Professional Documents

Culture Documents

Features Description: High-Integrated Green-Mode PWM Controller

Features Description: High-Integrated Green-Mode PWM Controller

Uploaded by

manda fanoaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Features Description: High-Integrated Green-Mode PWM Controller

Features Description: High-Integrated Green-Mode PWM Controller

Uploaded by

manda fanoaCopyright:

Available Formats

Product Specification

High-integrated Green-mode PWM Controller SG6841

FEATURES DESCRIPTION

Green-mode PWM to support “Blue Angel” Norm This highly integrated PWM controllers, SG6841 series,

Low start up current 30uA provides several features to enhance the performance of

Low operation current 3mA low power flyback converters. To minimize standby

Leading-edge blanking power consumption, the proprietary green-mode

Built-in synchronized slope compensation function provides off-time modulation to linearly

Constant output power limit for universal AC input decrease the switching frequency under light-load

Current mode operation conditions. This green-mode function assists the power

Cycle-by-cycle current limiting supply to easily meet the power conservation

Under voltage lockout (UVLO) requirement. Due to BiCMOS process, the start-up

Programmable PWM frequency current and operation current is reduced to 30uA and

GATE output maximum voltage clamped at 18V 3mA, respectively, to improve power conversion

Totem pole output includes soft driving for better efficiency. Large start-up resistance can be used for

EMI further power saving. Built-in synchronized slope

Build-in limited-power-control to meet safety compensation ensures the stability of peak current mode

requirement control. A proprietary internal compensation ensures

Programmable over-temperature protection constant output power limit for universal AC input

Few external components & low cost solution voltage from 90VAC to 264VAC.

SG6841 provides many protection functions.

APPLICATIONS Pulse by pulse current limit ensures a constant output

General-purpose switching mode power supplies current under short circuit. If a short circuit failure or

and flyback power converters, and over load happens, the SG6841 will shut off after a

continuous high voltage detection on FB pin. The gate

Power Adapter

output is clamped at 18V to protect the power MOS

Open-frame SMPS

from over voltage damage. An external NTC

Battery Charger Adapter

thermistor can be applied to sense the ambient

temperature for over-temperature protection. The

SG6841 series are available in 8-pin DIP and SO

packages.

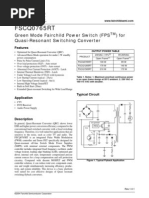

TYPICAL APPLICATION

From bridge rectifier

127~ 373VDC D1 From auxiliary

winding

RIN C IN

VIN VDD

RT Rg

Q1

GATE

RA

RI SG6842

RT SENSE

RI RS

FB

GND

©System General Corp. -1- www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

MARKING DIAGRAMS PIN CONFIGURATION

T: D = DIP, S = SOP GND GATE

P: Z = Lead Free

FB VDD

SG6841TP Null=regular package

XXXXXXXYYWWV

XXXXXXX: Wafer Lot

VIN SENSE

YY: Year; WW: Week

V: Assembly Location RI RT

ORDERING INFORMATION

Part Number Package

SG6841S 8-Pin SOP

SG6841D 8-Pin DIP

SG6841SZ 8-Pin SOP(Lead Free)

SG6841DZ 8-Pin DIP(Lead Free)

PIN DESCRIPTIONS

Pin No. Symbol Function Description

1 GND Ground Ground.

The signal from external compensation circuit is feed into this pin. The PWM duty cycle is

2 FB Feedback

determined by this FB pin and current sense signal from Pin 6.

This pin is pulled high to the rectified line input through a resistor for start-up. Since the

start-up current requirement for SG6841 is very small, a large start-up resistance can be

3 VIN Start-Up Input

used to minimize power loss. Under normal operation, this pin is also used to detect line

voltage to compensate for constant output power limit for universal AC input.

A resistor from RI pin to ground will generate a constant current source forSG6841. This

current is used to charge an internal capacitor and hence the switching frequency are

4 Ri Reference Setting determined. Increasing the resistance will decrease the current source and reduce the

switching frequency. A 26kΩ resistor Ri creates a 50uA constant current Ii and generates

65kHz switching frequency.

For over-temperature protection. An external NTC thermistor is connected from this pin

Temperature

5 RT to ground. The impedance of the NTC will decrease under high temperature. Once the

Protection

voltage on RT pin drops below a fixed limit, the PWM output will be disabled.

Current sense. The sensed voltage is used for current mode control and pulse-by-pulse

6 SENSE Current Sense

current limiting.

7 VDD Power supply Power Supply.

The totem-pole output driver for the power MOSFET. A soft driving waveform is

8 GATE Driver Output

implemented to improve EMI.

©System General Corp. -2- www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

BLOCK DIAGRAM

RI

4

VDD

0.85V

ON/OFF

VIN 3 +

_ Driver

8 GATE

Internal Q S OSC Green Mode

BIAS Controller

R

UVLO

VDD 7 +

_

6 SENSE

16V/10V

Comp

Slope

6V

Compensation

I RT 2R

2 FB

RT 5 + Limited Power Comp

_ Controller R

0.65V 4.2V

GND

©System General Corp. -3- www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

DC Supply Voltage 30 V

VDD

Zener clamp 32 V

Zener current 10 mA

IOUT Gate Output Current 500 mA

VFB Input Voltage to FB Pin -0.3 to 7V V

VSense Input Voltage to SENSE Pin -0.3 to 7V V

VRT Input Voltage to RT Pin -0.3 to 7V V

VRI Input Voltage to Ri Pin -0.3 to 7V V

PD Power Dissipation 1 W

Thermal Resistance Junction-air

RΘ j-a DIP 82.5 °C /W

SOP 141

TJ Operating Junction Temperature 150 °C

TA Operating Ambient Temperature -30 to 85 °C

Tstg Storage Temperature Range -55 to +150 °C

TL Lead Temperature (Wave soldering or IR, 10 seconds) 260 °C

ESD Capability, HBM model 3.0 KV

ESD Capability, Machine model 250 V

RECOMMENDED OPERATING CONDITIONS

Symbol Parameter Value Unit

VDD DC Supply Voltage <20 V

TA Operating Ambient Temperature -20 to +85 ℃

RI Current source Setting 26 KΩ

ELECTRICAL CHARACTERISTICS

Feedback Input Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

AV Input-voltage to current-sense attenuation 1/3.25 1/3 1/2.75 V/V

ZFB Input impedance 2 4.5 8 KΩ

IFB Bias current 2 mA

VOZ Input voltage for zero duty cycle 1.2 V

©System General Corp. -4- www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

Current Sense Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

ZCS Input impedance 8 12 16 KΩ

TPD Delay to Output 150 200 ns

VTH Threshold voltage for current limit IVIN = 0 uA 0.8 0.85 0.9 V

The change of threshold voltage versus the input

ΔVTH @ IVIN IVIN = 220 uA -0.09 -0.15 -0.21 V

current of the Vin

VSENSE0 Threshold voltage for IVIN = 80uA IVIN = 80 uA 0.73 0.81 0.89 V

Tdelay-lps The delay time of limited-power-control RI=26KOhms 31 ms

Oscillator Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

FOSC Frequency in nominal mode RI=26KOhms 60 65 70 KHz

Fosc-green Frequency in green mode RI=26KOhms 10 16 KHz

VG End of green mode voltage at FB pin 1.4 V

VN Beginning of frequency reducing at FB pin 2.1 V

SG Slope for green mode modulation RI=26KOhms 50 80 120 Hz/mV

FDV Frequency variation versus VDD deviation VDD=10 to 20V 5 %

FDT Frequency variation versus Temp. deviation TA=-30 to 85 ℃ 5 %

PWM Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

DC (MAX) Maximum Duty Cycle 75 80 90 %

DC (MIN) Minimum Duty Cycle - - 0 %

Bnk Leading edge blanking time 200 270 350 ns

Output Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

VOL Output Voltage Low VDD = 12V, Io = 150mA 1.5 V

VOH Output Voltage High VDD = 12V, Io = 50mA 8V V

tr Rising Time VDD =13V, CL=1nF 150 250 350 ns

tf Falling Time VDD =13V, CL=1nF 30 50 90 ns

Under-voltage Lockout Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

VTH(ON) Start Threshold Voltage 15 16 17 V

VDD(min) Min. Operating Voltage 9 10 11 V

©System General Corp. -5- www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

Over-Temperature Protection Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

IRT Output current of pin RT RI=26KOhms 92 100 108 uA

VOTP,STOP Threshold voltage for over-temperature protection. 0.585 0.62 0.655 V

Turn-off point. Duty cycle is reduced to 0%.

VOTP,START Threshold voltage for over-temperature protection. 0.65 V

Starting point. Duty cycle starts to decrease.

Total Standby Current Section

Symbol Parameter Test Condition Min. Typ. Max. Unit

IDD ST Start-up Current VDD=14.5V 30 40 uA

IDD OP Operating Supply Current FB=SENSE=0V 3 5 mA

GATE=1000pF

VDD=15.5V

©System General Corp. -6- www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

TYPICAL CHARACTERISTICS

Start-up Current (IDD ST) vs Tem perature Start-up Current (IDD ST) vs VDD Voltage

25.5 35

30

Start-up Current (uA)

25.0

Start-up Current (uA)

24.5 25

24.0 20

23.5 15

23.0 10

22.5 5

22.0 0

-40 -25 -10 5 20 35 50 65 80 95 110 125 0 2 4 6 8 10 12 14 16

TEMPERATURE (℃ ) VDD VOLTAGE (V)

Frequency vs. FB Voltage Frequency in green mode (Fosc-green) vs

Temperature

70

60 10.52

10.50

Frequency (KHz)

50

Fosc-green (KHz)

10.48

40 10.46

10.44

30

10.42

20 10.40

10 10.38

10.36

0

10.34

1.1 1.4 1.7 2 2.3 2.6 2.9

-40 -25 -10 5 20 35 50 65 80 95 110 125

FB VOLTAGE (V) TEMPERATURE (℃)

PWM Oscillator Frequency (Fosc) vs Maximum Duty Cycle DC(MAX.)vs

Tem perature Temperature

64.4

64.3 84.75

84.70

Max. Duty Cycle (%)

64.2 84.65

Fosc (KHz)

84.60

64.1 84.55

64.0 84.50

84.45

63.9 84.40

84.35

63.8 84.30

84.25

63.7 84.20

-40 -25 -10 5 20 35 50 65 80 95 110 125 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE (℃ )

TEMPERATURE (℃)

©System General Corp. -7- www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

Min. Operating Voltage (V DD(min)) vs Start Threshold Voltage (V TH(ON)) vs

Tem perature Tem perature

16.60

10.20 16.55

10.15

10.10 16.50

10.05

VDD(min) (V)

VTH(ON) (V)

16.45

10.00

9.95 16.40

9.90

16.35

9.85

9.80 16.30

9.75

16.25

9.70

-40 -25 -10 5 20 35 50 65 80 95 110 125 16.20

-40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE (℃ )

TEMPERATURE (℃ )

RT Voltage vs Ton Output Current of pin RT (IRT) vs

Temperature

14

12

101.5

10

101.0

8

Ton (uS)

100.5

IRT (uA)

6

100.0

4

2 99.5

0 99.0

-2 98.5

0.620 0.628 0.636 0.644 0.652 0.660 -40 -25 -10 5 20 35 50 65 80 95 110 125

RT VOLTAGE (V) TEMPERATURE (℃)

V OTP, STOP vs Tem perature

VSENSE vs IVIN

0.63

0.84

0.62

0.79

0.74

VOTP, STOP (V)

0.62

0.69

VSENSE

0.61

0.64

0.61 0.59

0.54

0.60

0.49

0.44

0.60

0 40 80 120 160 200 240 280 320 360

-40 -25 -10 5 20 35 50 65 80 95 110 125

IVIN (uA)

TEMPERATURE (℃ )

©System General Corp. -8- www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

OPERATION DESCRIPTION Current sensing and PWM current

Start-up current limiting

Typical start-up current is only 30uA so that a high Peak current mode control is utilized in SG6841 to

resistance, and low-wattage, start-up resistor can be used regulate output voltage and provide pulse by pulse current

to minimize power loss. For an AC/DC adapter with limiting. The switch current is detected by a sense resistor

universal input range, a 1.5 MΩ, 0.25W, start-up resistor into the sense pin of SG6841. The PWM duty cycle is

and a 10uF/25V VDD hold-up capacitor are enough for determined by this current sense signal and VFB, the

this application. feedback voltage. When the voltage on sense pin reaches

VCOMP = (VFB–1.0)/3, a switch cycle will be terminated

Operating current immediately. VCOMP is internally clamped to a variable

Operating current has been reduced to 3mA. The low voltage around 0.85v for output power limit.

operating current enables a better efficiency and reduces

the requirement of VDD hold-up capacitance.

Leading Edge Blanking

Each time when the power MOSFET is switched on,

Green Mode Operation a turn-on spike will inevitably occur on the sense-resistor.

The patented green-mode function provides an To avoid premature termination of the switching pulse, a

off-time modulation to reduce the switching frequency in 270 nsec leading-edge blanking time is built in.

the light load and no load conditions. The on time is Conventional RC filtering can therefore be omitted.

limited for better abnormal or brownout protection. VFB, During this blanking period, the current-limit comparator

which is derived from the voltage feedback loop, is taken is disabled and it cannot switch off the gate driver.

as the reference. Once VFB is lower than the threshold

voltage, switching frequency will be linearly decreased to

Under-voltage lockout (UVLO)

the minimum green mode frequency around 10kHz (Ri The turn-on and turn-off threshold of SG6841 are

=26kΩ). fixed internally at 16V/10V. During start-up, the hold-up

capacitor must be charged to 16V through the start-up

Oscillator Operation resistor so that SG6841 will be enabled. The hold-up

A resistor from RI pin to ground will generate a capacitor will continue to supply VDD before the energy

constant current source for SG6841. This current is used can be delivered from auxiliary winding of the main

to charge an internal capacitor and hence the internal transformer. VDD must not drop below 10V during this

clock and switching frequency are determined. Increase start-up process. This UVLO hysteresis window insures

the resistance will decrease the current source and reduce that hold-up capacitor is adequate to supply VDD during

the switching frequency. A 26kΩ resistor Ri creates a start-up.

50uA constant current Ii and generates 65kHz switching

frequency. The relation between Ri and switching

Gate Output / Soft Driving

freauency is: The SG6841 BiCMOS output stage is a fast totem

pole gate driver. Cross conduction has been avoided to

1690 minimize heat dissipation, increases efficiency and

fPWM = (kHz ) ---------------------------- (1) enhances reliability. The output driver is clamped by an

RI (kΩ )

internal 18V Zener diode in order to protect power

MOSFET transistors against undesirable gate over

The range of the PWM oscillation frequency is

voltage. A soft driving waveform is implemented to

designed as 50kHz ~ 90kHz.

minimize EMI.

©System General Corp. -9- www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

At high ambient temperature, Rntc will be smaller

Built-in Slope Compensation

such that VRT will decrease. When VRT is less than 0.65V

The sensed voltage across the current sense resistor (VOTP,START), the PWM duty cycle will be decreased to

is used for current mode control and pulse-by-pulse lower the internal temperature of power supply. If the

current limiting. Built-in slope compensation will over heating situation still exists such that VRT decreases

improve stability or prevent sub-harmonic oscillation of further to 0.62V (VOTP,STOP), the PWM will be completely

peak current mode control. SG6841 inserts a turned off.

synchronized positive-going ramp at every switching

cycle. Vs-comp = 0.33V. Limited Power Control

Every time when the output of power supply is

Constant Output Power Limit

shorted or over loaded, the FB voltage will increase. If the

When the SENSE voltage, across the sense resistor FB voltage is higher than a designed threshold, 4.2V, for

Rs, reaches the threshold voltage, around 1.0V, the output longer than 31msec, the PWM output will then be turned

GATE drive will be turned off after a small propagation off eternally. VDD, the supply voltage for SG6841, will

delay tD. This propagation delay will introduce an decrease due to the supply current for SG6841. When VDD

additional current proportional to tD*Vin/Lp. Since the is lower than the turn-off threshold such as 10V, SG6841

propagation delay is nearly constant regardless of the will be totally shut down. Due to the start up resistor, VDD

input line voltage VIN. Higher input line voltage will result will be charged up to the turn-on threshold voltage 16V

in a larger additional current and hence the output power until SG6841 is enabled again. If the over loading

limit is also higher than that under low input line voltage. condition still exists, above protection will take place

To compensate this variation for wide AC input range, the repeatedly. This will prevent the power supply from being

threshold voltage is adjusted by the VIN current. Since overheated under over loading condition.

VIN pin is connected to the rectified input line voltage

through the start-up resistor, a higher line voltage will Noise immunity

generate higher VIN current into the VIN pin. The Noise on the current sense or control signal may

threshold voltage is decreased if the VIN current is

cause significant pulse width jitter, particularly in the

increased. Smaller threshold voltage, forces the output continuous conduction mode. Slope compensation helps

GATE drive to terminate earlier, thus reduce the total

alleviate this problem. Good placement and layout

PWM turn-on time and make the output power equal to practices should be followed. Avoiding long PCB traces

that of low line input. This proprietary internal

and component leads, locating compensation and filter

compensation ensures a constant output power limit for components near to the SG6841, and increasing the power

wide AC input voltage from 90VAC to 264VAC.

MOS gate resistance will always help.

Thermal Protection

An NTC thermistor Rntc in series with a resistor Ra

can be connected from pin RT to ground. A constant

current IRT is output from pin RT. The voltage on RT pin

can be expressed as VRT = IRT × (Rntc + Ra) in which IRT =

2 x (1.3V / Ri).

©System General Corp. - 10 - www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

REFERENCE CIRCUIT

Circuit

F1

2

CN1 BD1

R1

1

3 L1 4 3 L2 4

1

4 1

2 C1 C2

3 VZ1 1 2 1 2

THER1 R2 C3 R3 Q1 L3

+ 1

2

C4 1,2 8,9 3 2 1 2 Vo+

3

1,2 8,9

2

1 2

1

D2 D1

R5

1

C5 R4 C6 C7 + +

3

4 3 C8 D3

1

4

R7

R6

2

2

U1

Q2

1 8 1 5 6,7

GND GATE 5 6,7

2 7

3

FB VDD

3 6

VIN SENSE

4 5

RI RT

R8

SG6841

R9 R10 R11

R12 D4

2

1 2

THER2

+ C9

U2

1

4 1

3 2

R13

C10

3

R14

U3 1

Vo+

R15

2

BOM

Reference Component Reference Component

BD1 BD 4A/600V R1,R2 R 1Mohm 1/4W

C1 XC 0.1uF/275V R3 R 100Kohm 1/2W

C2 XC 0.22uF/275V R4 R 47ohm 1/4W

C3 CC 0.01uF/500V R5,R7 R 750Kohm 1/4W

C4 EC 120u/400V R6 R 20Kohm 1/8W

C5 YC 222p/Y1 R8 R 0.3ohm 2W

C6 CC 1000pF/100V R9 R 33Kohm 1/8W

C7 CC 1000pF/50V R9 R 20Kohm 1/8W 1%

C8 EC 1000uF/35V R11 R 220ohm 1/8W

C9 EC 220uF/35V R12 R 4.7ohm 1/8W

D1 LED R13 R 6.8Kohm 1/8W

D2 Diode FR157 R14 R 154Kohm 1/8W

D3 ZD 18V R15 R 390Kohm 1/8W

D4 Diode FR102 THER1 Thermistor SCK054

F1 FUSE 4A/250V T1 Transformer

L1 900uH U1 IC SG6841

L2 15mH U2 IC PC817

Q1 Diode 20A100V U3 IC TL431

Q2 MOS 7A/600V VZ1 VZ 9G

©System General Corp. - 11 - www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

PACKAGE INFORMATION

8 PINS– DIP (D)

D

Θ°

8 5

E1 e

B

E

1 4

A2

A1

b1

e

b

Dimension

Symbol Millimeter Inch

Min. Typ. Max. Min. Typ. Max.

A 5.334 0.210

A1 0.381 0.015

A2 3.175 3.302 3.429 0.125 0.130 0.135

b 1.524 0.060

b1 0.457 0.018

D 9.017 9.271 10.160 0.355 0.365 0.400

E 7.620 0.300

E1 6.223 6.350 6.477 0.245 0.250 0.255

e 2.540 0.100

L 2.921 3.302 3.810 0.115 0.130 0.150

eB 8.509 9.017 9.525 0.335 0.355 0.375

θ° 0° 7° 15° 0° 7° 15°

©System General Corp. - 12 - www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

8 PINS– SOP (S)

C

8 5

E

H

1 4

b

e

Θ

L

A1 A

Dimension

Symbol Millimeter Inch

Min. Typ. Max. Min. Typ. Max.

A 1.346 1.752 0.053 0.069

A1 0.101 0.254 0.004 0.010

b 0.406 0.016

c 0.203 0.008

D 4.648 4.978 0.183 0.196

E 0.381 3.987 0.150 0.157

e 1.270 0.050

F 0.381X45° 0.015X45°

H 5.791 6.197 0.228 0.244

L 0.406 1.270 0.016 0.050

θ° 0° 8° 0° 8°

©System General Corp. - 13 - www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

Product Specification

High-integrated Green-mode PWM Controller SG6841

DISCLAIMERS

LIFE SUPPORT

System General’s products are not designed to be used as components in devices intended to support or sustain

human life. Use of System General’s products in components intended for surgical implant into the body, or other

applications in which failure of the System General’s products could create a situation where personal death or injury may

occur, is not authorized without the express written approval of System General’s Chief Executive Officer. System

General will not be held liable for any damages or claims resulting from the use of its products in medical applications.

MILITARY

System General's products are not designed for use in military applications. Use of System General’s products in

military applications is not authorized without the express written approval of System General’s Chief Executive Officer.

System General will not be held liable for any damages or claims resulting from the use of its products in military

applications.

RIGHT TO MAKE CHANGES

System General reserves the right to change this document and/or this product without notice. Customers are advised

to consult their System General sales representative before ordering.

©System General Corp. - 14 - www.sg.com.tw

Version 2.1 (IRO33.0001.B5) Jun.15,2006

You might also like

- Bizantium and The Northern Islands Sneak PreviewDocument32 pagesBizantium and The Northern Islands Sneak PreviewStefano Chiaramonti100% (1)

- Risk Assessment Plant Room / Boiler House (Access and Carrying Out Maintenance Work - Staff & Contractors)Document2 pagesRisk Assessment Plant Room / Boiler House (Access and Carrying Out Maintenance Work - Staff & Contractors)Naveenkumar KuppanNo ratings yet

- Analog Circuit Design Volume Three: Design Note CollectionFrom EverandAnalog Circuit Design Volume Three: Design Note CollectionRating: 3 out of 5 stars3/5 (2)

- ELECTRONICDocument13 pagesELECTRONICMahmoued YasinNo ratings yet

- Description: Green-Power PWM Controller With Freq. JigglingDocument8 pagesDescription: Green-Power PWM Controller With Freq. JigglingLuis GuevaraNo ratings yet

- SG6848 Aahbp To Je PDFDocument13 pagesSG6848 Aahbp To Je PDFVukica IvicNo ratings yet

- OB2269Document12 pagesOB2269Juan Ballon100% (1)

- Aajfk Sg6859aDocument13 pagesAajfk Sg6859azarevgNo ratings yet

- DM0265Document19 pagesDM0265liberthNo ratings yet

- GM7230-V1 01Document10 pagesGM7230-V1 01Alfredo Valencia RodriguezNo ratings yet

- Green Mode PWM Controller Ap384XgDocument13 pagesGreen Mode PWM Controller Ap384XgbaphometabaddonNo ratings yet

- Datasheet 53315Document30 pagesDatasheet 53315Bladimir AngamarcaNo ratings yet

- Tda 8780Document16 pagesTda 8780Andrey DolgovNo ratings yet

- 700ma H V A C R W E C: IGH Oltage Djustable Urrent Egulator ITH Nable OntrolDocument6 pages700ma H V A C R W E C: IGH Oltage Djustable Urrent Egulator ITH Nable OntrolNathan WilliamsNo ratings yet

- Data SheetDocument12 pagesData SheetMarcoAntonioCamanTraihuelNo ratings yet

- IC-ON-LINE - CN dm0465r 44841Document20 pagesIC-ON-LINE - CN dm0465r 44841ubhagavanNo ratings yet

- Feature General Description: HT7A6005 Low Power, Wide Temperature Range General Purpose Current Mode PWM ControllerDocument11 pagesFeature General Description: HT7A6005 Low Power, Wide Temperature Range General Purpose Current Mode PWM ControllerEnéas BaroneNo ratings yet

- L6565Document18 pagesL6565Sergio Daniel BarretoNo ratings yet

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDocument10 pagesNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânNo ratings yet

- FAN7602 - Green Current Mode PWM Controller - Fairchild SemiconductorDocument17 pagesFAN7602 - Green Current Mode PWM Controller - Fairchild SemiconductorVijay MistryNo ratings yet

- IC-ON-LINE - CN dm0365r 44840Document20 pagesIC-ON-LINE - CN dm0365r 44840MoscandoNo ratings yet

- 1565 RTDocument24 pages1565 RTJose Samuel Robelto RNo ratings yet

- LM3530 High Efficiency White LED Driver With Programmable Ambient Light Sensing Capability and I C-Compatible InterfaceDocument45 pagesLM3530 High Efficiency White LED Driver With Programmable Ambient Light Sensing Capability and I C-Compatible Interfacethoth2487No ratings yet

- L 6565Document17 pagesL 6565tatatabuchoNo ratings yet

- Pt1806 by PTCDocument10 pagesPt1806 by PTCtolomeo10No ratings yet

- Green-Mode PWM Controller: General Description FeaturesDocument10 pagesGreen-Mode PWM Controller: General Description FeaturesLuis Luis GarciaNo ratings yet

- Current Sensor - LTSR 15-NPDocument3 pagesCurrent Sensor - LTSR 15-NPFadhil Tresna NugrahaNo ratings yet

- ACPI Regulator/Controller For Dual Channel DDR Memory Systems FeaturesDocument15 pagesACPI Regulator/Controller For Dual Channel DDR Memory Systems FeaturesnakameiyoNo ratings yet

- P1027P65 (SMPS)Document30 pagesP1027P65 (SMPS)Jesus Silva67% (3)

- Irams 06 Up 60 ADocument18 pagesIrams 06 Up 60 AAndré Roberto EvangelistaNo ratings yet

- Data SheetDocument7 pagesData SheetOvi PanteaNo ratings yet

- Datasheet PDFDocument32 pagesDatasheet PDFMochamad AlbiNo ratings yet

- MP3389 r1.04Document16 pagesMP3389 r1.04Andres Alegria100% (1)

- Feature Applications General Description: Rev. 1.10 1 August 23, 2012 Rev. 1.00 PB August 23, 2012Document11 pagesFeature Applications General Description: Rev. 1.10 1 August 23, 2012 Rev. 1.00 PB August 23, 2012Enéas BaroneNo ratings yet

- Fet 60NF06Document9 pagesFet 60NF06Anh Nguyễn HoàngNo ratings yet

- TDA7262Document9 pagesTDA7262Nelson PereiraNo ratings yet

- DL 0165 RDocument20 pagesDL 0165 Rledu035No ratings yet

- LD7750-DS Fuente TCL GermanDocument20 pagesLD7750-DS Fuente TCL GermanAndres Alegria100% (1)

- FSDH0265RN, FSDM0265RN: Green Mode Fairchild Power Switch (FPS)Document20 pagesFSDH0265RN, FSDM0265RN: Green Mode Fairchild Power Switch (FPS)Wsad WsadNo ratings yet

- 3685 FBDocument24 pages3685 FBPravin MevadaNo ratings yet

- CQ 0765RTDocument24 pagesCQ 0765RTsonivitel100% (2)

- Datasheet sg6105dDocument13 pagesDatasheet sg6105dCartman SantosNo ratings yet

- IRAMX16UP60ADocument18 pagesIRAMX16UP60Atheylor1990No ratings yet

- 000 1 L6380Document9 pages000 1 L6380Ishak Khan GulamNo ratings yet

- Richtek RT7247ADocument15 pagesRichtek RT7247Ajhg-crackmeNo ratings yet

- STR W6735Document14 pagesSTR W6735proctepNo ratings yet

- CCFL Inverter IC OZ960Document12 pagesCCFL Inverter IC OZ960davesworkshopNo ratings yet

- Intelligent CCFL Inverter Controller: FeaturesDocument12 pagesIntelligent CCFL Inverter Controller: FeaturesMirosław DżumakNo ratings yet

- Tda 7372Document10 pagesTda 7372tuanbkfetNo ratings yet

- Ap 8012Document10 pagesAp 8012Shubham AdkeNo ratings yet

- SG3524Document9 pagesSG3524gettinNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Oyster ShellDocument3 pagesOyster ShellCheyzeeNo ratings yet

- CA Rohan Nimbalkar - Summary - NotesDocument78 pagesCA Rohan Nimbalkar - Summary - NotesPrachi GuptaNo ratings yet

- Business Finance - Chapter 2 Assessment 1 - Rudsan T.Document3 pagesBusiness Finance - Chapter 2 Assessment 1 - Rudsan T.Rudsan TurquezaNo ratings yet

- Alpha BrochureDocument9 pagesAlpha BrochurefaisalNo ratings yet

- World Trade Center PhysicsDocument16 pagesWorld Trade Center PhysicsmarxshultzNo ratings yet

- Control Lab Report 1Document11 pagesControl Lab Report 1Waqas IqrarNo ratings yet

- Bio Mechanics of The KneeDocument69 pagesBio Mechanics of The KneeOnwaree Ing95% (19)

- GC 1999 10 The Siege of HarnaldaDocument5 pagesGC 1999 10 The Siege of HarnaldaErszebeth100% (3)

- Limited Liability Company Articles of Organization: Guila Marie PrietoDocument4 pagesLimited Liability Company Articles of Organization: Guila Marie PrietoH.I.M Dr. Lawiy Zodok100% (1)

- Waste Management Strategies of Class Advisers of Pag-Asa National High School For The SY: 2018-2019Document12 pagesWaste Management Strategies of Class Advisers of Pag-Asa National High School For The SY: 2018-2019ShekinahNo ratings yet

- Causes of DeforestationDocument3 pagesCauses of DeforestationZakaria GhaniNo ratings yet

- Unit 1: SAP S/4HANA Production Planning OverviewDocument2 pagesUnit 1: SAP S/4HANA Production Planning OverviewSaphana CfinNo ratings yet

- Karnataka Apartment Act 1972Document7 pagesKarnataka Apartment Act 1972cnath_1No ratings yet

- MSD DRRM Coordinator International Seminar WorkshopDocument4 pagesMSD DRRM Coordinator International Seminar WorkshopRojanie EstuitaNo ratings yet

- A Survey of Energy and Environmental Applications of Glass: Richard K. Brow, Melodie L. SchmittDocument9 pagesA Survey of Energy and Environmental Applications of Glass: Richard K. Brow, Melodie L. SchmittSupriya RaiNo ratings yet

- Leonardo Da Vinci's Most Famous Masterpiece Mona Lisa, Oil On WoodDocument3 pagesLeonardo Da Vinci's Most Famous Masterpiece Mona Lisa, Oil On WoodLianna RodriguezNo ratings yet

- Community Medicine: Cagayan State University-Carig CampusDocument5 pagesCommunity Medicine: Cagayan State University-Carig CampusRich MarkNo ratings yet

- Maths P1 - Topic Revision Memos (XL)Document103 pagesMaths P1 - Topic Revision Memos (XL)mvelonhlemsimangoNo ratings yet

- 3 CH 6Document149 pages3 CH 6eeesolomon2124No ratings yet

- Diesel Smoke Emissions EngDocument8 pagesDiesel Smoke Emissions EngVincent De VeraNo ratings yet

- Part 61 MOS Vol 1Document74 pagesPart 61 MOS Vol 1Jake BlatchfordNo ratings yet

- Assessment: Manage Risk BSBRSK501Document54 pagesAssessment: Manage Risk BSBRSK501Nidhi GuptaNo ratings yet

- Effect of Air Services Availability On International Visitors To New ZealandDocument32 pagesEffect of Air Services Availability On International Visitors To New Zealanddtduval2258No ratings yet

- DiluentsDocument15 pagesDiluentsvishnukiranniperNo ratings yet

- Color Monitor: Service ManualDocument32 pagesColor Monitor: Service ManualDeki PericNo ratings yet

- g9 1q HealthDocument3 pagesg9 1q HealthMikoy DenlosNo ratings yet

- Doc Exam Ppla Lapla en GesamtDocument252 pagesDoc Exam Ppla Lapla en GesamtFhnbnnv100% (1)

- New-Era 190825 03 PDFDocument2 pagesNew-Era 190825 03 PDFGNo ratings yet