Professional Documents

Culture Documents

19ae5301 Amp

Uploaded by

Kathirvel KOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

19ae5301 Amp

Uploaded by

Kathirvel KCopyright:

Available Formats

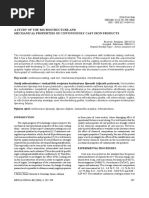

Reg.

No:

Hindusthan College of Engineering and Technology

(An Autonomous Institution, Affiliated to Anna University, Chennai)

Valley Campus, Pollachi Highway, Coimbatore – 641032

END SEMESTER UG/PG DEGREE EXAMINATIONS – NOV/DEC 2021

Department : AERONAUTICAL ENGINEERING

Course Code & Name: 19AE5301 & AIRCRAFT MATERIALS AND PROCESSES

Semester: V QP CODE: 19AE5301

Duration: 3 Hours Maximum: 100 Marks

BLOOMS TAXONOMY LEVEL (BTL)

LEVEL L1 L2 L3 L4 L5 L6 TOTAL

% 25 54 7 7 7 - 100

Part A – (10 X 2 = 20 Marks)

Q. No. Question BTL CO# Mark

1. State Bragg law. (R) CO1 2

2. Define Strain hardening. (U) CO1 2

3. What is meant by stress corrosion cracking? (U) CO2 2

4. What is the effect of addition of chromium in steel? (U) CO2 2

5. What do you mean Shape memory alloys? (U) CO3 2

6. What are the uses of boron carbide? (R) CO3 2

7. What are the characteristics of high temperature materialsɁ (U) CO4 2

8. Name a few examples of super alloys used for high temperature applicationsɁ (R) CO4 2

9. Define casting. (U) CO5 2

10. What is closed mould process? (U) CO5 2

Part B – (5 X 14 = 70 Marks)

11. Explain in detail Bauschinger’s effect. (A) CO1 14

(Or)

12. List the imperfections in crystals. And explain them. (R) CO1 14

13. Examine the role of alloying elements in preventing corrosion in carbon steels. (AN) CO2 14

(Or)

14. Explain in detail about any four types of corrosion. (R) CO2 14

15. Explain the process of Powder metallurgy. (U) CO3 14

(Or)

16. What are shape memory alloys?. How it can be used in aerospace industry? (R) CO3 14

17. Explain how the mechanical properties vary with temperature for high temperature (E) CO4 14

materials.

(Or)

18. Explain the super alloys based on its chemical composition (U) CO4 14

19. Explain metal die casting and also write its applications. (U) CO5 14

(Or)

20. Explain ram type injection moulding with a neat sketch (U) CO5 14

PART – C (1 X 10 = 10)

(Application/Design/Analysis/Evaluation/Creativity/Case Study)

21. a) Explain in detail the requirements of materials in aerospace industries (U) CO2 10

(Or)

21. b) Explain compression moulding with a neat sketch. (U) CO5 10

1 | Page

You might also like

- Am2213 Set 2Document2 pagesAm2213 Set 2r.rabinNo ratings yet

- Bethlahem Institute of Engineering Karungal-629 157Document2 pagesBethlahem Institute of Engineering Karungal-629 157Ʀoʛeʀ Ɩeo ƖɩbɩŋNo ratings yet

- Model 2Document2 pagesModel 2Ram RajNo ratings yet

- Am2213 Set 1Document2 pagesAm2213 Set 1r.rabinNo ratings yet

- Bethlahem Institute of Engineering: KARUNGAL - 629 157Document4 pagesBethlahem Institute of Engineering: KARUNGAL - 629 157prasadNo ratings yet

- 20ME102-Fundamentals of Mechanical EnggDocument2 pages20ME102-Fundamentals of Mechanical EnggK.GAYATHRINo ratings yet

- Ucmp Model Set ADocument2 pagesUcmp Model Set ASAMUEL SANJAY RAJA R MECHNo ratings yet

- CS3351 - ModelDocument2 pagesCS3351 - Modelrkkumar07No ratings yet

- Part A: (Government Aided Autonomous Institution)Document2 pagesPart A: (Government Aided Autonomous Institution)Dr.V.R.VelmuruganNo ratings yet

- AE3301 EAE Model QPDocument2 pagesAE3301 EAE Model QPVivekananda SubramaniNo ratings yet

- OPR752 Processing of PolymerDocument2 pagesOPR752 Processing of PolymerVivekananda SubramaniNo ratings yet

- CE8392 - Engineering GeologyDocument2 pagesCE8392 - Engineering GeologyA.Sai Kumar Assistant Professor - CVLNo ratings yet

- Question Paper Code:: PART A - (10 X 2 20 Marks) 1. State Gibbs Phase RuleDocument2 pagesQuestion Paper Code:: PART A - (10 X 2 20 Marks) 1. State Gibbs Phase RuleKanagasabai SabaNo ratings yet

- PH8151 - Engineering PhysicsDocument3 pagesPH8151 - Engineering PhysicsK.GAYATHRINo ratings yet

- Manufacturing Technology 2 Int 1 Question PaperDocument1 pageManufacturing Technology 2 Int 1 Question PaperRamNo ratings yet

- Year/Sem:II/III Duration: 3 Hour Max. Marks: 100: BAN301-Fundamentals of Aeronautics and AstronauticsDocument2 pagesYear/Sem:II/III Duration: 3 Hour Max. Marks: 100: BAN301-Fundamentals of Aeronautics and AstronauticsMuthukrishnan biherNo ratings yet

- Iat I Set IiDocument2 pagesIat I Set IiarulsivagiriNo ratings yet

- Ramaiah: MSEE02Document2 pagesRamaiah: MSEE02hari krishnaNo ratings yet

- Question Paper Code:: CO1: CO2: CO3: CO4: CO5Document3 pagesQuestion Paper Code:: CO1: CO2: CO3: CO4: CO5yaro oruvanNo ratings yet

- Aircraft Materials and ProcessesDocument4 pagesAircraft Materials and ProcessesthandialNo ratings yet

- NAME - 2013-2014 (L-2, T-1)Document18 pagesNAME - 2013-2014 (L-2, T-1)partho RoyNo ratings yet

- Bethlahem Institute of Engineering Karungal-629 157: Question Set: 01 Roll Number: Register NumberDocument1 pageBethlahem Institute of Engineering Karungal-629 157: Question Set: 01 Roll Number: Register NumberƦoʛeʀ Ɩeo ƖɩbɩŋNo ratings yet

- Part-A Q. No Question(s) Skills CO: 34032 & Electrical Circuits and InstrumentationDocument2 pagesPart-A Q. No Question(s) Skills CO: 34032 & Electrical Circuits and InstrumentationDr.V.R.VelmuruganNo ratings yet

- WWW - Manaresults.Co - In: B.Tech Ii Year I Semester (R13) Supplementary Examinations June 2017Document2 pagesWWW - Manaresults.Co - In: B.Tech Ii Year I Semester (R13) Supplementary Examinations June 2017KKNo ratings yet

- Chem Even 22Document10 pagesChem Even 22rounitmakheja5No ratings yet

- Year/Sem:II/III Duration: 3hour Max. Marks: 100: BAN301-Fundamentals of Aeronautics and AstronauticsDocument2 pagesYear/Sem:II/III Duration: 3hour Max. Marks: 100: BAN301-Fundamentals of Aeronautics and AstronauticsMuthukrishnan biherNo ratings yet

- 18ME15 - VTU QP'sDocument16 pages18ME15 - VTU QP'sHari Kiran M PNo ratings yet

- Iii Cse Ay 2022-2023 Odd Sem Model - I Set - 1Document2 pagesIii Cse Ay 2022-2023 Odd Sem Model - I Set - 1saran SanjayNo ratings yet

- CAT I - Robotics QPDocument1 pageCAT I - Robotics QPveerapandianNo ratings yet

- Course Outcome/CODocument2 pagesCourse Outcome/COdeepakkumarNo ratings yet

- Salem-Campus, Attur Main Road, Minnampalli, Salem - 636 106.: Mahendra College of EngineeringDocument2 pagesSalem-Campus, Attur Main Road, Minnampalli, Salem - 636 106.: Mahendra College of EngineeringAnonymous Ndsvh2soNo ratings yet

- Vlsi Model 4-QPDocument2 pagesVlsi Model 4-QPsanthoshNo ratings yet

- Nba Ptam Ia I RTDocument1 pageNba Ptam Ia I RTƦoʛeʀ Ɩeo ƖɩbɩŋNo ratings yet

- AE606703 - Manufacturing Processes QBDocument10 pagesAE606703 - Manufacturing Processes QBpsncetaerofinalyearNo ratings yet

- BLE1Document2 pagesBLE1Neethu BhaskaranNo ratings yet

- Sri Eshwar College of Engineering Internal Test Question PaperDocument2 pagesSri Eshwar College of Engineering Internal Test Question PaperSivakumar MuthuNo ratings yet

- Missile Aerodynamics - SOET CIA-2 8th Sem - 202305SDocument1 pageMissile Aerodynamics - SOET CIA-2 8th Sem - 202305Sae00505No ratings yet

- BAE302Document4 pagesBAE302khadkaashok72No ratings yet

- Department of Electrical and Electronics Engineering Internal Assessment Test - IDocument1 pageDepartment of Electrical and Electronics Engineering Internal Assessment Test - Isyed1188No ratings yet

- Internal Assessment Test on Fundamentals of Aeronautics and AstronauticsDocument2 pagesInternal Assessment Test on Fundamentals of Aeronautics and AstronauticsMuthukrishnan biherNo ratings yet

- Am2219 Set 2Document2 pagesAm2219 Set 2r.rabinNo ratings yet

- Airframe Iat1Document1 pageAirframe Iat1Ram RajNo ratings yet

- L-1, T-2, IPE, 2018-2019 (Online)Document14 pagesL-1, T-2, IPE, 2018-2019 (Online)Nazmus Sakib TntNo ratings yet

- Blob:https:/web Whatsapp ComDocument2 pagesBlob:https:/web Whatsapp ComShanu RawNo ratings yet

- B.Tech VI Semester (R20) I Midterm Examinations, April 2022: Section-I Marks CO BTDocument3 pagesB.Tech VI Semester (R20) I Midterm Examinations, April 2022: Section-I Marks CO BTgowthami sirana baluNo ratings yet

- Third Semester B.Tech. (Engineering) Degree Examination, October 2011Document2 pagesThird Semester B.Tech. (Engineering) Degree Examination, October 2011Dhruve EBNo ratings yet

- Agni College Internal Assessment TestDocument2 pagesAgni College Internal Assessment TestohmshankarNo ratings yet

- AE6015 - Rockets and Missiles Part - A (8 X 3 24) Answer Any Eight QuestionsDocument2 pagesAE6015 - Rockets and Missiles Part - A (8 X 3 24) Answer Any Eight QuestionspugazhNo ratings yet

- Register Number Assessment Test Mechanical Engineering DepartmentDocument1 pageRegister Number Assessment Test Mechanical Engineering DepartmentMECH HODNo ratings yet

- St. Michael College of Engg. & Tech., St. Michael College of Engg. & Tech.Document2 pagesSt. Michael College of Engg. & Tech., St. Michael College of Engg. & Tech.RamNo ratings yet

- EC8751 - Optical Communication - CIA 2 - S E T 1Document1 pageEC8751 - Optical Communication - CIA 2 - S E T 1xacasib574No ratings yet

- (Government Aided Autonomous Institution) : Part ADocument1 page(Government Aided Autonomous Institution) : Part ADr.V.R.VelmuruganNo ratings yet

- Ucmp Model Set BDocument2 pagesUcmp Model Set BSAMUEL SANJAY RAJA R MECHNo ratings yet

- Am2503 Set 1Document2 pagesAm2503 Set 1r.rabinNo ratings yet

- Am2503 Set 1Document2 pagesAm2503 Set 1r.rabinNo ratings yet

- Ee 3503Document1 pageEe 3503syed1188No ratings yet

- Chemistry exam questionsDocument14 pagesChemistry exam questionsShivacharan HollaNo ratings yet

- ASSESSMENT TESTI CPC QUESTION CH8351 NewDocument1 pageASSESSMENT TESTI CPC QUESTION CH8351 NewbeevifathimamtNo ratings yet

- QP IAT I WT SET 1 Oro551Document1 pageQP IAT I WT SET 1 Oro551arulsivagiriNo ratings yet

- Two MarksDocument18 pagesTwo MarksKathirvel KNo ratings yet

- (Merge) AmpDocument19 pages(Merge) AmpKathirvel KNo ratings yet

- Aircraft Materials Processes QuestionsDocument14 pagesAircraft Materials Processes QuestionsKathirvel KNo ratings yet

- Hindusthan College of Engineering and Technology: AircraftDocument12 pagesHindusthan College of Engineering and Technology: AircraftKathirvel KNo ratings yet

- Aircraft Materials Course Code 19AE5301Document1 pageAircraft Materials Course Code 19AE5301Kathirvel KNo ratings yet

- Sma Microproject (Me5ib)Document13 pagesSma Microproject (Me5ib)ME5047OMKAR JADHAVNo ratings yet

- HMTDocument6 pagesHMTHarshmani GuptaNo ratings yet

- Mechanical Properties: Element Content (%)Document2 pagesMechanical Properties: Element Content (%)SANNI KUMARNo ratings yet

- Pickling and Passivation: Technical NoteDocument4 pagesPickling and Passivation: Technical NoteBhushan PableNo ratings yet

- Risks and Safety Measures Intig Welding ProcessDocument5 pagesRisks and Safety Measures Intig Welding ProcessSeminarski radoviNo ratings yet

- Datasheet For Steel Grades Structure Steel 45MnDocument2 pagesDatasheet For Steel Grades Structure Steel 45MnJhon ChitNo ratings yet

- CHE421Document1 pageCHE421Eko SuherNo ratings yet

- CFS Lift Product Range PDFDocument9 pagesCFS Lift Product Range PDFShamaNo ratings yet

- Class 125/250 Globe Type Silent Check ValveDocument1 pageClass 125/250 Globe Type Silent Check ValveNam ĐỗNo ratings yet

- The Charpy Impact Test and Its Applications: The Journal of Pipeline Engineering September 2013Document17 pagesThe Charpy Impact Test and Its Applications: The Journal of Pipeline Engineering September 2013Tamaduianu IoanNo ratings yet

- Metal Protective OilDocument2 pagesMetal Protective OilGuillermo Gonsales100% (1)

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetjon perez diezNo ratings yet

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinNo ratings yet

- Welding ProceduresDocument68 pagesWelding ProceduresTeox100% (1)

- 243 DMR Keystock Shim Catalogue C0H W01Document36 pages243 DMR Keystock Shim Catalogue C0H W01Han's AryanNo ratings yet

- SAWDocument4 pagesSAWLuis LugoNo ratings yet

- Steel MillDocument6 pagesSteel MillRenato Gigliotti MPhNo ratings yet

- Mechanical Properties of MaterialsDocument4 pagesMechanical Properties of MaterialsJomarie SojorNo ratings yet

- Casting Process ComparisonDocument6 pagesCasting Process ComparisonRajaSekarsajjaNo ratings yet

- Weld Australia Guidance Note TGN SG03 AS NZS 2980 A Summary of Changes PDFDocument14 pagesWeld Australia Guidance Note TGN SG03 AS NZS 2980 A Summary of Changes PDFRodolfoMarínNo ratings yet

- Alloying and Microstructural Management in Developing SMAW Electrodes For HSLA-100 SteelDocument14 pagesAlloying and Microstructural Management in Developing SMAW Electrodes For HSLA-100 SteelNOOB ONLYNo ratings yet

- Microstructure and properties of continuously cast ironDocument4 pagesMicrostructure and properties of continuously cast ironFARID MIFTAHUL ANWARNo ratings yet

- S058-000659-20-Tub-Et-0001-02 Material Data SheetDocument193 pagesS058-000659-20-Tub-Et-0001-02 Material Data Sheetpjcs1974No ratings yet

- Self Clinch Metric 2011 Small PDFDocument34 pagesSelf Clinch Metric 2011 Small PDFpaula09No ratings yet

- Inconel 718 PDFDocument33 pagesInconel 718 PDFMukesh kumarNo ratings yet

- EstimateDocument1 pageEstimateAlemar Soriano MalintadNo ratings yet

- Molecular Masses and Percent Composition CalculatorDocument4 pagesMolecular Masses and Percent Composition CalculatorsristisekharNo ratings yet

- Workshop HandbookDocument86 pagesWorkshop HandbookDenis Alibor MajhenNo ratings yet

- En 13835Document12 pagesEn 13835Aditya PratapNo ratings yet

- Tapered Thread Couplers: For The Construction IndustryDocument12 pagesTapered Thread Couplers: For The Construction Industrytrimble20No ratings yet