Professional Documents

Culture Documents

SRC Technical Data

Uploaded by

Kamel Nait0 ratings0% found this document useful (0 votes)

46 views6 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views6 pagesSRC Technical Data

Uploaded by

Kamel NaitCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

NEW GENERATION, ENERGY EFFICIENT INJECTION MOULDING MACHINES

SRC 60 - 2100 TON

STANDARD PARTS Adjustable machine leveling function

KEBA Controller units (Austria) Customized color (free)

KEB Driver (Germany)

ECKERLE or SUMITOMO pump (Servo) (Germany / Japan)

BOSCH - REXROTH, VICKERS Hydraulic valves (Germany / U.S.A) SPARE PARTS

BOSCH - REXR0TH, VICKERS Pumps (Germany / U.S.A) 1 pcs rocket, ring set

NOVOTECHNIK Transducer (Germany) 1 set various O-rings

FESTO Pneumatic System (Germany) 1 pcs extended Nozzle

SCHNEIDER Electric components (France) 1 pcs heather bands

CALZONI Hydraulic Motor (≥650T) (Italy) 1 pcs nozzle key

INTERMOT Hydraulic Motor (Italy) 1 pcs ceramic resistance

YUKEN Proportional valve (Japan) 1 pcs lubrication oil

Robot Interface Euromap 67 Professional tools

I/O Testing function Manual for machine and PLC system

SSR temperature control Set of 8 mold clamps for T-Slot or thread

2 Pcs core valves (4 pcs core valves for 570 Ton – 2100 Ton)

1 Pcs air valves (4 pcs air valves for 570 Ton – 2100 Ton)

1 Pcs core valve function with electrical

Proportional valve for mold open/close control

Water regulator

Pressure transmitter

Ceramic heater bands

T-Slot mould platen

Suck back function

Automatic purge function

Double-cylinder balanced injection system

6 Stage injection pressure/ speed control

5 Stage injection hold pressure control

5 Stage pressure, speed and time control for plasticizing

Injection cushion position monitoring function

Fast mould closing function

Automatic mould adjustment

Unlimited mould data memory

High precision mould protection function

Multi ejector system

Central lubrication level and pressure switches

Oil high and low temperature alarm

Oil level switch

By pass oil filter

Photo sensor

Mould cooling water flow regulator

Phase sequences and phase protection relay

Door safety relay

Mechanical, hydromechanical and electric safety system

Electric stabilizer

USB port data connecting

SRC MACHINES STANDARD EQUIPMENTS

ADVANTAGES OF SERVO MOTOR TECHNOLOGY

Energy savings up to 30-80%

High Response - Faster response time of the drive system. It requires only 0.005 seconds to reach the maximum power output.

Reduced Heat Generation - Only delivers hydraulic oil as it is needed.

Internal Gear Pump Increase reliability & lower maintenance cost.

Reduced Energy Consumption - Servo motor rpm can vary from 0 to 3000 rpm.

Noise Reduction - Quiet gear pump & Variable speed operations when required.

Reliable Holding Pressure - during holding pressure, servo motor reduces rotation and consumes low energy.

SRC MACHINES MAIN EQUIPMENTS

Hydraulic Pump BOSCH - REXR0TH, VICKERS GERMANY / USA

Servo Motor PHASE ITALY (China Factory)

Servo Driver KEB GERMANY

Hydraulic Valves BOSCH - REXROTH, VICKERS GERMANY / USA

Hydraulic Motor INTERMOT ITALY

Hydraulic Hose MANULI ITALY

Electrical Components SCHNEIDER FRANCE

Linear Transducer NOVOTECHNIK GERMANY

TECHNICAL SPECIFICATIONS

CLAMPING UNIT UNIT SRC 570 SRC 1000 SRC 1600

Clamping force KN 5700 10000 16000

Toggle Stroke mm 850 1200 1600

Space between tie bars mm 835 x 835 1120 x 1120 1500 x 1415

Platen dimensions(H x V) mm 1240 x 1250 1680 x 1780 2180 x 2180

Max.Mould Heigh mm 880 1200 1500

Min.Mould Heigh mm 350 500 700

Ejector Stroke mm 250 320 350

Ejector Force KN 158 215 318

INJECTION UNIT A B C D A B C D A B C D

Screw Diameter mm 75 84 90 100 100 110 120 130 120 130 140 150

Screw L/D ratio L/D 23.6 21.1 19.7 17.7 24.3 22.1 20.2 18.7 26.1 24.1 22.4 20.9

Shot Volume cmᶟ 1987 2492 2861 3532 4004 4844 5765 6766 6669 7827 9078 10421

Shot weight (PS) g 1788 2242 2575 3179 3603 4360 5189 6089 6002 7045 8170 9379

Shot weight (PS) oz 63.1 79.1 90.8 112.1 127.1 153.8 183 214.8 211.7 248.5 288.2 330.8

Injection pressure bar 2050 1630 1420 1150 2110 1740 1460 1250 1930 1640 1420 1230

Injection Speed mm/s 115 115 115 115 105 105 105 105 114 114 114 114

Injection Rate (PS) g/s 362 454 521 643 650 787 937 1099 1070 1256 1457 1672

Plasticizing Capacity (PS) g/s 56,3 77,9 89,4 110,4 83,3 100,8 120 133,8 123 147,6 171,2 186,7

Injection Stroke mm 450 510 590

Screw speed rpm 0 ~ 110 0 ~ 107 0 ~ 99

OTHERS

Max.Pump Pressure bar 160 160 160

Pump Motor Power KW 55 45 + 45 45 + 45 + 45

Servo Motor Power KW 29 + 29 39.4 + 29 + 29 29 + 39.4 + 39.4 + 39.4

Heater Power KW 36.9 79.35 101.85

Machine Dimensions(LxWxH) m 8.82 x 2.32 x 2.80 12.0 x 3.0 x 3.3 13.85 x 3.43 x 4.20

Oil Tank Capacity Liter 1000 1900 2800

Machine weight Ton 27 55 105

You might also like

- Champ Gyro User Guide Rev4.1Document33 pagesChamp Gyro User Guide Rev4.1Vicente AguirreNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- GIS Mapping Powers Electricity Planning in BasraDocument25 pagesGIS Mapping Powers Electricity Planning in BasraYaser Al-SolimiNo ratings yet

- Plastic Injection Moulding Machines: Mega NH SeriesDocument12 pagesPlastic Injection Moulding Machines: Mega NH SeriesMarcelo BoneNo ratings yet

- MNPTP - 01 - 8-16A Ton IntroductionDocument20 pagesMNPTP - 01 - 8-16A Ton IntroductionGlobal Teknik Abadi100% (1)

- Best Air CurtainDocument8 pagesBest Air Curtainmike okpeNo ratings yet

- Oemer DC Motors QCCDocument21 pagesOemer DC Motors QCCTroformasNo ratings yet

- Centrifugal Pumps Guide for 2CDX Series PumpsDocument13 pagesCentrifugal Pumps Guide for 2CDX Series PumpsDirector Tecnico y Operaciones Baying SASNo ratings yet

- R9350 EN New PDFDocument123 pagesR9350 EN New PDFSubairi bain100% (1)

- WATSON MARLOW SQP 500 DatenblattDocument4 pagesWATSON MARLOW SQP 500 DatenblattDicle KarabiberNo ratings yet

- Full Line Brochure 7-2021Document32 pagesFull Line Brochure 7-2021PrudzNo ratings yet

- Handling gauges and instruments for boatsDocument12 pagesHandling gauges and instruments for boatssughieantoNo ratings yet

- Bomba MecanicaDocument2 pagesBomba MecanicaBanupriya BalasubramanianNo ratings yet

- Engineering Catalog: CD250M Dri-Prime Pump Engineering DataDocument7 pagesEngineering Catalog: CD250M Dri-Prime Pump Engineering DataNils Enrique Hansen GamarraNo ratings yet

- MB8 3+1 Axis CNC Hydraulic Servo Press Brake Machine - DELEM DA52SDocument8 pagesMB8 3+1 Axis CNC Hydraulic Servo Press Brake Machine - DELEM DA52SryneleeNo ratings yet

- ACSCW Cat FEB 2024Document14 pagesACSCW Cat FEB 2024Kiran Kumar Nethrakere/EMD/UAENo ratings yet

- Motores Auxiliares 3508BDocument10 pagesMotores Auxiliares 3508BIris IlsasNo ratings yet

- The Engine For Construction Equipment.: 92 - 235 KW at 2000 - 2300 RPMDocument6 pagesThe Engine For Construction Equipment.: 92 - 235 KW at 2000 - 2300 RPMFranz JW Monteza100% (1)

- Stepping Motors 3 PhasesDocument12 pagesStepping Motors 3 PhasesTamas RaduNo ratings yet

- WEG 132kW SpecificationDocument8 pagesWEG 132kW Specificationbonginkosi mathunjwaNo ratings yet

- T0221 0013E-Rev.5 S16R2 PTAW2 E-50HzDocument5 pagesT0221 0013E-Rev.5 S16R2 PTAW2 E-50HzParinyaNo ratings yet

- Fiche Technique QES 390 CDDocument6 pagesFiche Technique QES 390 CDMProd AmmoNo ratings yet

- DataBook_cdxDocument15 pagesDataBook_cdxLê Anh TuấnNo ratings yet

- Manual de Operacion DGW310MC 220Document11 pagesManual de Operacion DGW310MC 220Uma A. UcheNo ratings yet

- 3828A24006XDocument51 pages3828A24006XMarco KersulNo ratings yet

- FCU Submittal Part 3 of 3Document90 pagesFCU Submittal Part 3 of 3ClarkFedele27No ratings yet

- AccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21Document5 pagesAccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21EnriqueMiguelPriceNo ratings yet

- High-Pressure Internal Gear Pumps Technical Data SheetDocument14 pagesHigh-Pressure Internal Gear Pumps Technical Data Sheetabdelhanin bouzianeNo ratings yet

- INJECTION MACHINE HY-1200 For 8cavityCAP 2023-2-20)Document4 pagesINJECTION MACHINE HY-1200 For 8cavityCAP 2023-2-20)johanel urbinaNo ratings yet

- Diesel Engines 8V/12V/16V 4000 M70 for VesselsDocument2 pagesDiesel Engines 8V/12V/16V 4000 M70 for Vesselsbakhouche100% (1)

- TJ1400PE6Document26 pagesTJ1400PE6Christian Rivera FloverNo ratings yet

- Genset 79-102-125 kVADocument2 pagesGenset 79-102-125 kVANatthawut CheencharoenNo ratings yet

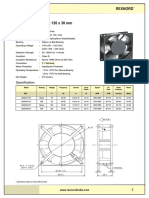

- 120 X 120 X 38 MMDocument1 page120 X 120 X 38 MMSarat KumarNo ratings yet

- AC Servo Motor and Driver Designation and SpecificationsDocument39 pagesAC Servo Motor and Driver Designation and SpecificationsAnes BelNo ratings yet

- GMBM80 DatasheetDocument7 pagesGMBM80 DatasheetServomotores SimairNo ratings yet

- MGS0900B (MG HC6J)Document4 pagesMGS0900B (MG HC6J)niesandNo ratings yet

- Mtu 16v4000m60Document2 pagesMtu 16v4000m60Juan Diego Sarango100% (1)

- KD88Document11 pagesKD88Maker PhạmNo ratings yet

- TCM250 TCM250CDocument5 pagesTCM250 TCM250CAung MhNo ratings yet

- Mitsubishi Electronics mgs2700c Manual de UsuarioDocument4 pagesMitsubishi Electronics mgs2700c Manual de UsuarioEsteban JaramilloNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN SOFTWARESNo ratings yet

- VRF Indoor Unit Four Way Cassette (2 Generation DC Series, 50/60Hz)Document2 pagesVRF Indoor Unit Four Way Cassette (2 Generation DC Series, 50/60Hz)JAQANo ratings yet

- Transmotec Datasheet SDS80120ADocument1 pageTransmotec Datasheet SDS80120Asaxadi4814No ratings yet

- Item:130ST Series Servo Motor: SpecificationsDocument4 pagesItem:130ST Series Servo Motor: Specificationsn13t0314No ratings yet

- 1 C221 D 01Document4 pages1 C221 D 01Azka AiraNo ratings yet

- 40LM1-A15-7PD - 40 - 100 - REV6 - Conceal DuctDocument18 pages40LM1-A15-7PD - 40 - 100 - REV6 - Conceal DuctPhuNguyenHoangNo ratings yet

- Diesel Generator Set KTA50 Series Engine - Specification SheetDocument4 pagesDiesel Generator Set KTA50 Series Engine - Specification SheetIrwin JoseNo ratings yet

- Eco Smart Compression Testing Machine PDFDocument2 pagesEco Smart Compression Testing Machine PDFsyed sulemanNo ratings yet

- BRAKES Air Cooled BrakesDocument6 pagesBRAKES Air Cooled Brakes张淼No ratings yet

- KORD3!20!074 Technical Information For V1505Document27 pagesKORD3!20!074 Technical Information For V1505carlos miras mondejarNo ratings yet

- LT3 00010 1 - P6 7 8 11 14 24 30 Piston PumpsDocument84 pagesLT3 00010 1 - P6 7 8 11 14 24 30 Piston PumpsNelson PaicoNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- Inverter Range DatasheetDocument1 pageInverter Range DatasheetvasilzhmendakNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- Specification S16R2 PTAWDocument4 pagesSpecification S16R2 PTAWMuhammad rizki100% (1)

- Edwarad Oil Sealling Vacuum PumpDocument5 pagesEdwarad Oil Sealling Vacuum PumpDurrani SonsNo ratings yet

- Kta50-G3 0 PDFDocument3 pagesKta50-G3 0 PDFAlisabel Muñoz de Morales0% (1)

- ZRS320E SpecificationDocument7 pagesZRS320E SpecificationSabahNo ratings yet

- MTU Datasheet s4000px3 Constant SpeedDocument2 pagesMTU Datasheet s4000px3 Constant SpeedKrish100% (1)

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- Turn TutorialDocument129 pagesTurn TutorialИгорь ПлугатырёвNo ratings yet

- PLC 9613 ENDocument4 pagesPLC 9613 ENKamel NaitNo ratings yet

- Handtop HT2500UV - User Manual (EN)Document71 pagesHandtop HT2500UV - User Manual (EN)Kamel NaitNo ratings yet

- XPSLCMUT1160 - Muting Safety Module For Safety Light Curtains - User ManualDocument54 pagesXPSLCMUT1160 - Muting Safety Module For Safety Light Curtains - User ManualKerim JumanazarowNo ratings yet

- GM11 Regular-Glass Straight-Line Edging MachineDocument5 pagesGM11 Regular-Glass Straight-Line Edging MachineKamel NaitNo ratings yet

- 23 Work Centres Cutting and Shaping RoutersDocument1 page23 Work Centres Cutting and Shaping RoutersKamel NaitNo ratings yet

- Combo Router-Frese ComboDocument1 pageCombo Router-Frese ComboKamel NaitNo ratings yet

- Dia CatGen GLASS Lug19 ENG LR PDFDocument48 pagesDia CatGen GLASS Lug19 ENG LR PDFKamel NaitNo ratings yet

- CIRCULAR SAW BLADES GUIDEDocument44 pagesCIRCULAR SAW BLADES GUIDEKamel NaitNo ratings yet

- IP Camera Data Sheet: LN-400Document2 pagesIP Camera Data Sheet: LN-400Kamel NaitNo ratings yet

- MD Cabinet DoorsDocument4 pagesMD Cabinet DoorsKamel NaitNo ratings yet

- CMS Glass Machinery Insulated Glass Catalog enDocument40 pagesCMS Glass Machinery Insulated Glass Catalog enKamel NaitNo ratings yet

- NCP1010, NCP1011, NCP1012, NCP1013, NCP1014 Self-Supplied Monolithic Switcher For Low Standby-Power Offline SMPSDocument25 pagesNCP1010, NCP1011, NCP1012, NCP1013, NCP1014 Self-Supplied Monolithic Switcher For Low Standby-Power Offline SMPSKamel NaitNo ratings yet

- Pou LiesDocument34 pagesPou LiesKamel NaitNo ratings yet

- Sloar Pumping Inverter-Quick Installation Guideline - V1.0.2015Document62 pagesSloar Pumping Inverter-Quick Installation Guideline - V1.0.2015Kamel NaitNo ratings yet

- Temperature PTC PTTC Application: 675°F/357°C 775°F/413°C 875°F/468°C 925°F/496°C PTCDocument2 pagesTemperature PTC PTTC Application: 675°F/357°C 775°F/413°C 875°F/468°C 925°F/496°C PTCKamel NaitNo ratings yet

- Projects in ElectronicsDocument216 pagesProjects in ElectronicsSathiya Moorthy C A92% (39)

- Engineering Data Sheet: Bill of MaterialDocument7 pagesEngineering Data Sheet: Bill of MaterialJairo andres Guarnizo SuarezNo ratings yet

- Chapter 10Document9 pagesChapter 10J.K HomerNo ratings yet

- Safety PrecautionDocument1 pageSafety PrecautionSJ Chua100% (1)

- Daily production report for 17-JUN-19 highlights units, targets, actualsDocument1 pageDaily production report for 17-JUN-19 highlights units, targets, actualsSergio Quisbert P.100% (1)

- DAL Keystones SSDocument8 pagesDAL Keystones SSyordanNo ratings yet

- Yogesh Kumar Garg Resume Mechanical EngineerDocument3 pagesYogesh Kumar Garg Resume Mechanical EngineerYogeshGargNo ratings yet

- Wire Size Chart NEC 2011Document1 pageWire Size Chart NEC 2011Gustavo TovarNo ratings yet

- Waller Park Preview 2021Document7 pagesWaller Park Preview 2021Jason DelgadoNo ratings yet

- 32C240 241Document34 pages32C240 241Priya TaylorNo ratings yet

- KBMM PDFDocument2 pagesKBMM PDFRicardo Garcia FuentesNo ratings yet

- LG LED TV Owners ManualDocument44 pagesLG LED TV Owners ManualBa humbugNo ratings yet

- SJ-20100630164932-027-ZXSS10 SS1b (V2.0.1.07) SoftSwitch Control Equipment Data Configuration Guide Subscriber Allocation - 280443Document31 pagesSJ-20100630164932-027-ZXSS10 SS1b (V2.0.1.07) SoftSwitch Control Equipment Data Configuration Guide Subscriber Allocation - 280443منصورالمغربيNo ratings yet

- Backscatter and Seabed Image ReflectivityDocument5 pagesBackscatter and Seabed Image ReflectivityJuan David SantanaNo ratings yet

- Maytag Cycle GuideDocument9 pagesMaytag Cycle GuideReggieNo ratings yet

- Princecraft Bateaux enDocument70 pagesPrincecraft Bateaux enkhussonNo ratings yet

- Component-Based Development Ben Fairfax Thursday 21st September 2006Document65 pagesComponent-Based Development Ben Fairfax Thursday 21st September 2006sdimi51No ratings yet

- Configure Switching FeaturesDocument28 pagesConfigure Switching FeaturesCinco PredragNo ratings yet

- Torre Sauter 4 PosiçõesDocument22 pagesTorre Sauter 4 PosiçõesPaulo Henrique ValérioNo ratings yet

- Procedure System of Plant & Equipment ManagementDocument19 pagesProcedure System of Plant & Equipment ManagementImtiyaz Akhtar100% (1)

- Husqvarna R322 Owners ManualDocument40 pagesHusqvarna R322 Owners Manualsheba1023No ratings yet

- Install GuideDocument63 pagesInstall GuideĐểGióCuốnĐiNo ratings yet

- ! Assembly ItemsDocument60 pages! Assembly ItemsCostin AngelescuNo ratings yet

- Schneider Price ListDocument22 pagesSchneider Price ListAbhishek RajputNo ratings yet

- Aseptic Process TechnologyDocument19 pagesAseptic Process TechnologyHimanshu ShahuNo ratings yet

- Gorni SFHTHandbookDocument83 pagesGorni SFHTHandbookapi-3762011No ratings yet

- Ieee 1578-2007 PDFDocument32 pagesIeee 1578-2007 PDFNataGBNo ratings yet

- (Multi V Task) Technical Seminar - Multi V AHU Solution - FinalDocument36 pages(Multi V Task) Technical Seminar - Multi V AHU Solution - FinalPaulo Augusto GarayNo ratings yet

- C3 - WO9 - Steel Structure Works - Internal Schedule (Metal Building Factory) PDFDocument1 pageC3 - WO9 - Steel Structure Works - Internal Schedule (Metal Building Factory) PDFAdel MorsyNo ratings yet