Professional Documents

Culture Documents

TG Technical Data Sheet

Uploaded by

Pinak ProjectsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TG Technical Data Sheet

Uploaded by

Pinak ProjectsCopyright:

Available Formats

Document No.

Rev

SIEMENS LTD. 0-20400-41585-90

Responsible Department: Take over Department: Document Type: Folder No.

GP PG IST COE IND CAL GP PG IST COE IND TPE TI (RESTRICTED)

Valid for: Derived from: Replaces: E File no.:

GP PG IST PM

Prepared: Checked: Approved: Language Page:

AP VAS ADP EN Page 1

Technical Data Sheet

(External pipe connections, Thermal expansion & Foundation loads)

Project : Nathdwara WHRS -1x 13 MW, UltraTech Cement

Limited

Customer : Ultratech Nathdwara Cement Limited

Turbine : SST 300 C 2S/V45.8 SUB

- 17.12.2019 First release AP VAS ADP

Rev. Date Description Prepared Checked Approved

We reserve the rights in this document and in the information contained therein. Reproduction, use, communication or

disclosure to third parties without express authority is strictly forbidden. © SIEMENS LTD.

Format No: IP-Q-F 3029/C Power & Gas – Steam turbine

Rev/Date: 29.12.2014 Restricted

Page: Document No. Rev.

Technical data sheet

2 0-20400-41585-90

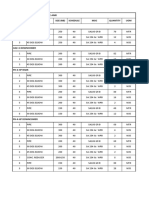

1. Turbine connection points

No. Connection Size Rating Joint Norm

1 Live Steam 14 inch 300 lbs Flanged ANSI

2 Injection top 14 inch 150 lbs Flanged ANSI

3 Injection bottom 14 inch 150 lbs Flanged ANSI

4 Exhaust DN1800 - Flanged Siemens

Also refer steam turbine general arrangement drawing EO0122351 for

orientation of connections.

2. Co-ordinate axis for turbine

Format No: IP-Q-F 3029/C Power & Gas – Steam Turbine

Rev. Date: 29.12.2014 Restricted

Page: Document No. Rev.

Technical data sheet

3 0-20400-41585-90

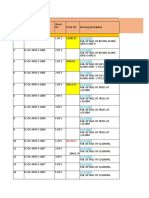

3. Thermal movement of connection points

No-load operation

Movements

Connections

ΔX mm ΔY mm ΔZ mm

Live Steam -4.00 8.30 8.90

Injection top -1.10 5.70 5.75

Injection bottom -1.10 -2.30 5.75

Exhaust 0.00 2.85 0.00

Normal operation

Movements

Connections

ΔX mm ΔY mm ΔZ mm

Live Steam -4.40 8.30 8.90

Injection top -1.60 5.55 5.60

Injection bottom -1.60 -2.30 5.60

Exhaust 0.00 4.50 0.00

Note:

Thermal expansion calculated with respect to fixed point of turbine as indicated in the

turbine GA with ambient temperature considered as 2 °C

Format No: IP-Q-F 3029/C Power & Gas – Steam Turbine

Rev. Date: 29.12.2014 Restricted

Page: Document No. Rev.

Technical data sheet

4 0-20400-41585-90

4. Maximum allowed external forces and moments on turbine

connections

a. The piping must be connected without pre-stress at ambient temperature

by means of fixed points, supports, springs & hangers etc adjusted in a

ways that the flanges or the weld ends are located in the specified

distance and parallelism.

b. No additional forces are allowed when

connecting the piping to the turbine.

c. Allowed F&M for each connection to be within (0,F) to (M,0)

Allowed forces & moments

Fx Fy Fz Mx My Mz

Connection

(N) (N) (N) (Nm) (Nm) (Nm)

+/- +/- +/- +/- +/- +/-

Live Steam

7200 3800 7200 2600 5200 2600

Injection top 7200 3800 7200 2600 5200 2600

Injection bottom 7200 3800 7200 2600 5200 2600

Exhaust +67000/

17500 17500 22000 22000 10000

-315000

d. The stated forces and moments only refer to the leakproofness of a flanged

connection with similar nominal bore and pressure stage.

e. For the turbine stability check, the actual forces and moments of the connecting

pipes have to be stated to SIEMENS Ltd.

5. Heat-loss from turbine approximately 5 kW

6. Weight data:

Weight of core turbine with Base-frame 371 kN

Max weight - Upper part 127 kN

Rotor weight 50 kN

Format No: IP-Q-F 3029/C Power & Gas – Steam Turbine

Rev. Date: 29.12.2014 Restricted

Page: Document No. Rev.

Technical data sheet

5 0-20400-41585-90

7. Foundation loads

1 2 3

Point

Static Static load due to Load due to thermal

of

load rated torque expansion

load

Fy (kN) Fy (kN) Fx (kN) Fz (kN)

L1 -60.00 +6.00 -30.00 -30.00

L2 -62.00 +6.00 -1.75 -31.00

L3 -63.50 +6.00 31.75 -31.75

L4 -63.50 -6.00 31.75 31.75

L5 -62.00 -6.00 -1.75 31.00

L6 -60.00 -6.00 -30.00 30.00

4 5 6 7

Operating Operating Operating Operating unbalance

unbalance in unbalance in unbalance in in transverse(G40)

vertical(G6.3) transverse(G6.3) vertical(G40)

Fy (kN) Fz (kN) Fy (kN) Fy (kN) Fz (kN) Fy (kN)

±9.10 ±9.10 ±11.50 ±57.70 ±57.70 ±73

±9.10 ±9.10 ±11.50 ±57.70 ±57.70 ±73

±9.10 ±9.10 ±11.50 ±57.70 ±57.70 ±73

±9.10 ±9.10 ∓11.50 ±57.70 ±57.70 ∓73

±9.10 ±9.10 ∓11.50 ±57.70 ±57.70 ∓73

±9.10 ±9.10 ∓11.50 ±57.70 ±57.70 ∓73

a) Above foundation loads are without external pipe forces.

b) Loads in column-3 to be considered with changing signs (±)

c) Loads in column-5 & 6 to be considered alternatively as dynamic

loads at normal operating speed range taking in to account natural

frequencies of foundation

d) Rotor speed : Normal – 5700rpm / Trip – 6270rpm

e) Turbine rotor Inertia : 220 kgm2

f) For foundation layout refer next page

Main steam Pressure & Temp limits as per EN ISO 60045-1

(At Turbine Inlet)

Format No: IP-Q-F 3029/C Power & Gas – Steam Turbine

Rev. Date: 29.12.2014 Restricted

Live steam pressure Limits (%) Time period / Tripping

Rated 100% Normal

Main steam Pressure & Temp limits as per EN ISO 60045-1

Overpressure 100% to 105% Normal

Only alarm, for 12 hours every 12

Overpressure 105% to 120%

months

Accidental swings > 120% Trip

(At Turbine Inlet)

Beyond 12 hours within a year-Trip

Accidental swings >105%

reset to 105%

Live steam temperature Limits (%) Time period / Tripping

Rated 100% Normal

Over temp upto +8 °C Normal

Accidental swings +8 °C to +14 °C 400 hours for every 12 months

Accidental swings of 15

+14 °C to +28 °C 80 hours for every 12 months

minute or less

Accidental swings of > 15

+14 °C to +28 °C Trip

minute

Beyond permissible hours- trip reset

Accidental swings > +8 °C

to +8 C

Format No: IP-Q-F 3029/C Power & Gas – Steam Turbine

Rev. Date: 29.12.2014 Restricted

1.1 Turbine Rotor data:

Parameter Value Unit Remark

Direction of Viewed in the direction of

CCW

rotation steam flow in turbine

Rated speed 5700 RPM

Operating

5700 RPM

speed

First Critical

3135 RPM

Speed

Turning speed ≥ 120 RPM For turbine only

Over speed 10% above rated

Rotor Weight 4950 kg

Journal – 200

Front Bearing mm Tilting pad bearing

Thrust – 280

Rear Bearing Journal – 200 mm Tilting pad bearing

Lube oil Minimum required at

1.0 Bar(g)

pressure bearing inlet

Lube oil

49 ºC At bearing inlet

temperature

Refer section on oil

Lube oil type ISO VG 46 specification &

supervision

Not Required for

Jacking oil

turbine bearings

Turbine shaft Alarm : 88

µm S(p_p)

vibration limits Trip : 115

Format No: IP-Q-F 3029/C Power & Gas – Steam Turbine

Rev. Date: 29.12.2014 Restricted

Vacuum breaking not allowed during coasting down

Continuous operation above 105% of operating speed is

not recommended.

Format No: IP-Q-F 3029/C Power & Gas – Steam Turbine

Rev. Date: 29.12.2014 Restricted

You might also like

- Project Design Deliverables Sequence PDD PDFDocument14 pagesProject Design Deliverables Sequence PDD PDFKhaled SlevinNo ratings yet

- Lighting CalculationDocument19 pagesLighting CalculationPinak ProjectsNo ratings yet

- Steam Turbine O&M ManualDocument183 pagesSteam Turbine O&M ManualErin Ward100% (9)

- Manual for TURBULO Separator Pump Type TSPDocument12 pagesManual for TURBULO Separator Pump Type TSPerolNo ratings yet

- Manual Tecnico - Cooling Tower Pumbing and PipingDocument40 pagesManual Tecnico - Cooling Tower Pumbing and Pipingcarmen hernandezNo ratings yet

- 500MW Boiler NotesDocument360 pages500MW Boiler NotesGanga Prasad100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Centrifugal Pump CalculatorDocument43 pagesCentrifugal Pump CalculatorPinak ProjectsNo ratings yet

- Centrifugal Pump CalculatorDocument43 pagesCentrifugal Pump CalculatorPinak ProjectsNo ratings yet

- 1900 MTPD Ammonia Plant Venturi Flow Element Data SheetDocument40 pages1900 MTPD Ammonia Plant Venturi Flow Element Data SheetJan Richardo GultomNo ratings yet

- C Tower SpreadsheetDocument17 pagesC Tower SpreadsheetJulio Cisneros GrandaNo ratings yet

- AN INTERIM GUIDE ON Standard BOQ Section 1 Roadworks JKRDocument165 pagesAN INTERIM GUIDE ON Standard BOQ Section 1 Roadworks JKRekia_my100% (2)

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- Autoform training manual and video tutorial downloadDocument2 pagesAutoform training manual and video tutorial downloadRobinson Parraga25% (8)

- 2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Document2 pages2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Jennifer FigueroaNo ratings yet

- Anexo 1 Forma ADocument7 pagesAnexo 1 Forma AFelipeNo ratings yet

- S2D300-BP02-35 Datasheet Distribuidor EbmpapstDocument6 pagesS2D300-BP02-35 Datasheet Distribuidor EbmpapstMateus MendonçaNo ratings yet

- Hfy 3800 0000 Ved 192 QC PD 0006 - A RF Pad Leak Test ProcedureDocument8 pagesHfy 3800 0000 Ved 192 QC PD 0006 - A RF Pad Leak Test ProcedureMohamed FarisNo ratings yet

- Sizing PSV-100 R0Document5 pagesSizing PSV-100 R0XxavierNo ratings yet

- Sydex FMS 60.4 Caj6 PDFDocument4 pagesSydex FMS 60.4 Caj6 PDFSergei KurpishNo ratings yet

- 2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Document2 pages2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Jennifer FigueroaNo ratings yet

- AC Axial ebmpapstDocument6 pagesAC Axial ebmpapstrobson.cerqueiraNo ratings yet

- Hermetic Compressors - General InformationDocument38 pagesHermetic Compressors - General InformationYordis Daniel Rojas ChirinosNo ratings yet

- Ebmpapst 07082019 A4D350AA0601 KM96928 - 1620780Document7 pagesEbmpapst 07082019 A4D350AA0601 KM96928 - 1620780rickyngsNo ratings yet

- 7.14 CP14571 Blower PackageDocument29 pages7.14 CP14571 Blower PackageIsaias de la CruzNo ratings yet

- A4D450AO1809Document6 pagesA4D450AO1809adeNo ratings yet

- AC Axial Fan: W4D350-CA06-14Document6 pagesAC Axial Fan: W4D350-CA06-14fivep29121No ratings yet

- S4d350an0830 EngDocument6 pagesS4d350an0830 EngAdemar FukeNo ratings yet

- Sum21504 4Document14 pagesSum21504 4Jonathan Franco NuñezNo ratings yet

- HD Válvulas On-OffDocument1 pageHD Válvulas On-Offcristian W. saravia vegaNo ratings yet

- CNE 2AC - 341 m3ph @200 M (Sump Depth 2000m)Document3 pagesCNE 2AC - 341 m3ph @200 M (Sump Depth 2000m)Wibowo ArieNo ratings yet

- AC Axial Fan: Sickle-Shaped Blades (S Series) A2D300-AP02-02Document6 pagesAC Axial Fan: Sickle-Shaped Blades (S Series) A2D300-AP02-02mow_roNo ratings yet

- Grundfos Pompa PDFDocument9 pagesGrundfos Pompa PDFAnastasia Lova DiantoroNo ratings yet

- AC axial fan specsDocument5 pagesAC axial fan specsTrần Thị Hà MyNo ratings yet

- 42TPM English PDC 60Hz V4Document16 pages42TPM English PDC 60Hz V4maqsood ahmedNo ratings yet

- Drawings For Approval 2013-11-12 Rev.00Document84 pagesDrawings For Approval 2013-11-12 Rev.00M Ridho AgungNo ratings yet

- S6D800 Af05 03Document6 pagesS6D800 Af05 03El PestoNo ratings yet

- Datos Tecnicos Serie 4200G InglesDocument2 pagesDatos Tecnicos Serie 4200G InglesMichael Alayo carrionNo ratings yet

- S4d400as0657 - EngDocument6 pagesS4d400as0657 - EngAdemar FukeNo ratings yet

- AC axial compact fan technical specificationsDocument5 pagesAC axial compact fan technical specificationsdhanasekhar27No ratings yet

- R4e310 Ra06 17Document6 pagesR4e310 Ra06 17Petrucio AlcantaraNo ratings yet

- Centrifugal Pumps Guide for 2CDX Series PumpsDocument13 pagesCentrifugal Pumps Guide for 2CDX Series PumpsDirector Tecnico y Operaciones Baying SASNo ratings yet

- AC axial fan with sickle-shaped bladesDocument5 pagesAC axial fan with sickle-shaped bladesArnold Olivares GomezNo ratings yet

- Sea Water Intake PumpDocument10 pagesSea Water Intake PumpmbgprsmsNo ratings yet

- AC Axial Fan: A4S250-AA02-02Document6 pagesAC Axial Fan: A4S250-AA02-02DanieleNo ratings yet

- Groundfos Pompa Submersible 98826883 - SP - 918Document3 pagesGroundfos Pompa Submersible 98826883 - SP - 918teknisiptpakkodianNo ratings yet

- Groundfos Pompa Submersible 98826918 - SP - 1420Document3 pagesGroundfos Pompa Submersible 98826918 - SP - 1420teknisiptpakkodianNo ratings yet

- 06hegw 1Document17 pages06hegw 1Mohamed MusaNo ratings yet

- W2S130-AA25-01 AC axial compact fanDocument6 pagesW2S130-AA25-01 AC axial compact fanhector pinoargoteNo ratings yet

- 8317077882-Spec S4D400G01Document6 pages8317077882-Spec S4D400G01Arnold Olivares GómezNo ratings yet

- Sizing PSV-201 301 401 501 601 701 Glycol CASE R0Document5 pagesSizing PSV-201 301 401 501 601 701 Glycol CASE R0XxavierNo ratings yet

- Solenoid ValveDocument2 pagesSolenoid ValveHeru PurwantoNo ratings yet

- H-1 HoseDocument8 pagesH-1 HoseValentin A.No ratings yet

- EN - Inverter Split System Model EXH09HL1W PDFDocument62 pagesEN - Inverter Split System Model EXH09HL1W PDFIdenilson SilvaNo ratings yet

- VRV Technology in A Compact Size.: VRVIII-S 208-230V Heat PumpDocument1 pageVRV Technology in A Compact Size.: VRVIII-S 208-230V Heat PumpJosephRusselVizmanosNo ratings yet

- A2E200AH3801Document6 pagesA2E200AH3801Ademar FukeNo ratings yet

- Distribution Atmos TERA SCH 400.490 750 Lps @48 MDocument3 pagesDistribution Atmos TERA SCH 400.490 750 Lps @48 MwawanNo ratings yet

- FR2411GL Hoja TecnicaDocument2 pagesFR2411GL Hoja TecnicaWILSON ZURITANo ratings yet

- Grundfos 98826884 - SP - 921Document9 pagesGrundfos 98826884 - SP - 921dumbadamboNo ratings yet

- Submersible Sewage Pumps Specifications and Performance CurvesDocument16 pagesSubmersible Sewage Pumps Specifications and Performance CurvesGonzalo PimentelNo ratings yet

- Grundfos - SP 5A 21Document12 pagesGrundfos - SP 5A 21godbugNo ratings yet

- BoQ For HVAC Requirement For ZPPLDocument2 pagesBoQ For HVAC Requirement For ZPPLBehram CiodiaNo ratings yet

- CBT - Leaflets - 1340G - Van cân bằng nhiệt tự động - MDocument2 pagesCBT - Leaflets - 1340G - Van cân bằng nhiệt tự động - MNguyễn Xuân HùngNo ratings yet

- Lamina Brasado Bphe Produto NPDocument2 pagesLamina Brasado Bphe Produto NP伊藤 哲ウンベルト(Tabibito)No ratings yet

- CR 536 AfgjaehqqeDocument6 pagesCR 536 AfgjaehqqeAriesNo ratings yet

- Laser PSV Data SheetDocument6 pagesLaser PSV Data SheetZaw Htet WinNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN SOFTWARESNo ratings yet

- Planta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEDocument1 pagePlanta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEAnthony InostrozaNo ratings yet

- Home cement industry pipe material listDocument2 pagesHome cement industry pipe material listPinak ProjectsNo ratings yet

- Stress Analysis Report For RALLIS CPRG - Piping From Boiler To Steam Header and To PRDSDocument79 pagesStress Analysis Report For RALLIS CPRG - Piping From Boiler To Steam Header and To PRDSPinak ProjectsNo ratings yet

- Table of ContentsDocument77 pagesTable of ContentsPinak ProjectsNo ratings yet

- CalculationsDocument2 pagesCalculationsAliAliNo ratings yet

- LOT I OrderedDocument34 pagesLOT I OrderedPinak ProjectsNo ratings yet

- Kalyanpur AFR Shed BOQ-Column and TrussDocument38 pagesKalyanpur AFR Shed BOQ-Column and TrussPinak ProjectsNo ratings yet

- PurlinsDocument1 pagePurlinsPinak ProjectsNo ratings yet

- Kalyanpur AFR Shed BOQ-Column and TrussDocument38 pagesKalyanpur AFR Shed BOQ-Column and TrussPinak ProjectsNo ratings yet

- Section11Document43 pagesSection11Pinak ProjectsNo ratings yet

- Kalyanpur AFR Shed BOQ-Column and TrussDocument38 pagesKalyanpur AFR Shed BOQ-Column and TrussPinak ProjectsNo ratings yet

- Kalyanpur-AFR Shed - Fabrication ScheduleDocument2 pagesKalyanpur-AFR Shed - Fabrication SchedulePinak ProjectsNo ratings yet

- Kalyanpur-AFR Shed - Fabrication ScheduleDocument2 pagesKalyanpur-AFR Shed - Fabrication SchedulePinak ProjectsNo ratings yet

- Kalyanpur AFR Shed BOQ - LOT-1Document34 pagesKalyanpur AFR Shed BOQ - LOT-1Pinak ProjectsNo ratings yet

- AFR Structural DrawingsDocument12 pagesAFR Structural DrawingsPinak ProjectsNo ratings yet

- LOT I OrderedDocument34 pagesLOT I OrderedPinak ProjectsNo ratings yet

- Kalyanpur AFR Shed BOQ-Column and TrussDocument38 pagesKalyanpur AFR Shed BOQ-Column and TrussPinak ProjectsNo ratings yet

- Shikrapur-Cooling Water Piping BomDocument6 pagesShikrapur-Cooling Water Piping BomPinak ProjectsNo ratings yet

- Cooling Tower. Application - TreybalDocument89 pagesCooling Tower. Application - TreybalPinak ProjectsNo ratings yet

- Section11Document43 pagesSection11Pinak ProjectsNo ratings yet

- Section - 11 - Cooling - Towers - XLSXDocument48 pagesSection - 11 - Cooling - Towers - XLSXPinak ProjectsNo ratings yet

- Water Cooling Sizing Guide for Injection MoldingDocument2 pagesWater Cooling Sizing Guide for Injection MoldingPinak ProjectsNo ratings yet

- Cooling Water Requirement For Molding MachinesDocument5 pagesCooling Water Requirement For Molding MachinesPinak ProjectsNo ratings yet

- Cooling Tower. Application - TreybalDocument89 pagesCooling Tower. Application - TreybalPinak ProjectsNo ratings yet

- Amateur Radio Internet GatewayDocument176 pagesAmateur Radio Internet GatewayLuna García PadrónNo ratings yet

- Omnivision III ASEBI-Service and Installation Guide-English-47753-0316 - CCv0003Document452 pagesOmnivision III ASEBI-Service and Installation Guide-English-47753-0316 - CCv0003Yerkin Martinez100% (1)

- Modeling and Simulation of Discrete Event SystemsDocument8 pagesModeling and Simulation of Discrete Event Systemssar1988No ratings yet

- DHL Proposes LMS System to Enhance Supply ChainDocument14 pagesDHL Proposes LMS System to Enhance Supply Chaincynthiama7777No ratings yet

- A Synopsis ON "Supply Chain Management": Annexure-IDocument10 pagesA Synopsis ON "Supply Chain Management": Annexure-Ijitender6566No ratings yet

- VOS 8000FTR Installation ManualDocument12 pagesVOS 8000FTR Installation ManualRamesh BabuNo ratings yet

- OM0105037E02 0109 YA-1NCseries ControllerDocument64 pagesOM0105037E02 0109 YA-1NCseries ControllerThiago RossiNo ratings yet

- PLC BSL BottlingDocument23 pagesPLC BSL BottlingkingmltNo ratings yet

- ZXSDR BS8900A Quick Installation Guide R2.0 - CH - ENDocument37 pagesZXSDR BS8900A Quick Installation Guide R2.0 - CH - ENMuhammad AliNo ratings yet

- KOBIL - PSD2 - 7 Layers of SecurityDocument4 pagesKOBIL - PSD2 - 7 Layers of Securityvlado10305No ratings yet

- Leah Klein Resume - Graphic Designer and IllustratorDocument1 pageLeah Klein Resume - Graphic Designer and IllustratorAbi C. WareNo ratings yet

- Active Autowerke X6/X6M X5/X5M DME DME Removal Instructions: Tools NeededDocument5 pagesActive Autowerke X6/X6M X5/X5M DME DME Removal Instructions: Tools NeededIemel holgersonNo ratings yet

- 1ST Summative TestDocument4 pages1ST Summative TestFeo FranciscoNo ratings yet

- Square ReportDocument15 pagesSquare ReportAditya BaglaNo ratings yet

- At - LF: - L :: .. Ipilli4Document1 pageAt - LF: - L :: .. Ipilli4Vivek SinghNo ratings yet

- A Micro-Project Report On "": Partial Fulfilment of The Requirement For The Diploma in Computer EngineeringDocument15 pagesA Micro-Project Report On "": Partial Fulfilment of The Requirement For The Diploma in Computer EngineeringAtul PawarNo ratings yet

- GS2210-8 V4.30 Ed1Document444 pagesGS2210-8 V4.30 Ed1BestCieloNo ratings yet

- Views On Business Continuity and Disaster RecoveryDocument16 pagesViews On Business Continuity and Disaster RecoveryPero WarrenNo ratings yet

- Microprocessor and InterfacingDocument2 pagesMicroprocessor and InterfacingDharmendra ParmarNo ratings yet

- GRB100D 6F2S0882-2.1r PDFDocument510 pagesGRB100D 6F2S0882-2.1r PDFAzrul Alif ZailanNo ratings yet

- Dawn of The NetDocument16 pagesDawn of The NetSwayamprakash Rout100% (1)

- Analyze Your Scratch Projects With Dr. Scratch and Assess Your Computational Thinking SkillsDocument34 pagesAnalyze Your Scratch Projects With Dr. Scratch and Assess Your Computational Thinking Skillsfaizah rozaliNo ratings yet

- Project Report MiniDocument27 pagesProject Report Minisumit gandhi86% (21)

- NETFLIX-Leading Streaming ServiceDocument7 pagesNETFLIX-Leading Streaming ServiceMd HussainNo ratings yet

- Com - Com: Solid State Protective RelaysDocument23 pagesCom - Com: Solid State Protective Relaysshehroz baigNo ratings yet

- Development With WebLogic Server 12c and MavenDocument50 pagesDevelopment With WebLogic Server 12c and MavenWilson VerardiNo ratings yet

- 2022 Metrologyx Manila Training ScheduleDocument4 pages2022 Metrologyx Manila Training ScheduleMikee FelipeNo ratings yet

- TX2A/RX2A: UHF FM Data Transmitter and Receiver ModulesDocument10 pagesTX2A/RX2A: UHF FM Data Transmitter and Receiver ModulesMoisesNo ratings yet