Professional Documents

Culture Documents

Thermostat Type KP 98 (Cross Ambient) : Installation Guide

Uploaded by

Robson SpricigoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermostat Type KP 98 (Cross Ambient) : Installation Guide

Uploaded by

Robson SpricigoCopyright:

Available Formats

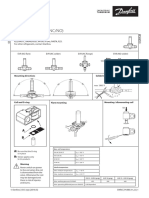

Installation guide

Thermostat

Type KP 98 (cross ambient)

060R9749

060R9749

60-1416.10

Danfoss

Oil temp. High temp.

(OIL) bulb (HT) bulb

KP 98 man. (OIL)/man.(HT) reset

Note:

Code no. stamped on top of control.

Ambient temperatures Max. bulb temperatures

60-1416.10

60-1416.10

Danfoss

Danfoss

min. -40 °F (-40 °C) max. 300 °F (150 °C) max. 480 °F (250 °C)

max. 150 °F ( 65 °C)

(175 °F (80 °C) for max. 2 hours)

Enclosure Cable entry

60-786.12

~ NEMA 1

Danfoss

CAUTION:

The mounting panel must be plane to avoid

damage of control.

Mounting Small pipe size Large pipe size

OD > 3.5 in.

60-1419.10

Danfoss

Mount OIL temperature bulb in compressor O.D.

crankcase and the HT bulb on/in discharge line

as shown.

© Danfoss A/S (RC-MDP / jmn), 2014-08 DKRCC.PI.CA0.A6.22 / 520H8513 1

Wiring

CAUTION: disconnect power supply

SPST

before wiring connections are made

Terminal block

to avoid possible electrical shock or

damage to equipment.

All wiring should conform to the National

CAUTION: Use terminal screws furnished in the

Electrical Code and local regulations.

contact block. Use tightening torque 20 lb. in. (2.3 Nm).

Use copper wire only.

Contact load ratings

B-C open on oil temperature rise

120 V a.c. 16 FLA, 96 LRA

B-C open on discharge

temperature rise

240 V a.c. 8 FLA, 48 LRA

A is not used

240 V d.c. 12 W pilot duty

See label for current

See label inside cover.

wiring inside cover.

Manual tripping

(Electrical contacts/wiring test)

OIL side HT side

Contact position Contact position

B C

TRIP

use FINGERS ONLY!

(Do NOT use screwdriver)

Contact position

60-801.13

Danfoss

B C Contact position

Manual reset

OIL HT

To resume control operation after safety reset man. reset

cut-out, push man. reset knob as indicated

Note:

OIL/HT man. reset is possible only after oil

or discharge temperature is equal to or has

dropped below cut-in value.

Adjustment spindle(s) location

KP 98 A. MAN./MAN. RESET

2 DKRCC.PI.CA0.A6.22 / 520H8513 © Danfoss A/S (RC-MDP / jmn), 2014-08

Setting

Oil temp. (OIL) side setting High temp. (HT) side setting

OIL temp. HT

scale 1. Adjust range spindle to scale

1. Adjust range spindle to

desired CUT-OUT value desired CUT-OUT value

60-1418.10

Cut out

60-1417.10

Cut out

(max. allowable

Danfoss

Danfoss

(max. allowable

oil temp.) discharge temp.)

2. Differential (DIFF.) 2. Differential (DIFF.)

is fixed 25 °F (14 °C) is fixed 45 °F (25 °C)

Value printed on Value printed on

scale plate Diff. scale plate Diff.

CUT OUT minus DIFFERENTIAL equals CUT OUT minus DIFFERENTIAL equals

CUT-IN CUT-IN

Example: Example:

CUT-OUT – DIFF. = CUT-IN CUT-OUT - DIFF. = CUT-IN

200 °F – 25 °F = 175 °F 325 °F - 45 °F = 280 °F

(93 °C) (14 °C) (79 °C) (163 °C) (25 °C) (138 °C)

Note:

CUT-OUT = compressor cut-out

CUT-IN = compressor cut-in

Adjustment

60-802.12

Danfoss

Note:

Remove lockplate before adjustment.

Replace lockplate after adjustment (if desired).

3 DKRCC.PI.CA0.A6.22 / 520H8513 © Danfoss A/S (RC-MDP / jmn), 2014-08

You might also like

- Scheda Tecnica Hmk12aaDocument4 pagesScheda Tecnica Hmk12aaMarcos EvansNo ratings yet

- 4we10d31b CW220RN9Z5LDocument12 pages4we10d31b CW220RN9Z5LElenilton MelchiorsNo ratings yet

- Circuit Breaker Operating TemperaturesDocument3 pagesCircuit Breaker Operating TemperaturesVũDuyTânNo ratings yet

- 1508333679MP 5200Document20 pages1508333679MP 5200engenhariahabNo ratings yet

- Dkrci Pi C00 C2 22Document4 pagesDkrci Pi C00 C2 22Muhamad Zul Faisal Salleh MustafaNo ratings yet

- CS060 2019 enDocument1 pageCS060 2019 enasdrinkerNo ratings yet

- HMK95AADocument4 pagesHMK95AASamsung SamsungNo ratings yet

- EBV Series - Energy Balancing ValveDocument4 pagesEBV Series - Energy Balancing ValveFrio EspecializadoNo ratings yet

- Flt93 B Flexswitch: Premium Flow, Level and Temperature MonitorDocument2 pagesFlt93 B Flexswitch: Premium Flow, Level and Temperature MonitorJESUS LURITANo ratings yet

- Tieu Chuan Lap Dat Solenoid Van Evr 2Document2 pagesTieu Chuan Lap Dat Solenoid Van Evr 2Đình QuangNo ratings yet

- GL50AA1Document4 pagesGL50AA1أبو زينب المهندسNo ratings yet

- Omc Oil Controls en 6038886Document1 pageOmc Oil Controls en 6038886chalo malaNo ratings yet

- Control Relays M3FFR 1 ADocument1 pageControl Relays M3FFR 1 AamrNo ratings yet

- BR 211140Document7 pagesBR 211140Felipe SoffiattiNo ratings yet

- Angle Seat Motor Valve 7210: 1/4" Up To 2"Document5 pagesAngle Seat Motor Valve 7210: 1/4" Up To 2"camus1125No ratings yet

- Solenoid Valve Types EVR 32, EVR 40: Installation GuideDocument2 pagesSolenoid Valve Types EVR 32, EVR 40: Installation GuidebenjaminfarfarNo ratings yet

- 15.3 MVA - 15kV Rev 09 04 2012Document5 pages15.3 MVA - 15kV Rev 09 04 2012Eléctrico EléctricoNo ratings yet

- Aquastato Manometro TermometroDocument3 pagesAquastato Manometro Termometroing_pablonicolasNo ratings yet

- TS1935BCX5: Taiwan SemiconductorDocument9 pagesTS1935BCX5: Taiwan Semiconductorn tanevarNo ratings yet

- Coil 481000Document1 pageCoil 481000Fabian DiazNo ratings yet

- Irf 4104Document13 pagesIrf 4104siconsolutionsNo ratings yet

- Aot4n60 Aotf4n60 Aotf4n60lDocument9 pagesAot4n60 Aotf4n60 Aotf4n60lCamilo JuniorNo ratings yet

- Small Semiconductor Heater RC 016 - : Wide Voltage Range Dynamic Heating Up Energy Saving CompactDocument1 pageSmall Semiconductor Heater RC 016 - : Wide Voltage Range Dynamic Heating Up Energy Saving CompactDieter van RooyenNo ratings yet

- SM1A23NSFPDocument10 pagesSM1A23NSFPAbdalla AhmedNo ratings yet

- Ogden Etr-900 Temperature Controller Manual PDFDocument4 pagesOgden Etr-900 Temperature Controller Manual PDFAlejandroCoilaNo ratings yet

- FTP04N60D Fta04n60dDocument9 pagesFTP04N60D Fta04n60dgigiNo ratings yet

- Contax ContactorDocument4 pagesContax Contactorheri fauziNo ratings yet

- Unisonic Technologies Co., LTD: Programmable Unijunction TransistorDocument4 pagesUnisonic Technologies Co., LTD: Programmable Unijunction TransistorManivannabNo ratings yet

- Pressure Switch: Installation GuideDocument4 pagesPressure Switch: Installation GuideRobson SpricigoNo ratings yet

- Cinta de Tracing Heat TraceDocument2 pagesCinta de Tracing Heat TracemmNo ratings yet

- LPT46 Artesyn Power SupplyDocument4 pagesLPT46 Artesyn Power SupplythereminplanetNo ratings yet

- 6N90C Mosfet N PDFDocument10 pages6N90C Mosfet N PDFHưng HQNo ratings yet

- HeaterPTC CSF060 SeriesDocument3 pagesHeaterPTC CSF060 SeriesPreda AndreiNo ratings yet

- W60N10Document11 pagesW60N10Alin MarianNo ratings yet

- T-HA Series: Panasonic Industrial CompanyDocument6 pagesT-HA Series: Panasonic Industrial CompanyP HandokoNo ratings yet

- Heat Tracing Installation RequirementsDocument3 pagesHeat Tracing Installation RequirementsscotixNo ratings yet

- FQPF13N06L 1306265 PDFDocument11 pagesFQPF13N06L 1306265 PDFCristianNo ratings yet

- SV48 26 225 2 PDFDocument6 pagesSV48 26 225 2 PDFamit singhNo ratings yet

- MBR1090CT, MBR10100CT: Vishay General SemiconductorDocument5 pagesMBR1090CT, MBR10100CT: Vishay General SemiconductorBeres DanNo ratings yet

- VNB10N07/K10N07FM VNP10N07FI/VNV10N07: "Omnifet": Fully Autoprotected Power MosfetDocument14 pagesVNB10N07/K10N07FM VNP10N07FI/VNV10N07: "Omnifet": Fully Autoprotected Power MosfetEduardo MontoyaNo ratings yet

- 160V 6F Module - Ds - 3002017 EN.5 1Document10 pages160V 6F Module - Ds - 3002017 EN.5 1Hugo MendesNo ratings yet

- Vishay Siliconix: Features ApplicationsDocument4 pagesVishay Siliconix: Features ApplicationsJuan CarlosNo ratings yet

- ON/OFF Zone Valve - PN 16 AMZ 112, AMZ 113: Data SheetDocument8 pagesON/OFF Zone Valve - PN 16 AMZ 112, AMZ 113: Data SheetDavid HayesNo ratings yet

- Matsushita DHS73C12RBU Compressor Spec SheetDocument1 pageMatsushita DHS73C12RBU Compressor Spec SheetBenjamin DoverNo ratings yet

- ON/OFF Zone Valves (PN 16) AMZ 112, AMZ 113: Data SheetDocument8 pagesON/OFF Zone Valves (PN 16) AMZ 112, AMZ 113: Data SheetAndrei-Lucian MilitaruNo ratings yet

- Datasheet DRST 160xx t3 Series 2182Document2 pagesDatasheet DRST 160xx t3 Series 2182Juan GimenesNo ratings yet

- 8-2 Electric System and Spec PDFDocument7 pages8-2 Electric System and Spec PDFSumitomo Laos Sumitomo Laos100% (1)

- PVT 412Document4 pagesPVT 412Mario Marcos PedrosoNo ratings yet

- 3-Terminal Adjustable Regulators: D E S C R I P T I O NDocument3 pages3-Terminal Adjustable Regulators: D E S C R I P T I O Nمحمد عبد شهريNo ratings yet

- 3300 Power Supplies DatasheetsDocument9 pages3300 Power Supplies DatasheetsSyed Mohammad NaveedNo ratings yet

- fdp054n10 PDFDocument8 pagesfdp054n10 PDFAldi DwprstwnNo ratings yet

- 1925389Document3 pages1925389Akhram GruddithNo ratings yet

- Gs01c20d01-00e (19) Ej310Document8 pagesGs01c20d01-00e (19) Ej310Nguyen ThuongNo ratings yet

- KP Thermostats DanfossDocument21 pagesKP Thermostats DanfossAleksej KanjuhNo ratings yet

- Guide SSHV2Document4 pagesGuide SSHV2vinhson65-1No ratings yet

- 2/2-Way Solenoid Valve, Direct-Acting: Type 741Document4 pages2/2-Way Solenoid Valve, Direct-Acting: Type 741Francisco Mones RuizNo ratings yet

- Protective RelayDocument3 pagesProtective RelayJames Jr.No ratings yet

- DJK51C73RAUDocument9 pagesDJK51C73RAUAndres Roncajolo100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Captura de Tela 2020-03-10 À(s) 11.02.33Document21 pagesCaptura de Tela 2020-03-10 À(s) 11.02.33Rafael De Paula LimaNo ratings yet

- Manual Programação VLT-5000-The Modbus PlusDocument65 pagesManual Programação VLT-5000-The Modbus PlusRobson SpricigoNo ratings yet

- Pressure Switch Types KP 1 and KP 7W: Installation GuideDocument2 pagesPressure Switch Types KP 1 and KP 7W: Installation GuideRobson SpricigoNo ratings yet

- Guia de Aplicação - Detectores de Gás GD - Inglês 2018Document36 pagesGuia de Aplicação - Detectores de Gás GD - Inglês 2018Robson SpricigoNo ratings yet

- Pressure Switch: Installation GuideDocument4 pagesPressure Switch: Installation GuideRobson SpricigoNo ratings yet

- Developers GuideDocument100 pagesDevelopers GuideRobson SpricigoNo ratings yet

- Balluf - RFID - CatálogoDocument436 pagesBalluf - RFID - CatálogoRobson SpricigoNo ratings yet

- Organization of Brigada Eskwela Steering and Working CommitteesDocument2 pagesOrganization of Brigada Eskwela Steering and Working CommitteesCherry Lou RiofrirNo ratings yet

- Home Work (Satistics AIUB)Document5 pagesHome Work (Satistics AIUB)fukscribdNo ratings yet

- Maverick Research: World Order 2.0: The Birth of Virtual NationsDocument9 pagesMaverick Research: World Order 2.0: The Birth of Virtual NationsСергей КолосовNo ratings yet

- Telstra InterviewsDocument3 pagesTelstra InterviewsDaxShenNo ratings yet

- Pa 28 151 161 - mmv1995 PDFDocument585 pagesPa 28 151 161 - mmv1995 PDFJonatan JonatanBernalNo ratings yet

- Far160 Pyq Feb2023Document8 pagesFar160 Pyq Feb2023nazzyusoffNo ratings yet

- Road To Recovery: Moving To A New NormalDocument10 pagesRoad To Recovery: Moving To A New NormalFOX5 VegasNo ratings yet

- Hardening'-Australian For Transformation: A Monograph by MAJ David J. Wainwright Australian Regular ArmyDocument89 pagesHardening'-Australian For Transformation: A Monograph by MAJ David J. Wainwright Australian Regular ArmyJet VissanuNo ratings yet

- Project Guidelines (Issued by CBSE) : CA. (DR.) G.S. GrewalDocument51 pagesProject Guidelines (Issued by CBSE) : CA. (DR.) G.S. GrewalShruti Yadav0% (1)

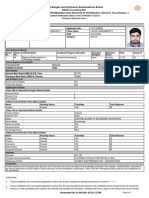

- West Bengal Joint Entrance Examinations Board: Provisional Admission LetterDocument2 pagesWest Bengal Joint Entrance Examinations Board: Provisional Admission Lettertapas chakrabortyNo ratings yet

- Ibt - Module 2 International Trade - Theories Are: Classical and Are From The PerspectiveDocument9 pagesIbt - Module 2 International Trade - Theories Are: Classical and Are From The PerspectiveLyca NegrosNo ratings yet

- Q3 Week 1 Homeroom Guidance JGRDocument9 pagesQ3 Week 1 Homeroom Guidance JGRJasmin Goot Rayos50% (4)

- Kilifi HRH Strategic Plan 2018-2021Document106 pagesKilifi HRH Strategic Plan 2018-2021Philip OlesitauNo ratings yet

- Order To Cash Cycle Group 1Document4 pagesOrder To Cash Cycle Group 1AswinAniNo ratings yet

- Eudemon8000E XDocument2 pagesEudemon8000E XGladys Medina100% (1)

- Template For Homework6Document2 pagesTemplate For Homework6Никола СтефановићNo ratings yet

- Surface News - 20130704 - Low Res PDFDocument9 pagesSurface News - 20130704 - Low Res PDFYoko GoldingNo ratings yet

- War As I Knew ItDocument2 pagesWar As I Knew ItShreyansNo ratings yet

- Study For 33KV Sub-Marine Cable Crossings PDFDocument80 pagesStudy For 33KV Sub-Marine Cable Crossings PDFOGBONNAYA MARTINSNo ratings yet

- Optical Fibre CommunicationDocument60 pagesOptical Fibre CommunicationN.ChanduNo ratings yet

- User Custom PP Install74Document2 pagesUser Custom PP Install74Zixi FongNo ratings yet

- Lab 1Document8 pagesLab 1Нурболат ТаласбайNo ratings yet

- Alfa Laval Plate Heat Exchangers: A Product Catalogue For Comfort Heating and CoolingDocument8 pagesAlfa Laval Plate Heat Exchangers: A Product Catalogue For Comfort Heating and CoolingvictoryanezNo ratings yet

- Midterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsDocument3 pagesMidterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsGarp Barroca100% (1)

- PraxiarDocument8 pagesPraxiara_roy003No ratings yet

- AET Assignment C Kate ThomsonDocument12 pagesAET Assignment C Kate ThomsonaymenmoatazNo ratings yet

- Guglielmo 2000 DiapirosDocument14 pagesGuglielmo 2000 DiapirosJuan Carlos Caicedo AndradeNo ratings yet

- Steinway Case - CH 03Document5 pagesSteinway Case - CH 03Twēéty TuiñkleNo ratings yet

- HR Q and ADocument87 pagesHR Q and Asanjeeb88No ratings yet

- Hilti AnchorDocument5 pagesHilti AnchorGopi KrishnanNo ratings yet