Professional Documents

Culture Documents

Warping Constant W-Section With A Channel Cap

Uploaded by

rilopiyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Warping Constant W-Section With A Channel Cap

Uploaded by

rilopiyCopyright:

Available Formats

The Warping Constant for the W-Section

with a Channel Cap

TONY LUE AND DUANE S. ELLIFRITT

Iyt = moment of inertia of the tension flange about the axis

It is common practice in crane runway beams to place a parallel to web

channel, open-side down, over the top flange of a W-section, hc = distance from the centroid of the compression flange

as shown in Figure 1, to increase its lateral stability. This is to the centroid of the tension flange

done because it is not always convenient to brace the h = distance from the shear center of the compression

compression flange between columns. flange to the centroid of the tension flange

The lateral-torsional buckling capacity of a singly e = distance from the shear center of the compression

symmetric section may be determined by the formulas flange to the centroid of the compression flange

(Footnote c on page 6-96 of the current LRFD manual1) DL = the depth of the lip

without knowing the warping section constant. However, BC = the width of the lipped flange

these formulas were developed from research on three-plate TL = the thickness of the lip

monosymmetric sections.2,3,4,5,6,7 If one is to develop a similar

equation for the case of the W-section with a channel cap, it

is necessary to return to the basic theory of lateral-torsional

buckling and that means that one must calculate the warping

constant (Cwc) for the cross-section.

It is not a difficult matter to do this with a computer, but

since the program may not be available to everyone, it would

be useful to develop a simple empirical equation for

preliminary design, making use of the section properties

already given in the AISC steel manual.

According to Kitipornchai and Trahair,3 Equation 1,

which provides for calculating the warping section constant,

"is exact for an unlipped section and approximate for a lipped

section." Their "lipped" section of Figure 2 closely

approximates the subject of this paper, the W-section with a

channel cap. Fig. 1. Crane runway beam.

2 2

Iw=a Iyc+b Iyt (1)

where

a = (1 – ρ )h b = ρh

h=hc+e ρ = Iyc/Iy e = ( DL2 Bc2 TL ) / (4ρΙ y )

Iw = warping section constant

Iy = moment of inertia of the combined section about the

axis parallel to web

Iyc = moment of inertia of the compression flange about the

axis parallel to web

Tony Lue is Graduate Assistant, University of Florida, Gainesville,

FL.

Duane S. Ellifritt is Crom Professor, University of Forida,

Gainesville, FL. Fig. 2. W-section with lipped flange.

FIRST QUARTER / 1993 31

© 2003 by American Institute of Steel Construction, Inc. All rights reserved. This publication or any part thereof must not be reproduced in any form without the written permission of the publisher.

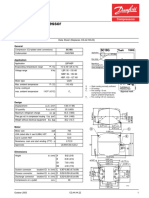

Table 1.

W C or MC Ac Aw Cwc Cw Ac/Aw Cwc/Cw

36×150 15×33.9 9.96 44.20 146,275 82,200 0.2250 1.780

33×141 15×33.9 9.96 41.60 117,627 64,400 0.2390 1.827

24×84 12×20.7 6.09 24.70 24,215 12,800 0.2470 1.892

36×150 *18×42.7 12.60 44.20 160,492 82,200 0.2850 1.952

33×118 15×33.9 9.96 34.70 91,050 48,300 0.2870 1.885

30×116 15×33.9 9.96 34.20 68,520 34,900 0.2910 1.963

33×141 *18×42.7 12.60 41.60 128,892 64,400 0.3029 2.001

24×68 12×20.7 6.09 20.10 18,386 9,430 0.3030 1.950

21×68 12×20.7 6.09 20.00 13,753 6,760 0.3050 2.034

21×62 12×20.7 6.09 18.30 12,272 5,960 0.3330 2.059

30×99 15×33.9 9.96 29.10 53,937 26,800 0.3420 2.013

27×94 15×33.9 9.96 27.70 43,840 21,300 0.3600 2.058

33×118 *18×42.7 12.60 34.70 98,928 48,300 0.3630 2.048

30×116 *18×42.7 12.60 34.20 74,319 34,900 0.3680 2.129

27×84 15×33.9 9.96 24.80 37,518 17,900 0.4020 2.096

24×84 15×33.9 9.96 24.70 28,050 12,800 0.4030 2.191

18×50 12×20.7 6.09 14.70 6,746 3,040 0.4140 2.219

30×99 *18×42.7 12.60 29.10 58,101 26,800 0.4330 2.168

24×68 15×33.9 9.96 20.10 20,998 9,430 0.4960 2.227

21×68 15×33.9 9.96 20.00 15,750 6,760 0.4980 2.330

14×30 10×15.3 4.49 8.85 2,024 887 0.5070 2.282

21×62 15×33.9 9.96 18.30 13,990 5,960 0.5440 2.347

16×36 12×20.7 6.09 10.60 3,477 1,460 0.5740 2.382

12×26 10×15.3 4.49 7.65 1,459 607 0.5870 2.404

18×50 15×33.9 9.96 14.70 7,711 3,040 0.6780 2.537

14×30 12×20.7 6.09 8.85 2,255 887 0.6880 2.542

12×26 12×20.7 6.09 7.65 1,645 607 0.7960 2.710

16×36 15×33.9 9.96 10.60 4,058 1,460 0.9400 2.779

W—W-section; C—Channel; MC—Miscellaneous Channel

Ac—Area of channel, in.2; Aw—Area of W-section, in.2

Cwc—Warping section constant (in.6) for the W-section with a channel cap, which is obtained by using the program as mentioned in this paper

Cw—Warping section constant (in.6) for the W-section alone, which can be found in the AISC steel manual

*MC

Metric Conversion:

To convert to Multiply by

Inches(in.) millimeters(mm) 25.4

The authors have enhanced a computer program, which mentioned program, as shown in Figure 4, it can be observed

was originally written in BASIC language by Professor that Equation 1 gives a very conservative estimate (–7

Theodore V. Galambos of the University of Minnesota in percent to –17 percent) for this case (the W-section with a

Minneapolis and converted to FORTRAN language by Dr. channel cap). The equation also has the added disadvantage

Thomas Sputo of the University of Florida, to calculate the of requiring the user to calculate certain section properties

exact values of warping section constants (Cwc) of the W- and parameters (Iy, Iyt, Iyc, p, hc, h, e, a, and b) first.

section with a channel cap. The user need only input the W- The purpose of this paper is, therefore, to present a

section and channel dimensions. The 28 combined sections reasonably accurate method of calculating the warping

shown on pages 1-98 and 1-99 of the AISC LRFD steel section constant (Cwc), using a simple model which can be

manual are shown in Table 1 with their warping section expressed by Equations 2, 3, or 4 and known section

constants (Cwc) as calculated by the program described. properties that can be found in the AISC steel manual.

The ratios of Cwc/Cw are plotted against the ratios of The proposed method which seemed to offer the most

Ac/Aw, as shown in Figure 3 for the 28 combined sections, promise was to use the ratio of the channel area (Ac) to the

where Cw, Ac, and Aw are explained in Table 1. W-section area (Aw) as the independent variable and plot it

When Equation 1 was applied to the case of the W- against the ratio of the warping section constant (Cwc) for the

section with a channel cap and the results Iw/Cw were combined section to the warping section constant (Cw) for the

compared with the Cwc/Cw values obtained from the above- W-section alone.

32 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

© 2003 by American Institute of Steel Construction, Inc. All rights reserved. This publication or any part thereof must not be reproduced in any form without the written permission of the publisher.

Several curves (or models) were then fit to these data REFERENCES

which are shown in Fiqure 3. These curves are represented

by the following equations. 1. American Institute of Steel Construction,Load and Resistance

Factor Design, First Edition, Chicago, Illinois, 1986.

2. Anderson, J. M., Trahair, N. S., "Stability of Monosymmetric

A A

2

A

3

Beams and Cantilevers," Journal of the Structural Division,

Cwc = Cw 131 . c + 0.29 c

. + 2.55 c − 131 (2) ASCE, Vol. 98, No. ST1, January 1972.

Aw Aw Aw

3. Kitipornchai, S., Trahair, N. S., "Buckling Properties of

Monosymmetric I-Beams," Journal of the Structural Division,

A A

2

A

3 ASCE, Vol. 106, No. ST5, May 1980.

Cwc = Cw 125 . c + 0.29 c

. + 2.55 c − 131 (3) 4. Kitipornchai, S., Wang, C. M., Trahair, N. S., "Buckling of

Aw Aw Aw Monosymmetric I-Beams under Moment Gradient,"Journal of

the Structural Division, ASCE, Vol. 112, No. 4, April 1986.

5. Bradford, M. A., Cuk, P. E., "Elastic Buckling of Tapered

Ac

Cwc = Cw 17. + 1 (4) Monosymmetric I-Beams," Journal of the Structural Division,

Aw ASCE, Vol. 114, No. 5, May 1988.

6. Galambos, T. V., Guide to Stability Design Criteria for Metal

Equations 2, 3, and 4 were superimposed on the data of Structures (SSRC), Wiley, New York, 1988.

Figure 3, and plotted in Figure 5. Equation 2 results in an 7. Trahair, N. S., Bradford, M. A., The Behaviour and Design of

Steel Structures, Chapman and Hall, London, 1988.

estimated error of –2.9 percent to +2.9 percent, and Equation

3 with an estimated error of –5.9 percent to 0. Equation 4 is a

simplified model with fewer terms involved, with an

estimated error of –7.1 percent to +1.5 percent. Equations 2

and 3 were derived based on the multiple linear regression

technique of statistics using the data of Figure 3. Equation 4

was also based on the same statistical technique with some

further modifications.

Equation 2 is the best fit curve for the data of Figure 3,

but does overestimate the warping section constant (Cwc) by

as much as 2.9 percent. Equation 3 is simply Equation 2

shifted down until all the data points fall above the curve and

may be up to 5.9 percent conservative. However, for those

who want a formula that they can easily memorize and still

get a conservative result within 7.1 percent, Equation 4 is

offered.

The Equations 2, 3, and 4 proposed by the authors

require no calculation of certain section properties and

parameters, and are close to an exact solution. The required Fig. 4. Iw/Cw compared with the data of Figure 3 Cwc is exact

parameters for these equations are the channel area (Ac), the for the W-section with a channel cap. Iw is an approximation

from Reference 3 for the W-section with a channel cap (see

area of the W-section (Aw), and its warping section constant

Equation 1).

(Cw), all of which can be found in the AISC steel manual.

Fig. 3. Plot of Cwc/CwVS. Ac/Aw Fig. 5. Equations 2, 3, and 4 fit to the data of Figure 3.

FIRST QUARTER / 1993 33

© 2003 by American Institute of Steel Construction, Inc. All rights reserved. This publication or any part thereof must not be reproduced in any form without the written permission of the publisher.

You might also like

- Meshsparse MDocument3 pagesMeshsparse MrilopiyNo ratings yet

- Y12m PRB OutputDocument3 pagesY12m PRB OutputrilopiyNo ratings yet

- Meshnd Quality OutDocument16 pagesMeshnd Quality OutrilopiyNo ratings yet

- Devall 2003 Introduction enDocument14 pagesDevall 2003 Introduction enrilopiyNo ratings yet

- Proposed Change Modification ProposéeDocument40 pagesProposed Change Modification ProposéerilopiyNo ratings yet

- Behavior of Transverse Fillet Welds: Experimental Program: Specification For Structural Steel Buildings (AISC, 1999)Document16 pagesBehavior of Transverse Fillet Welds: Experimental Program: Specification For Structural Steel Buildings (AISC, 1999)rilopiyNo ratings yet

- Simplified Model AnalysisDocument23 pagesSimplified Model AnalysisrilopiyNo ratings yet

- Canadian Institute of Steel Construction: RE: Updated Properties and Dimensions of W-ShapesDocument18 pagesCanadian Institute of Steel Construction: RE: Updated Properties and Dimensions of W-ShapesrilopiyNo ratings yet

- Designing With Structural TubingDocument9 pagesDesigning With Structural TubingrilopiyNo ratings yet

- NASCC05 CBFcourseRTremblay050406Document74 pagesNASCC05 CBFcourseRTremblay050406rilopiyNo ratings yet

- Structal Welded BeamDocument4 pagesStructal Welded BeamrilopiyNo ratings yet

- Astm A500 Soft - Conversion - BrochureDocument8 pagesAstm A500 Soft - Conversion - BrochurerilopiyNo ratings yet

- References: Resistance Factor Design (2 Ed.), Vols. I & II, Chicago, IllinoisDocument11 pagesReferences: Resistance Factor Design (2 Ed.), Vols. I & II, Chicago, IllinoisrilopiyNo ratings yet

- Experimental Test and ResultsDocument19 pagesExperimental Test and ResultsrilopiyNo ratings yet

- Canada Pontage AnglaisDocument24 pagesCanada Pontage AnglaisrilopiyNo ratings yet

- CH 1Document16 pagesCH 1rilopiyNo ratings yet

- Torsion of Rolled Sections in Building StructuresDocument27 pagesTorsion of Rolled Sections in Building StructuresrilopiyNo ratings yet

- Design of W Shapes Bending TorsionDocument7 pagesDesign of W Shapes Bending TorsionrilopiyNo ratings yet

- Double Angle Framing Connections Subjected To Shear and TensionDocument16 pagesDouble Angle Framing Connections Subjected To Shear and TensionrilopiyNo ratings yet

- ASTM A500 Metric - DimsecDocument24 pagesASTM A500 Metric - DimsecrilopiyNo ratings yet

- 3rd Edition LRFD - 2nd Printing ErrataDocument79 pages3rd Edition LRFD - 2nd Printing ErratarilopiyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Guideline For Ambient Air Pollution PDFDocument83 pagesGuideline For Ambient Air Pollution PDFtsrinivasan5083No ratings yet

- Manual ViscosimetroDocument55 pagesManual ViscosimetroLUIS XV100% (1)

- Pitching AdvantageDocument4 pagesPitching Advantageapi-474065092No ratings yet

- Annex-4-JDVP-Certificate-of-Learners-Mastery Jimley CSS - MasteredDocument17 pagesAnnex-4-JDVP-Certificate-of-Learners-Mastery Jimley CSS - MasteredJimley CanillaNo ratings yet

- FT-4XR/FT-4XE FT-4VR/FT-4VE Technical Supplement: Vhf/Uhf Dual Band FM Transceiver VHF FM TransceiverDocument16 pagesFT-4XR/FT-4XE FT-4VR/FT-4VE Technical Supplement: Vhf/Uhf Dual Band FM Transceiver VHF FM TransceiverdenisNo ratings yet

- Product CatalogueDocument24 pagesProduct Cataloguerupa thakkarNo ratings yet

- SCHEMA 99: Service ManualDocument62 pagesSCHEMA 99: Service Manualpipe vinascoNo ratings yet

- Pipes For Civi and Industrial Installations OK PDFDocument24 pagesPipes For Civi and Industrial Installations OK PDFBruno ReisNo ratings yet

- KST ConveyorTech 51 enDocument57 pagesKST ConveyorTech 51 enOscar Jiménez gilNo ratings yet

- Ansys Statics2 v61Document7 pagesAnsys Statics2 v61api-3833671No ratings yet

- TV Mas en 3Document23 pagesTV Mas en 3Rendra ArdyantoNo ratings yet

- Slides 6 Dimensional Analysis and Hydraulic SimilarityDocument43 pagesSlides 6 Dimensional Analysis and Hydraulic SimilarityTing Wee KietNo ratings yet

- ICL8038Document14 pagesICL8038RAYLINo ratings yet

- MMW Chapter 3 Practice Activity - CAMACHO PDFDocument7 pagesMMW Chapter 3 Practice Activity - CAMACHO PDFJustin Maree CamachoNo ratings yet

- SC18G R134a 115V 60Hz 10-03 Cg44h422Document2 pagesSC18G R134a 115V 60Hz 10-03 Cg44h422Jesus Maria Medina SanchezNo ratings yet

- Moment To Force Ratio Center of Rotation and ForceDocument6 pagesMoment To Force Ratio Center of Rotation and ForcezaidNo ratings yet

- Elements, Atoms, Isotopes: Physics in Life ScienceDocument33 pagesElements, Atoms, Isotopes: Physics in Life Sciencedeelol99No ratings yet

- Principles and Developments in Soil Grouting: A Historical ReviewDocument17 pagesPrinciples and Developments in Soil Grouting: A Historical ReviewVetriselvan ArumugamNo ratings yet

- Geochemist S Workbench Dongle Crack PDFDocument3 pagesGeochemist S Workbench Dongle Crack PDFJohnNo ratings yet

- First PagesDocument11 pagesFirst PagesEswar KarriNo ratings yet

- Javascript Advanced TutorialDocument9 pagesJavascript Advanced TutorialMarius Hanganu92% (25)

- Image Processing VerilogDocument17 pagesImage Processing VeriloggoutamkgNo ratings yet

- Kimya 3 - RaporuDocument4 pagesKimya 3 - RaporuFiras 01No ratings yet

- Pega Study Tutorial Interview QuestionsDocument318 pagesPega Study Tutorial Interview QuestionssubbaraogaddamNo ratings yet

- Chapter 3 Multiple Linear Regression: Ray-Bing Chen Institute of Statistics National University of KaohsiungDocument45 pagesChapter 3 Multiple Linear Regression: Ray-Bing Chen Institute of Statistics National University of KaohsiungTrina Mae GarciaNo ratings yet

- Clevo w24h0 W240humb W240huq W241huq W245huq W249huq - 6-7p-w24h5-002Document98 pagesClevo w24h0 W240humb W240huq W241huq W245huq W249huq - 6-7p-w24h5-002Leonardo Gomes0% (1)

- 9080 Optimass 7300 Flowmeter ManualDocument146 pages9080 Optimass 7300 Flowmeter ManualMaruti HuleNo ratings yet

- Control Panel Space OptimizationDocument12 pagesControl Panel Space Optimizationyopy_yogieNo ratings yet

- System Requirement Specification (SRS) : Project: Recruitment Solution Agency (RSA)Document36 pagesSystem Requirement Specification (SRS) : Project: Recruitment Solution Agency (RSA)Nur HazlindaNo ratings yet

- Determination of Physical Properties of Some Agricultural GrainsDocument7 pagesDetermination of Physical Properties of Some Agricultural GrainsPedro Casanova TretoNo ratings yet