Professional Documents

Culture Documents

KNPC

KNPC

Uploaded by

Ubed Kudachi0 ratings0% found this document useful (0 votes)

80 views26 pagesKnpc

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKnpc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

80 views26 pagesKNPC

KNPC

Uploaded by

Ubed KudachiKnpc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 26

STANDARD SPECIFICATION NO. 83A1

PAINTING

KUWAIT NATIONAL PETROLEUM COMPANY (K.S.C.)

Jan. 27, 1984

PAINTING KNPC ENG STD 83AL

TABLE OF CONTENTS

PAGE

1 GENERAL

1.2 Scope a 3

2.2 Vendors Responsibility 3

1.3. The Vendor 3

Le Requirements 4

LS to be Paintea 4

16 Hot to be Painted 5

1.7 Protection of Surfaces 6

1.8 Shipping Identification 6

1.9 Paint storage é

1.10 Paint Mater: 6

1.12 Surface Preparation 9

1112 Lamieations 20

1.13 Padnt Application at

1.14 Manufacturer's Racommendations a

1.18 Dry Film Thickness 12

1:38 Feld Erected Bquipment 12

1.17 Pield Repair of Painted Surfaces 3

1.18 Field Inspection 3

2-19 Galvanizing - 13

1.20 Repair of Galvanized Surfaces 16

1.21 Shipping Marking 16

1.22 Repair of Aluminized Surfaces 1s

2° COAPING SCHEDULE

2.1 Definition 4

2.2 Coating Schedules 16

3. APTACEMENTS

TABLE I Colors of Piping 24

TABLE IZ Munsell Ref Colors + 25

TABLE Itt Shipping Making 25

FIGURE I Painted Parts of Inewlated Bquipment 26

PAINTING

Page 3

Rev. 2

Dater Jan. 27, 1964

KUEC ENG STD 63A1

2 GENERAL

Lb

1.3

SCOPE

This specification establishes the minimum

Fequirenenta for the surface preparation, coating

materials, application and inspection of the paintea

and galvanized surfaces for all items of all

commodities for the Kuwait Mena Abdulla Refinery

Expansion unless specifically exempte’ herein.

Specific surfaces not covered by this specification

are buried piping, instrument control panels, below

grade waterproofing, fireproofing, insulation, and

architectural coatings 2a applied to office

structures and control building:

This specification does

paint

jot_ cover color achemas or

atem for surfaces above 800°F.

VENDORS RESPONSIBILITY

All equipment, structural steel, piping and shop

fabricated components of field erected items that are

specified to be painted or galvanized, shall, as 2

minimum, receive surface preparation and priming or

galvanizing by the Vendor prior to shipment to the

jobsite unless specifically exempted by the

purchasing contract, Field fabricated items and

field run piping shall be surface prepared and primed

in the field prior to or at the time of exection.

All finish painting of shop and field primed items

shall be done in the field.

Certain equipment (pumps, compressors, motors,

instrument items and electrical items) wil) bo

supplied with manufacturer‘s standard finish paint.

No #leld painting will be required, excest for repair

of any damaged surfaces.

‘tae veNDoR,

The term Vendor, a6 used heroin, means the party with

whom the Purchaser has contracted to furnish material

and/or services, whether he be manufacturer,

fapriextor, erector or contractor.

PALITING

La

15

Page 4

Rev. 2

Date: Jan. 27, 1984

KNPC ENG STD 83A2

QUALETY REQUIREMENTS

‘The Vendor chal} surface propare and paint in

accordance with ehis specification using the paints

and paint systema specified in the coating achedule.

‘The work shall be performed by qualified craftsmen,

ang shall result in properly painted curfaces free

gro pinholes, runs, “eae, tnin opote, dire

inclusions and other evidence of poor workmanship.

Every effort shall be exercised to prevent damage to

the coated surfaces waile handling and shipping.

SURFACES TO BE PAINTED

Prepare and paint the following surfaces, unless

otherwise noted, in accordance with the coat

schedule of this specification. ‘The list indicates

typical items and is not necessarily all inclusive.

Structural steel, supports, miscellaneous eteel

including ladders, ladder Gages, platforms, steire,

stair stringers, checkered plate and hand rails,

and clips that are welded to equipment. See

Paragraph 1.6 €or specific exceptions.

Cazbon steel and iow alloy steel apparatus, columns,

exchangers, heaters, tanke and vos: ineluding

their supports auch az legs, saddles and skirts which

are not firaproofed.

Carbon steel and low alloy a! piping, not buried,

including flanges, fittings, valves, strainers,

traps, etc.

Roquiremente for painting of “Piping” include entire

Ai tem (pipe, fittings, flanges, valves,

traps, etc), Carbon steel piping of

oquipment insulated for Personnel Protection shall

be considered as “uninsulated" where painting

requirements are concerned. Stainless steel piping

to be insulated for Personnel Protection will be

painted in the gield. Uninulated portions of

neulated equipment oz piping systems (eg, vessel,

nozzles, saiway covers, valves, xolief valves, stc)

shall be painted.

valving

LS

1.6

Page 5

Rev. 2

Date: Jan. 27, 1984

KUPC ENG STD 83A1

SURFACES TO BE PAINTED continued

Machinery, motors, pumps and other equipment.

Carbon steel and low alloy steel attachments to itens

not painted by reason of the following paragraph,

fneluding clips that may project through the

ineulation.

Stainless steal exposed to chlorides oz near

galvanizing. See Group F of Peragraph 2.2.

SURFACES NOT To BE PAINTED

Do not paint the following surfaces unless othexwi:

instructed by this specification.

Non~ferrous metal or alloy steel

copper, braes, none) or stainle:

noted in Paragraph 1.5.

Grating (To be galvanized).

Glass, tile or other ceramic surfac

ch as aluminum,

steel, except as

Wameplates or identification tags of any kind.

Valve stems, flange faces or other machined contact.

surfaces.

Contact surfaces of structural steel members to be

joined with Eriction type connections using high

atrength bolts. (NOTE - these surfaces may ba

Dilast cleaned and inorganic ginc-primed only, no

other paint is permitted.

Inside surfaces of columns, exchangers, piping,

tanke and vesacls unless specifically specified.

Galvanized or metalized surfaces.

Insulation & weatherproofing.

Buried piping.

Plastica, trausite or wood.

Concrete.

Within 2" of field welded joints.

PAINTING

L7

19

2.10

Page 6

Rev. 2

Date: Jan. 27, 1984

ci KNPC ENG STD 83A1

PROTECTION OF SURFACES

Protect all surfaces from damage or from paint

products by adequate temporary coverings during all

operations of surface preparations and priming.

Burfaces to be protected include such items as the

following,

Surfaces that ure not to be painted, as

Listed in Paragraph 1.6

Previously painted surfaces.

Floors, watke an® rosdvaya.

Adjacent structur

and equipment.

Remove paint that may have fallen on these surfaces.

SHIPPING IDEUPIPICATION

ALL shipping taga, wires, strings and other means

of temporary or shipping identification on surfaces

to be painted shall be Zomoved, but only after

checking with and receiving authorization from KNPC

representative.

PAINT STORAGE

Paint applicator shall provide a t jorary builéii

for storage and mixing of paint materiale, see

Applicator shall provide adequate fire fighting

equipment, satisfactory to KNPC for the temporary

building and at all locations where painting work

is in progress.

PAINT MATERIALS

Use only the following materials, or Purchaser

approved substitute materials, where they sppear in

the coating achedule. ‘The material, as delivered

to the applicator, must be in the manufacturer's

original containers bearing the manufacturer's name

and brand number.

PAINTING

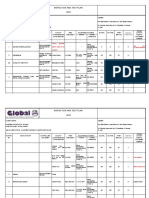

PAINT NUMBER

e100

P+101

Be102

Pe103

PHl04

Page 7

Rev, 2

Bate: Jan. 27, 1994

RNPC ENG STD S3AL

ACCEPTABLE PAINTING MATERIALS Continued

TPE

Red-Lead OiL Alkyd

Inorganic Zinc,

Selé-Cure,

Solvent Base

Silicone (for

Stainless Steel)

Exterior O11 Alkyd

Primer

Interior Alkyd

Primsr

MANOFACTURER

Mobil 13-R-52

Sherwin Williams Kromik

Metal Primer, E4LNL

Admiral AD=300

International Paint/Matcote

Interprime CPA 404 Red

Porter 273

Prufcoat 805-20-00

Amercoat 5105

Carboline AD 30

Napko 1313

Carboline Carbo Zinc $12

Amercoat Dimetcote BZ IL

Mobilsine 7 13

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Screenshot 2022-01-08 at 11.21.05 AMDocument6 pagesScreenshot 2022-01-08 at 11.21.05 AMUbed KudachiNo ratings yet

- Final KOC-P-004 Part 7 - Rev 2.docx As On 30.06 KOC Standard For CoatingDocument34 pagesFinal KOC-P-004 Part 7 - Rev 2.docx As On 30.06 KOC Standard For CoatingUbed Kudachi100% (2)

- Painting Procedure GlobalDocument15 pagesPainting Procedure GlobalUbed KudachiNo ratings yet

- Inspection and Test Plan: DOC: GBL/QC/2015/ITP-001/REV 01 Dtd.04/01/2017Document4 pagesInspection and Test Plan: DOC: GBL/QC/2015/ITP-001/REV 01 Dtd.04/01/2017Ubed KudachiNo ratings yet

- Piping Material Receiving Inspection Checklist (Pipe & Pipe Fittings) Contractor Procured MaterialsDocument1 pagePiping Material Receiving Inspection Checklist (Pipe & Pipe Fittings) Contractor Procured MaterialsUbed KudachiNo ratings yet

- Helping Verbs in TensesDocument9 pagesHelping Verbs in TensesUbed KudachiNo ratings yet