Professional Documents

Culture Documents

Unit 4 - Week 3: Assignment 3

Uploaded by

Jayaganesh KhandigeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit 4 - Week 3: Assignment 3

Uploaded by

Jayaganesh KhandigeCopyright:

Available Formats

Joining Technologies for metals - - Unit 4 - Week 3 https://onlinecourses-archive.nptel.ac.in/noc19...

reviewer4@nptel.iitm.ac.in ▼

Courses » Joining Technologies for metals

Announcements Course Ask a Question Progress FAQ

Unit 4 - Week 3

Register for

Certification exam Assignment 3

The due date for submitting this assignment has passed.

Course As per our records you have not submitted this Due on 2019-03-20, 23:59 IST.

outline

assignment.

How to access 1) The function of background current in pulse GTAW is 1 point

the portal

Maintain the welding arc

Week 1

To facilitate cooling and solidification

Week 2 To fuse the substrate material

Both a and b

Week 3

No, the answer is incorrect.

Lec 11 - Newer

Score: 0

variants of Gas

tungsten arc Accepted Answers:

welding Both a and b

Lec 12 - Gas 2) The principle mechanism involved in activated flux GTAW process includes 1 point

metal arc

welding

Reversal of marangoni convection

Lec 13 -

Submerged arc

Constriction of arc plasma

welding Plastic deformation

Lec 14 - Both a and b

Electro-slag

and Electro-gas No, the answer is incorrect.

welding Score: 0

Lec 15 - Laser Accepted Answers:

beam welding Both a and b

Quiz :

3) Compared to spray transfer, the short circuit transfer requires 1 point

Assignment 3

Solution for Smaller arc gap

Assignment No.

3 Larger arc gap

Arc gap does not matter

Week 4

High welding current

© 2014 NPTEL - Privacy & Terms - Honor Code - FAQs -

A project of In association with

Funded by

1 of 3 Thursday 20 June 2019 05:52 PM

Joining Technologies for metals - - Unit 4 - Week 3 https://onlinecourses-archive.nptel.ac.in/noc19...

Poweredcurrent

High welding by

DOWNLOAD

VIDEOS

High welding voltage

Interaction High welding speed

Session

All of above

No, the answer is incorrect.

Score: 0

Accepted Answers:

High welding current

5) Constant voltage and self-regulating arc with DCEP polarity is not suitable for 1 point

Small electrode diameter

Large electrode diameter

Large electrode extension

High electrical resistivity

No, the answer is incorrect.

Score: 0

Accepted Answers:

Large electrode diameter

6) For given value of current and voltage, increase in electrode diameter during SAW process 1 point

will lead to

Wider weld bead and deeper penetration

Wider weld bead and shallow penetration

Narrow weld bead and deeper penetration

Narrow weld bead and wider penetration

No, the answer is incorrect.

Score: 0

Accepted Answers:

Wider weld bead and shallow penetration

7) Weld metal of submerged arc weld joint as compared to GTAW weld joint will have 1 point

Coarser grain structure

Finer grain structure

Wider heat affected zone

Both a and c

No, the answer is incorrect.

Score: 0

Accepted Answers:

Both a and c

8) The role of copper shoes in ESW process to 1 point

Restrict flow of molten metal outside

Act as sink to heat generated during welding

Both a and b

Generate arc

No, the answer is incorrect.

Score: 0

2 of 3 Thursday 20 June 2019 05:52 PM

Joining Technologies for metals - - Unit 4 - Week 3 https://onlinecourses-archive.nptel.ac.in/noc19...

Accepted Answers:

Both a and b

9) For a given Laser scanning speed, highest power density is required for 1 point

Melting

Alloying

Heating

Machining

No, the answer is incorrect.

Score: 0

Accepted Answers:

Machining

10)Laser welding of Al and Cu alloys is found difficult due to 1 point

High reflectivity

High thermal conductivity

Low thermal conductivity

Both a and b

No, the answer is incorrect.

Score: 0

Accepted Answers:

Both a and b

Previous Page End

3 of 3 Thursday 20 June 2019 05:52 PM

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

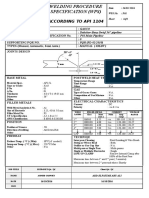

- Welding Procedure Specification Pipe - 6GDocument3 pagesWelding Procedure Specification Pipe - 6Gdndudc97% (29)

- Sample Procedure Qualification Record (PQR) : (Smaw, Gmaw, Gtaw, Fcaw, Ofw, Paw)Document2 pagesSample Procedure Qualification Record (PQR) : (Smaw, Gmaw, Gtaw, Fcaw, Ofw, Paw)Thanakit Srisaeng0% (1)

- Module 2 - Welding and Cutting Proccess PDFDocument148 pagesModule 2 - Welding and Cutting Proccess PDFTuhoyito TarahaoNo ratings yet

- NDT ReportDocument4 pagesNDT ReportTHI SEN NGUYENNo ratings yet

- HP Lub and HydraulicDocument180 pagesHP Lub and HydraulicFiliberto RodriguezNo ratings yet

- TS en Iso 15614-8Document51 pagesTS en Iso 15614-8Emin GulerNo ratings yet

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- Ecoflam Catalogue 2012Document60 pagesEcoflam Catalogue 2012manikandanNo ratings yet

- ASME IX Interpretation-Part12Document39 pagesASME IX Interpretation-Part12kevin herryNo ratings yet

- Unit 7 - Week 6: Assignment 6Document3 pagesUnit 7 - Week 6: Assignment 6Jayaganesh KhandigeNo ratings yet

- Unit 3 - Week 2: Assignment 2Document4 pagesUnit 3 - Week 2: Assignment 2Jayaganesh KhandigeNo ratings yet

- Unit 2 - Week 1: Assignment 1Document3 pagesUnit 2 - Week 1: Assignment 1Jayaganesh KhandigeNo ratings yet

- Fundamentals of Metal Forming: Fig 1.1 Fig 1.2Document49 pagesFundamentals of Metal Forming: Fig 1.1 Fig 1.2Jayaganesh KhandigeNo ratings yet

- Deformation Zone GeometryDocument8 pagesDeformation Zone GeometryJayaganesh KhandigeNo ratings yet

- Elasticity: R. Chandramouli Associate Dean-Research SASTRA University, Thanjavur-613 401Document10 pagesElasticity: R. Chandramouli Associate Dean-Research SASTRA University, Thanjavur-613 401Jayaganesh KhandigeNo ratings yet

- FORM-AT-MANU-015-E Welding Inspection ReportDocument3 pagesFORM-AT-MANU-015-E Welding Inspection ReportBOUZAIDANo ratings yet

- Poster Weldingpositions en SWDocument1 pagePoster Weldingpositions en SWAbin sha john The gipsyNo ratings yet

- Dinlasan - Electric Arc Safety WeldingDocument9 pagesDinlasan - Electric Arc Safety Weldingshin deiruNo ratings yet

- PT. Anugerah Mega Energi Daily Report: Work Time: 07.00 18.00 Work Time: 07.00 18.00Document1 pagePT. Anugerah Mega Energi Daily Report: Work Time: 07.00 18.00 Work Time: 07.00 18.00heri_prasetyadiNo ratings yet

- Mandatory Appendix e Asme BPVC Sec Ix 2023Document3 pagesMandatory Appendix e Asme BPVC Sec Ix 2023mr.bakhtiari.mahmoudNo ratings yet

- Product Catalog: Horizontal Concealed Chilled Water Fan Coil Unit Airfl Ow: 200 1400 CFMDocument18 pagesProduct Catalog: Horizontal Concealed Chilled Water Fan Coil Unit Airfl Ow: 200 1400 CFMjorge de la cruzNo ratings yet

- What Is Fusion Welding - TWI PDFDocument6 pagesWhat Is Fusion Welding - TWI PDFFarid Ahmed KhwajaNo ratings yet

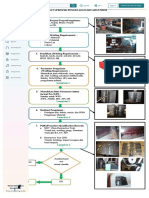

- Tugas Destructive Test Welding UNY 2017Document10 pagesTugas Destructive Test Welding UNY 2017G. YUDHA FATRIA EGIANSYAH gyudha.2019No ratings yet

- Line History SheetDocument4 pagesLine History SheetBethel NdifonNo ratings yet

- Welding Lecture 4 Fusion (Liquid) State Welding Processes (Resistance Welding)Document30 pagesWelding Lecture 4 Fusion (Liquid) State Welding Processes (Resistance Welding)Adel AbdelmaboudNo ratings yet

- Flush-Mount Room Thermostats With RS485 ModbusDocument18 pagesFlush-Mount Room Thermostats With RS485 ModbusMaximilien URBESNo ratings yet

- Kobelco Welding HandbookDocument202 pagesKobelco Welding HandbookSantiago PatitucciNo ratings yet

- RT Request: Client: Project: Epcc of Service Station SS/FD/DR Phase 2 21 (15 Units) Station Model: F10000 STOCK15Document3 pagesRT Request: Client: Project: Epcc of Service Station SS/FD/DR Phase 2 21 (15 Units) Station Model: F10000 STOCK15Muhammad Irwan MuhamadNo ratings yet

- Betag 2014Document7 pagesBetag 2014MelmakPolytronNo ratings yet

- CAT 320 Reparar BaldeDocument46 pagesCAT 320 Reparar BaldeTaller PahrNo ratings yet

- Grade 7 Shielded Metal Arc Welding (SMAW) Supplementary Learning MaterialDocument11 pagesGrade 7 Shielded Metal Arc Welding (SMAW) Supplementary Learning MaterialLorenzo InofreNo ratings yet

- Carrier 42txp-Pdc03Document16 pagesCarrier 42txp-Pdc03jake langNo ratings yet

- PQR 3G Fcaw SF71Document3 pagesPQR 3G Fcaw SF71long phamNo ratings yet

- Welding Torch As End Effector: Siddharth Kumar A. K., Rohan M VasishtaDocument4 pagesWelding Torch As End Effector: Siddharth Kumar A. K., Rohan M VasishtaRohan VashishtaNo ratings yet

- Form Request OvertimeDocument21 pagesForm Request OvertimeAndika ArdaNo ratings yet

- Application of Fan and Blower in Room Air Heater: Engineering Design (Ta 103) ProjectDocument11 pagesApplication of Fan and Blower in Room Air Heater: Engineering Design (Ta 103) ProjectManan AroraNo ratings yet