Professional Documents

Culture Documents

Crystalline Waterproofing Technology

Uploaded by

Kiran Kumar JhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crystalline Waterproofing Technology

Uploaded by

Kiran Kumar JhaCopyright:

Available Formats

FAIRMATE CRYSTALLINE WATERPROOFING TECHNOLOGY

Crystalline Technology waterproofs and thus enhances the durability of concrete structures

by pore-blocking mechanism, where in the pores, capillaries and micro-cracks in the

concrete are blocked with a non-soluble, crystalline formation.

Concrete is a product of an irreversible chemical reaction. During hydration of cement

particle, the reaction between water and the cement causes the concrete to become a hard,

solid mass. The reaction also produces chemical by-products such as calcium hydroxide,

sulphates and carbonates of sodium potassium and calcium as well as un-hydrated or

partially hydrated cement particles. These by-products exist in the pores and capillary tracts

of the concrete.

Crystalline products contain special additives, which react with the by-products of cement

hydration, in the presence of moisture, initiating a chemical reaction producing a non-

soluble crystalline formation. This crystalline formation occurs only in areas having

presence of moisture. Thus it will form only in the pores, capillary tracts, and shrinkage

cracks of the concrete. In the absence of moisture, these chemicals remain dormant in the

pores of concrete. These proprietary additives also have the characteristics of travelling, by

diffusion, into the finer concrete pores and voids which are developed during the

evaporation of water. The reaction will continue until the chemicals are either exhausted or

the concrete becomes moisture-free. The crystalline formation fills and plugs the voids in

concrete becoming an integral and permanent part of the concrete matrix. This also in turn

helps in producing a denser concrete enhancing the durability characteristics of concrete.

FAIRMATE | In technical collaboration with M/s. RBP Ltd. UK 1

Advantages

Since crystalline systems become an integral part of the concrete, the risk of damages as in

the case of waterproofing membranes is reduced. Hence it does not require any protection.

This makes crystalline admixture an ideal choice for large areas such as basement rafts,

retaining walls, podium terraces, terrace areas, etc., where possibility of damages to the

waterproofing treatment during protection (spreading, brickbat cobs, etc.) itself is high.

It also seals hairline cracks up to 0.4-0.5 mm width. The chemical resistance of crystalline

systems (pH range between 3 and 11 under constant contact, and 2 and 12 under periodic

contact) makes it an ideal choice in areas subject to extreme chemical conditions such as

sub-soil and marine conditions, chemicals retaining tanks, sewage treatment plants, etc.

Due to the non-toxic nature of the material it can also be used for potable water storage

areas. Selection of Suitable Crystalline method.

CRYSTALLINE WATERPROOFING products are available in powder form. There

are three different application methods -

1. Surface applied coating for an existing Concrete Structure

2. As an Admixture.

3. Dry shake application for fresh concrete

CRYSTALLINE WATERPROOFING COATING

Crystalline waterproofing as a coating system (E.g. WATERGUARD CRYSTALLINE) can

be brush-applied or sprayed. The crystalline waterproofing coating system has a unique

chemical diffusion characteristic. Hence for efficient results, workmanship, viz. surface

preparation, surface saturation, dosage and curing, etc. is highly important.

Concrete surfaces where crystalline waterproofing coating (E.g.WATERGUARD

CRYSTALLINE) is to be carried out should have an open pore texture to allow the transfer

of the crystalline additives from the surface coating into the concrete. The surface also

needs to be clean and free of dirt, mould release oil, and other foreign matter as this can

clog the pores and prevent the effective diffusion of the additives into the concrete.

Surface preparation may be carried out by water jetting, sand blasting or acid etching. Sand

blasting is normally required when steel formworks have been used and the concrete has

smooth finish. Acid etching can be accomplished using either muriatic acid or citrus-based

products when the use of an acid is not environmentally acceptable. It is advisable to clean

the area again with water after acid etching to neutralize the surface.

FAIRMATE | In technical collaboration with M/s. RBP Ltd. UK 2

WETTING THE SURFACE

Another prerequisite for an efficient crystalline waterproofing system is that, the concrete

surface should be in a saturated, surface damp condition. This is to facilitate the diffusion of

the chemicals from the coating into the capillary tracts of the concrete. For vertical surfaces,

walls have to be wetted with clean water for about ten hours. In conditions with hot sun and

wind it is better to proceed in small convenient areas at a time.

COATING/SPRAYING APPLICATION

The crystalline waterproofing coating materials are mixed with water at a ratio of 2.5-3 parts

powder to 1 part water by volume and is applied with a brush at a coverage rate of 1.0- 1.25

kg per Sqm for 2 coats. The application can also be carried out with specialized spray

equipments. Under normal conditions, the crystalline waterproofing coating will set in 2-3

hours. The second coat can be done at this point. If the first coat has dried, it must be lightly

sprayed with water prior to the application of the second coat.

CURING

Curing of the crystalline waterproofing system is crucial for efficient and effective

performance and is particularly important for two reasons:

First and foremost, crystalline waterproofing uses water as a medium for diffusion of the

chemicals from the coating into the saturated concrete substrate. If adequate curing of the

crystalline waterproofing does not take place, evaporation will first dry out the coating and

then begin to pull moisture from concrete. This prevents the effective diffusion of the

chemicals into the concrete substrate.

Secondly, curing also ensures proper hardening of the coating and adhesion of the coating

to the concrete surface. Curing has to be carried out by spraying with water.

Curing should begin as soon as the coating has hardened sufficiently. Under normal

conditions, curing can begin two to three hours after coating, and can be done by misting

with a fog spray of clean water at least three times a day for two to three days. In warm

climates or on hot windy days, the frequency of curing has to be increased. During the

curing period, treated surfaces must also be protected from rain and freezing temperatures.

The overall process of crystalline formation may take two to three weeks to reach full

maturity.

Curing should begin as soon as the coating has hardened sufficiently. Under normal

conditions, curing can begin two to three hours after coating, and can be done by misting

with a fog spray of clean water at least three times a day for two to three days. In warm

climates or on hot windy days, the frequency of curing has to be increased. During the

curing period, treated surfaces must also be protected from rain and freezing temperatures.

FAIRMATE | In technical collaboration with M/s. RBP Ltd. UK 3

The overall process of crystalline formation may take two to three weeks to reach full

maturity.

CRYSTALLINE WATERPROOFING ADMIXTURE

CRYSTALLINE ADMIXTURE (E.g. FAIRCRETE RMW CRYSTALLINE) forms part of

concrete and helps in making the concrete dense and watertight. Hence the major part of

the waterproofing activity is completed during concreting itself, needing only the joint

treatment after the concrete sets and hardens. Adding crystalline waterproofing chemicals

to the concrete mix ensures homogenous dispersion of the additives throughout the

structure, rather than penetrating from the surface as would be the case with a coating

application. This is most efficient in areas such as raft slabs, retaining walls, etc.

CRYSTALLINE WATERPROOFING ADMIXTURES (E.g. FAIRCRETE RMW

CRYSTALLINE) also help to reduce concrete shrinkage and increase compressive

strength. When the crystalline admixture is added directly to the concrete mix, the

construction costs, especially waterproofing costs are significantly reduced because only

the construction joints have to be treated after the hardening of the concrete. Hence labour

required for surface treatment application is eliminated and the time required is reduced.

The crystalline waterproofing admixture can be added to concrete at the time of batching as

well as at the site immediately before pouring of the concrete.

CRYSTALLINE WATERPROOFING ADMIXTURES (E.g. FAIRCRETE RMW

CRYSTALLINE ) are compatible with other chemical admixtures such as superplasticizers,

air entraining agents and water reducers. These can also be used in conjunction with

mineral admixtures such as fly ash, and other supplementary cementing materials. When

crystalline admixtures are used, it is always advisable to conduct site trials to meet the

workability requirements of the design mixes.

DRY-SHAKE (BROADCASTING) FOR NEW SLAB CONSTRUCTION

Crystalline waterproofing can also be applied by the dry-shake (E.g. WATERGUARD DS

CRYSTALLINE) application method to new slabs during construction. This process

requires the crystalline powder compound to be sprinkled onto the PCC surface or the top

of slabs. When applied over the PCC, the crystalline admixture broadcasting has to be

done after the reinforcement is tied. The raft concrete can be cast on the broadcasted

surface.

FAIRMATE | In technical collaboration with M/s. RBP Ltd. UK 4

NEGATIVE SIDE WATERPROOFING

Existing basements that are subject to water seepage through foundation walls and floors

can be treated by crystalline waterproofing on the negative side, i.e the inside of the

structure. Coatings that depend on their adhesion to the surface will delaminate. Since

crystalline waterproofing penetrates into the concrete and blocks the pores beneath the

surface, it does not depend on surface adhesion and therefore will not peel off.

FAIRMATE Enhances Concrete at its best

1. Section of dry concrete wall showing the natural free lime and moisture in the capillary

system.

2. Concrete wall exposed to water. The water has forced it’s way into the capillaries.

Longterm effect: leaky, damaged concrete.

3. WATERGUARD CRYSTALLINE treatment: The reaction between the free lime,

moisture and WATERGUARD CRYSTALLINE has set in.

4. The concrete is now watertight. WATERGUARD CRYSTALLINE penetrates the

concrete forming crystals which Substantially constrict the capillaries but still allow

water vapour to pass.

5. Crystals remain in the concrete, ready to reactivate upon water impact. The crystals

have now penetrated deeply into the solid concrete.

FAIRMATE | In technical collaboration with M/s. RBP Ltd. UK 5

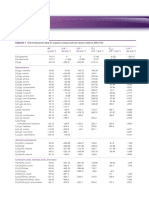

FAIRMATE TREATED CRYSTALLINE WATERPROOFING

TOPIC IMPROVEMENT BENEFIT

CHLORIDE- higher abrasion resistance of the

5 fold reduction of Chloride diffusion

BARRIER concrete

SULPHATE Virtually eliminate sulphate attack for higher ageing resistance of the

RESISTANCE a period of 20 – 30 years concrete

concrete protection against: sea

WEAR / Weight loss by abrasion reduced 70 –

water, waste water, aggressive

ABRASION 75 %

ground water, chemical solutions

When using WATERGUARD

VAPOUR

CRYSTALLINE below an Epoxy floor concrete is still able to breathe

DIFFUSION

coating no blisters formed.

after partial removal of

waterproofing function remains

WATERPROOFING WATERGUARD CRYSTALLINE no

integral in concrete

moisture detected

COMPRESSIVE Up to + 7.3 % increase when powder increased performance of concrete

STRENGTH sprinkled generally

FAIRMATE | In technical collaboration with M/s. RBP Ltd. UK 6

Fairmate International Manufacturing Hubs

MYANMAR QATAR

GET IN TOUCH

If you are looking to place an order or if you require any further information,

please don’t hesitate to get in touch.

In technical collaboration with Ms. RBP Ltd. UK

FAIRMATE CHEMICALS PVT. LTD. 0091 265 2331193, 2331399 enquiry@fairmate.com

8/1, “SAI SUDHA”, 0091 265 2330803 sales@fairmate.com

Arunoday Society, Alkapuri 0091 265 2338733 (Fax) www.fairmate.com

Vadodara 390 007. Gujarat, India www.fairmatebuildingsolutions.com

+91 7574 8346 03

1800 12345 34 (Toll Free)

Important Note

Any information contained herein and any advice given by Fairmate is made to the best of our ability on the basis of current industrial practice and our own knowledge and experience. Any responsibility for damages resulting from the use of or reliance

upon such information or products such information refers to is limited pursuant to our conditions of sale and delivery. Neither our advice nor any information contained herein shall cause the purchaser or any other person or entity using our products to

refrain from testing our products and verifying any suggestions contained in our information or reviewing conflicting patent and proprietary rights; and we expressly request and invite the customer or such other user of our products to perform such tests

or have such tests performed prior to any commercial use or application of our products for the specific use and application intended.

® - Registered Trade Mark FM/07/19/A

You might also like

- FAIRFIBRE - Technical BulletinDocument4 pagesFAIRFIBRE - Technical BulletinKiran Kumar JhaNo ratings yet

- Coating Problem Solver: Adhesion (Blocking) : DescriptionDocument24 pagesCoating Problem Solver: Adhesion (Blocking) : DescriptionKiran Kumar JhaNo ratings yet

- Car Parking System: FairmateDocument5 pagesCar Parking System: FairmateKiran Kumar JhaNo ratings yet

- Dream House With Excellent Finish: DescriptionDocument1 pageDream House With Excellent Finish: DescriptionKiran Kumar JhaNo ratings yet

- Soil Less GardeningDocument52 pagesSoil Less Gardeningacpd75No ratings yet

- FAQs On SBL (Secured Business Loan)Document10 pagesFAQs On SBL (Secured Business Loan)Kiran Kumar JhaNo ratings yet

- Sales ReportDocument54 pagesSales ReportKiran Kumar Jha100% (1)

- Multi ChemDocument5 pagesMulti ChemKiran Kumar JhaNo ratings yet

- Basement WaterproofingDocument2 pagesBasement WaterproofingKiran Kumar JhaNo ratings yet

- LED Light Comparisons and SavingsDocument4 pagesLED Light Comparisons and Savingswww.vlasi.orgNo ratings yet

- Basic Cost ConceptsDocument27 pagesBasic Cost ConceptsGautam Chaini100% (17)

- General Boq Waterproofing Nina WaterproofingDocument19 pagesGeneral Boq Waterproofing Nina WaterproofingKiran Kumar Jha100% (2)

- Mizoram Sor 2008Document54 pagesMizoram Sor 2008Kiran Kumar JhaNo ratings yet

- B.H.P. Single Phase Three Phase 230 Volts 400 Volts 440 VoltsDocument1 pageB.H.P. Single Phase Three Phase 230 Volts 400 Volts 440 VoltsKiran Kumar JhaNo ratings yet

- Fugabella Epoxy enDocument6 pagesFugabella Epoxy enKiran Kumar JhaNo ratings yet

- Pressure GroutingDocument1 pagePressure GroutingKiran Kumar JhaNo ratings yet

- Presentation On Basement Waterproofing-1Document70 pagesPresentation On Basement Waterproofing-1shrikant78% (9)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Iso 14687 3 2014Document11 pagesIso 14687 3 2014Tatiana Sainara Maia FernandesNo ratings yet

- Refrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFDocument13 pagesRefrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFMurillo MendesNo ratings yet

- Calculations in Furnace TechnologyDocument277 pagesCalculations in Furnace Technologysakthivel100% (2)

- Mixture RequirementsDocument11 pagesMixture Requirementsrajesh0% (1)

- Enviromental Toxicity and EvaluationDocument25 pagesEnviromental Toxicity and EvaluationSalma ShadNo ratings yet

- Unit 5.12 PrecipitationDocument16 pagesUnit 5.12 PrecipitationMutale InongeNo ratings yet

- Chili Pepper Extract As TreatmentDocument29 pagesChili Pepper Extract As TreatmentRC Yvann Dela CruzNo ratings yet

- Agricultural Control Chemicals (1950)Document277 pagesAgricultural Control Chemicals (1950)Sveti JeronimNo ratings yet

- ACTI-PLUS® 2818: Safety Data SheetDocument12 pagesACTI-PLUS® 2818: Safety Data SheetCharbel WannesNo ratings yet

- Chromatography PharmacyDocument41 pagesChromatography PharmacyfarisaNo ratings yet

- DS335 - E - Earthing ImprovementDocument2 pagesDS335 - E - Earthing ImprovementCarlos PintoNo ratings yet

- Work Instructions (W.I.)Document18 pagesWork Instructions (W.I.)Shamsul Azhar MohdNo ratings yet

- Density MethodDocument5 pagesDensity MethodMajed DawaNo ratings yet

- Cut Diet Lean MassDocument62 pagesCut Diet Lean Masspakzeeshan167% (3)

- 51314-3985-Methanol-Induced Internal Stress CorrosDocument18 pages51314-3985-Methanol-Induced Internal Stress CorrosMahmoud GamalNo ratings yet

- Handbook of Carbon Nanotubes Polymer NanDocument182 pagesHandbook of Carbon Nanotubes Polymer NanMario Allesina JuniorNo ratings yet

- Completions and WorkoverDocument309 pagesCompletions and WorkoverFan Jack67% (3)

- Atkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Document7 pagesAtkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Roselle Mea EderNo ratings yet

- Valuable CattleDocument2 pagesValuable CattleGurmeet BrarNo ratings yet

- UNIT 4 Raman Spectroscopy 12309Document24 pagesUNIT 4 Raman Spectroscopy 12309NathanianNo ratings yet

- Cell Wall: Presented by M. Vijaya LakshmiDocument9 pagesCell Wall: Presented by M. Vijaya LakshmiATCHUNALA SAINo ratings yet

- Gen Bio W3-5Document9 pagesGen Bio W3-5Alyson EscuderoNo ratings yet

- Hagglunds CaDocument19 pagesHagglunds CaJonathan Giraldo100% (1)

- Indian Regulations On Food PackgingDocument20 pagesIndian Regulations On Food PackgingchoudhurykisanNo ratings yet

- Adsc of Amorphous Sugar - Mettler ToledoDocument3 pagesAdsc of Amorphous Sugar - Mettler ToledoMarthaLuceroPerezNo ratings yet

- Installation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg GermanyDocument28 pagesInstallation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg GermanyRenārs BērtiņšNo ratings yet

- Oxidation NumberDocument21 pagesOxidation NumberChristian LopezNo ratings yet

- InternshipDocument16 pagesInternshipSarthak SinghNo ratings yet

- Waterborne Acrylic Primer Nacorr Synergy With Halox SZP-391: Formulation Ci-101Document2 pagesWaterborne Acrylic Primer Nacorr Synergy With Halox SZP-391: Formulation Ci-101Swapnil AlandNo ratings yet