Professional Documents

Culture Documents

Lamina Brasado Bphe Produto NP

Uploaded by

伊藤 哲ウンベルト(Tabibito)Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lamina Brasado Bphe Produto NP

Uploaded by

伊藤 哲ウンベルト(Tabibito)Copyright:

Available Formats

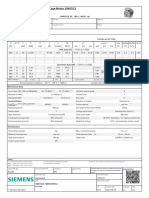

NP Series – Brazed Plate Heat Exchangers

The ideal alternative when

copper is not enough

GEA PHE Systems NP Series of nickel brazed plate heat exchangers are precision

made to provide a number of features for increasing system performance and

reliability. Designed to offer true counter current flow and high turbulence in the

working fluids they offer outstanding heat transfer options, even at low flow rates.

GEA PHE Systems NP Series brazed plate heat exchangers offer all the

advantages of copper brazed heat exchangers and are optimally suited for:

• refrigerant to liquid and liquid to liquid applications

• ammonia systems

• extra pure water applications

• de-ionized water and corrosive liquids

So when copper is simply not enough, look for the silver colored NP Series

for absolute performance.

NP

Features and benefits

Safety Chamber™ Robust Plate Design

™

Our patented Safety Chamber absorbs the stress from thermal This special plate design by GEA PHE Systems, the Rolled Edge

shock and pressure pulsations that would damage other brazed plate Lock System™, guarantees a consistent braze joint at the plate overlap

heat exchangers. When overloaded, encapsulated contact points around and makes for stronger and more leak-proof heat exchanger. The contact

the ports take up the forces and stretch, protecting against internal leaks points, extended and larger in design, result in stronger braze joints

and premature failure. A GEA PHE Systems exclusive safety factor. between the plates, thus guaranteeing high heat exchanger strength.

Delta Injection™ for Advanced Evaporator - AE line Full-Flow System™

A GEA PHE Systems patented Delta Injection™ refrigerant Originally developed for the nickel brazed plate heat exchangers

distribution system is specially developed for evaporator applications. (NP Series), every new plate design is now equipped with the Full-Flow

It provides precise metering of refrigerant to the channels, guaran- System™. This unique flow system insures continuous flow around the

™

teeing the highest evaporator performance. The Delta Injection is port area to prevent freezing and also feeds the working fluid equally

fully integrated into the stainless steel heat-transfer plate. over the channel to guarantee maximum use of the heat transfer area.

Additional protection and performance from GEA PHE Systems.

Process Equipment Division

GEA PHE Systems

9902-708_Produktb_NP_RZ_neu_E.in1 1 06.10.2008 20:09:55 Uhr

NP Series: Technical data

Plate material: Stainles steel AISI 316 / 1.4401

Brazing material: Nickel alloy

Performance: up to 16 bar, 195°C

Third party approval: PED (CE), TÜV, ASME, UL, CSA. KHK, other on request

Features:

Option:

Extended Corrosion Resistance – XCR line

GEA PHE Systems’ XCR models feature increased resistance to corrosion using higher quality stainless steel plate material.

Well suited for harsh environments, chlorine-loaded media such as swimming pool, spa heaters and ground source heat pumps.

Nickel Advanced

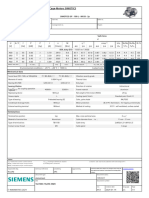

F Weight Max. flowrate Max. no.

brazed stain- Evaporator A B C D E N = number of plates N = number of plates

Volume

water plates

less steel -AE

Type Standard dimensions (mm) (kg) (liter/ch) (m3/h)

NP 1 – 74 204 40 170 15 10,0+2,30xN 0,70+0,050xN 0,025 4 50

NP 2 – 90 231 43 182 20 13,0+2,35xN 1,10+0,060xN 0,030 6 50

NP 22 – 90 328 43 279 20 13,0+2,35xN 1,30+0,080xN 0,046 6 50

Technical modification reserved · NP · 10/08 freitag van geigk

NP 24 – 90 464 43 415 20 12,0+2,30xN 2,04+0,140xN 0,070 6 50

NP 3 – 124 173 73 120 25 13,0+2,35xN 1,20+0,060xN 0,030 10 50

NP 4 - AE 124 335 73 281 25 13,0+2,30xN 1,60+0,130xN 0,065 10 100

NP 5 - AE 124 532 73 478 25 13,0+2,30xN 2,00+0,240xN 0,100 10 100

NP 7 - AE 271 532 200 460 40 13,5+2,35xN 9,60+0,540xN 0,230 27 150

NP 8 - AE 271 532 161 421 65 13,5+2,35xN 10,0+0,540xN 0,221 70 150

The specifications contained in this printing unit are intended only to serve the non-binding description Your contact:

of our products and services and are not subject to guarantee. Binding specifications, especially pertaining

to performance data and suitability for specific operating purposes, are dependent upon the individual

circumstances at the operation location and can, therefore, only be made in terms of precise requests.

Process Equipment Division

GEA Ecoflex GmbH GEA WTT GmbH GEA Ecobraze AB GEA PHE Systems NA, Inc.

Karl-Schiller-Straße 1-3 Remsaer Straße 2a Stuverigatan 5 100 GEA Drive

31157 Sarstedt · Germany 04603 Nobitz-Wilchwitz · Germany 26 135 Landskrona · Sweden York, PA 17406 · USA

Phone: +49 5066 601-0 Phone: +49 3447 5539-0 Phone: +46 418 446-160 Phone: +1 717 268-62 00

Fax: +49 5066 601-104 Fax: +49 3447 5539-30 Fax: +46 418 446-177 Fax: +1 717 268-61 63

info@gea-ecoflex.com sales@geawtt.com info@gea-ecobraze.se info@geaphena.com

www.gea-ecoflex.com www.geawtt.com www.gea-ecobraze.se www.geaphena.com

9902-708_Produktb_NP_RZ_neu_E.in2 2 06.10.2008 20:09:57 Uhr

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- GEA PHE WP En-5.2Document2 pagesGEA PHE WP En-5.2Oscar CamposNo ratings yet

- Lamina Brasado Bphe Produto GBHDocument2 pagesLamina Brasado Bphe Produto GBH伊藤 哲ウンベルト(Tabibito)No ratings yet

- XCR Series - Brazed Plate Heat Exchangers: For Pleasant-Temperature MomentsDocument2 pagesXCR Series - Brazed Plate Heat Exchangers: For Pleasant-Temperature Momentsjcastell100No ratings yet

- 1LE1003 0DA21 7AB4 Datasheet enDocument1 page1LE1003 0DA21 7AB4 Datasheet enkamal_arbabNo ratings yet

- Z-Flow E TCEVZ 1200Ã 31630Document3 pagesZ-Flow E TCEVZ 1200Ã 31630AbdulSattarNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- 1LE1003-1AA43-4FA4-Z B02 Datasheet enDocument2 pages1LE1003-1AA43-4FA4-Z B02 Datasheet enRefresh DrNo ratings yet

- 1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enDocument1 page1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enavinash mathurNo ratings yet

- TI Expansion ValveDocument1 pageTI Expansion Valveronin68xNo ratings yet

- TI Series - : W/interchangeable CartridgesDocument1 pageTI Series - : W/interchangeable CartridgesAlejandra M. SánchezNo ratings yet

- Design E-100 GT PMB N GN Kemala 15 MM Main CaseDocument103 pagesDesign E-100 GT PMB N GN Kemala 15 MM Main Casewahyu hidayatNo ratings yet

- SRC Technical DataDocument6 pagesSRC Technical DataKamel NaitNo ratings yet

- 1LE1501-3AB53-4AB4 Datasheet enDocument1 page1LE1501-3AB53-4AB4 Datasheet enfarid.chira2No ratings yet

- 250kW VDFDocument3 pages250kW VDFalex.burgosNo ratings yet

- Marine Broshure 95100-9520 PDFDocument12 pagesMarine Broshure 95100-9520 PDFrox fNo ratings yet

- Etachrom NC Bomba 1700m011-m012-m013Document16 pagesEtachrom NC Bomba 1700m011-m012-m013Miguel Morales SandovalNo ratings yet

- Sample Gas Cooler EGK 1/2: Bühler Constant Regulating SystemDocument4 pagesSample Gas Cooler EGK 1/2: Bühler Constant Regulating SystemFrank LuizNo ratings yet

- 285FPJ 270Document2 pages285FPJ 270dip461No ratings yet

- Description: Mechanical DataDocument2 pagesDescription: Mechanical Datadip461No ratings yet

- DataBook Jesx - 60 PDFDocument12 pagesDataBook Jesx - 60 PDFyossef rojas taparaNo ratings yet

- 1LE1001-0EB42-2FB4 Datasheet enDocument1 page1LE1001-0EB42-2FB4 Datasheet enAde FaisalNo ratings yet

- 1le5533 3ab63 4ab3Document2 pages1le5533 3ab63 4ab3Whipman ArduinoNo ratings yet

- Specification Sheet: Centrifuge For Petrol and Mineral OilsDocument3 pagesSpecification Sheet: Centrifuge For Petrol and Mineral Oilsh8pb8jzyhgNo ratings yet

- 1LE1501 2DA03 4AA4 Datasheet enDocument1 page1LE1501 2DA03 4AA4 Datasheet enGismart 11No ratings yet

- Ebara CDX 2 Poles 50 en LDocument20 pagesEbara CDX 2 Poles 50 en LAdi AlsonNo ratings yet

- GTB v6Document7 pagesGTB v6Chan Shiaw SyanNo ratings yet

- Ebara 2CDXDocument13 pagesEbara 2CDXDirector Tecnico y Operaciones Baying SASNo ratings yet

- P2-805 - Parts - 2011Document73 pagesP2-805 - Parts - 2011Centrifugal SeparatorNo ratings yet

- Aldec g2-95 - Parts - 2010Document63 pagesAldec g2-95 - Parts - 2010Centrifugal SeparatorNo ratings yet

- DataBook CDXDocument15 pagesDataBook CDXLê Anh TuấnNo ratings yet

- 11 - TW Thermo-KineticsDocument14 pages11 - TW Thermo-Kineticsthomas_v501925No ratings yet

- VAV TerminalsDocument18 pagesVAV TerminalsFaquruddinNo ratings yet

- Eq EtDocument1 pageEq EtSKYhabiaNo ratings yet

- Asme Cal in TabularDocument14 pagesAsme Cal in TabularSundara MoorthyNo ratings yet

- 00215A9B05B41EE793A9CDE81D09A343Document8 pages00215A9B05B41EE793A9CDE81D09A343gambetzNo ratings yet

- Alfa Laval Alfacond 400 - enDocument2 pagesAlfa Laval Alfacond 400 - enAjayNo ratings yet

- 1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enDocument2 pages1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enrianandiyahooNo ratings yet

- Flange Connection With DiapraghmDocument2 pagesFlange Connection With DiapraghmKania ZahrawatiNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZOmair FarooqNo ratings yet

- Boulder Stream Cascade PumpDocument3 pagesBoulder Stream Cascade PumpJawNo ratings yet

- 250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Document3 pages250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Vamshika SutarNo ratings yet

- 1le5503 3ab63 4ab3Document2 pages1le5503 3ab63 4ab3Whipman ArduinoNo ratings yet

- Ebara DwoDocument12 pagesEbara DwoDirector Tecnico y Operaciones Baying SASNo ratings yet

- DataBook CD PDFDocument15 pagesDataBook CD PDFsanti_sari_6No ratings yet

- ALDEC 30 - Parts - 2012Document57 pagesALDEC 30 - Parts - 2012Centrifugal Separator100% (1)

- CBT - Leaflets - 13100 - Van cân bằng nhiệt tự động - FDocument2 pagesCBT - Leaflets - 13100 - Van cân bằng nhiệt tự động - FNguyễn Xuân HùngNo ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- Techflow TV - Series: Vacuum Jacketed Cryogenic ValvesDocument2 pagesTechflow TV - Series: Vacuum Jacketed Cryogenic ValvesJust RysdanNo ratings yet

- CBT - Leaflets - 1340G - Van cân bằng nhiệt tự động - MDocument2 pagesCBT - Leaflets - 1340G - Van cân bằng nhiệt tự động - MNguyễn Xuân HùngNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- Sae J 403-Aisi 1042 1045 - ForminDocument2 pagesSae J 403-Aisi 1042 1045 - ForminKenvi AlarconNo ratings yet

- Ebara DWDocument16 pagesEbara DWDirector Tecnico y Operaciones Baying SASNo ratings yet

- 0141db60en DW Dwvox BDocument16 pages0141db60en DW Dwvox BGonzalo PimentelNo ratings yet

- Buna EP LanxessDocument51 pagesBuna EP LanxessANHVUDRCNo ratings yet

- 1LE1504-3AB23-4AB4 Datasheet enDocument1 page1LE1504-3AB23-4AB4 Datasheet enOkke BoykeNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- KSB Pump Multitec SpecDocument8 pagesKSB Pump Multitec Specgaryianderson100% (1)

- 1le5584 3aa03 4ab4Document2 pages1le5584 3aa03 4ab4Dharmesh ChanawalaNo ratings yet

- 1LE1503-2BB03-4AA4 Datasheet enDocument1 page1LE1503-2BB03-4AA4 Datasheet enAnil Kumar KnNo ratings yet

- Buku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 10 - Fase BDocument8 pagesBuku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 10 - Fase BKeni KenizaNo ratings yet

- CHEM333 Syllabus 2020 2021Document4 pagesCHEM333 Syllabus 2020 2021lina kwikNo ratings yet

- Measuring Salinity in Crude Oils Evaluation of MetDocument9 pagesMeasuring Salinity in Crude Oils Evaluation of Metarmando fuentesNo ratings yet

- Annals of The New York Academy of Sciences - 2023 - Hess - Accelerating Action To Reduce Anemia Review of Causes and RiskDocument13 pagesAnnals of The New York Academy of Sciences - 2023 - Hess - Accelerating Action To Reduce Anemia Review of Causes and RiskIdmNo ratings yet

- The Past Is A Foreign Country-1.2Document25 pagesThe Past Is A Foreign Country-1.2Xinyu DongNo ratings yet

- An Automated Energy Meter Reading System Using GSM TechnologyDocument8 pagesAn Automated Energy Meter Reading System Using GSM TechnologyBarNo ratings yet

- XVI - Magneticpropertiesofmanganese ContainingsolidsolutionsofbismuthorthoniobateBiNiO4Document7 pagesXVI - Magneticpropertiesofmanganese ContainingsolidsolutionsofbismuthorthoniobateBiNiO4Chukwuebuka UgochukwuNo ratings yet

- Report On RoboticsDocument40 pagesReport On Roboticsangelcrystl4774No ratings yet

- Taiwan API Manufacturer ListDocument4 pagesTaiwan API Manufacturer Listkalyani dynamicsNo ratings yet

- Manual de Despiece Honda Beat 100Document84 pagesManual de Despiece Honda Beat 100jorgeeu8833% (3)

- Advanced Automatic ControlDocument26 pagesAdvanced Automatic Controlabdullah 3mar abou reashaNo ratings yet

- HorticultureDocument12 pagesHorticultureवरुण राठीNo ratings yet

- PTFE HZ-2 HoerbigerDocument2 pagesPTFE HZ-2 HoerbigerТатьяна ВасильеваNo ratings yet

- Final Tana Beles - pdf2222Document72 pagesFinal Tana Beles - pdf2222Tiruneh Yeneneh100% (1)

- 1 N117Geriatric Nursing Lecture 1 BABY BOOMERSDocument4 pages1 N117Geriatric Nursing Lecture 1 BABY BOOMERSqygwfvbysgbcnntgrvbNo ratings yet

- PX 150 UsaDocument138 pagesPX 150 UsaramiroNo ratings yet

- MOE XT2-XT4 110... 125V Ac/dcDocument3 pagesMOE XT2-XT4 110... 125V Ac/dcLê Xuân ĐịnhNo ratings yet

- Video Wall, Digital Signage & C'Type Serial NumberDocument8 pagesVideo Wall, Digital Signage & C'Type Serial NumberAbhijit BarmanNo ratings yet

- Architect As An Environmental PlannerDocument14 pagesArchitect As An Environmental PlannerJames Adrian MoralNo ratings yet

- 10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtDocument145 pages10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtVuong DiepNo ratings yet

- Required Obstacle ClearanceDocument14 pagesRequired Obstacle ClearancePero PericNo ratings yet

- CPHL 214 Assignment 6Document2 pagesCPHL 214 Assignment 6NazNo ratings yet

- Flood RateDocument367 pagesFlood RatetpktpkNo ratings yet

- Proposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Document1 pageProposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Jehan TangonanNo ratings yet

- Nfpa 13d 2007 IndexDocument3 pagesNfpa 13d 2007 Indexsaladin1977No ratings yet

- Lit 1 ReportDocument21 pagesLit 1 ReportTrexie De Vera JaymeNo ratings yet

- Journal of Environmental Management: Ajay Singh TDocument7 pagesJournal of Environmental Management: Ajay Singh TNestor Garay CahuanaNo ratings yet

- Federal Bylaw 12 Air Pollution 2006 English Translation v2 OCRDocument63 pagesFederal Bylaw 12 Air Pollution 2006 English Translation v2 OCRIsmail SultanNo ratings yet

- Lenskart Solutions PVT LTD Company ProfileDocument13 pagesLenskart Solutions PVT LTD Company ProfileAnujaNo ratings yet

- Liquid SizingDocument38 pagesLiquid SizingChetan ChuriNo ratings yet