Professional Documents

Culture Documents

Dunlop 32-40-1 (17) 30700 Ah52688

Uploaded by

danilo0 ratings0% found this document useful (0 votes)

45 views40 pagesTrenes JS-32 ah52688 series

Original Title

DUNLOP 32-40-1(17) 30700 AH52688

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTrenes JS-32 ah52688 series

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

45 views40 pagesDunlop 32-40-1 (17) 30700 Ah52688

Uploaded by

daniloTrenes JS-32 ah52688 series

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 40

DUNLOP AIRCRAFT EQUIPMENT

OVERHAUL MANUAL

For

NOSE WHEEL

PART Nos. AH52590, AH52688,

AH53374 & AH53375

STATEMENT OF INITIAL CERTIFICATION

This manual complies with Chapters A6-2 and A3-1 and has been

prepared to procedures defined in accordance with Chapter A8-1

of British Civil Airworthiness Requirements.

Signed Mi : Date: __4th January 1967

C.A.A. Approval No.DAI/3133/S0

The above certification does not apply to revisions made after the date

of initial certification by other approved Organisations. Revisions or

Amendments made by other approved Organisations must each be

separately certified and recorded on separate record sheets

All Rights Reserved

This publication or any part thereof may not be reproduced or transmitted

in any form or by any means, including photocopying, electronic transfer

and/or recording, without the written permission of the Copyright holder,

application for which should be addressed to Technical Publications dept,

Dunlop Limited, Aviation Division, Foleshill, Coventry, CV6 44 England

The following are trade marks of Dunlop Limited: ~

Dunlop % Symbol Dunlostrut —_ Dunloride

AC ACA ACM ACO AH AHA AHO AE AEA AEM AEO

© DUNLOP LIMITED AVIATION DIVISION 1967, 1989

32-40-1(17)

PRINTED IN ENGLAND Revs: Oct 2oie7 ¢

Regstered in England No. 995293. Registered Office: Sivertown House, Vincent Square, London SWIP 2A. A Subsdbary of BTR ple

GENERAL

NOTES

This Overhaul Manual has been prepared to A.T.A, 100 Specification. it is complete

with illustrated parts list and contains full descriptive and operating notes complete with

procedures for disassembly, inspection,renewal and repair of parts,assembly and testing

of the units described when used in an approved system. The technicians of the Dunlop

Company will be pleased to advise on the suitability or adaptability of the unit for use in

new systems. Reference should be made to the Aviation Division, Foleshill, Coventry.

Lists are included, where necessary of special tools, fixtures, equipment and lubricants.

Comprehensive general information on storage conditions, shelf life and service life of

rubber components is given in DM, 32-40-21, Any variation of shelf or service life for

individual components or units will be given under the applicable heading.

ULTIMATE LIFE

‘The ultimate life of any unit covered in this manual depends upon the frequency and con-

ditions of use,and reference should be made to the Aircraft Maintenance Manual and/or

Approved Maintenance Schedule for the maximum permissible period of use. Any ulti-

mate life recommendation given in this manual for a unit or a component of a unit, must

be regarded as subject to approval by the appropriate Airworthiness Authority in regard

to a specified operator's maintenance schedule.

FITS AND CLEARANCES

Except where otherwise stated, measureable wear affecting the serviceability of this unit

is not anticipated and therefore dimensional checking need not be undertaken.

AIRCRAFT APPLICABILITY

1 BAe JETSTREAM

32-40-1(17)

pai/3133/50 Rev.5, Oct.26/89

®@ DUNLOP LIMITED

NOSE WHEEL

OVERHAUL MANUAL.

LIST OF EFFECTIVE PAGES

SUBJECT PAGE DATE

Title Page a Oct.26/89

General Notes 1 .

List of Effective Pages 1 "

Record of Revisions 1 Jan.4/67

Record of Temporary Revisions 1 .

Modification Record 1 March 1/78

1 July 16/84

2 "

3 March 1/78

5 w

6 July 16/84

7 a

8 0

8-1 “

9 March 1/78

10

1 Oct.26/89

13 Jan. 4/67

202 iu

203 Oct.26/89

204 March 1/78

205 “

32-40-1(17)

List of Effective Pages

DAI/3133/50 PRINTED IN ENGLANO Rev.5, Oct.26/89

Oo

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

RECORD OF REVISIONS

{Incorporated under ARB Design Approval No, AD. 1030/39)

Retain this record in the front of the Manual. On receipt of Revision, revise as

detailed in the Letter of Transmittal and record the incorporation of the revision

on this sheet. The introduction of any amendment or revision not certified in

accordance with British Civil Airworthiness Requirements will invalidate the

‘statement of certification on the face sheet of this Manual, Amendments or re-

visions embodied in this Manual, which have been certified under approval auth-

orisations other than that applicable to the initial certification must be recorded

on separate record sheets

Revision Insertion Revised by ey ieen aasaraea| eo mewlsadley,

Pant 2 |Makewlg) punLoe

Bat | Tau] Dereer

5 oho 2

moa

Jan. 4/67 32-40-1(17)

PRINTED IN ENGLAND

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

RECORD OF TEMPORARY REVISIONS

(Incorporated under ARB Design Approval No. AD. 1030/39)

Retain this record of Temporary Revisions at the front of the Manual immediately

following the Record of Revisions. On receipt of Temporary Revision, revise as

detailed in the Letter of Transmittal and record the incorporation of the revision

on this sheet. The introduction of any amendment or revision not certified in

accordance with British Civil Airworthiness Requirements will invalidate the

statement of certification on the face sheet of this Manual, Amendments or revi-

sions embodied in this Manual, which have been certified under approval authori-

sations other than that applicable to the initial certification must be recorded on

separate record sheets.

=o ancelled oar ancelled

Temporary | rsertton | © Temporary | tesertton | &

‘No. Date By | Date No. Date By | Date

32-40-1(17)

Jan, 4/67

To follow Record of Revisions

PRINTED IN ENGLAND

©

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

JETSTREAM INTERNATIONAL AIRLINES

RECORD OF TEMPORARY REVISIONS

Tempora neelle emporar ancelle

ec ereEYg | (trmertien|| iceman Temporary | insertion | Ceneeted

No. Date By | Date No. Date By | Date

}

J 704-2 f

L

TATE

DUNLOP.

NOSE WHEEL

OVERHAUL MANUAL

(ODIFICATION RECORD.

MoD. MoD. MOD. MoD mop.

No No No No

‘AH, 52590 ‘AH, 52688 AH. $3375

All mods. All mods. Introduced Introduced

approved approved by Mod, by Mod.

prior to prior to M, 1425 M1425,

neste) + [1.3.78 *

* Fully Covered

- No Cover Required

NOTE; Suffix 'O' Mods. when included are for information only. These are general

Mods. covering drawing corrections, minor design improvements ete. , aot

affecting interchangeability or raising the issue/mod. state of the unit(s).

— s2-40-117]

DAI/ 3133/50 Rev. 3, March 1/78

®DUNLOP LIMITED

NOSE WHEEL

OVERHAUL MANUAL

CONTENTS

DESCRIPTION AND DATA Page

DESCRIPTION... So tw wo 6 oo of 3

DATA ee 3

DISASSEMBLY

TYRE REMOVAL no 0 0 eS

A. Preparation

B. Removal Procedure

WHEELSDIGAGGEMB IV) fete 5

CLEANING bob. 6 ee 6

INSPECTION

AT EACH TYRE CHANGE ee 6

AT EACH OVERHAUL eee 6

NON-DESTRUCTIVE TEST PROCEDURE (N.D.T.) 2 2. 7

REPAIR

REPAIR OF DAMAGE TO HALF HUBS of ho ono 8-1

ANTI-CORROSIVE TREATMENT OF HALF HUBS .. .. .. 8-1

REMOVAL OR RENEWAL OF SERRATED SLEEVE 5 8-1

ASSEMBLY

ASSEMBLY LUBRICANTS 5 6 00 oF oo 9

ASSEMBLY PROCEDURE 5 5 oo 1 oo 9

A. Assembly with Tubeless Tyre

B. Assembly with Tyre and Tube

FITS AND CLEARANCES

WEAR LIMITS .. G oo oo ao 10

ASSEMBLY DATA -. ee ee eee woe 10

TESTING

32-40-1(17)

Page 1

DAI /3133/50 PRINTED IN ENGLAND Rev.4, July 16/24

® DUNLOP LIMITED

NOSE WHEEL

OVERHAUL MANUAL

STORAGE INSTRUCTIONS

STORAGE CONDITIONS . 5 09 60 6 oo DG 10

STORAGE LIMITING PERIOD (SHELF LIFE) .. -. 2. 10

OVERHAUL SCHEDULE... om co mn n

SPECIAL TOOLS, FIXTURES AND EQUIPMENT foo ool

|LLUSTRATED PARTS LIST 203

ILLUSTRATIONS

Fig.

Section of Nose Wheel 1

Outlined Inspection Areas (N.D.T.) 2

Scan Path Periphery of Valve Hole So

Parts List Illustration ee 201

Parts List Illustration.) -. sk - 202

32-40-1(17)

Page 2

DAI/3133/50 PRINTED IN ENGLANO : Rev.4, July 16/84

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

DESCRIPTION AND DATA

DESCRIPTION

‘This split type wheel is for use with a tubeless tyre or tyre/tube combination and

is designed to be fitted to a live axle. The tubeless version of the wheel is illus~

trated in Figure 1, The tyre/tube version is identical except for deletion of the

valve and re-positioning of the valve hole, Refer to Fig, 202,

Section of Nose Wheel

Figure 1

2

Tyre Size Tyre Half Hub

in, Type Material

6.00 - 6 Tubeless Magnesium Alloy

6.00 - 6 Tubeless Aluminium Alloy

6,00 - 6 Tyre/Tube Magnesium Alloy

AH, 53374 6.00 - 6 Tyre/Tube Aluminium Alloy

NOTE: AH, 52688 is similar to AH, 52590 except that the half hubs are

lightened by recessed pockets in the diaphragm, AH, 53375 and

AH, 53374 are tyre/tube versions of AH, 52590 and Al

respectively,

32-

Rev, 3, March 1/78

PRINTED IN ENGLAND,

DAI/ 3133/50

+ 52688,

Li7]

Page 3

40-1

JETSTREAM INTERNATIONAL AIRLINES:

TEMPORARY REVISION

This revision is to notify Jetstream International

Airlines Maintenance Personnel of Dunlop Service Newsletter

J31/ 32-32-3.

The Newsletter changes the requirements for the Radial

Distortion check for the Dunlop nosewheels used on J3i

aircraft.

@ Radial distortion check is only required following a

reported Hard or Overweight Landing or whenever the wheel has

rolled on a deflated tire.

NOTE: DUE TO THE ARRANGEMENT OF QUR NOSEWHEEL TIRES, BOTH

TIRES MUST HAVE BEEN DEFLATED TO REQUIRE THE RADIAL

DISTORTION CHECK.

The mechanics in the tire shop are responsible to route

the tires that are tagged, with the discrepancies above, to

the Stores Department. The Stores Department will route the

wheels to a approved repair vendor for the completion of the

Radial Distortion Check.

TR-1 32-40-1(17)

PAGE 6A

7-20-92

AIONLOP LIMITED

AVIATION DIVISION

TECHNICAL SUPPORT

Holbrook Lane, Coventry CV 4AA, England.

‘phine BSCS GIES Teer S67? Pcs: 652284 Direct ne: (0203)

SERVICE NEWSLETTER

AIRCRAFT: Bae Jetstream

VARIANTS: J31, 932

TITLE: Nosewheel

MOD STATE: Not Affected

PART NUMBER: AH 53374, AH 53375, AH 52688

Manual 32-40-1 (17) page 6 currently calls for radial distortion

check of the nosewheel at every overhaul.

This Service Newsletter is igsued to advise that this manual

requirement will be changed at the next revision and to

authorise operators that they need only perform the radiel

distortion check on the nosewheel following a reported heavy

landing, or whenever the whee) hes rolled on a deflated tyre.

The technical content of. this Service Newsletter {s approved

under the Authority of CAA approval No. DAI/3133/50.

co Ss +

SM SMITH | ———___

SALES AND TECHNICAL SUPPORT CHIEF AIRWORTHINESS ENGINEER

MANAGER

Service Newsletter: J31/32-32-3 Date of Issue: & July 1992

& Reference: SAT/BV/027 Issue No. 2

whe Page 1 of 1

DUNLOP.

NOSE WHEEL

OVERHAUL MANUAL

DISSASS.

BLY

TYRE REMOVAL

A. Preparation

(1) Check wheel assemblies fitted with tubes for tyre creep before deflating,

‘This instruction applies at both tyre change and wheel overhaul, If

creep has exceeded the limit of the creep mary. painted on the tyre/wheel,

identify the tyre and tube to ensure that particular attention will be paid

to the tyre bead areas, the tube valve and valve base rubber, during inspec-

tion,

(2) It is recommended that during disassembly, the wheel be placed on a rv

ber or felt mat to protect it from damage.

WARNING: DURING DEFLATION TEMPORARY BLOCKAGE OF THE

VALVE DUE TO ICE FORMATION MAY OCCUR SEVERAL

TIMES BEFORE DEFLATION IS COMPLETE. ALLOW

SUFFICIENT TIME TO ELAPSE TO ENSURE FULL DE-

FLATION (DO NOT PROBE) BEFORE REMOVING THE

VALVE CORE.

(3) Remove the dust cap from the inflation valve and fit the special 'screw-

on! type deflator to fully deflate the assembly. Screw out the valve core,

B, Removal Procedure

WARNING: BEFORE ANY ATTEMPT IS MADE TO DISASSEMBLE A WHEEL,

ENSURE THAT THE ASSEMBLY IS FULLY DEFLATED ANDTHE

VALVE CORE IS REMOVED, FAILURE TO OBSERVE THESE

PRECAUTIONS MAY RESULT IN INJURY TO THE OPERATOR.

(1) Free the beads of the tyre from adhesion to the bead seats of the wheel

by using @ tyre removal machine as detailed in 32-40-11(12).

(2) Place the wheel on a sultable mat, Remove the valve body and seal,

| {tubeless tyres) or push the valve stem well into the tyre (tubed tyres}.

(3) Remove the nuts, bolts and washers securing the half hubs together and

separate the half hubs, Detach the 'O' ring and tyre (tubeless tyres) oF

| separate the tube from the tyre (tubed tyres).

4, WHEEL DISASSEMBLY

No further disassembly of the wheel is necessary, after removal of the tyre, except

for renewal of the serrated sleeve when found defective during the overhaul inspec-

tion,

32-40-1(17)

DUNLOP.

NOSE WHEEL

OVERHAUL MANUAL

CLEANING

CAUTION; DO NOT ALLOW CLEANING FLUID TO COME INTO CONTACT WITH

THE RUBBER COMPONENTS.

‘Thoroughly clean and dry all metallic components, Ensure that the tyre bead seat

areas are entirely free from grease, oil or other foreign matter.

NOTE:

6

c

INSPECTION

For the numerical values of the letters quoted in the following instructions re-

fer to Fits and Clearances, para.13,

AT EACH TYRE CHANGE

a)

(2)

Examine the half hubs for damage and corrosion, Refer to para.7(1).

Examine the half hubs for cracks as detailed in para.7-1. Pay particular

attention to the area around the valve hole of tyre/tube type wheels,

AT EACH OVERHAUL

Q)

(2)

3)

(4)

(5)

(6)

Examine the half hubs for damage and corrosion, particularly in the vicinity of

the flanges and tyre bead seats. Excessive damage or corrosion will render

the wheel unserviceable, Superficial damage or corrosion should be treated

as detailed in Repair, para. 8,

Examine the half hubs for cracks as detailed in para.7-1, Pay particular

attention to the area around the valve hole of tyre/tabe type wheels.

Check the wheel for radial distortion by fitting a suitable mandrel and setting

up between centres, or alternatively, mount each half hub in a lathe with the

chuck jaws locating around the joint face end.

NOTE: If the latter method is employed the setting must be such that the hub

centre at the outer end is concentric to within 0,002 in. dial gauge

indicator reading.

Apply an indicator to the tyre bead seat(s) of the wheel or half hub and make a

radial check throughout 360 degrees to ascertain the amount of radial distor-

tion, Distortion in excess of Ain. renders the wheel or half hub unserviceable,

Check the serrated sleeve in situ for damage to the bore and the serrations,

Using a feeler gauge, check that any gap between the sleeve flange and the half

hub abutment face does not exceed 0.0015 in, Defective serrated sleeves may

be renewed as detailed in Repair, para. 10,

Examine the inflation valve assembly for damage, renew if defective.

Examine the 'O! ring seals for deformation, permanent set, ageing and general

damage, It is recommended however, that the 'O ring seals be renewed at

each overhaul.

32-40-1(47)

Page

DAI/ 3133/50 Rev.4, July 16/34

® DUNLOP LIMITED

NOSE WHEEL,

OVERHAUL MANUAL

7-1, NON-DESTRUCTIVE TEST PROCEDURES (N.D

A. Methods

(1) Examine the half hubs for crack in areas A + B outlined in

Figure 2 using equipment and techniques detailed in Dunlop

General Practices Manual 20-00-01

(2) On wheels AH5S3374 and AHS3375 (tyre/tube versions) examine

additional area X for cracks as illustrated in Figure 3 using

equipment detailed in Dunlop General Practices Manual 20-00-01,

the distance of scan path from hole should be 0.04 in. (1 mm)

B. Areas to be inspected

Figure 2

Reference Area

A Fiange rim/tyre seat area

B Bolt holes

x Valve hole (tyre/tube versions)

Outlined Inspection Areas (N.D.T.)

Figure 2

32-40-1(17)

Page 7

DA\/3133/50 PRINTED IN ENGLAND, Rev.4, July 16/84

® DUNLOP LIMITED

NOSE WHEEL

OVERHAUL MANUAL

scan Park

Scan Path Periphery of Valve Hole

Figure 3

32-40-1(17)

Page &

DAI/3133/50 PRINTED IN ENGLAND Rev.4, July 16/84

qa)

(2)

S DUNLOP LIMITED

NOSE WHEEL

OVERHAUL MANUAL

REPAIR

REPAIR OF DAMAGE TO HALF HUBS

Carefully dress out superficial cuts and abrasions, and slight surface

corrosion with a smooth file and emery cloth, blending any sharp

edges to maintain the essential curvature (where applicable) as far as

possible. The maximum permitted depth of dressing is 0.020 in. (0,5

mm).

After dressing restore the protective treatment as detailed in

32-40-21(3).

9. ANTI-CORROSIVE TREATMENT OF HALF HUBS

Refer to 32-40-21(3) for full details of stripping and restoration procedurs.

10. REMOVAL OR RENEWAL OF SERRATED SLEEVE

a)

(2)

(3)

(a)

(5)

Press the serrated sleeve out of the half hub

Heat the half hub to 150 deg.c.

Coat the mating surfaces of the new serrated sleeve and the half hub

with Araldite, refer to 32-40-21(5), Process 2.

Using the special tools, align the bolt holes in the sieeve with the

bolt holes in the half hub and press the sleeve fully home, while the

half hub retains its heat. Remove all traces of Araldite which has

exuded from the mating surfaces.

Allow the assembly to cool and check with a feeler gauge that any

gap between the sleeve flange and the half hub abutment face does

Rot exceed 0.0015 in. (0,03 mm)

32-40-1(17)

Page 8-1

DAI/3133/50 PRINTED IN ENGLANO Rev.4, July 16/84

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

ASSEMBLY

11, ASSEMBLY LUBRICANTS

Titanine LR. 4871 Assembly lubricant for half hub 'O"

or rings, spigots and adjacent abutment

MS. 33 (DC. 33) faces

D.T.D, 897

MS. 33 (DC. 33) Assembly lubricant for inflation

D.T.D.897 valve seals, bolts, washers and nuts

12, ASSEMBLY PROCEDURE

NOTE: (1) When renewing a half hub, record the new component serial number

together with the date of mating on the wheel assembly history card

(refer to 32-40-21(6)).

(2) Before commencing tyre fitting, refer to 32-40-11(12) for informa-

tion on awl venting of tyres,

(3) For the numerical values of the letters quoted in the following in-

structions refer to Assembly Data, para. 14,

A, Assembly with Tubeless Tyre

(1) Fit the seal to the valve assembly and fit the assembly in the half hub.

(2) Fi

t the 'O! ring to the spigot in the half hub,

(3) CAUTION: WHEN FITTING A TYRE ENSURE THAT THE TYRE BEADS

DO NOT BECOME CONTAMINATED WITH GREASE.

Position the tyre on the half hub and line up the red spot en the tyre with

the valve location, It is recommended that the tyre be fitted dry,

(4) Assemble the half hubs together, ensure that the 'O! ring is not disturbed

and that the bolt holes are aligned,

(5) Smear the bolt shanks, underside of the bolt heads and the washers with

the specified grease, Fit the bolts to the half hubs, ensure that the ex-

tended bolt is fitted to the bolt hole diametrically opposed to the valve

assembly and that the bolt heads abut the serrated sleeve. Fit the

washers ard the nuts,and alternately tighten diametrically opposed nuts

toa torque of C Ib. ft. Temporarily fit the locking device securing nut

to the extended bolt,

(6) Inflate the wheel assembly as detailed in 32-40-11(12), After inflation

tighten the valve assembly to a torque of B Ib. ft

(7) Test the assembled wheel as detailed in Testing, para.15, On comple-

tion of testing, fit the valve cap,

B. Assembly with Tyre and Tube

(1) Dust the tube and the inside of the tyre with French chalk and shake off

any excess.

32-40-1L17]

DAI/ 3133/50 a Rev.3, March 1/78

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

(2) Align the red line (heavy spot) on the tube with the red mark (light spot)

on the tyre and assemble the tube into the tyre, Using the fingers, smooth

out any creases in the tube to lessen the possibility of trapping air.

(3) Inflate the tube just sufficiently to round it out and position the tyre/tube

combination on the valve side half hub ensuring that the valve stem is

correctly located,

CAUTION

DO NOT FIT AN 'O! RING SEAL BETWEEN THE HALF.

HUBS OF WHEELS EQUIPPED WITH A TYRE AND TUBE,

(4) Assemble the half hubs together, ensuring that the valve retains its cor-

‘rect position and that the tube does not become trapped between the half

hub mating faces,

(5) Complete the remaining assembly procedure as detailed in para, 12A(5)

and (6).

(6) Teat the assembled wheel as detailed in Testing, para.15. On comple-

tion of testing, fit the valve cap,

(7) Using synthetic white paintspainta one inch wide creep mark on the side-

wall of the tyre and extend the mark on to the wheel rim,

FITS AND CLEARANCES

13, WEAR LIMITS

Radial Distortion

Wheel Limit .

Part No, Ain,

AH, 52590

AH, 52688 t

‘AH 53375 ee

AH. 83374

14, ASSEMBLY DATA

Torque Loading (Greased)

Wheel Valve Assembly Hub Nuts

Part No, B ib, ft. C ib, ft

AH, 52590 6 17

AH, 52688 6 28

AH, 53375 6 17

‘AH.53374 6 28

TESTING E

15, After all servicing operations which involve tyre deflation, test the wheel assembly

for leakage as detailed in 32-40-2(22), Main Wheel.

STORAGE INSTRUCTIONS

16, STORAGE CONDITIONS

(1) The inflation pressure of wheels fitted with tyres should be reduced to 20% of

the normal operating pressure before storage or transit.

32-40- IL 17]

Page 10

ev.3,Mareh 1/78

DAI/ 3133/50 a Cu)

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

(2) Tubeless wheels are prepared for transit with the ‘0! ring seal folded once

and enclosed ina bag within the hub centre, On receipt of the wheel the seal

must be removed, unfolded and stored ina relaxed position, Refer to

Bpea0-ath).

17, STORAGE LIMITING PERIOD (SHELF LIFE)

Refer to 32-40-21(1) for comprehensive information concerning the Shelf Life of

rubber components.

OVERHAUL SCHEDULE

18, The period given for the overhaul of thie wheel is a recommended maximum, the

actual period should be determined by the Operator, in conjunction with the appro-

priate Airworthiness Authority, based on experience with the wheel under his opera-

ting conditions and to align with the overhaul periods of associated equipment.

Wheel Recommended

Part No. Overhaul Period

AH, 52590

an S78 Every Tyre Change.

AH, 53374

SPECIAL TOOL!

IXTURES AND EQUIPMENT

19, The following table lists the special tools, fixtures and equipment required for

complete overhaul.

Wheel Tool

Part No. Part No. Description Remarks

AH,52590 AO,102081 — Mandrel and base assembly To press serrated

AH,52688 AO,113002 Pressing in sleeve sleeve into half hub

‘AH.53375 AO,113003 Packing collar

‘AH.53374 AO1113004 Alignment plugs (2 off)

DSR. 1662/17 Std. in.sq.drive torque

(Acratork spanner

Model C1)

DSR. 2043/1 Torque spanner adapter For hub bolts

(ED, 500

Britool)

DSR, 2051/1 3 in, Tee extension

(E. 96 Britool)

DSR. 2041/2 Torque spanner adapter For valve assembly

(EB. 437

Britool)

A,10444 ‘Tyre removal rig Refer to 32-40-11(12)

A.12000 ‘Tyre removal rig Alternative to A.10444

AM,20744 Tyre removal rings (2 off) Use with removal rig

32 Page ”)

DAI/ 3133/50 PRINTED IN ENGLAND Rev.5, Oct.26/89

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

AO. 102081 AQ. 113003]

AO, 113002 AO. 113004]

Splined Sleeve Pressing-in Tools

Jan, 4/67

AD, 1030/39

DTS. 507

32-40-1(17) >

PRINTED IN ENGLAND Page 13

DUNLOP.

NOSE WHEEL

OVERHAUL MANUAL

FIG.201 NOSE WHEEL

32-40-1(17) Jan, 4/67

Page 202 AD, 1030/39

Reverse side intentionally left blank

ILLUSTRATED PARTS LIST

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

Reet Z| paar wunoen NOMENCLATUE 33 \oae

201 [2] AHB2550 WHEEL ASSEMBLY NOSE T

os 3) 5766-1 STEM VALVE SCHRADER DSR1178-1 i

06 2) 42FLWa428 NUT DSR588-1 py

o7 2) 42FLW-624 NUT OSR588-3 5

09 2 | AHO84359 BOLT 1

lo 2) OsR591-24 BOLT MS21250=06024 4

12 2| AHM6 783. JHALF HUS 1

Ol | 2) TR752-03 VALVE ASSY SCHRADER OSR1174 1

04 | 3] DAS2155-2 RING SEALING 2

06 | 2] 42FLW-428 NUT osrsee-1 1

08 |2| oas20s2-3 WASHE 5

og | 2] avo8435s9 BOLT 2

10 |2| DSR4357/1224 BOLT 4

11/2] AHO84361 SLEEVE 2

13° |2| DAS2124-14 RING SEALING 1

|

Rev.5, Oct.26/89

AD.1030/39

PRINTED IN ENGLAND

32-40-1417)

Page 203

>

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

DAI/ 3133/50

FIG, 202 NOSE WHEEL

32-40-1(17)

Page 204

Rev, 3, March'1/78

ci

DUNLOP

NOSE WHEEL

OVERHAUL MANUAL

TEE] E | varrunesn eran Hee

= | a

Be a aS WHEEL ASSEMBLY OSE

wre || szeuwaze wt bsastees ;

tao | 3] cbeekage ne tibateo' osesas-3 :

nso || cassosses [unser

nae [3] ansaesge ait

nen [3] osassicee [aot 521250-06026 ;

nan [3] ancseses retve :

ogo || amezas eceets ;

ta [3] Anoszsee BILE mUe ASSEMBLY 1

non 2) DASZTZ5~2 PLUG BLANKING a

zoz || ansss7 vigeL——_assensuy nose

ore || certwaze a presered ;

nae | 3] <3eubeae ny tabenes osesas-3 :

030 2] DAS2082-3 WASHER S

A460 2| AHOAG35S9 BOLT 1

nso 3) engetcze (Bett 4521250-06026 :

nso | 3] tebbeses ttove :

ago |g] sunesas fur gua

090 2] DAS2325~-2 PLUG BLANKING 1

DAL/ 3133/50

32-40-

Rev. 3. M:

\

Pa

17]

2 205

1738

You might also like

- CMM32 44 53 - Rev4Document126 pagesCMM32 44 53 - Rev4daniloNo ratings yet

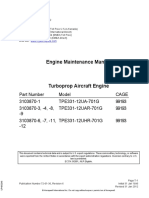

- Engine Maintenance ManualDocument2,311 pagesEngine Maintenance Manualdanilo100% (1)

- 3-1481 Nose Wheel Asse - DissaDocument78 pages3-1481 Nose Wheel Asse - DissadaniloNo ratings yet

- Component Maintenance Manual With Illustrated Parts List: CM40-170A Main Wheel AssemblyDocument55 pagesComponent Maintenance Manual With Illustrated Parts List: CM40-170A Main Wheel AssemblydaniloNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)