Professional Documents

Culture Documents

Tool Model: Hy-10Xlt: Standard Torque Chart

Tool Model: Hy-10Xlt: Standard Torque Chart

Uploaded by

JaimEdu CortesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tool Model: Hy-10Xlt: Standard Torque Chart

Tool Model: Hy-10Xlt: Standard Torque Chart

Uploaded by

JaimEdu CortesCopyright:

Available Formats

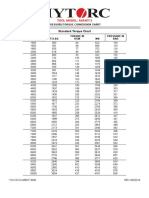

HYTORC

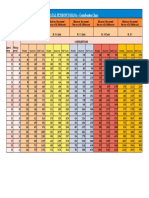

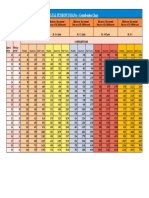

TOOL MODEL: HY-10XLT

PRESSURE/TORQUE CONVERSION CHART

Standard Torque Chart

PRESSURE IN TORQUE IN PRESSURE IN

PSI FT. LBS. KGM NM BAR

1500 1755 243 2379 104

1600 1864 258 2527 110

1800 2082 288 2822 124

2000 2300 318 3118 138

2200 2526 349 3424 152

2400 2752 381 3731 165

2600 2978 412 4037 179

2800 3204 443 4343 193

3000 3430 474 4650 207

3200 3656 506 4956 220

3400 3882 537 5262 234

3600 4108 568 5569 248

3800 4334 599 5875 262

4000 4560 631 6182 276

4200 4792 663 6496 290

4400 5024 695 6811 303

4600 5256 727 7125 317

4800 5488 759 7440 331

5000 5720 791 7754 345

5200 5948 823 8063 358

5400 6176 854 8372 372

5600 6404 886 8681 386

5800 6632 917 8990 400

6000 6860 949 9299 414

6200 7094 981 9617 427

6400 7328 1013 9934 441

6600 7562 1046 10251 455

6800 7796 1078 10568 468

7000 8030 1111 10885 482

7200 8264 1143 11203 496

7400 8498 1175 11520 510

7600 8732 1208 11837 524

7800 8966 1240 12154 538

8000 9200 1272 12472 552

8200 9432 1304 12786 565

8400 9664 1337 13101 579

8600 9896 1369 13415 593

8800 10128 1401 13730 607

9000 10360 1433 14044 620

9200 10592 1465 14359 634

9400 10824 1497 14673 648

9600 11056 1529 14988 662

9800 11288 1561 15302 676

10000 11520 1593 15617 690

* ISO DOCUMENT 9000 REV. 09/1993

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Your HYTORC TORQUE MACHINE is a power tool, and as with any power tool, certain safety precautions should be

observed to avoid accidents or personal injury. The following tips will assist you.

• READ ALL INSTUCTIONS.

• KEEP WORK AREA CLEAN AND WELL LIT.

• CONSIDER WORK AREA ENVIRONMENT. Electrical Pumps should never be used in an atmosphere which can be

considered potentially volatile. If there is any doubt, use an air pump. Also Note: metal to metal contact can cause sparks, precautions

should be taken.

• AVOID PREMATURE TOOL STARTING. The Pump Remote Control is for the TOOL OPERATOR only.

• STAY CLEAR DURING OPERATION. In most cases, the tool will allow “hands free” operation. If the tool must be held or steadied

during operation, use alternative means of securing the tool to the application

• GUARD AGAINS ELECTRIC SHOCK. Ensure the pump is properly grounded and the proper voltage is being used.

• STORE IDLE TOOLS. When not in use, tool sand accessories should be properly stored to avoid deterioration

• USE RIGHT TOOL. Don’t force small tools or attachments to do the job of a larger tool. Don’t use a tool for purposes not intended.

• PROPER SAFETY ATTIRE. When handling/operating hydraulic equipment use work gloves, hard hats, safety shoes and other

applicable clothing.

• USE SAFETY GLASSES.

• MOVING EQUIPMENT. Do not use hydraulic hoses, uni-swivels, pump power or remote cords as means of moving the equipment.

• MAINTAIN TOOLS WITH CARE. For top performance, inspect tools, powerpack and accessories for visual damage frequently and

always prior to use. Always follow instruction for proper tool and pump maintenance. Refer to the Operations Maintenance Section for

further clarification

• STAY ALERT. Watch what you are doing. Use Common sense. Do not use power equipment under the influence of any mood altering

substances.

• PRIOR TO OPERATION

Ensure that all hydraulic connections are securely connected and there is no leakage

Verify that the Hydraulic hoses are not kinked or otherwise damaged.

Ensure the square drive and its retainer are fully and securely engaged.

Be certain that all connectors, elbows, fitting and swivels are not bent, loose or damaged.

• PRIOR TO USE.

Check sockets for size, quality and flaws. (Do not use if questionable)

Cycle tool to ensure proper function.

Locate a solid, secure reaction point.

Be sure the reaction arm retaining clamp is fully engaged.

Be sure the hydraulic hoses are free of the reaction point.

Pressurize the system momentarily; if the tool tends to “ride up” or to “creep”, stop and re-adjust the reaction arm to a more solid and

secure position.

NOTE: Remain clear of the reaction arm during operation and never put body parts between reaction arm and reaction surfaces.

• ALWAYS USE QUALITY ACCESSORIES. Always use top quality impact sockets in good condition which are the correct size and

fully engage the nut. Hidden flaws, however, remain a possibility which could cause breakage, so stay clear of sockets during operation

• DO NOR USE other equipment to enhance performance (Hammer on Socket/Tool)

NOTE: Hytorc Pumps are designed to operate Hytorc Tools only. Damage may occur to the pump or the product that is being operated

due to misuse.

SAVE THESE INSTRUCTIONS FOR FUTURE USE!

You might also like

- 1333-How To Stroke Wrinkles Right Out of Your FaceDocument5 pages1333-How To Stroke Wrinkles Right Out of Your FaceTinuola WritingNo ratings yet

- Claude Lévi-Strauss - The Way of The Masks (2008, UBC Press - University of Washington Press) PDFDocument267 pagesClaude Lévi-Strauss - The Way of The Masks (2008, UBC Press - University of Washington Press) PDFBerin Ceskic100% (1)

- AVANTI 3 Torque Conversion ChartDocument2 pagesAVANTI 3 Torque Conversion ChartJovani SecrettiNo ratings yet

- XLCT 14Document2 pagesXLCT 14carlosNo ratings yet

- Hytorc Avanti 3 Torque ChartDocument2 pagesHytorc Avanti 3 Torque ChartDarwin Tovar ZuriqueNo ratings yet

- Tabla STEALTH 14Document2 pagesTabla STEALTH 14luz_cuellar_15No ratings yet

- mxt10 PDFDocument2 pagesmxt10 PDFTaufikNo ratings yet

- Captura de Pantalla 2022-03-30 A La(s) 20.30.14Document2 pagesCaptura de Pantalla 2022-03-30 A La(s) 20.30.14Manuel CaipoNo ratings yet

- Tool Model: HY-3MXT: Pressure/Torque Conversion ChartDocument2 pagesTool Model: HY-3MXT: Pressure/Torque Conversion ChartBhavin GamiNo ratings yet

- ICE 1 Torque Conversion ChartDocument2 pagesICE 1 Torque Conversion ChartDeivid BezerraNo ratings yet

- Standard Torque Chart: Tool Model: MXT 1Document2 pagesStandard Torque Chart: Tool Model: MXT 1Wahyu WidiyantoNo ratings yet

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- EDGE 6 - Torque - Conversion - ChartDocument1 pageEDGE 6 - Torque - Conversion - ChartindunilNo ratings yet

- GC-3000 Torque ChartDocument1 pageGC-3000 Torque Chartgerryocnahron86No ratings yet

- RTX04 Torque ChartDocument1 pageRTX04 Torque ChartYang Kyo OhNo ratings yet

- RT10 Torque ChartDocument2 pagesRT10 Torque ChartRoy Ramos100% (1)

- Pressure Versus Torque - S-Series Torque WrenchesDocument5 pagesPressure Versus Torque - S-Series Torque WrenchesManga MinNo ratings yet

- Atlas Copco TFX08 Torque ChartDocument1 pageAtlas Copco TFX08 Torque Chartgauthamac07No ratings yet

- Pressure Vs Torque Conversion Chart: Titan T Series ToolsDocument1 pagePressure Vs Torque Conversion Chart: Titan T Series ToolsHanselPerezAguirreNo ratings yet

- HTL DS Series Torque Pressure ChartDocument1 pageHTL DS Series Torque Pressure ChartElmo JuiceNo ratings yet

- Sitio WebDocument15 pagesSitio WebRoberto RodriguezNo ratings yet

- HighTensileFastners PDFDocument24 pagesHighTensileFastners PDFMallika SahniNo ratings yet

- Polycab Price List 16th October 2021Document2 pagesPolycab Price List 16th October 2021Kushal DixitNo ratings yet

- Satuan GDocument1 pageSatuan GWoro IndrianiNo ratings yet

- DIN 2215 V Belt SpecificationDocument1 pageDIN 2215 V Belt SpecificationumeshNo ratings yet

- Stealth Torque Pressure ChartDocument3 pagesStealth Torque Pressure Chartnarft narftNo ratings yet

- PH Hydraulic Torque Wrench Instruction ManualDocument23 pagesPH Hydraulic Torque Wrench Instruction ManualLikLiek WahahaNo ratings yet

- Partial Horizontal Tank Volumes: ParametersDocument4 pagesPartial Horizontal Tank Volumes: ParametersSagar DhuriNo ratings yet

- FLOWTITE Handling and StorageDocument13 pagesFLOWTITE Handling and StorageMohammed khaleelNo ratings yet

- 3MXT Torque ConversionDocument2 pages3MXT Torque ConversionRodrigo SanzNo ratings yet

- Kode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)Document7 pagesKode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)eniNo ratings yet

- Indice IntraindustrialDocument17 pagesIndice IntraindustrialJuan Camilo ArboledaNo ratings yet

- XLCTTorqueDocument4 pagesXLCTTorqueSebastin DrignyNo ratings yet

- catchment area to runoff yield 2 ١Document1 pagecatchment area to runoff yield 2 ١Ahmed NabilNo ratings yet

- Load Inertia TablesDocument7 pagesLoad Inertia TablesgabrielaNo ratings yet

- Test 11Document3 pagesTest 11shinjuvijayNo ratings yet

- RR KABEL Price List - LT HT Cables - 01st February 2023Document4 pagesRR KABEL Price List - LT HT Cables - 01st February 2023threephase electricNo ratings yet

- Laboratory Exercise No. 5 Rheological PropertiesDocument16 pagesLaboratory Exercise No. 5 Rheological PropertiesANIME CHANNo ratings yet

- Measurements For Anchor-Chain and AccessoriesDocument4 pagesMeasurements For Anchor-Chain and AccessoriesOzata TersanesiNo ratings yet

- Phone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Document2 pagesPhone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Akhila kumarNo ratings yet

- Apy ChartDocument1 pageApy ChartClassicaverNo ratings yet

- PMAPY ChartDocument1 pagePMAPY ChartRamsharan KumarNo ratings yet

- Apy ChartDocument1 pageApy ChartTechnology GamerNo ratings yet

- Apy ChartDocument1 pageApy ChartMohit PathaniaNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFPravrutti DahiwaleNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFSHUBHAJIT NANDINo ratings yet

- Apy ChartDocument1 pageApy ChartPRANAV MUKTIBODHNo ratings yet

- Apy ChartDocument1 pageApy ChartUday GopalNo ratings yet

- Apy ChartDocument1 pageApy Chartvinay chaudhariNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFchannel SNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFDhirendra Singh patwalNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFavinash1987100% (1)

- APY Chart PDFDocument1 pageAPY Chart PDFRahul TadeNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFAswin AbiNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFsabarishgandavarapuNo ratings yet

- Apy ChartDocument1 pageApy Chartkrishna garaiNo ratings yet

- Apy ChartDocument1 pageApy Chartvmcon kkl 2020No ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFDeep Kumar0% (1)

- Apy ChartDocument1 pageApy ChartJai mishraNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionFrom EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionNo ratings yet

- Mini Project Report - Format (2023-24) (AI)Document17 pagesMini Project Report - Format (2023-24) (AI)nikunjNo ratings yet

- Index: FTP Corporation Private LimitedDocument7 pagesIndex: FTP Corporation Private LimitedNavjosh Singh AtwalNo ratings yet

- Reference Examples: Republic of Singapore NavyDocument3 pagesReference Examples: Republic of Singapore Navyappril26No ratings yet

- Pir SensorDocument3 pagesPir SensorratheeshbrNo ratings yet

- Saac Newton: Early Life and EducationDocument9 pagesSaac Newton: Early Life and EducationGabriel André AlvesNo ratings yet

- Aluminum Alloys Designation NormDocument15 pagesAluminum Alloys Designation NormBurcu YıldızNo ratings yet

- Lab Manual 03: University of Engineering and Technology, Taxila Faculty of Telecommunication and Information EngineeringDocument11 pagesLab Manual 03: University of Engineering and Technology, Taxila Faculty of Telecommunication and Information EngineeringSaheli MazumderNo ratings yet

- Soal Inggris-1Document8 pagesSoal Inggris-1Rigel n drum0% (1)

- Identifying Good Layer From Non LayerDocument24 pagesIdentifying Good Layer From Non Layergemma salomonNo ratings yet

- Pearl Community Rating SystemDocument560 pagesPearl Community Rating SystemAlina BarbuceanuNo ratings yet

- Megamat 10: The New Powerful Generation of MEGAMAT Single DrivesDocument2 pagesMegamat 10: The New Powerful Generation of MEGAMAT Single DrivesAndresMarcanoNo ratings yet

- Department of Education: Wekly Home Learning PlanDocument3 pagesDepartment of Education: Wekly Home Learning PlanKrizna Dingding DotillosNo ratings yet

- Evaluation HorticultureDocument1 pageEvaluation HorticultureHisham HishamNo ratings yet

- Fit Accuracy of Removable Partial Denture Metal Frameworks Using Conventional and 3D Printed TechniquesDocument6 pagesFit Accuracy of Removable Partial Denture Metal Frameworks Using Conventional and 3D Printed TechniquesArushi AgarwalNo ratings yet

- Parts Guide Manual: Bizhub C20P A00F014Document59 pagesParts Guide Manual: Bizhub C20P A00F014ANDYNo ratings yet

- Intro To Computational NeuroscienceDocument156 pagesIntro To Computational NeuroscienceMohammad Haikal bin Mohammad IsaNo ratings yet

- Part 4 Physical ScienceDocument9 pagesPart 4 Physical Sciencejerick de veraNo ratings yet

- Technical Paper-French Standard NFC 17-102 (2011)Document10 pagesTechnical Paper-French Standard NFC 17-102 (2011)Mohamad HishamNo ratings yet

- Comfort Mains All Day Breakfast: Taj Autograph CollectionDocument2 pagesComfort Mains All Day Breakfast: Taj Autograph CollectionANURAG SHELARNo ratings yet

- Introduction To Psychology II: Motivation-Ii Miss Adeela AslamDocument31 pagesIntroduction To Psychology II: Motivation-Ii Miss Adeela AslamMSaqibKhanNo ratings yet

- ESH Surveillance ChecklistDocument4 pagesESH Surveillance ChecklistIZZATI YAACOBNo ratings yet

- Aldehydes & Ketones MKA SIRDocument51 pagesAldehydes & Ketones MKA SIRcrawlskullNo ratings yet

- The African Experience - Erwin Rommel An PDFDocument66 pagesThe African Experience - Erwin Rommel An PDFAlexStoican0% (1)

- Plastics Material Selection Criteria: BY N.Mohan Kumar Cipet ChennaiDocument16 pagesPlastics Material Selection Criteria: BY N.Mohan Kumar Cipet ChennaisouravNo ratings yet

- TDC 3000 DcsDocument7 pagesTDC 3000 DcsneoamnNo ratings yet

- Analysis and Design of Analog Integrated Circuits: Unit 1 Single Stage AmplifiersDocument58 pagesAnalysis and Design of Analog Integrated Circuits: Unit 1 Single Stage AmplifiersjeevithaNo ratings yet

- Take Home Assignment of MEOW: PHY F111Document1 pageTake Home Assignment of MEOW: PHY F111renu chawlaNo ratings yet

- MinipookiesDocument3 pagesMinipookiesPotato HeadNo ratings yet