Professional Documents

Culture Documents

The Hierarchy of Controls (Administrative Controls)

Uploaded by

Mohamed Abdullah Khojali0 ratings0% found this document useful (0 votes)

10 views3 pagesThis document discusses administrative controls as part of the Hierarchy of Controls. Administrative controls include warning alarms, labeling systems, training programs, and reducing employee exposure time to hazards. While administrative controls can help mitigate hazards, they are not as effective as engineering controls or eliminating the hazard completely. Administrative controls should be used in conjunction with other controls to best protect employees.

Original Description:

Original Title

Adminstrative Control

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses administrative controls as part of the Hierarchy of Controls. Administrative controls include warning alarms, labeling systems, training programs, and reducing employee exposure time to hazards. While administrative controls can help mitigate hazards, they are not as effective as engineering controls or eliminating the hazard completely. Administrative controls should be used in conjunction with other controls to best protect employees.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views3 pagesThe Hierarchy of Controls (Administrative Controls)

Uploaded by

Mohamed Abdullah KhojaliThis document discusses administrative controls as part of the Hierarchy of Controls. Administrative controls include warning alarms, labeling systems, training programs, and reducing employee exposure time to hazards. While administrative controls can help mitigate hazards, they are not as effective as engineering controls or eliminating the hazard completely. Administrative controls should be used in conjunction with other controls to best protect employees.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

The Hierarchy of Controls (Administrative Controls)

In the first two articles on the Hierarchy of Controls, we discussed

controls that were intended to mitigate hazards at their source

either through elimination, substitution, or an engineering solution

that made it so the employee was no longer exposed. With

administrative controls, we take a little bit of a turn from that

approach. At this point in the hierarchy, the reality is that the

hazard is one that must be – or can be – lived with, so long as certain

precautions are taken or certain levels of exposure are not

exceeded. Administrative controls, which may be used in

conjunction with engineering controls and/or PPE, would also be

required if work was to continue while engineering controls are

being developed. Ultimately, though, administrative controls are

not the optimal solution and cannot be the selected method of

abatement if a hazard, or employee exposure to that hazard, can be

eliminated.

Examples of administrative controls are fairly simple: warning

alarms, for example, are just that alarms that let you know when

something isn’t right. An alarm might notify you of something as

common as a guard being left open on a machine in a

manufacturing process or it might be on the rotating structure of a

crane working near power lines that could not be de-energized, to

let you know you cannot swing any further. Obviously, neither of

these by themselves would eliminate a hazard, but they would

provide an employee with a warning. A more effective approach for

the guard would be an engineering control: to have an interlock that

prevented the machine from running when the guard was open.

Without it, an employee could ignore the alarm and reach into the

machine. For the crane, the alarm would not prevent the crane

from swinging closer to the power lines. Instead, you are relying on

the operator to heed the warning.

Labeling systems would also be considered administrative controls.

We see safety labels everywhere, but clearly they are not sufficient

to protect workers. Labels are often used along with other controls

to keep employees safe. Warning of high voltage, a certain chemical

in use, or that an area is a high-noise area, among many other

things, labels act as a good reminder for workers not to enter areas

in which they do not belong, to follow certain procedures, or to wear

certain PPE. They, alone, will not protect a soul if they are not

heeded by the employees.

This brings us to another form of administrative control: training.

You can put as many engineering controls in place as you want, you

can require PPE, you can warn of hazards in an area, but if you

don’t train your employees how to comply with the safety

requirements, controls can still be bypassed. Somebody who is not

trained on the dangers of entering a high noise area may think it’s

really not that big of a deal, for instance. Perhaps you’ve

substituted a non-silica product for sand in your sandblasting

operations, but you still need sand in your facility for other

applications. If you don’t train your employees on the hazards of

silica as well as what your new procedure is, how will they know to

use the safer product (or why will they bother if they can’t find any,

but sand is readily available)? You may not have realized that

training was an administrative control, but hopefully you’ve been

using it all along.

One final method that needs to be discussed is a little more on the

complicated side, compared to other administrative controls.

Reducing the amount of time somebody is exposed to a hazard can

be an effective control, but it’s not as simple as placing a sign or

adding a warning alarm. For instance, hazards like noise and

chemical exposure are often given permissible exposure limits

(PELs) by OSHA that are measured in time-weighted averages

(TWAs). So for instance, Carbon Monoxide (CO) has a PEL of 50

parts per million (ppm). This does not mean that the moment

somebody is exposed to Carbon Monoxide in an amount greater

than 50 ppm they are going to die, it just means that when you

average out the amount an employee is exposed to over the course of

an eight-hour day, it needs to be below 50 ppm. There are also

Short-Term Exposure Limits (STELs) and Action Levels (ALs) to be

concerned with, and though we can see that determining an allowed

exposure time might be a bit involved, we’d need more room/time

than this article allows to go into detail on it. Suffice it to say, as

long as employee rotation through a job can keep the employee

under all applicable limits, then it is an acceptable solution. While

CO has a limit, in many cases, employers would find the source of

emission and eliminate it because CO is much too dangerous. A

more common application of controlling exposure time might be in a

high noise area or a hot work area. By rotating other workers into

these areas throughout the day or by simply putting a cap on the

amount of time spent in them, workers can be kept below the

allowable exposures for noise or heat.

Administrative controls can be simple, but remember, they are often

not the best or sole solution. Using administrative controls should

almost always be looked at in the context of other controls that are

being put in place to determine how they can be paired to provide

employees with the best actual protection possible. Now, with

elimination, substitution, engineering controls, and administrative

controls covered, we are left with one final level of the hierarchy in

the next article: PPE. Yet, if it’s the final level of the hierarchy, why

is it that it is so often the first solution employers turn to? The final

article in our series will explain just that.

You might also like

- Engineering ControlsDocument6 pagesEngineering ControlsFakhri YudhaNo ratings yet

- 05 Hazard Control Hirearchy of Control PPEsDocument20 pages05 Hazard Control Hirearchy of Control PPEsImranNo ratings yet

- 2ND Toolbox Meeting PpeDocument4 pages2ND Toolbox Meeting PpeIbrahim KamaracbNo ratings yet

- Hierarchy of ControlsDocument6 pagesHierarchy of Controlssharon Aisha malroyNo ratings yet

- Hierarchy of ControlsDocument4 pagesHierarchy of Controlschimezie EmmaNo ratings yet

- Element 3Document17 pagesElement 3JK AlmaNo ratings yet

- Css For Grade 7&8 - FQL3 - BC4 - 3. Control Hazards and Risk - LMS - 2021 - 2022Document10 pagesCss For Grade 7&8 - FQL3 - BC4 - 3. Control Hazards and Risk - LMS - 2021 - 2022Nemino Catulay RickyNo ratings yet

- Controls Measure For OSHDocument16 pagesControls Measure For OSHricardo martinezNo ratings yet

- PpeDocument10 pagesPpeDonothan SookrajNo ratings yet

- SLM g8 Hairdresssing Module6 TambalgueDocument13 pagesSLM g8 Hairdresssing Module6 TambalgueElaeca AbenNo ratings yet

- A6 - 4 FIVE Ways That Hierarchy of Controls Reduces or Eliminates HazardsDocument3 pagesA6 - 4 FIVE Ways That Hierarchy of Controls Reduces or Eliminates HazardsAgustin, Rolly MaeNo ratings yet

- Day 1 Week 4Document21 pagesDay 1 Week 4Nicky John Doroca Dela MercedNo ratings yet

- 5 Pitfalls To PreventiveDocument3 pages5 Pitfalls To PreventiveJose Luis RattiaNo ratings yet

- 9.-Hierarchy of Controls - SPHERADocument6 pages9.-Hierarchy of Controls - SPHERApipolino6666No ratings yet

- Controlling Hazard and RiskDocument5 pagesControlling Hazard and RiskRose GutierrezNo ratings yet

- 5 Pitfalls To PreventiveDocument3 pages5 Pitfalls To PreventiveJuan RiveraNo ratings yet

- Advice Sheet 3Document4 pagesAdvice Sheet 3KenjohnA.CarlosNo ratings yet

- Unit 7 - VideoClipRef - 2021Document6 pagesUnit 7 - VideoClipRef - 2021Nella NellaNo ratings yet

- MNO2605Document11 pagesMNO2605Hlulani Basil MaringaNo ratings yet

- Aldobash The Osha Ppe StandardsDocument12 pagesAldobash The Osha Ppe StandardsRaad AljuboryNo ratings yet

- Chapter 3 Concept of Hazard AvoidanceDocument53 pagesChapter 3 Concept of Hazard AvoidanceAnas HussainNo ratings yet

- Nebosh IGC Element 6 Principles of Control (Notes)Document6 pagesNebosh IGC Element 6 Principles of Control (Notes)kkalvi100% (26)

- Job Hazard Analysis-Job Safety AnalysisDocument4 pagesJob Hazard Analysis-Job Safety AnalysisImran AlamNo ratings yet

- Identify and Implement Appropriate Control 24 JAN WORKDocument6 pagesIdentify and Implement Appropriate Control 24 JAN WORKceazerstanleyNo ratings yet

- Job Hazard AnalysisDocument4 pagesJob Hazard AnalysisJoanna MarieNo ratings yet

- Prevention and Hazard ControlDocument21 pagesPrevention and Hazard ControlKladees WorldNo ratings yet

- Worksite Safety 05: OSHA Personal Protective Equipment: Course DescriptionDocument21 pagesWorksite Safety 05: OSHA Personal Protective Equipment: Course Descriptionraimundo.ojeda.12No ratings yet

- Part C Basic Management Systems (Sms & Ems)Document9 pagesPart C Basic Management Systems (Sms & Ems)DrakzNo ratings yet

- WS Counter Measures, Control Options andDocument13 pagesWS Counter Measures, Control Options andJulia AbalosNo ratings yet

- LOTO NotesDocument12 pagesLOTO NotesShirishNo ratings yet

- Safeguarding Against Falling Objects (Draft)Document21 pagesSafeguarding Against Falling Objects (Draft)lwin_oo2435No ratings yet

- Plant Floor Safety by CFE MEDIADocument79 pagesPlant Floor Safety by CFE MEDIAsasasNo ratings yet

- Module 7 Heirarchy of ControlsDocument56 pagesModule 7 Heirarchy of ControlsDaneNo ratings yet

- SHP Safety Walk Arounds For ManagersDocument2 pagesSHP Safety Walk Arounds For ManagersIoana UrsanNo ratings yet

- UETTDRRF03Document13 pagesUETTDRRF03Trained UpNo ratings yet

- Health, Safety and Environment: Afaq Ali 190301005 Sir Abdul WadoodDocument3 pagesHealth, Safety and Environment: Afaq Ali 190301005 Sir Abdul Wadoodmc170202750 Alishba WazahatNo ratings yet

- Control Hazards and RisksDocument13 pagesControl Hazards and RisksJoannix V VillanuevaNo ratings yet

- Controlling HazardsDocument5 pagesControlling HazardsTeodoro EsquilloNo ratings yet

- What Is A Cost Benefit Analysis?Document6 pagesWhat Is A Cost Benefit Analysis?Willy Ramos PakpahanNo ratings yet

- Process Safety PhilosophyDocument20 pagesProcess Safety Philosophyvyto100% (2)

- Chapter 2: Basic Safety Concepts "2.5: The Organizational Accident"Document3 pagesChapter 2: Basic Safety Concepts "2.5: The Organizational Accident"LarisonUmandalNo ratings yet

- Safe Design and Operation of PlantsDocument7 pagesSafe Design and Operation of PlantsAlfie Delos Reyes100% (1)

- Control Measures For OSH Hazards-Labordo, M.E.-4GNDocument13 pagesControl Measures For OSH Hazards-Labordo, M.E.-4GNeric labordoNo ratings yet

- 1337045188-Tlif1001a SampleDocument10 pages1337045188-Tlif1001a SampleMocha Arie TowamasuNo ratings yet

- ISA-77.22 Working Draft 07.01.09Document22 pagesISA-77.22 Working Draft 07.01.09Nigo VillanNo ratings yet

- Safe Work Procedures: Safe Business Is Good BusinessDocument4 pagesSafe Work Procedures: Safe Business Is Good BusinessAndreas 'gondez' SiallaganNo ratings yet

- Energy Control Planning: A Guide To The Key Lockout/Tagout ConsiderationsDocument4 pagesEnergy Control Planning: A Guide To The Key Lockout/Tagout ConsiderationsHassen40No ratings yet

- HazardDocument10 pagesHazardElvin LstNo ratings yet

- Designing Instrumentation and Control For Process SafetyDocument7 pagesDesigning Instrumentation and Control For Process SafetyAdebamboAinaNo ratings yet

- Inherently Safer Designðits Scope and FutureDocument5 pagesInherently Safer Designðits Scope and FutureJohn HopkinsNo ratings yet

- Hierarchy of ControlsDocument6 pagesHierarchy of ControlsMANOJ KUMARNo ratings yet

- 998 2095 01 26 15ar0 - enDocument10 pages998 2095 01 26 15ar0 - enRichard AmorinNo ratings yet

- EVT (Sop)Document21 pagesEVT (Sop)Farvin FleetNo ratings yet

- Bus Passenger Safety Risk Assessment and SolutionDocument14 pagesBus Passenger Safety Risk Assessment and SolutionSatya Prakash BarikNo ratings yet

- Assignment 2Document3 pagesAssignment 2Pradeep Dahiya100% (1)

- Safety and The EnvironmentDocument10 pagesSafety and The EnvironmentYong Kai MingNo ratings yet

- Hazard ControlDocument30 pagesHazard ControlELVIS KIPKORIRNo ratings yet

- Hazard Analysis in The WorkplaceDocument7 pagesHazard Analysis in The WorkplaceUghlahnNo ratings yet

- An Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleFrom EverandAn Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleNo ratings yet

- Fault Diagnosis and Sustainable Control of Wind Turbines: Robust Data-Driven and Model-Based StrategiesFrom EverandFault Diagnosis and Sustainable Control of Wind Turbines: Robust Data-Driven and Model-Based StrategiesRating: 4 out of 5 stars4/5 (1)

- 8 CSP Training and EducationDocument29 pages8 CSP Training and EducationMohamed Abdullah KhojaliNo ratings yet

- FatahDocument4 pagesFatahMohamed Abdullah KhojaliNo ratings yet

- 10 - Fire Protection and Prevention (My Notes)Document6 pages10 - Fire Protection and Prevention (My Notes)Mohamed Abdullah KhojaliNo ratings yet

- Effectivenessofmaintenanceapproachesfor High Reliability OrganizatioDocument7 pagesEffectivenessofmaintenanceapproachesfor High Reliability OrganizatioMohamed Abdullah KhojaliNo ratings yet

- Leadership and Employee Commitment For QDocument13 pagesLeadership and Employee Commitment For QMohamed Abdullah KhojaliNo ratings yet

- Critical Factors of Success For QualityDocument12 pagesCritical Factors of Success For QualityMohamed Abdullah KhojaliNo ratings yet

- Workers With DisabilitiesDocument13 pagesWorkers With DisabilitiesMohamed Abdullah KhojaliNo ratings yet

- Ethics in Record KeepingDocument1 pageEthics in Record KeepingMohamed Abdullah KhojaliNo ratings yet

- Core Concepts in Anatomy and PhysiologyDocument50 pagesCore Concepts in Anatomy and PhysiologyMohamed Abdullah KhojaliNo ratings yet

- Chemical Process Safety ManagementDocument27 pagesChemical Process Safety ManagementMohamed Abdullah KhojaliNo ratings yet

- Final Year Project "Addressing Marketing and Growth Issues of Chattha's Pakistani Street Food" BBA-8Document143 pagesFinal Year Project "Addressing Marketing and Growth Issues of Chattha's Pakistani Street Food" BBA-8Muhammad Humayun KhanNo ratings yet

- Design Calculations MalidduwaDocument72 pagesDesign Calculations MalidduwaUmesg100% (1)

- State Wise Installed Capacity As On 30.06.2019Document2 pagesState Wise Installed Capacity As On 30.06.2019Bhom Singh NokhaNo ratings yet

- Problems and Constraints in Banana Cultivation: A Case Study in Bhagalpur District of Bihar, IndiaDocument9 pagesProblems and Constraints in Banana Cultivation: A Case Study in Bhagalpur District of Bihar, IndiaVasan MohanNo ratings yet

- Corporate Information Security HandbookDocument101 pagesCorporate Information Security HandbookSeenivasagam SeenuNo ratings yet

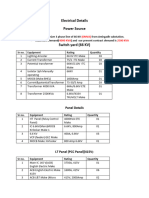

- 10, Electrical DetailDocument4 pages10, Electrical Detailrp63337651No ratings yet

- FPS Scope matrix-NSC-KRCDocument27 pagesFPS Scope matrix-NSC-KRCBaladaru Krishna PrasadNo ratings yet

- A Study On Job Satisfaction Among Nursing Staff in A Tertiary Care Teaching HospitalDocument5 pagesA Study On Job Satisfaction Among Nursing Staff in A Tertiary Care Teaching HospitalIOSRjournalNo ratings yet

- EssayDocument2 pagesEssayEar Choungchhay100% (6)

- PVC Pipe Industry Analysis in PakistanDocument4 pagesPVC Pipe Industry Analysis in PakistanOlufemi MoyegunNo ratings yet

- Manual e Mini Wind TunnelDocument10 pagesManual e Mini Wind TunnelWilson Rodríguez CalderónNo ratings yet

- Number of Starbucks Stores Globally, 1992-2016Document2 pagesNumber of Starbucks Stores Globally, 1992-2016Utkarsh SinhaNo ratings yet

- B2 Progress TestDocument3 pagesB2 Progress TestDenisa NeagoeNo ratings yet

- Problem 1.6Document1 pageProblem 1.6SamerNo ratings yet

- Csec Poa June 2015 p2Document33 pagesCsec Poa June 2015 p2goseinvarunNo ratings yet

- Navigating The Landscape of Higher Engineering EducationDocument120 pagesNavigating The Landscape of Higher Engineering EducationWatchara KhoviNo ratings yet

- (Korea) Real Estate Rental GuideDocument2 pages(Korea) Real Estate Rental GuideRepublic of Korea (Korea.net)No ratings yet

- Schneider PLC and Unity Pro XLDocument18 pagesSchneider PLC and Unity Pro XLSrinivas VenkatramanNo ratings yet

- 360 Degree FeedbackDocument31 pages360 Degree FeedbackcherrymaniarNo ratings yet

- Umao Annex B Supplementary GuidelinesDocument21 pagesUmao Annex B Supplementary GuidelinessasrfNo ratings yet

- F-Engine S2200ME-B Carrier Ethernet Switch CLI Manual (V3.0)Document295 pagesF-Engine S2200ME-B Carrier Ethernet Switch CLI Manual (V3.0)Francisco Moraga75% (4)

- RogueLike - FovDocument21 pagesRogueLike - FovMgDolusNo ratings yet

- 1.6 Ethical Legal Cultural and Environmental Impacts of Digital Technology End of Topic QuizDocument12 pages1.6 Ethical Legal Cultural and Environmental Impacts of Digital Technology End of Topic Quizcecelegend16No ratings yet

- Case IH Case International 2090 Tractor Service Repair Manual PDFDocument16 pagesCase IH Case International 2090 Tractor Service Repair Manual PDFfisekkkd0% (1)

- Defect Origin (J) Phase Requirement Analysis Design Coding Unit TestingDocument87 pagesDefect Origin (J) Phase Requirement Analysis Design Coding Unit Testingashish_jain_csNo ratings yet

- On-Load Tap-Changer Oiltap® M: Operating InstructionsDocument66 pagesOn-Load Tap-Changer Oiltap® M: Operating InstructionskienNo ratings yet

- Military Resistance 9H21: Mene Mene Tekel UpharsinDocument28 pagesMilitary Resistance 9H21: Mene Mene Tekel Upharsinpaola pisiNo ratings yet

- Managing Change in OrganizationsDocument11 pagesManaging Change in OrganizationsakhilgrajNo ratings yet

- Serena Comparex DatasheetDocument4 pagesSerena Comparex DatasheetprincerajaNo ratings yet

- Responsibility For RelationshipsDocument6 pagesResponsibility For RelationshipsManjulaNo ratings yet