Professional Documents

Culture Documents

MX-3114N 20220626 193017

MX-3114N 20220626 193017

Uploaded by

m.ali0 ratings0% found this document useful (0 votes)

11 views19 pagesOriginal Title

MX-3114N_20220626_193017

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views19 pagesMX-3114N 20220626 193017

MX-3114N 20220626 193017

Uploaded by

m.aliCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 19

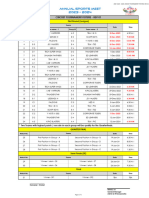

se Aaah & Pe Geen Yang &conracting ce

NBTC Tethers Dion

MECHANICAL TESTING LABORATORY

ene REAR A:

TEST REPORT - WELDED SAMPLE

Tran : naar ai

bbe Tt nhc ae heat eaten

eer ro ae

Pree ra ea a ROE nb OvarRa

re. : se oo nT

et FSA Wat wa

welding Pac oo ai Fa

ele te ar ano

ele ig Patan soup

eseronen tab Tonpetune BS

REFERENCE

ana aa Tag OTTO bin Geno Teme

taupe oe etation se

ket i TE Gipson iar

Fel Spe Asta es 6 on Prose Wo _ ae

TENSILE TEST

a Tesasonmam | ~ata_| eidionl | velSreem[Uriatetond] —Tonie en]

Wain [tne [met | vaanin [where [es | ew | We [1

in se | [we | = | = [ =» ®

acar o aca

ot ere

GRAPH

Plunger Ola Resulk

rer Face Berd 00 76 a a ‘Satiacory

on Root Berd 300 aa a a ‘Suiactory

fRequvemente ‘Bs per ASTIN SITs SWONGINT TO po) Tea STN AS NEO)

Remarks +The et et ces wth above mentioned sands

witnessed 6

Test esis peta to sumples received of NBTC Lab. Te fst report shal ote be ceproduced encept nfl without opprove ofthe laboratory

Block 5, Sua industrial Area -.0.80x 9088,Ahmad! 61001 Kuwait 1oOF2

“Teb{+965) 186777 ext4252/4262 Faxc{+965) 2228444 - E-mail tech services@abteuwall.com Web:vnvitnBtrOUP.com

Nove TEFOMLI Revot

Wr Mada rie Gone Trang Contracting CW

HNBTC Tec Sees Diston

MECHANICAL TESTING LABORATORY

TEST REPORT - WELDED SAMPLE

Report No. 50 fue 75107 Date 1 25an2022

Date of Receipt; 2aun20z2

yer Engineering Company -Kowale DateofTest ———: Baumann

lent ow [wre ‘ab no. Reiss

Project Name ‘Urn Al Hayman Wastewater Project Job Order No, 50/22/2882

Project Wo, : Ske 7 ODS mS men Tic

ateral = ASTM A312 T3264, Heat 8A 2100896 / eR 336, WPS No, 7D wan

Welding Process ‘Graw PORNO. AT-MIPO POR OF

Welder Name ANTHR ALL War NO. =

[Welder 1D/ No. v0 -w-002 ‘Welding Position: 66 Up

[be + Welding Procedore Qualfiation Test Lab Temperature; 235°C

REFERENCE

Equipment 7 Universal Testing Machine (TSD-UTIN OOH (Caliration Certicate No: F/o10/2

Equipment SiNO. or ‘allsration Date 1 Dean 2002

Make / Model Sian esting Eaupment /WAW 1000 Galloration Dus Date: han 008

ef std./ spec 7 ASTM A312 /85EN 50256163 / 24895 E4910 Procedure No, MBTES/taLw-ot

TENSILE TEST

ay Dimension nm ‘Area | _Yekd Wood | viellstengen [timate lad] Tensie Svenqth

‘wiath [Thickness [wom | (o2%juw | wim? |e i [Wm |

te 25.00 co ee 5 6 isa oa »

Fracture location I Tipe ofFracire

(Out Sie Wold metal

FReauiremencs ‘Aspe ASTO™A SIZ Weld Strength 170 tba) Trae Seengeh a5 HO)

Remarks The tet cel conga with above merttonedstondards

"Test rests pero to amps ecb at HETC Lab The et eport hel ote be roroduced econ fal witout approval ofthe aboalon

Block~S, Shuaiba industrial Area -?.0.80x 9088,Ahmad! 61003 Kuwait 20F2

“Tok:(+965) 1867777 Ext4252/4262 Fa:(+965) 22284444 - E-maiktech services@nbte-kuwalt.com Webswwn:nbtegroup.com

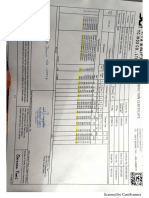

Naser M, AL-Baddah & Partner General Trading & Contracting Co. Wal

Technical Services Division

MECHANICAL TESTING LABORATORY

(5 aa F850 17025 Aceeedieed Laboratge)<

‘TEST REPORT - HARDNESS WELDED SAMPLE

HNBTC

Tapa Terre Conan ae

SORTS yea a tates 7 ame

Client MW / WIE a Lab No, 5 AGIs

octane _ ianain a bone worayam

Project No. pat Size 00 273 mm X94 mm Thick

i [Aa eR wit =

Weg es om rates WM

Welter none ana warner

eli ieee dng Pooe > op

Desa ern aT aTenpentiw ae

REFERENCE

apm i Cincom Coen no 7 era

vet aan Gc oe an

Wake ee ‘en lp Caio es

ete Sp eens fonwma Prwetne racial

HARDNESS TEST

Gainey Aneh Rieecttathas ams

Location - Top PM. ‘HAZ i Weld WAZ PM

re 166 | 160 | 162 | 199 | 191 | 192] 194 | 192 | 220 | 208 | 206 | 210] 216 | 208 | 18a | 192 | 187 | 183 195] 166 160] 169)

teats he wae | wa |

2[*[2 [||] [=

eee 90] 185) 184) 205 | 210 196 | 191 194.

ian i wa via wa 7

=[2[91]5]=[>]=]=]°[*12[[«[s]«]"]=[s

Seer +167 | 162 | 166 | 188 | 194] 192| 190) 190 | 215 | 210] 209| 283) 181 190] 181 | 192 167 | 165 | 170]

rated od hone Machines ae Chanel

nat be reproduced except fl without pproral of he oboratory

Block-5, Shuaiba Industrial Area-.0.80x 9088,Ahmadi 61001 Kuwait

“el(+965) 1967777 Ext:4252/4262 Faxc(+965) 22284448 -E-maletech services @abte kuwait.com Webw.nbtegroup.com

1OF1

NeTe-3FOMA} Rerot

Terme ke

N B Cc Technical Services Division

MECHANICAL TESTING LABORATORY

al RE Ae

TEST REPORT - IMPACT _

7150 /Fae Date oftecepe|

+ Hate ereing Crp Gate offet: asamanz

ent 7 Tab ro

Project Name + Un Al aon Wastewter Pec Tob Order a, wo/mayaas

‘ater 7 ASIA Tait, eat PA ZIONS /ERSIL WS No, i= mro-vns- 08

Woking Process Zea Pam, ‘an raat

Welder Name TAR Warn,

Welder b/w. 1 0-08 Welding Postion; coup

Description 7 ‘Welding Procedure Qualification Test Lab Temperature; 235°C

REFERENCE

Equipment endl irpae Testing Machine (TSDSTM-02) Calibration Caricate No,

Equioment Sino 2010/36 Caliration Date

Make / Mode! Fine Testing Machines IT 300 ASTM Callration Due bate

et std /Spee. ‘su is0asei64 / EN TS Procedure No.

TEST DETAILS |

Specimen Dimension nm | Te Seenned case?

Specimen 10 Notch Location Temperature ‘average (J)

fh ‘wath [rrickness] Longin | PE souls) ee |

wi Weld emer ols | s 0 % {

we wosscaeer wl s | s 0 7» na

we wel coner w fs | ss 0 n i

m Heat fected 7on0 w fos | os a0 %

ne test teed Zone wo fos | s a0 0 Bs

ES 10 “

[Rote Terrie Measuring warner {TSD-ALDI, SiN BBAGRa, Cerificate No ats, Bon Date 03 gant 200?

IRemarks + Thetest esi compes with cbove mentored sonderd:

Test ests pertain to somes received ot MBTC ob Te test report shal tab reproduced encanta ul without eporoval fe laboratory

Block-5, Shuaibo industrial rea -P.0.8ex 9088,Ahmadi 61003 Kuwalt oa

Tet(+965) 1867777 Exts4252/4262 Far (+965) 22284444 -€-maltech services@nbte-kuwalt.com Webswmw.abtegroup.com

NeTeTSFOML? Revot

widah & Partner General Trading & Contracting Co. W.Ll

Technical Services Division

(MECHANICAL TESTING LABORATORY

REIS 700 che Lab sray

TEST REPORT - MACRO ETCHING

NBTC™””

Report No 130 / Mer /909| ome: 2502002 Date of Receipt; 220un2022

Sane + Hydro Engnaering Conmpany Kuwait Date of Test zn207

Biaddross

2 Mw / WE Lab No. on

+ Umm Al Heyman Wastewater Projet i Job Onder No, : 150/22/2552

Size + 00 273 mm X 9.4 rm Tek

+ ASTMAS12 T 336, Hoot #A 2100696 / R345. WPS No. =P - ws 03

Welding Process : omAW PAR No, ‘Hr-mapo-PaR 01

Welder Name ‘neva At war no.

‘1D-w 002 ‘Welding Position: 6oup Mm

Welding Procure Qualfietion Test ab Temperature

REFERENCE

TEST DETAILS -

Weed)

SN Cevieweyiarnessen

ber

co fe

To

ot NBC Lab. The test report shal aote be reproduced except I fll. without aporavalef te laboratory

Block- 5, Shuaiba indus Area -?.0.80x 9088,Ahmadi 61002 Kuwait

1OF1

eb{+965) 1967777 ext:4252/4262 Fax(+365) 22784444 - E-malltech services @nbtc kuwait. com Web:vowa.nbtegroup.com

NaTeTBFOAL Rovot

Nasr M. AL Baa & Prine Gener adn &Controdting Co. Wi)

NBTC Teche Services Division

MECHANICAL TESTING LABORATORY

‘RSE FIRE 1705 Reig eaboratany

‘TEST REPORT - WELDED SAMPLE

1: 15D / MR/ 518 Date; 25402032 Date of Receipt: tadunamae

+ Mrdrotek gineering Cnepany-Kiwale Date of Test oad

ad tab No. nee

Project Name + Umm Al Hayman Wrastewater Project Job Order No. 90/22/2352

Project No. sie (0D 219A mm X Bram Ti

Material ASTM A332 7 346L, Hoot # A 2100885 / ER SU6L/€316L WS No, NT MPD =P 03

Welding Process P GTAW + SAW POR Wo. HY MID -PQR=08

Welder Name + SUEESH WATNO,

[Welder 1D /No. YD - Wo ‘Welding Position; 66 Up Hil

Description 7 Welding Procedure Qualification Test LabTemperature B5°C

REFERENCE

7 Universe Testing Machine (TSD-UTM-03) Calibration Certificate No. F/ 030/22

Equipment S.No. ac) ‘allbration Date 2a 2002

Make / wodel = ian Testing Eaupent / WAW 10008 Calibration Due Date nd

RefStd./ Spec. + ASTMASI2 /B5EN 10 156104 E4885 / EN 910 Procedure No. NOTCTS/ MLW

“TENSILE TEST

Dimension in mim ‘area | Weld toad Wield Strength [ultimate Load] __ Tensile Strength

Specimen 10

wiath [Thickness [ma® | (02%)KN | Mmm? | KSl co Wen? [KSI

TH 7540 a0 33 a8 a @ aa a6 %

Fracture Lecation ‘Type of Fracture

Wide (ram) | Thick (mm) | Bend Angie Plunger a Result

“Sie sond 70.08) zy or = Sttactony

‘Ste ene we ia 1 m Setefactry

[Requirement ‘As py ASTU'A 3D bag (170M Tere Sworn a5)

[Remarks The st su complies wi above meron standards

Taboratory

| votes rd

Webcal

‘Test els pertain to samples received ot NBTC Lab The teat epor shal note be reproduced eeept nfl wihoot approval ofthe laboratory

Block-5, Shuaba Industrial ea -?.0.Box 9088 Ahmadi 61001 Kuwalt lore

‘Tel(v965) 1867777 ex:4252/4262 Faxc(+965) 2228440 -E-mailtecn servcestonte-kunalt.com Webiwrw.nbtegroup.com

NETE-TOROML Revot

Wore Poe Gon! an Conte VL

NBTC Tecnica! Seales ison

MECHANICAL TESTING LABORATORY

£2 Kail FRSCISO 17088 Recetas Labhatoty”

TEST REPORT - WELDED SAMPLE

Tso /nTn / 5138 Date: 254un2022 Date of Receipt

Hydrol Engineering Company - Kuwait Date of Test + Resun-202

Pw wre a ab Wo, GBS

‘Umm Al Hayman Wastownter Project Job OrderNo.—; TS0/m2/ 2352

i Sue + 0D 219.3 mmx 12 ram Thick

+ ASTMA3I2 TP 346, Meat A 2100685 /R 3161 /EI61 ‘WPS No. T= MIPD -WPS-08

GTAW 9 SmaW POR No, HF MPD = POR 08

‘Supers ‘war NO, =

=D Woot ‘Welding Position + 64 Up it

Welding Procedure Quaifiation Test Lab Temperature: 735°C

REFERENCE

Equipment 4 Universal Testing Machine (1SDUTM 008) Callbration Certificate No, : F/010/22

Equipment SLNo, Tomo Calibration Date 1 Bion 2002

Make /Model ‘nan Testing Equipment / WAW 1000 Calibration Ove Date en 203

Ref St. / Spec. 1 ASTM A332 /BSEN 160 156164 / EN 895/910 Procedure No. NBTCS/AML win

TENSILE TEST

cere Dimension in mm ‘Area_| Wield toad Yield Strength [Ultimate Load] Tensile Stenath

widtn [Thickness [7 mm? (0.2%)kN | Nimm? | hs iv ima | _ Ks

99) as @ 1 00 o

Tye of Fracture

BEND

‘width (mm) | Thick. (me) [Bend Angle Plunger Dla Rest

Len 1 a ‘Ststeay

a ‘Sataciony

[Reduirements AS par ASTIA A I2~d Sergeh| 190 Moo J Tere Sven [485 Noa)

Remarks The fs rest cones wih ove menaned tondarde

laboratory Witnessed By Ghent

‘Test ret pero to somplesecelved ct NTC Lab The test repat sl nate be reproduc eceot il without approval fe obOotary

Block -5, Shuafoa Industrial Area -.0,80x 9088 Ahmadi 61001 Kuwait

2OFe

“Tels+965) 1867777 Exta252/4262 Fax:\v965) 22284044 -E-mailtech services @nbte-kuwait.com Web: www ibtcgroup.com

Naser M. Al-Baddah & Partner General Trading & Contracting Co. W.L

NBTC Technic Services Division

MECHANICAL TESTING LABORATORY

"Ri i 7 ea

‘TEST REPORT - HARDNESS WELDED SAMPLE

Report wo, = 190/417 700 Date of Receipt

yeotk ngnnering Company Kuwait Date of Tet

ene

mew / wre tab No, 1 RGIS

Project Name ‘Un Al Hayman Wastewater Projet fib Order No, = 150/22/7382

Project No, : sae £00219. rmx 12 man Tae

‘sT A312 1P 316, Heat tA 2100893 / En 326/326. WPS Ne.

‘GTAW + SMAW PORN.

Welder name + SUDEESH ‘WaT No, :

Welder ID / No, 2 0-008 Welding Postion 66 UpHm

Description 1 Welding Procedure Gualfiation To ab Temperature 235%

REFERENCE

Equipment S.No, 7 S26 Calibration Date +: Pt 2022

ake / Model = Hnan Testing Equipment / any 5az itvation Due Date; 73460202

Refs. / spec. + BS ENISO 156144 / 2043 Procedure No, 1 NBTCS/MI/ NS

"HARDNESS TEST

i

‘Calibration Certificate No. ; F/ 000 /22 |

= 8

Location - Bottom PM Haz weld HAZ Pu

a] 2[s| «| s[es] 7] | | ofalels[«|s[«|o]s|o

Readings

162 266 x64] x00] x80] 128 x90] ss 205] za0] 200 | ams [ans] 290] 178 | a2 aoe | 265 | a6)

Max Hardness Valve Observed _:

Test ests pertcn to samples eahed et NBTC Lb The est reper shal oe be reprodocd except nul without aparoval fe aontary

Block- 5, Shusiba Industrial Area -.0,80x 9088,Ahmadi 61001 Kuwalt 10F)

Tel{+965) 1867777 6t:4252/4262 Fax{+965) 2284444 -E-malltech.services@nbtc-kuwal.com Web:werw:nbtegroup.com

Nero Tero Revor

Wer MAL dah rn ened Contacting.

HNBTC Techni ees Di

LABORATORY

180: tee Caaaly SAPS

TEST REPORT - IMPACT

Date > Penna Date offecept _: ownaaze

Report No. 30 /mar 7427

+ Mydotek Engnewsing Company -Kowalt Dateoftest ——: Haun2m2

client MP / WE tab No. 1 AGI

Project Name + Un Al Hayman Wastewater Projet ob OrderNe.; TO/m2/ Ea

Project No. : ‘Sie + 00219. mmx 2mm Thi

Material 1 ASTWA 312 TPaN6L, Weak WA 2100899 /ER346L/ E9861 WPS. 1 HT- MPD = WPS-08

Weoicing Process > GTAWsSMAW POR No. 7 AT- MD = Pons

Welder Name + SUDEESH WAT No. Be

Welder / Wo = WOW 00 Welding Postion 66 Up

Description + Wl Procedure Gutition Tet LabTempersture : 235-0

REFERENCE

[Essionent ~~: ritminpor Teng ach (To-mean2) ~~ *~d cain Cavin Ha

Equipment tN, 1000/36 albration Date apr 20z2

Make / Model "ine Testing Wachines/ 30 asia Calibration Due Date age 2008

Ret St. / Spee + BSW 50155103 / E4875 Procedure No| NeTeShanon

TEST DETAILS

‘Specimen Dimension in mm | Te® ‘Absorbed Energy

Tempermire verge

wath [ictnesd| tenath | "Veep Joules) eal

=» |= | °

Tenperatare Meosring instrument {TSO-CACED , Si #940024, Cerificate Na DEAS, Ove Date 03 gest 222

The test result complies wih above netoned onda

Gent

ieenewo farmesseD

pe

pal Morag [oe

Lyn oe

Testes pertain to sas ered et NET Lob The ot ep el eB plural OUR M ol won pron] We WbOwO

Block-5, aio Indes Are -.0.808 5088. Aad 61001 Kowa feet

‘Tol:(+965) 1867777 Ext-4252/4262 Faxc\¥965) 22288444 -E-malktech serdces@nbrcluwalt.com Webiwww nbtegroup.com

Report No.

NBTC

Technical Services Division

MECHANICAL TESTING LABORATORY

si 50s Ase ay

TEST REPORT - MACRO ETCHING

2 0/ ME /950

Naser M AL-Baddah & Partner General Trading & Contracting Co. Wl

Date of Receipt

NOTe-T9FOM7 Revot

+ Redan 2022

Customer Name

Aalsross

‘rote Engineering Company Kwa

Date of Test

+: naz

iene 7 new wre ‘ab, > aeaie

Projctname ne aya Wate Pat [iovordec na, : wb/an/aase

Projet. sie 1 002194

acral ASABE SIE, at ABNER ENE / EL wes. 1 TaD WPS

Weng Process + eta saw Pav, TAPP

Weller Name + SDE Warn

REFERENCE

TEST DETANLS

Welder 1D / No. D-¥-00n Welding Position: 66 up

Description + Well Procedure Qualiieaton Test Lab Temperature; 235°C

Indust

Tols{+965) 1867777 Ext4252/4262 Fax:(+965) 22284444 -E-altec.servces@ibt-uwait.com Web:vemw-nbtegroup.com

| Area -P.0.80% 9088,Ahad 61001 Kuwait

10F1

NBTC

NTE-TOFOML Revot

‘Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.LI

Technical Services Division

MECHANICAL TESTING LABORATORY

Mais Fs SO 7008 Keele alionatany

‘TEST REPORT - WELDED SAMPLE

RSE

Tran [ose mana On of Reaoe

nt Campy at Date

wi Tab nei

rjc So eb orerne ora

je : Sie Bama

Mat 1 AAG a NSH RI ws ko

eid ces PORN oa

Wel a 1A ARR ORT warn :

weir wot Weide 9a

epton Hs Pet Gano Lab Temperate BSE

REFERENCE

Expat onena Tstig mocha SOUT (Glvaton Gerttesowa_= Tomy |

Eaupment iN ca Calton Date 7 na

Make/Model on Tesi spent WA 006 Crain Bie bate, Sanaa

Rett. Spec. + AS AS29504 6O 5514/15 / OHO Procedure Wo, ARTE

TENSILE TEST.

————. —E

pa Dimension Ina ‘rea | Weld toad | WieldStrengin [Utimate Lood] Tense Swengih

‘wiaty [Thickness [mom | (02%)KN | N/mm? | Kah ol Winn? [1st

20 08 3022 sa

Tye of fracture

sr

‘Width (mm)

Thick (mm)

“Mae ene 00

mar |

Requirements

[Remarks

‘Sie ane

aa

“sper ASTW'A35- Weld renin 20 po) Tense Srength( 10 SS0 Me)

The st su corps with above mentioned andor

Ghent

Test resus peri to sopes rece ot NBTC La The (st eport sal rb reproduced excep nfl without poreva/of the laboratery

Block 5, Shualba industrial Area -?.0.8ox 9088 Ahmadi 61001 Kuwait

“els(+965) 1867777 Ex:4252/4262 Fax-(+965) 222844 -E-ma:tech. services €@nbtc-kuwal.com Web:waw.nbtegroup.com

Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.L1

NereTEFONL Reve!

MECHANICAL TESTING LABORATORY

(11S RaTCTSEISO W700 Aegealfed Laboraton) SS 7

TEST REPORT - WELDED SAMPLE

"507 re 7/50 Date; aeumama Date of Reet

rota gor Company Kowal Date ofest Bima

verwwe Tab No TAR?

Project name ‘Un Al aan Watewater Projet eb Order tio. _: Tv /22/52

Project No, 7 Se ome

etait ‘ASTWAG, ea RsA054 E7OIBA WPS Wo. H-Me0 = WS

‘Welding Process smaw_ He PQR No. HT -NMIPD - POR 05

welder ame RA an AGAR war NG :

Welder10/ No. 1 -w-008 ‘Welding Postion: 38 Up it

[escrito Weng Presario Test lab Temperawre 2 SC

REFERENCE

Eevipment ikea Teste Mace (TODA) Catbration Coricate No. _- #7018777 |

Equipment Sho, use ~~ [eatiortion Date Bon 2022 |

Make / Model 1 Hn Testing Eaubrane 7 WAW 300 Calraion ue Date; avanae@

etd. Spee. {ASTIN ASI2 / ASN SO AS6L64/EV095 BV 930 Procedure No NTETS/ncwna '

"TENSILE TEST

Dinonsion nt ‘Area_| Veldioad | VieldSvength [Ultimate Load]

width [ Thidness | mam? | (02%)kN | Nimo | __ Ke

Specimen IO

12 1206 37 am @

Type of Fracture

sea Sea Bana ia00 ae ae « ‘Snfecony

Requirements ‘Ase ASTI A 36 Wl tera [250 Tens Seng (400-550 ie)

Remaris The et re corps wth obove wanton standards

Test ests pertain to samples eae of NETC Lb Te Lest reper sl nate be reproduc exc! nfl witha apeova af he aor aary

Block-5, Shuaba Industrial Area -P.0.80x 9088 Ahmad 61001 Kuwalt, 2ore

Tab (+965) 1867777 642524262 Fay| 1965) 22284444 - E-malltech services @nbte-kuwaitcom Webswnnwnbtegroup.com

Wore reroA20 Root

ta Ah oer eae orca.

HNBTC Tec Serves Divison

MECHANICAL TESTING LABORATORY

Hii HOSE tas Rested Labia f

TEST REPORT - HARDNESS WELDED SAMPLE

30/4/72 : Date of Receipt; 22uma26r2

Tomer Nae

‘Hydote Engineering Company awk of Tes un-2022

ae ngheering Company DateofTest —: Za

Cent vow wre Ta Wo neuer

|

|

|

|

i

'

|

Project Name ‘Ur Al Hayman Wastewater Project Job Oreer no, 30/22/2352

Project No, 7 ‘Site me Pite

‘Material ‘AST A 6, ent #2140054 7670184 WPS No, T= MPO - WPS

Welding Process suaw POR No. 1 MT-MPD- POR-05

welder wame war No. =

welder ID / Wo. Welding Postion s6upam

Description lab Temperature: 235°C

REFERENCE

Calration Certificate No, ; F/009/22

Equipment s.no 1 526 Celration Date 2esen2022

Equipment 1 Digi Vicars Havdnee Terter

Make / Mode! 1 San Testing Equipment / MSZ [calibration Due Date; ven 3023

Refit, / Spec. + BSEN ISO 156144 / E2000. Procedure No, 1 NBTETSALWT

HARDNESS TEST

are aera

an Top vat we weld a a

PPE EPP PP) |=] =]*]s]=1=;a]= |

neat |

af ss |] es [a | ceetocd |

Location - Middle WAZ ‘Weld HAZ j

a]=[=) «=| =] »[s

ostes |

aera

Caton Baton mt ae we wm i

=]=[=[*[#] «>| ==] «]|«[@]@|«[e leap

pexdhes

| | | aera

Tapia on haw ae

Reman +The testesvkcomphes wih above mentioned sanders:

Block -5,Shualba Industiial Area P.0.2ox 9088 Ahmad 61001 Kuwait, aes

Tel (+965) 1867777 Exts4252/4262 Fax(+965) 2284444 - E-malltech services @ribt-kuwal.com Web:waw.nbtcsroUp.com

sereraroM vot

Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.LI

Technical Services Division

MECHANICAL TESTING LABORATORY

7 Slt tS STOR ae aba

TEST REPORT - IMPACT

130 /tar Fees ato: 25)un2002 Date ofReccipt_—: 2ehun-auza

+ Hotel ErneringComoary- wat DateoFtest—: aiwnama

ew / wre ‘ab No, 7 A657

{Um Al tayman Westewter rofect Job Order No, W30/ 22/2882

: Sue Am Pate

ASTI A36, Heat #2340805 70305 WPS No 1 Ab - WPS-05

Welding Process, 1 SHAW POR No, MT MPO POR 05

Weider Name 1 RARESUALARRSHA AGHA war no,

Welder 10 / Wo, 7 HYD -W 008 ‘Welding Poston: 36 Up Hin

Description + Weldng Proedtre Guaiieton Tost Lab Temperature: 235°C

REFERENCE

ene en pH

Eason Si ra

ate ode fo oe in FRAT carton

fet seco _ er sossn nas Pra

Tesi DETANS

Syecnen to wee ‘eee | soviet errey | erage (3)

Wold comer wo | wo | ss 0

‘Weld Contr w | wo | ss

Wild center w | o | s

eat fected Zone w | o | s 0

est ected Zone of] wo | s 0

eat ete Zone w | o | ss 0

Temperatre Measuring instrament {YS-€ALGO1), Sto 8340625, Cette Na P3ISGL, Ove bate 03 must 2022

The test eu complies with above marloned tondrde

oare YG 19%

Date:

Test ress portant amples ected ot NBTC Lob. The tet epet sal ae be Yeproduced est nul wRhou approl fe Taboraany

‘Block 5, Shuaiba Industrial Area -.0.8ox 9088 Ahmadi 61001 Kuwait 10F)

“Tel:{+965) 1867777 bxt4252/4262 Faxcl*965) 22284448 -E-malltach servcestonbte-tuwalt.com Webswww.nibtogroup.com

HNBTC

NaToTBFOANI7 Revot

"Naser M. Al-Baddah & Partner General Trading & Contracting Co, W.l.

Technical Services Division

MECHANICAL TESTING LABORATORY

lt Fri SO:1 7005 Acetate TabaeaIO6

‘TEST REPORT - MACRO ETCHING

Ret St. / Spec.

REFERENCE

+ BSN SO 456144 /EN 2324

near "ro one ae Se

brvialata Vb ony Rat DteolTe sas

cen "joe we —

roc name {Dep twtr Pe border no/aa/ae

octne ; se ‘Banri

tr [ae ws ae

eng rcess ran, wore

welsh NA AUT warvo, ;

ier 0-8 weld oon 36

econ {wg rr Gotan Cab Tonpentay me

NBTeS/Myw8

TEST DETAILS

a

Location

‘Test results pertain to somples received al NBTC La. The test report shal note be reproduced excep nfl, without approval of the latoratary

Slock-5, Shuaiba Industral Area -#.0.80x 9088,Ahmadi 61003 Kuwait Broa

“els(+965) 1867777 Ext: 4252/4262 Fax:(+965) 2228444 - E-mail tech.servcesq@nbte-kuwalt.com Webswrww.nbtcgroup.com

NOTE-TSO.ML Revor

a Nur Aba & Pare ont Ta &Conacting W

BNBTC Ted Serces Dison

MECHANICAL TESTING LABORATORY

CGR EB Tas Aina barat

‘TEST REPORT - WELDED SAMPLE

Report. ‘50 / TR / 5120 Date of Receipt

ene + Myra ngnering Company -Kowait Date of Test 2ue2022

[Cient ew wie Tab No. oy

Project Name + Un Al Hayman Wosteuater Project Job OrderNo, + 190/22/2352

ProjectNo. Sie 7 OD aBA SD en Tek

Materat ‘ASTINA 32 YP 3161, Heat 1615570 / ER 3I6L WPS no, 7 MT-MIPD-WPS-02

Welding Process roraw PAR No. AT-MIeD- POR

Welder wame 1 MONAMAD MAIROLLAN ANSARE WaT NO. 2

Welder 1D / No, 0 “W008 Welding Postion; 66upHil

Description + Wlng Procedure elation Tek LabTemperatine _: 5°C

REFERENCE.

Equipment Universal Tetng Machine (TSD-UTW 008) Colration Cnineate No: F/010/22

Equipment So om ‘Callraton Date 1 Been 2002

‘Make / Model 7 lan Testing ulpment 7 WA 1000 Colivration Ove Date; lan 2005

= ASTMA 12 / SEN 50256444 /EN895/ENS10 Procedure Wo,

TENSILE TEST.

Yield Load | vieldstrength [Utimate ood] Tensile Strength

ecimen 0

a (0.2%) kN | N/mm? ‘N/mm? isi

Th

|

‘width (rom) Plunger De

1000 a

[Reauirements ‘As per ASTHOA BER Weld Sangh (170 Mpa) Tse Sength (485 Noo)

Remarks The test rest complies with cove mentened andor

Test results pertain ta somelesreceved ot NOTC tas The test report sl ote be reproduced exceo ful without onerovl a he barorory

Block 5 Shuaiba Industrial Are -7.0.Box 9068,Ahmodi 61001 Kuwait 1OF2

“Tels965) 1867777 fx:4252/4262 Faxc\¥865) 2228444d -E-mailtech. services @nbte-kuwait.com Web:www.nbtcgroup.com

NeTE-TSHONE Rerot

ter ALE Pare Gener dig & Contacting WAL

HNBTC Technical Sonees Divison

MECHANICAL TESTING LagoRATORY

Neri ata

TEST REPORT - WELDED SAMPLE

Date; 2saun202 Date of Receipt: aaumaure

Date of Test Bano

lent = Mew WE Tab No. ‘aes

Project Name Umm Al Hayman Wastewater Projet ab Order No, "80/22/7352

Project No. : Sie (00 424X290 monic

Material ‘ASTM ASI2 TP 3161, Hest #1815570 /ERSIOL, WS No, {Hr MaPO- Wes 02

Welding Process ‘craw PaR Ne, AT MIPD-POR- a2

Welder Name WOHAVAMAD MABALLAW ANSAR) WaT NO. zl

[Welder 10 / No. WOW: 08 ‘Welding Position: 66up Hit

Description ‘Welding Precadore Guaiiaion To Lab Temperature: 235°C

REFERENCE

Univeral Testing Meclne (TSO-UTNOON) CGalbration Cortcate No, _; F/ 010/22

oe Calioration Date 1 Beven 2022

aR TT a |

1 ASTIN A332 /BSEN 150356144 /ENBIG/ENSIO Procedure Wo, = NBTES/aL wor

TENSILE TEST |

Dimension nme ‘rea | Weldtoad [ ViekdSteength | Ukimote Load] Tensile Swength

| wiath [thickness | mm? | (02e)kN | _wimm? | Kal a amme [¥s)

250 270 35 0 9 “6 wa 296 ” |

Fracture locaton Type of Fracture E i

‘Ot ie Weld metal Ductile

Specimen ID

oat Bend 1008 270, 200"

‘Arper ASTM ASD Wald Sangin (170 Mpa) Teale Sergih (465 Mpa)

Requirements

Remarks

Agplus®’

VELOS|

‘lock 5, tua Industrial Area -P.0.80x 9088,Ahmadi 61001 Kuwalt Bore

“Tebi{+965) 1867777 ex:4252/4262 Fax{+965) 22284444 -E-maltach services @nbte-kuwsit.com Web:wwa.nbtegroup.com

NeTe-TEFOML29 Revot

WserAa & Parer ener Trane ontacting Wi

NBTC Tesh Svcs von

MECHANICAL TESTING LABORATORY

TSO 417 703 1 250002002

yarotk Engineering Company Kowale 2202

Mow / wre neo

‘Une Al ayron Wastewater Project 50/22/2352

: + 00 2.4250 mm Thick

‘AST 312 77 346, Hon #1815570 / ER 316, HF -RPO - ws

welding Process 1: era PORN. r-PD -PaR 02

welder name = MOHAMMAD MAIMULLAN ANSARI ‘WaT NO. :

Welder Ib/ No, 10-0008 ‘welding Poston

Description + Welding Procedure Cuafcation Tet Lab Temperature

REFERENCE

Equipment + Digs Vita Hordnee Tatar

Equipment SLNo 1 s76 Calibration Date + besanana2

take / Model nan Testing Equpment / MV 502 Coloration Due Date Basan 003

Refs. / spec. + BS ENISO 156144 /_N 1088-8 Procedure No. 1 NBTETSINPIA

HARDNESS TEST

ype of Hardness

waz

Appled Load : ‘Max Hardness Value Observed +

or

VELOS!

‘Test rests pertain to samples received at NBTC LabThe text report shal note be rezroduced exceat nfl, without aperavol of he laboratory

DBlock-5, Shab Industrial Area -?.0.80x 9088 Ahmad 63001 Kuwait, a

“Teli{+965) 1867777 Exe4252/4262 Fax:+S65) 22288444 -E-malL. tech servicest@nbic- kuwait. com Webswnww.nbtroup.com

wercttromrmt |

Wer Aah ae ena ag & Contig |

HNBTC Tec Servers ison

MECHANICAL TESTING LABORATORY

‘await 50 7095 a cate Labora

TEST REPORT - MACRO ETCHING

Reporte Sor 1 Oe of ec

sonar ‘ya gern Coren Roa Oni of est

cent wow wre ‘abno nen

oe ame aio re fevowerna,—; worms

Proto : se + 0024x290

ea SA 7 900 Te Ww, a s-2

wean Process aw rane 1 a-ha

Welder Name + MOWAMIAD HARMULAN ANSARD ‘war no. -

Description +3 Welding Procedure Qualification Test Lab Temperature; 23.5°C |

REFERENCE. |

Ref Std. / Spe ‘SEN Iso tse04a/eW 1524, Procedure No NaTe=s/My/wi od |

TEST DETAILS,

a

Magnification

hs?

evosi|

Dates

Test results peta somes rece et NBTC Lab Theft repr sl ove be eprchiced exept nl wou opproval fe labo aary

Block -5,Shualba industrial Area -P.0.Box 9088,Ahmadl 61001 Kuwait 10F1

“Tels{+965) 1867777 f:4752/4262 Fax{+965) 22284444 -E-mal:tec servcas@nbtc-huwait.com Webswurw.nbtcgroup.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Empro® PVC WSDocument2 pagesEmpro® PVC WSm.aliNo ratings yet

- VolleyDocument1 pageVolleym.aliNo ratings yet

- Sidhique Ground Floor Ceiling PlanDocument5 pagesSidhique Ground Floor Ceiling Planm.aliNo ratings yet

- Foot BallDocument1 pageFoot Ballm.aliNo ratings yet

- Cric RoulDocument2 pagesCric Roulm.aliNo ratings yet

- Calibration ScheduleDocument1 pageCalibration Schedulem.aliNo ratings yet

- MTC HiltiDocument1 pageMTC Hiltim.aliNo ratings yet

- RecafcoDocument1 pageRecafcom.aliNo ratings yet

- Fixure Rev 01Document1 pageFixure Rev 01m.aliNo ratings yet

- ProfexDocument1 pageProfexm.aliNo ratings yet

- Sit Out CeilingDocument1 pageSit Out Ceilingm.aliNo ratings yet

- EasyTape WT - TDS - V3Document2 pagesEasyTape WT - TDS - V3m.aliNo ratings yet

- Technical Services Division: Mechanical Testing LaboratoryDocument1 pageTechnical Services Division: Mechanical Testing Laboratorym.aliNo ratings yet

- Technical Services Division: Mechanical Testing LaboratoryDocument1 pageTechnical Services Division: Mechanical Testing Laboratorym.aliNo ratings yet

- Wood-Plastics Composites (WPC)Document1 pageWood-Plastics Composites (WPC)m.aliNo ratings yet

- Door 3 PDFDocument1 pageDoor 3 PDFm.aliNo ratings yet

- Doors PDFDocument1 pageDoors PDFm.aliNo ratings yet

- Data SheetDocument2 pagesData Sheetm.aliNo ratings yet

- Stainless Steel Data SheetDocument1 pageStainless Steel Data Sheetm.aliNo ratings yet

- 33 PDFDocument1 page33 PDFm.aliNo ratings yet

- Elbows 32760 57207Document18 pagesElbows 32760 57207m.aliNo ratings yet

- NBTC-Cricket Tournament 2022-2023 Batting Records - NBTC-Cricket Tournament 2022-2023Document14 pagesNBTC-Cricket Tournament 2022-2023 Batting Records - NBTC-Cricket Tournament 2022-2023m.aliNo ratings yet

- Abufatera 1Document1 pageAbufatera 1m.aliNo ratings yet

- Emirates Steel MTCDocument3 pagesEmirates Steel MTCm.aliNo ratings yet

- Shandang MTCDocument1 pageShandang MTCm.aliNo ratings yet

- Pmi 57T0102Document2 pagesPmi 57T0102m.aliNo ratings yet

- UPVC Pipe Catalog 1Document22 pagesUPVC Pipe Catalog 1m.aliNo ratings yet

- City BoyzDocument1 pageCity Boyzm.aliNo ratings yet

- @T Sarga 13-10-2022Document1 page@T Sarga 13-10-2022m.aliNo ratings yet

- RoshacDocument2 pagesRoshacm.aliNo ratings yet