Professional Documents

Culture Documents

068 TECH F2000 Saddle Remote

Uploaded by

Tanveer AzizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

068 TECH F2000 Saddle Remote

Uploaded by

Tanveer AzizCopyright:

Available Formats

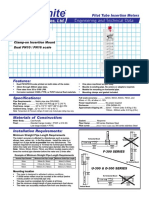

Blue-White

DigiFlo Digital Paddlewheel Meters

Industries, Ltd. Engineering and Technical Data

F-2000

Saddle Fitting

Remote Mount Display

Three Display Options:

Rate & Total Display Only

Rate, Total, Analog output

Rate, Total, Process Control

Features:

!High accuracy digital paddlewheel technology. ! Large, 8 digit LCD display, up to 4 decimal places.

! 1-1/2” thru 12” and 50mm thru 315mm pipe sizes. ! Remote mount display on panel, pipe or wall.

!Flow rate from 15 to 8000 GPM (70 to 27000 LPM) ! No significant pressure drop.

! Rate and total flow display. ! Total reset function can be disabled.

! Optional Process Control alarm or batch processing relay. ! Front panel security lock-out.

! Optional 4-20mA or 0-10VDC output. ! Field programmable.

Specifications:

Pipe Requirements: Full scale accuracy:......+/- 1%

(Inch dimensions) ...........IPS pipe size (ASTM-D-1785) Power input: ..................6-24VDC

(Metric dimensions) ........Metric pipe size (DIN 8062) Model RT units only: 4 AA batteries or AC/DC transformer

Max. Psi (bar): ...............300 PSI (20 bar) @ 70o F (21o C) All units: ................... AC/DC transformer

Max. fluid temp.: ..........PVDF saddle, 200o F (93o C) @ 0 PSI Signal Distance: ............ AC sine wave sensor = 200 ft (60 m)

........................................PVC saddle, 140o F (60o C) @ 0 PSI Optional Hall Effect sensor = 1 mile (1.6 km)

Max. ambient temp.: .....14o to 110o F/ -10o to 43o C Signal Cable: .................3 conductor shielded. Included 25 ft. (7,6 m)

Note: Temperature & Pressure ratings of meter only. Actual pipe rating may vary. Enclosure: .....................NEMA 4X (Ip56)

Max pressure drop: ......0 PSI (No significant pressure drop) Approx ship wt: ............4 lb. (1.8 kg)

Materials of Construction:

Saddle:................................... ...............PVDF or PVC

Sensor, paddlewheel, axle: ..................PVDF

Sensor & saddle O-ring seals: .............Vitonq (optional EP)

Pipe Clamp: ...........................................300 series Stainless Steel

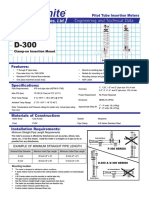

Installation Requirements: MINIMUM

Minimum Straight Pipe Length Requirements Horizontal Mount OUTPUT

LENGTH

The meter’s accuracy is affected by disturbances such as pumps, FLOW I.D.

elbows, tees, valves, etc., in the flow stream. Install the meter in a MINIMUM MINIMUM

straight run of pipe as far as possible from any disturbances. The INPUT

LENGTH

OUTPUT

LENGTH

distance required for accuracy will depend on the type of disturbance.

Recommended

Vertical

45° Acceptable 45° Acceptable

Type Of Disturbance Minimum Inlet Pipe Length Minimum Outlet Pipe Length

I.D.

MINIMUM

Flange 10 X Pipe I.D. 5 X Pipe I.D. INPUT

LENGTH

Reducer 15 X Pipe I.D. 5 X Pipe I.D.

90o Elbow 20 X Pipe I.D. 5 X Pipe I.D.

FLOW

Two Elbows -1 Direction 25 X Pipe I.D. 5 X Pipe I.D.

Two Elbows -2 Directions 40 X Pipe I.D. 5 X Pipe I.D.

Pump Or Gate Valves 50 X Pipe I.D. 5 X Pipe I.D.

Angle Mount on Horizontal Pipe Vertical Mount

Mounting location

! The meter is designed to withstand outdoor conditions. A cool, dry location, where the unit can be easily serviced is recommended.

! The meter can be mounted on horizontal or vertical runs of pipe. Mounting at the vertical (twelve o'clock) position on horizontal pipe is

recommended. Mounting anywhere around the diameter of vertical pipe is acceptable, however, the pipe must be completely full of water

at all times. Back pressure is essential on downward flows. See the minimum straight length of pipe requirement chart above.

! The meter can accurately measure flow from either direction.

Blue-White

R

DigiFlo Digital Paddlewheel Meters

Industries, Ltd.

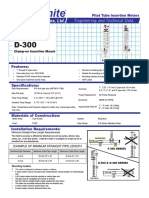

Dimensions: Maximum Temperature vs. Pressure

o o

200 F (93 C)

4.00 in.

(102 mm) Pipe Size A B 174oF (79oC)

PVDF SADDLES

1-1/2” (50mm) 3-3/16” (81) 2-9/16” (65) o o

200 F (93 C)

TEMPERATURE

®

2” (63mm) 3-3/16” (81) 2-9/16” (65) o o

148 F (64 C)

BLUE-WHITE INDUSTRIES

B 2-1/2” (75mm) 3-3/16” (81) 2-1/2” (64)

3” (90mm) 3-3/16” (81) 2-1/2” (64) 122oF (50oC)

4.00 in.

(102 mm) 8888.8888

MA BATCH # RATE TOTAL SETPOINT

4” (110mm) 3-3/16” (81) 2-1/2” (64) PVC SADDLES

o o

140 F (60 C)

6” (160mm) 3-3/16” (81) 2-7/16” (62) 96oF (36oC)

ENTER

CLEAR CLEAR Pipe O.D. 8” (200mm) 3-3/16” (81) 2-7/16” (62)

SETPOINT TOTAL

(Outside Diameter) 10” (250mm) 4-1/2” (114) 2-1/4” (57) 70oF (21oC)

A 12” (315mm) 4-1/2” (114) 2-1/4” (57) 0 60(4.1) 120(8.3) 180(12.4) 260(16.5) 300(20.7)

STATIC PRESSURE PSI (BAR)

Inches (mm)

Flow Stream Requirements:

Measuring accuracy requires a fully developed turbulent flow profile. Pulsating, swirling and other disruptions in the flow stream will effect

accuracy. Flow conditions with a Reynolds Number greater than 4000 will result in a fully developed turbulent flow. A Reynolds Number less

than 2000 is laminar flow and may result in inaccurate readings. Disturbed Flow

Fully Developed Laminar

Turbulent Flow Flow (due to swirling)

REYNOLDS NUMBER = 3160 x Q x G

D x V

Where:

Flow rate of the fluid in GPM = Q

Specific gravity of the fluid =G

Pipe inside diameter in inches = D

Fluid viscocity in centepoise = V Pipe Cross Section Flow Velocity Profile

Model Number Matrix: RT P 1 40 A4 GM 1

Display Function Calibration Flow Range

RT = Rate and Total flow 1 = Range 1

AO = Rate, Total, 4-20mA (Saddle units are offered in

PC = Rate, Total, Relay only one range)

AP = Rate, Total, 4-20mA, relay

Display Mount / Sensor Type Pipe size, type and saddle material

S = Display mounted on AC coil sensor IPS SCH40 PIPE

P = Display remote mount, AC coil sensor K4 = 1.5”, 2”, 3” PVDF

H = Display remote mount, Hall Effect sensor Calibration Units

A4 = 2.5”, 4”, 6”, 8”, 10”, 12” PVC

Pipe Size GM = U.S. Gal per min

Power IPS SCH80 PIPE GH = U.S. Gal per hour

15 = 1.5” 05 = 50mm

B = Battery holder with 4 AA cells (RT models only) K8 = 1.5”, 2”, 3” PVDF OM = U.S. Oz per min

20 = 2” 06 = 63mm

1 = U.S. Transformer, 115V60Hz/15Vdc, NEMA5/15 plug A8 = 2.5”, 4”, 6”, 8”, 10”, 12” PVC FM = Cubic Ft per min

25 = 2.5” 08 = 75mm

2 = Europe Transformer, 230V50Hz/15Vdc, CEE 7/VII plug 30 = 3” 09 = 90mm METRIC PN 10 PIPE AD = Acre Ft per day

3 = U.S. Transformer, 230V60Hz/15Vdc, NEMA 5/15 plug 40 = 4” 11 = 110mm K0 = 50, 63, 90mm PVDF LM = Liters per min

4 = U.S. Transformer, 115V60Hz and Battery back-up 60 = 6” 16 = 160mm A0 = 75, 110, 160, 200, 250, 315mm PVC LH = Liters per hour

5 = Europe Transformer, 230V50Hz and Battery back-up 80 = 8” 20 = 200mm METRIC PN 16 PIPE MH = Cubic Mtr per hour

6 = U.S. Transformer, 230V60Hz and Battery back-up 100 = 10” 25 = 250mm K6 = 50, 63, 90mm PVDF IM = Imperial Gal per min

X = No Selection (Customer must supply power) 120 = 12” 31 = 315mm A6 = 75, 110, 160, 200mm PVC IH = Imperial Gal per hour

Pipe Size, Flow Range and Display Model Options:

Models for U.S. IPS sch40 Pipe (ASTM 1785) Models for METRIC PN10 Pipe (DIN 8062)

Pipe GPM Rate & Total Analog Output Process Control Pipe LPM Rate & Total Analog Output Process Control

Size Flow Range Model Number Model Number Model Number Size Flow Range Model Number Model Number Model Number

1.5” 15 to 150 RTP115K4GM1 AOP115K4GM1 PCP115K4GM1 50mm 70 to 700 RTP105K0LM1 AOP105K0LM1 PCP105K0LM1

2” 30 to 300 RTP120K4GM1 AOP120K4GM1 PCP120K4GM1 63mm 110 to 1100 RTP106K0LM1 AOP106K0LM1 PCP106K0LM1

2.5” 40 to 400 RTP125A4GM1 AOP125A4GM1 PCP125A4GM1 75mm 150 to 1500 RTP108A0LM1 AOP108A0LM1 PCP108A0LM1

3” 60 to 600 RTP130K4GM1 AOP130K4GM1 PCP130K4GM1 90mm 230 to 2300 RTP109K0LM1 AOP109K0LM1 PCP109K0LM1

4” 100 to 1000 RTP140A4GM1 AOP140A4GM1 PCP140A4GM1 110mm 350 to 3500 RTP111A0LM1 AOP111A0LM1 PCP111A0LM1

6” 250 to 2500 RTP160A4GM1 AOP160A4GM1 PCP1B60A4GM1 160mm 720 to 7200 RTP116A0LM1 AOP116A0LM1 PCP116A0LM1

8” 400 to 4000 RTP180A4GM1 AOP180A4GM1 PCP180A4GM1 200mm 1150 to 11500 RTP120A0LM1 AOP120A0LM1 PCP120A0LM1

10” 600 to 6000 RTP1100A4GM1 AOP1100A4GM1 PCP1100A4GM1 250mm 1700 to 17000 RTP125A0LM1 AOP125A0LM1 PCP125A0LM1

12” 800 to 8000 RTP1120A4GM1 AOP1120A4GM1 PCP1120A4GM1 315mm 2700 to 27000 RTP131A0LM1 AOP131A0LM1 PCP131A0LM1

Blue-White Industries, Ltd.

R

5300 Business Drive, Huntington Beach, CA 92649

Tel: 714-893-8529 Fax: 714-894-9492 All trademarks are the property of their respective owners.

Technical data sheet #85000-068 rev.081806

www.blue-white.com Email: sales@blue-white.com

You might also like

- Convert HTML to PDF with Colors Using WkhtmltopdfDocument5 pagesConvert HTML to PDF with Colors Using WkhtmltopdfDJNo ratings yet

- Project TemplatesDocument66 pagesProject TemplatesfouzunNo ratings yet

- Al Jezeera Steel Work Profile PDFDocument44 pagesAl Jezeera Steel Work Profile PDFcetc qatarNo ratings yet

- Bit Hydraulics OptimizationDocument24 pagesBit Hydraulics OptimizationRebar Kaka100% (1)

- Te-025 System Test ScenariosDocument6 pagesTe-025 System Test Scenariosvinoth4iNo ratings yet

- Tower: Entering NEW SpheresDocument8 pagesTower: Entering NEW SpheresMitroKtaNo ratings yet

- Carbon Steel Plates TDCDocument3 pagesCarbon Steel Plates TDCshazanNo ratings yet

- Unit HydrographDocument31 pagesUnit Hydrographg7711637No ratings yet

- Design of Tank and Tubes - TransformersDocument6 pagesDesign of Tank and Tubes - TransformersAJAY KOSHY PS 18-20No ratings yet

- Method Statement Sample Fire AlarmDocument6 pagesMethod Statement Sample Fire AlarmFaress Aladdin100% (3)

- Flash Anf Fire PointDocument8 pagesFlash Anf Fire PointMUHAMMAD AKRAM100% (2)

- VANET SimulationDocument43 pagesVANET Simulationcthomas1990No ratings yet

- 070 EURO TECH F300 MetricDocument2 pages070 EURO TECH F300 MetricDaniel Andrés Ortiz MontoyaNo ratings yet

- Ficha Tecnica - Flujometro F-300Document2 pagesFicha Tecnica - Flujometro F-300PEDRO APOLONo ratings yet

- Measure flow rates from 30 to 5100 LPM with the F-300M clamp-on insertion meterDocument2 pagesMeasure flow rates from 30 to 5100 LPM with the F-300M clamp-on insertion meterJoaquin Contreras AlmidonNo ratings yet

- 85000-071 TECH F300 IPS-PipeDocument2 pages85000-071 TECH F300 IPS-PipeHenry MartinezNo ratings yet

- FLUJOMETROS BLUW WHITE 85000-071 - TECH - F300 - IPS Pipe - LIB22TMP FLUJOMETRODocument2 pagesFLUJOMETROS BLUW WHITE 85000-071 - TECH - F300 - IPS Pipe - LIB22TMP FLUJOMETROMIGUEL ANGEL VILLARREALNo ratings yet

- Almag Is 150109Document4 pagesAlmag Is 150109alisuseNo ratings yet

- Ultrasonic Flowmeter D116 Features & SpecsDocument8 pagesUltrasonic Flowmeter D116 Features & SpecsLe VinhNo ratings yet

- Ultrasonic Flowmeter SL1168PDocument8 pagesUltrasonic Flowmeter SL1168PmanoelNo ratings yet

- 203 DatasheetDocument4 pages203 DatasheetJavier Carrizo100% (1)

- P-I Transducer - P200-P290 PDFDocument4 pagesP-I Transducer - P200-P290 PDFman_y2kNo ratings yet

- SL3488D-Plus Multipath Ultrasonic Flowmeter BrochureDocument10 pagesSL3488D-Plus Multipath Ultrasonic Flowmeter BrochureNaji OmarNo ratings yet

- VIX Catálogo Flujómetro Ultrasónico Fijo UA105 UniArmsDocument4 pagesVIX Catálogo Flujómetro Ultrasónico Fijo UA105 UniArmspabloNo ratings yet

- 20200605-P117 Portable Ultrasonic FlowmeterDocument8 pages20200605-P117 Portable Ultrasonic FlowmeterRoger Cueva ZutaNo ratings yet

- Tpfada: Flush Diaphragm Pressure Transmitter With Digital Autozero & SpanDocument5 pagesTpfada: Flush Diaphragm Pressure Transmitter With Digital Autozero & SpanGopal HegdeNo ratings yet

- Mid Static Pressure-DUCTEDDocument29 pagesMid Static Pressure-DUCTEDsyed mustafa aliNo ratings yet

- 205i Innova SonicDocument4 pages205i Innova SonictengmorganNo ratings yet

- INSTRUMENSERVIS SAS-MEDIDOR DE FLUJO ULTRASÓNICO PORTÁTIL PFLOW P118iDocument8 pagesINSTRUMENSERVIS SAS-MEDIDOR DE FLUJO ULTRASÓNICO PORTÁTIL PFLOW P118iFabianAndresCuervoCuervoNo ratings yet

- 8017031Document4 pages8017031alisuseNo ratings yet

- Suspended Solid Flue GasDocument2 pagesSuspended Solid Flue Gasdeepdaman18891No ratings yet

- MCRWD-40SLPM-TFTRD-DB15-MODBUS-485-54X54-SAE-EPDM-CC: Alicat Part Number DecoderDocument1 pageMCRWD-40SLPM-TFTRD-DB15-MODBUS-485-54X54-SAE-EPDM-CC: Alicat Part Number DecoderGourav SharmaNo ratings yet

- B. Brosur - SUNCENT-X8 Product Brochure S Ver1 0 2021Document5 pagesB. Brosur - SUNCENT-X8 Product Brochure S Ver1 0 2021Muhammad Rizki SetiawanNo ratings yet

- FLOW38 - en 0217Document4 pagesFLOW38 - en 0217Diego CastroNo ratings yet

- Measuring compressed air and gas flowDocument20 pagesMeasuring compressed air and gas flowDaniel DanielNo ratings yet

- Fan Coil Expansión Directa 220V/1PH/60HzDocument2 pagesFan Coil Expansión Directa 220V/1PH/60HzDavid IslaNo ratings yet

- Bermad Combination Air Valve C75 - Product-Page - English - 9-2018Document4 pagesBermad Combination Air Valve C75 - Product-Page - English - 9-2018M MNo ratings yet

- Flow Meter Tech Specs F113AIDocument4 pagesFlow Meter Tech Specs F113AIhalcaldeNo ratings yet

- Vortex Flow Meter Yokogawa CatalogueDocument5 pagesVortex Flow Meter Yokogawa CataloguepsaayoNo ratings yet

- TVR LX 4TVD Media Presión DC Fan - Manual de Características Técnicas (Inglés)Document27 pagesTVR LX 4TVD Media Presión DC Fan - Manual de Características Técnicas (Inglés)Molnar LeventeNo ratings yet

- Contro Air 500 - SpecDocument4 pagesContro Air 500 - SpecGabriel MendezNo ratings yet

- Corona E: Electronic Meter - Multi-JetDocument5 pagesCorona E: Electronic Meter - Multi-JetSoluciones Integrales Ingetronik S.A.SNo ratings yet

- Finetek Diesel Oil Flowmeter EPR Paddle Wheel Flow Meter - New - 214250548Document16 pagesFinetek Diesel Oil Flowmeter EPR Paddle Wheel Flow Meter - New - 214250548ah14600146No ratings yet

- SONDAR 5000 ManualDocument44 pagesSONDAR 5000 ManualovadircNo ratings yet

- GLP-TDS-100 Clamp On Type Ultrasonic Flow Meter: Working PrincipleDocument14 pagesGLP-TDS-100 Clamp On Type Ultrasonic Flow Meter: Working PrincipleJuan DavidNo ratings yet

- Ultrasonic Flowmeter D118Document8 pagesUltrasonic Flowmeter D118Javier Carrizo100% (1)

- FTT20Document2 pagesFTT20mohamadhosein mohamadiNo ratings yet

- EPR Paddle Wheel Flow MeterDocument16 pagesEPR Paddle Wheel Flow MeterAndrés VargasNo ratings yet

- Air 70 Brink PrezentacijaDocument32 pagesAir 70 Brink PrezentacijaDjordjeNo ratings yet

- Ds - Kmicro-En - L Kmicro Data SheetDocument4 pagesDs - Kmicro-En - L Kmicro Data SheetJaime Nuñez BlancoNo ratings yet

- Co Sensor Transmitter Carbon Monoxide Co110Document4 pagesCo Sensor Transmitter Carbon Monoxide Co110mohamad chaudhariNo ratings yet

- JT 121 PP PDFDocument2 pagesJT 121 PP PDFRāĦul LuĦārNo ratings yet

- JT 121 PP PDFDocument2 pagesJT 121 PP PDFRāĦul LuĦārNo ratings yet

- EC EncodersDocument31 pagesEC EncodersDenny MaiaNo ratings yet

- TankPro Submersible Level SensorDocument2 pagesTankPro Submersible Level SensorhasaniconNo ratings yet

- Manual Rooftop On-OffDocument73 pagesManual Rooftop On-OffGerman CiclonNo ratings yet

- Pressure TransmitterDocument8 pagesPressure TransmitterPrihartono Danan WingusNo ratings yet

- HD 242 Flexible HoseDocument4 pagesHD 242 Flexible HoseSelvakumar EkambaramNo ratings yet

- Open Channel Flow Meter User ManualDocument24 pagesOpen Channel Flow Meter User ManualkepyarNo ratings yet

- Kview10: Quad Channel Controller With MODBUS RTU CommunicationsDocument2 pagesKview10: Quad Channel Controller With MODBUS RTU CommunicationsMahesh DivakarNo ratings yet

- Insertion Flow Meter Data-SheetDocument2 pagesInsertion Flow Meter Data-SheetKareem RMGNo ratings yet

- CIAC_CA41_CB41ADocument4 pagesCIAC_CA41_CB41AronnysiguasNo ratings yet

- Ab Tempblue - TBF41D Piso TechoDocument3 pagesAb Tempblue - TBF41D Piso TechoFrank Antony Velasquez TerronesNo ratings yet

- Microflex-D Ultrasonic Level Transmitter Technical SpecificationsDocument6 pagesMicroflex-D Ultrasonic Level Transmitter Technical SpecificationsTejas Shah0% (1)

- Bermad Combination Air Valve C70 - Product-Page - English - 9-2018Document4 pagesBermad Combination Air Valve C70 - Product-Page - English - 9-2018M MNo ratings yet

- ALTO-Q Service ManualDocument17 pagesALTO-Q Service ManualPablo GomsaNo ratings yet

- Pump Protection Valve OverviewDocument9 pagesPump Protection Valve OverviewReyNo ratings yet

- PRIMOTIG - AC - DC - New Tig MachineDocument2 pagesPRIMOTIG - AC - DC - New Tig MachineYm PrathishNo ratings yet

- DB WMZ DFS Imf enDocument4 pagesDB WMZ DFS Imf enZakaria Ait MehdiNo ratings yet

- Airborne Particle Classification Grades in Pharmaceutical ProductionDocument1 pageAirborne Particle Classification Grades in Pharmaceutical ProductionTanveer AzizNo ratings yet

- SEASIF Company ProfileDocument64 pagesSEASIF Company ProfileTanveer AzizNo ratings yet

- PROGER Company ProfileDocument122 pagesPROGER Company ProfileTanveer AzizNo ratings yet

- KsaprofileenDocument24 pagesKsaprofileenTanveer AzizNo ratings yet

- Mep BrochureDocument16 pagesMep BrochureTanveer AzizNo ratings yet

- Cleanroom Design FormDocument6 pagesCleanroom Design FormTanveer AzizNo ratings yet

- Mechanical Valves & Flexible Joints: Leading The Way in Piping NeedsDocument40 pagesMechanical Valves & Flexible Joints: Leading The Way in Piping NeedsTanveer AzizNo ratings yet

- 52000427BD-Alliance-Airport Expansion (R-2) - EmailDocument3 pages52000427BD-Alliance-Airport Expansion (R-2) - EmailTanveer AzizNo ratings yet

- ProfileDocument23 pagesProfileTanveer AzizNo ratings yet

- Control Valves: Leading The Way in Piping NeedsDocument32 pagesControl Valves: Leading The Way in Piping NeedsTanveer AzizNo ratings yet

- 4-1 EN Frese DELTA T Control System JUN 17Document5 pages4-1 EN Frese DELTA T Control System JUN 17Tanveer AzizNo ratings yet

- Working Principle of Holtop Fresh Air Dehumidification SystemsDocument1 pageWorking Principle of Holtop Fresh Air Dehumidification SystemsTanveer AzizNo ratings yet

- 03 - Thermostat & Accessories - EmailDocument24 pages03 - Thermostat & Accessories - EmailTanveer AzizNo ratings yet

- Eco-clean ERV Improves Air QualityDocument6 pagesEco-clean ERV Improves Air QualityTanveer AzizNo ratings yet

- UL Listed 42 Bar HFC-227ea (FM-200) Clean Agent SystemDocument6 pagesUL Listed 42 Bar HFC-227ea (FM-200) Clean Agent SystemTanveer AzizNo ratings yet

- OSID Smoke Detection: FeaturesDocument2 pagesOSID Smoke Detection: FeaturesTanveer AzizNo ratings yet

- MOSELECTRO Group of CompaniesDocument23 pagesMOSELECTRO Group of CompaniesTanveer AzizNo ratings yet

- ERV Intelligent Controllers: Latest Update For Holtop Intelligent Controllers: WIFI Connection FunctionDocument1 pageERV Intelligent Controllers: Latest Update For Holtop Intelligent Controllers: WIFI Connection FunctionTanveer AzizNo ratings yet

- Kruvent Industries Fan Spec SheetDocument1 pageKruvent Industries Fan Spec SheetTanveer AzizNo ratings yet

- 2 PDFDocument1 page2 PDFTanveer AzizNo ratings yet

- Item 9A Fan Model: CFT 630 C/W Fda 630 C SYSTEM: 21500 CFM at Est. 100 PA Motor: 11Kw / 4 Pole / Class FDocument1 pageItem 9A Fan Model: CFT 630 C/W Fda 630 C SYSTEM: 21500 CFM at Est. 100 PA Motor: 11Kw / 4 Pole / Class FTanveer AzizNo ratings yet

- Item 1 FAM MODEL: TDA 560/12AA/5/24 SYSTEM: 3400 CFM at 180 PA Motor: 0.75Kw / 4 Pole / Class FDocument1 pageItem 1 FAM MODEL: TDA 560/12AA/5/24 SYSTEM: 3400 CFM at 180 PA Motor: 0.75Kw / 4 Pole / Class FTanveer AzizNo ratings yet

- 2 PDFDocument1 page2 PDFTanveer AzizNo ratings yet

- 7Document1 page7Tanveer AzizNo ratings yet

- Item 1 FAM MODEL: TDA 560/12AA/5/24 SYSTEM: 3400 CFM at 180 PA Motor: 0.75Kw / 4 Pole / Class FDocument1 pageItem 1 FAM MODEL: TDA 560/12AA/5/24 SYSTEM: 3400 CFM at 180 PA Motor: 0.75Kw / 4 Pole / Class FTanveer AzizNo ratings yet

- Coil Selection FormatDocument6 pagesCoil Selection FormatTanveer AzizNo ratings yet

- Reb500 Test ProceduresDocument54 pagesReb500 Test ProceduresaladiperumalNo ratings yet

- Ancillary Products: DualproofDocument24 pagesAncillary Products: DualproofNightly OwlNo ratings yet

- Engineering Drawing: (NSQF) 1 YearDocument80 pagesEngineering Drawing: (NSQF) 1 YearAkshay Kumar KNo ratings yet

- Mixer SoundDocument12 pagesMixer SoundRebeca FernandezNo ratings yet

- Eview: Retentive Aids in Maxillofacial Prosthodontics - A ReviewDocument5 pagesEview: Retentive Aids in Maxillofacial Prosthodontics - A ReviewjoephinNo ratings yet

- SI3000 Mobile WiMAX en WebDocument8 pagesSI3000 Mobile WiMAX en WebBakyt-Bek MurzabaevNo ratings yet

- Logic GateDocument3 pagesLogic Gateglobalwarming106No ratings yet

- Thermodynamicspast QuestionsDocument29 pagesThermodynamicspast QuestionsHimal TimsinaNo ratings yet

- BARACARBDocument1 pageBARACARBvava86No ratings yet

- Kvpy Thermal Expansion PDFDocument7 pagesKvpy Thermal Expansion PDFstudysteps.inNo ratings yet

- Gravel Roads Maintenance and Design ManualDocument104 pagesGravel Roads Maintenance and Design ManualJhonnyTiradoChumaceroNo ratings yet

- The Tower Undergraduate Research Journal Volume VI, Issue IDocument92 pagesThe Tower Undergraduate Research Journal Volume VI, Issue IThe Tower Undergraduate Research JournalNo ratings yet

- Wall Connector Installation Manual 80A en USDocument39 pagesWall Connector Installation Manual 80A en USdaks4u100% (1)

- RISK ASSESSMENT White Paper: A Harmonious ApproachDocument8 pagesRISK ASSESSMENT White Paper: A Harmonious ApproachMaduroNo ratings yet

- Cooling Water System : Daily Log Sheet Date: .. Shift TimeDocument4 pagesCooling Water System : Daily Log Sheet Date: .. Shift TimeNata ChaNo ratings yet

- Patient Billing SystemDocument226 pagesPatient Billing SystemknaveenrajNo ratings yet

- Basilica of TrajanDocument9 pagesBasilica of TrajanKavya Eranagoudar MallanagoudarNo ratings yet

- Document From Mirha FatimaDocument16 pagesDocument From Mirha Fatimaafrah afriNo ratings yet

- CO DMA 1042 MetrologyDocument9 pagesCO DMA 1042 MetrologyfarizanNo ratings yet

- Computaion IntelligentDocument624 pagesComputaion IntelligentThaiHuynhNgocNo ratings yet

- TFFT Blow Out Procedures 1Document13 pagesTFFT Blow Out Procedures 1Nathaniel E. Barrios FuentesNo ratings yet

- How Many Watt Solar Panel To Charge Deep Cycle Battery - EditedDocument5 pagesHow Many Watt Solar Panel To Charge Deep Cycle Battery - EditedalexNo ratings yet