Arnold, S., Emerenciano, M. G. C., Cowley, J. A., Little, B., Rahman, A., and Perrin, 676–705. doi: 10.1111/raq.12494

T. (2020). Collaboration drives innovations in super-intensive indoor shrimp FAO (2020). The State of World Fisheries and Aquaculture 2020: Sustainability in

farming. Glob. Seafood Alliance. Action. Food and Agriculture Organization of the United Nations.

Avnimelech, Y. (2012). Biofloc Technology: A Practical Guide Book. Baton Rouge, Ferreira, G. S., Silva, V. F., Martins, M. A., Da Silva, A. C. C. P., Machado, C.,

Louisiana: The World Aquaculture Society. Seiffert, W. Q., et al. (2020). Strategies for ammonium and nitrite control in

Badiola, M., Basurko, O., Piedrahita, R., Hundley, P., and Mendiola, D. (2018). Litopenaeus vannamei nursery systems with bioflocs. Aquac. Eng. 88:102040.

Energy use in recirculating aquaculture systems (RAS): a review. Aquac. Eng. doi: 10.1016/j.aquaeng.2019.102040

81, 57–70. doi: 10.1016/j.aquaeng.2018.03.003 Fleckenstein, L. J., Tierney, T. W., Fisk, J. C., and Ray, A. J. (2020). The

Bauer, W., Prentice-Hernandez, C., Tesser, M. B., Wasielesky W. Jr., and effects of different solids and biological filters in intensive pacific white

Poersch, L. H. (2012). Substitution of fishmeal with microbial floc meal and shrimp (Litopenaeus vannamei) production systems. Aquac. Eng. 91:102120.

soy protein concentrate in diets for the pacific white shrimp Litopenaeus doi: 10.1016/j.aquaeng.2020.102120

vannamei. Aquaculture 342, 112–116. doi: 10.1016/j.aquaculture.2012. Furtado, P. S., Poersch, L. H., and Wasielesky, W. (2015). The effect of different

02.023 alkalinity levels on Litopenaeus vannamei reared with biofloc technology

Boaventura, M., Hetzel, G., Huynh Tran, C., Bakker, S., and Marc, C. (2020). A (BFT). Aquac. Int. 23, 345–358. doi: 10.1007/s10499-014-9819-x

practical experience at a shrimp nursery system in Vietnam. Aquac. Asia Pac. Holanda, M., Santana, G., Furtado, P., Rodrigues, R. V., Cerqueira, V. R.,

Burford, M. A., Thompson, P. J., Mcintosh, R. P., Bauman, R. H., and Pearson, Sampaio, L. A., et al. (2020). Evidence of total suspended solids control

D. C. (2004). The contribution of flocculated material to shrimp (Litopenaeus by Mugil liza reared in an integrated system with pacific white shrimp

vannamei) nutrition in a high-intensity, zero-exchange system. Aquaculture Litopenaeus vannamei using biofloc technology. Aquac. Rep. 18:100479.

232, 525–537. doi: 10.1016/S0044-8486(03)00541-6 doi: 10.1016/j.aqrep.2020.100479

Cardona, E., Lorgeoux, B., Chim, L., Goguenheim, J., Le Delliou, H., and Cahu, C. Hostins, B., Wasielesky, W., Decamp, O., Bossier, P., and De Schryver, P. (2019).

(2016). Biofloc contribution to antioxidant defence status, lipid nutrition and Managing input C/N ratio to reduce the risk of acute Hepatopancreatic

reproductive performance of broodstock of the shrimp Litopenaeus stylirostris: Necrosis Disease (AHPND) outbreaks in biofloc systems–A laboratory study.

consequences for the quality of eggs and larvae. Aquaculture 452, 252–262. Aquaculture 508, 60–65. doi: 10.1016/j.aquaculture.2019.04.055

doi: 10.1016/j.aquaculture.2015.08.003 Hussain, A. S., Mohammad, D. A., Sallam, W. S., Shoukry, N. M., and Davis,

Ching, C., Crespo, C., Pazmiño, A., and Ron, E. (2020). Sistemas Multifasicos: Una D. A. (2021). Effects of culturing the Pacific white shrimp Penaeus vannamei

oportunidad para crecer. Boletin Nicovita. in “biofloc” vs “synbiotic” systems on the growth and immune system.

Da Silva, B. C. E., Vieira, F. D. N., Mouriño, J. L. P., Bolivar, N., and Seiffert, Aquaculture 542:736905. doi: 10.1016/j.aquaculture.2021.736905

W. Q. (2016). Butyrate and propionate improve the growth performance of Kesselring, J. C., Gruber, C., Standen, B., and Wein, S. (2019). Continuous

Litopenaeus vannamei. Aquac. Res. 47, 612–623. doi: 10.1111/are.12520 and pulse-feeding application of multispecies probiotic bacteria in whiteleg

Da Silveira, L. G. P., Krummenauer, D., Poersch, L. H., Fóes, G. K., Rosas, V. shrimp, Litopenaeus vannamei. J. World Aquac. Soc. 50, 1123–1132.

T., and Wasielesky W. Jr. (2022). The effect of partial harvest on production doi: 10.1111/jwas.12640

and growth performance of Litopenaeus vannamei reared in biofloc technologic Krummenauer, D., Peixoto, S., Cavalli, R. O., Poersch, L. H., and Wasielesky W.

system. Aquaculture 546:737408. doi: 10.1016/j.aquaculture.2021.737408 Jr. (2011). Superintensive culture of white shrimp, Litopenaeus vannamei, in a

Da Silveira, L. G. P., Krummenauer, D., Poersch, L. H., Rosas, V. T., and Wasielesky biofloc technology system in southern Brazil at different stocking densities. J.

W. Jr. (2020). Hyperintensive stocking densities for Litopenaeus vannamei World Aquac. Soc. 42, 726–733. doi: 10.1111/j.1749-7345.2011.00507.x

grow-out in biofloc technology culture system. J. World Aquac. Soc. 51, Krummenauer, D., Poersch, L. H., Fóes, G., Lara, G., and Wasielesky

1290–1300. doi: 10.1111/jwas.12718 W. Jr. (2016). Survival and growth of Litopenaeus vannamei reared

Frontiers in Marine Science | www.frontiersin.org 4 December 2021 | Volume 8 | Article 813091

Emerenciano et al. Biofloc Technology in Shrimp Farming

in BFT system under different water depths. Aquaculture 465, 94–99. Thitamadee, S., Prachumwat, A., Srisala, J., Jaroenlak, P., Salachan, P.

doi: 10.1016/j.aquaculture.2016.09.002 V., Sritunyalucksana, K., et al. (2016). Review of current disease

Lara, G., Krummenauer, D., Abreu, P. C., Poersch, L. H., and Wasielesky, W. threats for cultivated penaeid shrimp in Asia. Aquaculture 452, 69–87.

(2017). The use of different aerators on Litopenaeus vannamei biofloc culture doi: 10.1016/j.aquaculture.2015.10.028

system: effects on water quality, shrimp growth and biofloc composition. Ulloa-Walker, D. A., Morales-Suazo, M. C., and Emerenciano, M. G. C. (2020).

Aquac. Int. 25, 147–162. doi: 10.1007/s10499-016-0019-8 Biofloc technology: principles focused on potential species and the case study

Legarda, E. C., Barcelos, S. S., Redig, J. C., Ramírez, N. C. B., Guimarães, of Chilean river shrimp Cryphiops caementarius. Rev. Aquac. 12, 1759–1782.

A. M., Santo, C. M. D. E., et al. (2018). Effects of stocking density doi: 10.1111/raq.12408

and artificial substrates on yield and water quality in a biofloc shrimp Wright, J. (2015). High-density shrimp producer wins innovation award. Seafood

nursery culture. Rev. Bras. Zootecnia 47:e20170060. doi: 10.1590/rbz4720 Alliance 1.

70060 Xu, W., Xu, Y., Su, H., Hu, X., Xu, Y., Li, Z., et al. (2021). Production

Legarda, E. C., Da Silva, D., Miranda, C. S., Pereira, P. K. M., Martins, performance, inorganic nitrogen control and bacterial community

M. A., Machado, C., et al. (2021). Sea lettuce integrated with Pacific characteristics in a controlled biofloc-based system for indoor and outdoor

white shrimp and mullet cultivation in biofloc impact system performance super-intensive culture of Litopenaeus vannamei. Aquaculture 531:735749.

and the sea lettuce nutritional composition. Aquaculture 534:736265. doi: 10.1016/j.aquaculture.2020.735749

doi: 10.1016/j.aquaculture.2020.736265 Xu, W., Xu, Y., Su, H., Hu, X., Yang, K., Wen, G., et al. (2020). Characteristics of

Martinez-Porchas, M., Ezquerra-Brauer, M., Mendoza-Cano, F., Higuera, J. ammonia removal and nitrifying microbial communities in a hybrid biofloc-

E. C., Vargas-Albores, F., and Martinez-Cordova, L. R. (2020). Effect RAS for intensive Litopenaeus vannamei culture: a pilot-scale study. Water

of supplementing heterotrophic and photoautotrophic biofloc, on the 12:3000. doi: 10.3390/w12113000

production response, physiological condition and post-harvest quality Yu, Z., Dai, Z. Y., Li, L., Qin, G. X., and Wu, L. F. (2021). Dietary

of the whiteleg shrimp, Litopenaeus vannamei. Aquac. Rep. 16:100257. supplementation with biofloc promotes growth, improves immune and

doi: 10.1016/j.aqrep.2019.100257 antioxidant status, and upregulates NF-κB/Nrf2 signalling molecules and stress

Panigrahi, A., Sundaram, M., Chakrapani, S., Rajasekar, S., Syama Dayal, J., resistance in Rhynchocypris lagowskii Dybowski. Aquac. Nutr. 27, 225–239.

Chavali, G. (2019). Effect of carbon and nitrogen ratio (C:N) manipulation on doi: 10.1111/anu.13180

the production performance and immunity of Pacific white shrimp Litopenaeus Zeng, S., Khoruamkid, S., Kongpakdee, W., Wei, D., Yu, L., Wang, H.,

vannamei (Boone, 1931) in a biofloc-based rearing system. Aquaculture Res. 50, et al. (2020). Dissimilarity of microbial diversity of pond water, shrimp

29–41. doi: 10.1111/are.13857 intestine and sediment in Aquamimicry system. AMB Express 10, 1–11.

Poli, M. A., Legarda, E. C., De Lorenzo, M. A., Martins, M. A., and Do doi: 10.1186/s13568-020-01119-y

Nascimento Vieira, F. (2019). Pacific white shrimp and Nile tilapia integrated in Zhou, L., Li, H., Qin, J. G., Wang, X., Chen, L., Xu, C., et al. (2020).

a biofloc system under different fish-stocking densities. Aquaculture 498, 83–89. Dietary prebiotic inulin benefits on growth performance, antioxidant

doi: 10.1016/j.aquaculture.2018.08.045 capacity, immune response and intestinal microbiota in Pacific white

Rahman, A., Xi, M., Dabrowski, J. J., Mcculloch, J., Arnold, S., Rana, M., et al. shrimp (Litopenaeus vannamei) at low salinity. Aquaculture 518:734847.

(2021). An integrated framework of sensing, machine learning, and augmented doi: 10.1016/j.aquaculture.2019.734847

reality for aquaculture prawn farm management. Aquac. Eng. 95:102192.

doi: 10.1016/j.aquaeng.2021.102192 Conflict of Interest: The authors declare that the research was conducted in the

Ray, A. J., Seaborn, G., Leffler, J. W., Wilde, S. B., Lawson, A., and Browdy, absence of any commercial or financial relationships that could be construed as a

C. L. (2010). Characterization of microbial communities in minimal- potential conflict of interest.

exchange, intensive aquaculture systems and the effects of suspended solids

management. Aquaculture 310, 130–138. doi: 10.1016/j.aquaculture.2010. Publisher’s Note: All claims expressed in this article are solely those of the authors

10.019 and do not necessarily represent those of their affiliated organizations, or those of

Reis, J., Peixoto, S., Soares, R., Rhodes, M., Ching, C., and Davis, A.

the publisher, the editors and the reviewers. Any product that may be evaluated in

(2022). Passive acoustic monitoring as a tool to assess feed response and

this article, or claim that may be made by its manufacturer, is not guaranteed or

growth of shrimp in ponds and research systems. Aquaculture 546:737326.

doi: 10.1016/j.aquaculture.2021.737326 endorsed by the publisher.

Subasinghe, R., Soto, D., and Jia, J. (2009). Global aquaculture

and its role in sustainable development. Rev. Aquac. 1, 2–9. Copyright © 2021 Emerenciano, Miranda-Baeza, Martínez-Porchas, Poli and Vieira.

doi: 10.1111/j.1753-5131.2008.01002.x This is an open-access article distributed under the terms of the Creative Commons

Susanti, L., Utomo, S. W., and Takarina, N. D. (2021). “Sustainability and Attribution License (CC BY). The use, distribution or reproduction in other forums

feasibility assessments of nanobubble aeration technology in economic- is permitted, provided the original author(s) and the copyright owner(s) are credited

socio environment of Penaeus vannamei shrimp farming,” in BIO Web and that the original publication in this journal is cited, in accordance with accepted

of Conferences: EDP Sciences (Yogyakarta). doi: 10.1051/bioconf/202133 academic practice. No use, distribution or reproduction is permitted which does not

05005 comply with these terms.

Frontiers in Marine Science | www.frontiersin.org 5 December 2021 | Volume 8 | Article 813091

You might also like

- Biodiversity for Food and Agriculture and Ecosystem Services: Thematic Study for the State of the World’s Biodiversity for Food and AgricultureFrom EverandBiodiversity for Food and Agriculture and Ecosystem Services: Thematic Study for the State of the World’s Biodiversity for Food and AgricultureNo ratings yet

- Understanding Diseases and Control in Seaweed Farming in ZanzibarFrom EverandUnderstanding Diseases and Control in Seaweed Farming in ZanzibarNo ratings yet

- Emerenciano Et Al. 2021Document6 pagesEmerenciano Et Al. 2021joao pedro FonsecaNo ratings yet

- El Sayed 2020 - BFT - Shrimp - ReviewDocument30 pagesEl Sayed 2020 - BFT - Shrimp - ReviewElisa AndradeNo ratings yet

- Microorganisms in Biofloc Aquaculture SystemDocument17 pagesMicroorganisms in Biofloc Aquaculture SystemMarylene PaivaNo ratings yet

- Holanda Et Al. 2020Document8 pagesHolanda Et Al. 2020joao pedro FonsecaNo ratings yet

- Bio Oc Technology Application in Aquaculture To Support Sustainable Development GoalsDocument5 pagesBio Oc Technology Application in Aquaculture To Support Sustainable Development Goalsload loadNo ratings yet

- Spoilage-Related Microbiota in Fish and Crustaceans During Storage: Research Progress and Future TrendsDocument37 pagesSpoilage-Related Microbiota in Fish and Crustaceans During Storage: Research Progress and Future TrendsPinitta HutagalungNo ratings yet

- My Synopsis ArticalDocument15 pagesMy Synopsis ArticalYousaf JamalNo ratings yet

- Hydroponic Solutions For Soilless Production Systems: Issues and Opportunities in A Smart Agriculture PerspectiveDocument17 pagesHydroponic Solutions For Soilless Production Systems: Issues and Opportunities in A Smart Agriculture PerspectiveStudent of agribusiness managementNo ratings yet

- 1 s2.0 S2468550X22001459 MainDocument12 pages1 s2.0 S2468550X22001459 Mainadelia intanNo ratings yet

- Srijit Chakravarty, Et AlDocument13 pagesSrijit Chakravarty, Et AlMaria Veronica Lopez100% (1)

- GRUPO 4. Rodkun Et Al 2021Document13 pagesGRUPO 4. Rodkun Et Al 2021plastiecoNo ratings yet

- Biofloc Technology For Sustainable Aquaculture ProductionDocument4 pagesBiofloc Technology For Sustainable Aquaculture ProductionMayar HatemNo ratings yet

- Current Status of Genetics and Genomics of Reared Penaeid Shrimp: Information Relevant To Access and Benefit SharingDocument14 pagesCurrent Status of Genetics and Genomics of Reared Penaeid Shrimp: Information Relevant To Access and Benefit Sharingelvind jordanalpouteyNo ratings yet

- Biofloc Technology For Sustainable Aquaculture ProductionDocument4 pagesBiofloc Technology For Sustainable Aquaculture ProductionMuhammad ImamNo ratings yet

- Monitoring and Managing Microbes in Aquaculture - Towards A Sustainable IndustryDocument9 pagesMonitoring and Managing Microbes in Aquaculture - Towards A Sustainable IndustrySusila AhmadNo ratings yet

- 1 s2.0 S2352513420306086 MainDocument7 pages1 s2.0 S2352513420306086 MainSandeep SinghNo ratings yet

- Antibacterial Spectrum of Synthetic Herbal-Based Polyphenols Against Vibrio Parahaemolyticus, Tinh 2021Document11 pagesAntibacterial Spectrum of Synthetic Herbal-Based Polyphenols Against Vibrio Parahaemolyticus, Tinh 2021afandi saputraNo ratings yet

- 5.effect of Nursery SystemDocument7 pages5.effect of Nursery Systemeulalio.arambulNo ratings yet

- 1 s2.0 S0044848622000230 MainDocument8 pages1 s2.0 S0044848622000230 MainAceScape ThermodynamcisNo ratings yet

- Dysbiosis and Restoration Dynamics Et Al - 2022Document17 pagesDysbiosis and Restoration Dynamics Et Al - 2022Ibon Garcia GallegoNo ratings yet

- cig4Document16 pagescig4Allison MaasNo ratings yet

- Raq 12356Document18 pagesRaq 12356sameh.eldahanNo ratings yet

- Sustainability 13 07255Document15 pagesSustainability 13 07255Niladri ChakrabortyNo ratings yet

- Fsufs 05 606815Document23 pagesFsufs 05 606815antonioNo ratings yet

- Aquamimicry 2022Document34 pagesAquamimicry 2022habibNo ratings yet

- Efficacy of Utilization of All-Plant-Based and ComDocument12 pagesEfficacy of Utilization of All-Plant-Based and Comhossainimam0079No ratings yet

- Probiotic-Based Cultivation of Clarias B PDFDocument12 pagesProbiotic-Based Cultivation of Clarias B PDFpushpen5115No ratings yet

- 2020 Understanding The Role of The Shrimp Gut Microbiome in Health and Disease. ArtículoDocument16 pages2020 Understanding The Role of The Shrimp Gut Microbiome in Health and Disease. ArtículoErnesto RonNo ratings yet

- Aquaculture: ReviewDocument16 pagesAquaculture: ReviewDamian ServoNo ratings yet

- 672-Article Text-1260-1-10-20210228Document14 pages672-Article Text-1260-1-10-20210228Benny OstaNo ratings yet

- 52219-Texto Do Artigo-751375224346-1-10-20210426Document7 pages52219-Texto Do Artigo-751375224346-1-10-20210426Manu MorpheusNo ratings yet

- 1 s2.0 S2666833523000266 MainDocument15 pages1 s2.0 S2666833523000266 MainkatrinaNo ratings yet

- 19. the SupplementationDocument10 pages19. the SupplementationValeria BotacheNo ratings yet

- Accepted Manuscript: 10.1016/j.scitotenv.2018.09.355Document62 pagesAccepted Manuscript: 10.1016/j.scitotenv.2018.09.355samagamaNo ratings yet

- Extra Botany: Global Crop Improvement Networks To Bridge Technology GapsDocument12 pagesExtra Botany: Global Crop Improvement Networks To Bridge Technology GapsAmber ZahraNo ratings yet

- Research On Citrus BreedingDocument15 pagesResearch On Citrus BreedingDaisy SarsueloNo ratings yet

- Agrobiotechnology in The AMERICASDocument8 pagesAgrobiotechnology in The AMERICASAnupma RaiNo ratings yet

- International Research Journal of Microbiology 2011Document8 pagesInternational Research Journal of Microbiology 2011Maurilio Lara FloresNo ratings yet

- Aquaculture: A A A A A B B ADocument8 pagesAquaculture: A A A A A B B AJeisson OmarNo ratings yet

- 1 s2.0 S2352513422002010 MainDocument11 pages1 s2.0 S2352513422002010 MainLuzby María Jiménez CastilloNo ratings yet

- Application of Probiotics and PrebioticsDocument6 pagesApplication of Probiotics and PrebioticsMishyree AndatuanNo ratings yet

- Bacillus Subtilis, An Ideal Probiotic Bacterium To Shrimp and FishDocument9 pagesBacillus Subtilis, An Ideal Probiotic Bacterium To Shrimp and FishsumanNo ratings yet

- Jwas 12589Document18 pagesJwas 12589WAPARAFOL100% (1)

- Inhibition of Melanosis in Whiteleg Shrimp LitopenDocument11 pagesInhibition of Melanosis in Whiteleg Shrimp LitopenRomulo BrissantNo ratings yet

- Food Security and The Dynamics of Wheat and Maize Value Chains in Africa and AsiaDocument17 pagesFood Security and The Dynamics of Wheat and Maize Value Chains in Africa and Asiamuhaba AdegeNo ratings yet

- Probiotics in Marine LarvicultureDocument24 pagesProbiotics in Marine LarviculturemaicolNo ratings yet

- Perniciosa and Moniliophthora RoreriDocument11 pagesPerniciosa and Moniliophthora RorerijeanpiereNo ratings yet

- 1 s2.0 S2352513420306025 MainDocument9 pages1 s2.0 S2352513420306025 MainSandeep SinghNo ratings yet

- Food Control: Xiaobao Nie, Ruichang Zhang, Lilin Cheng, Wenbo Zhu, Songlin Li, Xiaoming ChenDocument10 pagesFood Control: Xiaobao Nie, Ruichang Zhang, Lilin Cheng, Wenbo Zhu, Songlin Li, Xiaoming ChenCiterinNo ratings yet

- Microorganisms As A Sustainable Aquafeed Ingredient A ReviewDocument21 pagesMicroorganisms As A Sustainable Aquafeed Ingredient A ReviewHafez A MabroukNo ratings yet

- Probiotic Strains Used in Aquaculture: October 2018Document9 pagesProbiotic Strains Used in Aquaculture: October 2018Dr Mahesh100% (1)

- Bio e Stimulant EsDocument19 pagesBio e Stimulant Esfda.narvaezNo ratings yet

- The Genomics of The Farmed Shrimp Current Status and ApplicationDocument13 pagesThe Genomics of The Farmed Shrimp Current Status and ApplicationRama BangeraNo ratings yet

- Crop microbiome key to sustainable agricultureDocument2 pagesCrop microbiome key to sustainable agricultureFajar NugrahantoNo ratings yet

- FAO - Current and Future Genetic Technologies For Fisheries and Aquaculture - 2022Document68 pagesFAO - Current and Future Genetic Technologies For Fisheries and Aquaculture - 2022Joshelyn Paredes ZavalaNo ratings yet

- Scientia Agropecuaria: Deyvis Espinoza Augusto CastilloDocument14 pagesScientia Agropecuaria: Deyvis Espinoza Augusto CastilloEstefania AbarcaNo ratings yet

- The Role of Technology On AquacultureDocument7 pagesThe Role of Technology On AquacultureMî FiestaNo ratings yet

- Aquaculture: SciencedirectDocument11 pagesAquaculture: SciencedirectJeisson OmarNo ratings yet

- Shannon - Hartley TheoremDocument10 pagesShannon - Hartley TheoremVikas MehtaNo ratings yet

- Principles of Safe Design For WorkDocument41 pagesPrinciples of Safe Design For WorkTim Atega100% (1)

- Unit - 2Document89 pagesUnit - 2Bharti PatelNo ratings yet

- Lebanese International University School of EngineeringDocument9 pagesLebanese International University School of EngineeringMohamad AyoubNo ratings yet

- EN81-28 Risk of Trapping FlowChart v3Document1 pageEN81-28 Risk of Trapping FlowChart v3Ashraful ShohagNo ratings yet

- COCOMO - An Empirical Estimation Model For EffortDocument4 pagesCOCOMO - An Empirical Estimation Model For EffortAdnan RajperNo ratings yet

- Active Autowerke X6/X6M X5/X5M DME DME Removal Instructions: Tools NeededDocument5 pagesActive Autowerke X6/X6M X5/X5M DME DME Removal Instructions: Tools NeededIemel holgersonNo ratings yet

- Paper Cobot 4Document8 pagesPaper Cobot 4Jessica NovitaNo ratings yet

- Komputer, DLLDocument280 pagesKomputer, DLLEva SiswantiNo ratings yet

- MPLab Tutorial v1Document45 pagesMPLab Tutorial v1ASIM RIAZNo ratings yet

- Intro To EV3 ProgrammingDocument16 pagesIntro To EV3 ProgrammingJose GomesNo ratings yet

- Clock Domain Crossing (CDC) : Erik Seligman CS 510, Lecture 17, March 2009Document39 pagesClock Domain Crossing (CDC) : Erik Seligman CS 510, Lecture 17, March 2009Rohan PeterNo ratings yet

- Book I.KovaeviS - Didi HighRiseBuildingsStructuresandMaterials RGDocument46 pagesBook I.KovaeviS - Didi HighRiseBuildingsStructuresandMaterials RGKiro AnisNo ratings yet

- Revolusi Industri 4.0: Desain Perkembangan Transaksi Dan Sistem Akuntansi Keuangan Agung Prajanto Ririh Dian PratiwiDocument17 pagesRevolusi Industri 4.0: Desain Perkembangan Transaksi Dan Sistem Akuntansi Keuangan Agung Prajanto Ririh Dian PratiwiFirdausNo ratings yet

- TRAINING ON POWER GENERATION PROCESSESDocument19 pagesTRAINING ON POWER GENERATION PROCESSESPriyank Gaba100% (1)

- Sap BW ThesisDocument8 pagesSap BW ThesisKristen Flores100% (2)

- Apex Coding Guidelines V1Document25 pagesApex Coding Guidelines V1Kapil SaneNo ratings yet

- BQDVPADocument7 pagesBQDVPAmephir666No ratings yet

- TX2A/RX2A: UHF FM Data Transmitter and Receiver ModulesDocument10 pagesTX2A/RX2A: UHF FM Data Transmitter and Receiver ModulesMoisesNo ratings yet

- Linux TestDocument6 pagesLinux Testsvmendezw100% (1)

- MisMissile Systems Lethality Enhancement Through The Use of A Conducting Aerosol Plasma Warheadsile Systems Lethality Enhancement Through The Use of A Conducting Aerosol Plasma Warhead PDFDocument24 pagesMisMissile Systems Lethality Enhancement Through The Use of A Conducting Aerosol Plasma Warheadsile Systems Lethality Enhancement Through The Use of A Conducting Aerosol Plasma Warhead PDFvig1ilNo ratings yet

- Reduce Concrete Waste with Bubble Deck SlabsDocument11 pagesReduce Concrete Waste with Bubble Deck Slabsgpt krtlNo ratings yet

- Check Your ECDIS Uses Latest IHO S-52 StandardsDocument4 pagesCheck Your ECDIS Uses Latest IHO S-52 StandardsgongaxNo ratings yet

- Brand Rex LinkClickDocument170 pagesBrand Rex LinkClickniantonsNo ratings yet

- RRU3942 Hardware Description (04) (PDF) - ENDocument39 pagesRRU3942 Hardware Description (04) (PDF) - ENHENRYNo ratings yet

- 132kV Relay Cal Tender 17 June 2014Document5 pages132kV Relay Cal Tender 17 June 2014amirahNo ratings yet

- Gas Turbine Training Manual: Trip Oil SystemDocument3 pagesGas Turbine Training Manual: Trip Oil SystemsambhuNo ratings yet

- Create Your Platform: Aryflex 2 Top-ClassDocument7 pagesCreate Your Platform: Aryflex 2 Top-ClassAditya aherNo ratings yet

- Concrete International 2011 Media PlannerDocument10 pagesConcrete International 2011 Media Plannerbday23No ratings yet

- TraceDocument2 pagesTraceFakthur RahmanNo ratings yet