Professional Documents

Culture Documents

Installaton Vertical, Tiered Mountain

Uploaded by

Gizella Hernandez PairazamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installaton Vertical, Tiered Mountain

Uploaded by

Gizella Hernandez PairazamanCopyright:

Available Formats

S&C Omni-Rupter® Switches Vertical and Tiered-Outboard Mounting Configurations

Outdoor Distribution Catalog Number Supplement “R3” and Earliern

14.4 kV and 25 kV

Installation

Table of Contents

Section Page Section Page

Introduction Installation

Operating Considerations . . . . . . . . . . . . . . . . . . . . . . . 2 Operating Pipe Preparation. . . . . . . . . . . . . . . . . . . . . . . 9

Qualified Persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Mounting to Wood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Read this Instruction Sheet . . . . . . . . . . . . . . . . . . . . . . 3 Mounting the Switch Assembly. . . . . . . . . . . . . . . . . . . 10

Retain this Instruction Sheet. . . . . . . . . . . . . . . . . . . . . . 3 Installing the Optional Pole Band . . . . . . . . . . . . . . . . . 13

Proper Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Installing the Vertical Operating Pipe

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 and Operating Handle (³⁄₄ IPS). . . . . . . . . . . . . . . . 14

Installing the Vertical Operating Pipe

Safety Information and Operating Handle (1¹⁄₄ IPS) . . . . . . . . . . . . . . 19

Understanding Safety-Alert Messages. . . . . . . . . . . . . . 4

Dead-Ending Conductors . . . . . . . . . . . . . . . . . . . . . . . 23

Following Safety Instructions. . . . . . . . . . . . . . . . . . . . . . 4

Connecting High-Voltage Conductors. . . . . . . . . . . . . . 24

Replacement Instructions and Labels. . . . . . . . . . . . . . . 4

Locking the Operating Handle . . . . . . . . . . . . . . . . . . . 25

Location of Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . 5

Checking Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Packing and Inspection

Packing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

n For installation instructions for Omni-Rupter Switches with Catalog Number Supplement “R4,” please refer to your local S&C Sales Office. These

instructions are also available on www.sandc.com.

August 8, 2011© S&C Electric Company Instruction Sheet 765-505

Introduction

Operating

Ç CAUTION

Considerations

The equipment covered by this publication must be selected for a specific applica-

tion and it must be installed, operated, and maintained by qualified persons who

are thoroughly trained and who understand any hazards that may be involved. This

publication is written only for such qualified persons and is not intended to be a

substitute for adequate training and experience in safety procedures for this type

of equipment.

In most applications, these interrupter switches are capable of switching rated continuous

load currents at full voltage. Consequently, no interlocking with secondary protective

equipment is required.

Circuit making and breaking is involved in the normal operation of these interrupter

switches and, as a result, precautionary “partway” opening or closing is undesirable. To

operate, swing the operating handle vigorously through its full stroke without hesita-

tion. Do not assume that the operating-handle position necessarily indicates the open or

closed position of the interrupter-switch blades. Upon completion of an opening or clos-

ing operation, visually check the position of the interrupter-switch blades to determine

that the intended position has been attained. Then tag or padlock the operating handle

in accordance with standard system operating procedures. In all cases make certain that

the operating handle is locked before “walking away.” Note: These interrupter switches

are not intended for breaking fault currents.

Qualified Persons

Ç WARNING

The equipment covered by this publication must be installed, operated, and main-

tained by qualified persons who are knowledgeable in the installation, operation,

and maintenance of overhead electric power distribution equipment along with

associated hazards. A qualified person is one who is trained and competent in:

• The skills and techniques necessary to distinguish exposed live parts from nonlive

parts of electrical equipment.

• The skills and techniques necessary to determine the proper approach distances

corresponding to the voltage to which the qualified person will be exposed.

• The proper use of the special precautionary techniques, personal protective

equipment, insulating and shielding materials, and insulated tools for working

on or near exposed energized parts of electrical equipment.

These instructions are intended only for such qualified persons. They are not

intended to be a substitute for adequate training and experience in safety procedures

for this type of equipment.

2 S&C Instruction Sheet 765-505

Introduction

Read this Thoroughly and carefully read this instruction sheet before installing or operating your

Instruction Sheet S&C Omni-Rupter Switch. Familiarize yourself with “SAFETY INFORMATION” on pages

4 and 5.

Retain this NOTICE

Instruction Sheet

These instructions are for Omni-Rupter Switches with Catalog Number Supplement

“R3” and earlier. For installation instructions for Omni-Rupter Switches with Catalog

Number Supplement “R4,” please refer to your local S&C Sales Office. These instruc-

tions are also available on www.sandc.com.

This instruction sheet is a permanent part of your S&C Omni-Rupter Switch. Designate

a location where you can easily retrieve and refer to this publication.

Proper Application

Ç CAUTION

The equipment in this publication must be selected for a specific application. The

application must be within the ratings furnished for the equipment. Refer to S&C

Specification Bulletin 765-31 for complete application information.

Warranty The warranty and/or obligations described in S&C’s standard conditions of sale, as set

forth in Price Sheet 150, plus any special warranty provisions, as set forth in the appli-

cable product-line specification bulletin, are exclusive. The remedies provided in the

former for breach of these warranties shall constitute immediate purchaser’s or end

user’s exclusive remedy and a fulfillment of all seller’s liability. In no event shall seller’s

liability to immediate purchaser or end user exceed the price of the specific product

which gives rise to immediate purchaser’s or end user’s claim. All other warranties

whether express or implied or arising by operation of law, course of dealing, usage of

trade or otherwise, are excluded. The only warranties are those stated in Price Sheet 150,

and THERE ARE NO EXPRESS OR IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULR PURPOSE. ANY EXPRESS WARRANTY OR OTHER

OBLIGATION PROVIDED IN PRICE SHEET 150 IS GRANTED ONLY TO THE IMMEDI-

ATE PURCHASER AND END USER, AS DEFINED THEREIN. OTHER THAN AN END

USER, NO REMOTE PURCHASER MAY RELY ON ANY AFFIRMATION OF FACT OR

PROMISE THAT RELATES TO THE GOODS DESCRIBED HEREIN, ANY DESCRIP-

TION THAT RELATES TO THE GOODS, OR ANY REMEDIAL PROMISE INCLUDED

IN PRICE SHEET 150.

The seller’s warranties do not apply if the switch is power operated using a switch

operator of other than S&C manufacture.

S&C Instruction Sheet 765-505 3

Safety Information

Understanding There are several types of safety-alert messages which may appear throughout this instruc-

Safety-Alert Messages tion sheet as well as on labels and tags attached to the Omni-Rupter Switch. Familiarize

yourself with these types of messages and the importance of the various signal words,

as explained below.

Ç DANGER

“DANGER” identifies the most serious and immediate hazards which will likely

result in serious personal injury or death if instructions, including recommended

precautions, are not followed.

Ç WARNING

“WARNING” identifies hazards or unsafe practices which can result in serious

personal injury or death if instructions, including recommended precautions, are

not followed.

Ç CAUTION

“CAUTION” identifies hazards or unsafe practices which can result in minor per-

sonal injury or product or property damage if instructions, including recommended

precautions, are not followed.

NOTICE

“NOTICE” identifies important procedures or requirements that, if not followed, can

result in product or property damage if instructions are not followed.

Following Safety If you do not understand any portion of this instruction sheet and need assistance, contact

Instructions your nearest S&C Sales Office or S&C Authorized Distributor. Their telephone numbers

are listed on S&C’s website www.sandc.com. Or call S&C Headquarters at (773) 338-

1000; in Canada, call S&C Electric Canada Ltd. at (416) 249-9171.

NOTICE

Thoroughly and carefully read this

instruction sheet before operating your

S&C Omni-Rupter Switch.

Replacement If you need additional copies of this instruction sheet, contact your nearest S&C Sales

Instructions and Office, S&C Authorized Distributor; S&C Headquarters, or S&C Electric Canada Ltd.

Labels It is important that any missing, damaged, or faded labels on the equipment be replaced

immediately. Replacement labels are available by contacting your nearest S&C Sales

Office, S&C Authorized Distributor, S&C Headquarters, or S&C Electric Canada Ltd.

4 S&C Instruction Sheet 765-505

Safety Information

Location of Safety Labels

C B D E

A F

Reorder Information for Safety Labels

Location Safety Alert Message Description Number

Switches may be energized from either side and with blades

A Ç DANGER in any position . . .

G-6580-1

Switches may be energized from either side and with blades

B Ç DANGER in any position . . .

G-6580-2

C Ç WARNING Lifting Instructions G-10031

D Ç WARNING Lifting Instructions G-5928R3

E NOTICE Do not remove this lifting bracket until . . . G-4776R1

F NOTICE To avoid overloading the terminal pads . . . G-9094

This label is placed on both sides of switch base on opposite ends.

This part is a tag which is to be removed and discarded after the switch is installed and adjusted.

S&C Instruction Sheet 765-505 5

Safety Precautions

Ç DANGER

Omni-Rupter Switches operate at high voltage. Failure to observe the precautions

below will result in serious personal injury or death.

Some of these precautions may differ from company operating procedures and rules. Where

a discrepancy exists, users should follow their company’s operating procedures and rules.

1. QUALIFIED PERSONS. Access to switches and con- 6. LOAD-INTERRUPTER SWITCH POSITION. Always

trols must be restricted only to qualified persons. See confirm the open/close position of load-interrupter

“Qualified Persons” on page 2. switches by visually observing the position of the blades.

2. SAFETY PROCEDURES. Always follow safe operating Switches may be energized from either side and with the

procedures and rules. blades in any position. Do not assume that the operating

handle position necessarily indicates the open or closed

3. PERSONAL PROTECTIVE EQUIPMENT. Always use

position of the interrupter-switch blades.

suitable protective equipment such as rubber gloves,

rubber mats, hard hats, safety glasses, and flash clothing Switches may be energized from either side and with

in accordance with safe operating procedures and rules. the blades in any position.

4. SAFETY LABELS AND TAGS. Do not remove or 7. MAINTAINING PROPER CLEARANCE. Always

obscure any of the “DANGER,” “WARNING,” “CAU- maintain proper clearance from energized components.

TION,” or “NOTICE” labels and tags. Remove tags ONLY 8. OPERATION. Circuit making and breaking is involved

if instructed to do so. in the normal operation of this interrupter switch and,

5. ENERGIZED COMPONENTS. Always consider all as a result, “partway” opening or closing is undesirable.

parts live until de-energized, tested, and grounded. To operate, pull the operating handle down through its

full travel vigorously and without hesitation.

6 S&C Instruction Sheet 765-505

Packing and Inspection

Packing Study the erection drawing carefully and check the bill of material to be sure that all

parts are at hand. When a Standard Mounting Arrangement is specified, the shipment

will include:

1. A three-pole interrupter switch, complete with interphase drive, factory-assembled

on a single base. (Tiered-outboard or vertical-mounted.)

2. Four six-foot ten-inch vertical-operating pipe sections, predrilled, where required,

for attachment to the universal couplings.

3. Miscellaneous mounting hardware (less through-bolts) for securing the Omni-Rupter

switch to the pole.

4. The appropriate set of operating-mechanism components for the vertical operat-

ing pipe; e.g. handle, rod guide and couplings—each tagged and keyed to the bill of

material for ready identification.

5. If a Standard Minor Modification of a Standard Mounting Arrangement is specified,

the appropriate parts, as identified in the bill of materials under suffix : “-S2,” “-S6,”

“-S6L,” “-S10,” or “-S15,” will be included with the operating-mechanism components.

Specifically, the modifications designated by these suffixes are

-S2 One Cypoxy® Insulator unit in vertical operating shaft.

-S6 Key interlock—single lock for “locked open” application.

-S6 Key interlock—single lock for “locked open” application.

-S6L Provisions only for key interlocks—mounting bracket for interlock.

-S10 One one-inch diameter fiberglass insulating section in vertical operating

shaft. (Not available for switches supplied with heavy-duty vertical operating

shafts.)

-S15 Heavy-duty vertical operating shafts—1¹⁄₄-inch IPS pipe in lieu of ³⁄₄-IPS pipe.

6. A detailed erection drawing (ED) for the Omni-Rupter will be found in a water-

resistant envelope shipped with the switch. If a Standard Mounting Arrangement is

to be used, this erection drawing is a printed sheet. This same sheet is also furnished

when a Standard Minor Modification of a Standard Mounting Arrangement is to be

used. In the latter case, a copy of RD-3469 (Standard Minor Modifications, Rotating-

Type and Reciprocating-Type Operating Mechanisms) is included.

Drawings for Standard Mounting Arrangements show only minimum or suggested

locating dimensions for the vertical-operating-pipe guide bearings and the operating-

handle assembly. Specific locations are to be determined either on the job or by the

user’s engineering department.

S&C Instruction Sheet 765-505 7

Packing and Inspection

Inspection Examine the shipment for external evidence of damage as soon after receipt as possible,

preferably before removal from the carrier’s conveyance. Check the bill of lading to make

sure that shipping skids, crates, and containers listed thereon are present:

If there is visible loss and/or damage:

1. Notify the delivering carrier immediately.

2. Ask for a carrier inspection.

3. Note condition of shipment on all copies of the delivery receipt.

4. File a claim with the carrier.

If concealed damage is discovered:

1. Notify the delivering carrier within 15 days of receipt of shipment.

2. Ask for a carrier inspection.

3. File a claim with the carrier.

Also notify S&C Electric Company in all instances of loss and/or damage.

Each integer style Omni-Rupter switch is factory-assembled on a common base. All

switch adjustments, including those of the interphase drive, are made at the factory to

ensure proper switch operation during opening and closing. Ease of installation is assured

by following these step-by-step instructions.

Handling

Ç CAUTION

DO NOT lift the switch by rigging on the “live parts,” hookstick mechanism or

pole-unit bases, or subject these parts to undue stress from slings or fall lines. Mis-

alignment of the contacts and the interrupters may result. Misaligned contacts or

interrupters may cause arcing or premature degradation of the contacts.

8 S&C Instruction Sheet 765-505

Installation

Operating Pipe Preparation

If desired, the vertical operating pipe can be cut

to length (if not precut at the factory) before

proceeding to the job site. The standard lengths

of pipe supplied measure 69-100.Cutting dimen-

sions are shown on the erection drawing.

Mounting to Wood

When mounting the switch and its operating

mechanism to a wood pole, it is recommended

that suitably sized square washers be placed

against the wood pole, under the nuts that hold

the through-bolt. The use of spring-type washers

between the square washers and nuts is also

recommended to compensate for wood-pole

shrinkage and thus maintain fastener tightness.

Mounting the Switch Assembly

Step 1

Drill two ¹¹⁄₁₆-inch diameter holes in the utility

pole at the desired height for mounting the

switch. Refer to the erection drawing for details.

Step 2

Insert two ⁵⁄₈-inch diameter through-bolts (not

furnished) in the holes drilled in Step 1 and

secure loosely with the necessary square wash-

ers, flat washers, and nuts in such a manner that

the heads of the bolts project sufficiently from

the face of the pole to engage the switch-base

mounting bracket.

S&C Instruction Sheet 765-505 9

Installation

Step 3

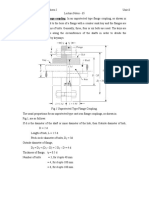

Vertical Mounting Configuration

Ç CAUTION

Do not lift the switch by rigging on the “live

parts” or pole-unit bases, nor subject these

parts to undue stress from slings or fall lines.

Misalignment of the contacts and the inter-

rupters may result, which may cause damage

to the switch during operation.

Hoisting slings

Ç WARNING

Lift the switch using the lifting brackets

provided. Do not allow lifting slings to stress

switch parts. Avoid allowing switch to swing

while lifting.

Lifting bracket

Lifting the switch by the live parts or pole

unit bases will damage the switch. Rough

handling may cause misalignment of the

blades and contacts.

Failure to lift the switch properly

can result in switch damage, causing

improper operation, arcing or electri-

cal shock.

Switches in the vertical mounting configuration

are provided with two lifting brackets bolted to

a 4 3 4 wood support member which is, in turn,

attached to the switch base. Since the wood sup-

port member is also a part of the shipping skid,

use care to avoid damage to it during unpacking.

Wood support members attached to switch base

Make sure that the switch is fully closed. (remove and discard after switch is mounted)

Attach hoisting slings to the lifting brackets

and take a light strain. Unbolt the wood sup- Figure 1. Hoisting vertical mounting configuration Omni-Rupter switch

port member from the skid. Then slowly and into position.

carefully hoist the switch as shown in Figure 1.

10 S&C Instruction Sheet 765-505

Installation

Step 4

When the switch assembly is hoisted to its Through-bolt

mounting level, guide the assembly so that the ¹⁄₂-inch lag (provided by customer)

through-bolts projecting from the utility pole screw

slip into the holes in the switch’s pole saddle.

(The bracket is provided with a keyhole and an

open slotted hole for this purpose; see Figure 2.)

Lower the switch slightly so that it bears on the

through-bolts. Fully tighten the through-bolts,

making sure that the flat washer for each bolt Pole saddle

is between the bolt head and the switch-base

pole saddle. See Figure 2.

Secure the pole band (optional) to the

mounting bracket on the switch, using the

J-bolts provided. See Figure 2. Two ¹⁄₄ 1 3

stiffening blocks are furnished to be used

behind the pole-band flanges, and underneath

the J-bolt nuts. Lag the pole band to the back

side of the pole through the hole in the center

of the band, using one of the three ¹⁄₂-inch

diameter lag screws provided. Then, lag the

pole saddle to the pole using the two remaining Second lag screw installed diagonally opposite on lower corner of mounting

bracket.

¹⁄₂-inch lag screws as shown in Figure 2.

Figure 2. Typical pole-band attachment detail (vertical mounting configu-

Step 5 ration illustrated).

Remove and discard the wood support members

and lifting brackets which were provided to

facilitate hoisting of the switch. See Figure 1.

S&C Instruction Sheet 765-505 11

Installation

Step 6

Tiered-Outboard Mounting

Configuration

Hoisting slings

Ç WARNING

Lift the switch using the lifting brackets

provided. Do not allow lifting slings to stress

switch parts. Avoid allowing switch to swing

while lifting.

Lifting the switch by the live parts or pole

unit bases will damage the switch. Rough

handling may cause misalignment of the

blades and contacts.

Failure to lift the switch properly

can result in switch damage, causing

improper operation, arcing or electri-

cal shock.

Ç CAUTION

Do not lift the switch by rigging on the “live

parts” or pole-unit bases, nor subject these

parts to undue stress from slings or fall

lines. Misalignment of the contacts and the

interrupters may result from such handling, Figure 3. Hoisting the tiered-outboard switch into position.

which may cause undue damage or wear to

the switch during operation.

Make sure that the switch is fully closed.

Attach hoisting slings to the switch base by

looping around the dead-ending bracket of the

uppermost switch pole and hoist the switch as

shown in Figure 3.

When the switch assembly is hoisted to its

mounting level, guide the assembly so that the

through-bolts projecting from the utility pole

slip into the holes in the brackets on the switch

base. (Each bracket is provided with a keyhole

for this purpose; see Figure 3.) Lower the switch

slightly so that it bears on the through-bolts.

Fully tighten the through-bolts, making sure

that the flat washer for each bolt is between

the bolt head and the switch-base mounting

bracket. See Figure 5.

12 S&C Instruction Sheet 765-505

Installation

Installing the Optional Pole Band

Through-bolt

Step 7 (provided by customer)

¹⁄₂-inch lag

Secure the pole band (optional) to the upper

screw

pole saddle on the switch using the J-bolts

furnished. See Figures 4 and 5. Two ¹⁄₄ 1 3

stiffening blocks are furnished to be used

behind the pole-band flanges and underneath

the J-bolt nuts. Lag the pole band to the back

side of the pole through the hole in the center

of the band, using the one of the three ¹⁄₂-inch Pole saddle

lag screws provided. Then lag the pole saddle

to the band using the two remaining Z\x-inch lag

screws as shown in Figures 4 and 5.

Pole band

¹⁄₄ 1 3

stiffening block

J-bolt

Second lag screw installed diagonally opposite on lower corner of mounting

bracket.

Figure 4. Typical pole-band attachment detail (vertical mounting configu-

ration illustrated).

Flat washer

Through-bolt

Mounting

bracket

¹⁄₂-inch lag screw

Pole band (ot shown)

Stiffening

block

J-bolt

Lag screws are installed on the rear

of the upper and lower pole bands.

Figure 5. Typical pole-band attachment detail. (Tiered-outboard mounting

configuration illustrated).

S&C Instruction Sheet 765-505 13

Installation

Installing the Vertical Operating Pipe

and Operating Handle (³⁄₄-inch IPS)

Step 8

NOTICE

Step 8 is for a Standard Mounting Arrangement Rigid

for which ³⁄₄ IPS vertical operating pipe is coupling

furnished. If, instead, the shipment includes

1¹⁄₄ IPS pipe, as signified by the addition

of the Standard Minor Modification Suffix

“-S15” to the erection drawing (ED) number,

proceed to Step 9.

NOTICE ⁵⁄₈ through-bolt,

Installing Piercing Set Screws (not furnished)

This equipment uses piercing set screws

to couple the operating mechanism to the

operating pipe, and to provide stability to

couplings joining one or more lengths of

pipe.

Before assembling a coupling, back the

piercing set screw out of the coupling so that Rod guide

the tip does not protrude into the body of the

coupling. This ensures that the coupling’s

clamp screws can be fully tightened.

After tightening the clamp bolts to their

final torque, tighten the set screws to pierce

and/or crimp the pipe.

When installing the vertical operating pipe, it is

advisable to completely make up each coupling

as work progresses. When installing operating

pipe in a rigid coupling, make certain that the Clamp

set screw does not protrude through the body bolts

of the coupling. Back the set screw out of the

coupling, if necessary. Torque the clamp bolt Piercing

to final tightness. Then, securely tighten the set screws

set screw. If a one-inch diameter fiberglass

insulating section is provided—furnished

when the erection drawing (ED) includes the

Standard Minor Modification Suffix “-S10”—do

not torque the piercing set screw so tightly as to

fracture the fiberglass. See Figure 6.

Proceed as follows:

a. Attach a rigid coupling to one end of an Rigid

coupling

unthreaded 6-10 section of vertical operat-

ing pipe. Next, slip a rod guide onto the pipe

(the rigid coupling will retain the rod guide). Coupling Detail

Clamp the other end of the pipe section in the

coupling at the switch drive lever. Securely Figure 6. Rod guide and rigid coupling (detail) for use with ³⁄₄ IPS

vertical operating pipe.

14 S&C Instruction Sheet 765-505

Installation

tighten the clamp bolts at both ends of the

pipe. Then, securely tighten the piercing set Grounding

strap Locknut Vertical

screws. See Figure 6.

operating

Install additional vertical-operating pipe pipe

sections in the same manner.

Pipe

b. Install the lower vertical-operating-pipe sec- coupling

tion by threading one end of the pipe into the

coupling on the operating handle. Approxi-

mately ¹⁄₄-inch of thread should extend

through the coupling. See Figure 7. Tighten

the locknut. Slip a rod guide onto the pipe

and attach the upper end of the pipe to the

lowest rigid coupling. Tighten the coupling

clamp bolts but do not tighten the associated Operating

set screw at this time. handle

c. Make sure that the switch poles are fully

closed and that the operating handle is held Locking bar

in its closed position by means of the locking

bar. See Figure 7.

Use the vertical operating pipe as a plumb

line to locate the operating handle radially to

the pole—see section D-D on the erection Grounding connector (for earth

drawing. Then, drill two ¹¹⁄₁₆-inch diameter ground connection—see text)

holes at the locations indicated on the erec- Without key interlock

tion drawing, and mount the handle using

⁵⁄₈-inch threaded rod or through-bolts (not-

furnished). At the same time, use one of the

operating-handle mounting bolts to attach

one end of the grounding strap (the end with

the grounding connector attached) to the

handle mounting plate. See Figure 7.

NOTICE

The grounding recommendations herein

Blocking screw

may differ from the standard operating and to be located

safety procedures of certain electric utility opposite locked

companies. Where a discrepancy exists, the position

operating procedures of the electric utility

apply.

Key interlock with zero bolt

projection and ³⁄₄ bolt travel

With key interlock

Figure 7. Operating handle assembly.

S&C Instruction Sheet 765-505 15

Installation

d. Drill an ¹¹⁄₁₆-inch diameter hole in the pole

for each rod-guide mounting location, as

indicated on the erection drawing. Position

the hole so that it is in line with the verti-

cal operating pipe. Also, where appropri-

Rigid coupling

ate, position the hole to provide a 10-inch

minimum clearance between the rod guide

and the rigid coupling immediately above

with the switch in the closed position. See

Figure 8.

e. Move the operating handle to its mid-position

and temporarily secure the handle in that

position with the locking bar. Refer to the

erection drawing. 10-inch minimum

distance (switch in

⁵⁄₈ through-bolt,

Ç WARNING (not furnished)

closed position)

This applies only when checking for

alignment and complete closure; when in

service, the interrupter switch should be

opened or closed vigorously through its

full travel without hesitation at any point.

Be prepared to apply additional force to

maintain full speed when operating effort

Rod guide

increases as the switch blades engage the

interrupters.

Figure 8. Rod guide for use with ³⁄₄ IPS vertical operating pipe. Maintain

10-inch distance between rod guide and rigid coupling.

Ç WARNING

DO NOT operate the Omni-Rupter switch

slowly, partway or use a chopping motion

when operating the switch after it is

energized.

When in service, the Omni-Rupter should

always be opened or closed vigorously

through its full travel without hesitation.

Apply additional force to maintain full speed

as the switch blades engage the interrupters.

Partial or slow-speed opening of

an energized Omni-Rupter switch may

cause arcing, which will damage the

blade and interrupter contacts. Personal

injury may result.

Install the rod guides using ⁵⁄₈–11 threaded

rods and nuts (not furnished), in the holes

previously drilled. Each threaded rod must

be of sufficient length to permit the vertical

operating pipe to be centered, as near as

practicable, in the rod-guide loop when the

handle is in the mid-position.

16 S&C Instruction Sheet 765-505

Installation

f. Remove the locking bar and move the handle

to the closed position. Make sure that the

switch poles are fully closed. Loosen the

clamp bolts on the lower portion of the rigid Operating pipe

coupling attached to the lowest operating-

pipe section.

Then, while holding the handle approxi-

mately 20 degrees from the closed position,

retighten the rigid-coupling clamp bolts. Do

not tighten the associated set screw. Finally, Insert ³⁄₈-inch bolt

move the handle to the fully closed position.

A definite resistance should be felt at the end

of the stroke, indicating that all slack in the

operating linkage has been taken up.

If this is not the case, the preceding pro-

cedure should be repeated except that the

operating handle should be moved more than

20 degrees in the opening direction before

tightening the clamp bolts. Conversely, if Operating handle

it is necessary to use considerable force to

move the handle to the fully open position,

loosen the clamp bolts at the lowest coupling

and then retighten them with the operating

handle at less than the 20-degree position.

g. With the operating handle adjusted for full

Figure 9. Operating handle in mid-position.

180-degree travel as described above, open

and close the interrupter switch slowly to see

that no operational difficulties are encoun-

tered due to undetected damage in shipping.

Check to be sure that the following condi-

tions exist:

• When the operating handle is completely

closed (and over center), all main contacts

of the interrupter switch are in the fully

closed position.

• When the operating handle is completely

open, the switch blades are 90 degrees from

the closed position.

S&C Instruction Sheet 765-505 17

Installation

In the unlikely event that the conditions

described above are not met, more switch-blade

travel is required. Proceed as follows: Clamp bolts

h. Move the operating handle to its mid-position

to take the strain off the operating-pipe link-

age. Secure the handle in that position by

inserting a ³⁄₈-inch bolt or metal pin into the

hole provided. See Figure 10.

i. Then, loosen the two clamp bolts on the

adjustable switch drive lever. Shorten

the drive lever one “step” (¹¹⁄₃₂ inch) and

retighten the bolts. (Shortening the lever

increases the amount of switch travel.)

Remove the ³⁄₈-inch bolt from the handle.

Recheck the switch-blade travel as described

in Step 5c on page 14. Repeat this proce-

dure shortening the drive lever in one-step Adjustable switch drive lever

increments, until full switch-blade travel is

attained. See Figure 10.

j. When satisfactory travel adjustment of Figure 10. Adjusting the switch drive lever. (Vertical mounting configura-

handle and switch is attained, make sure that tion shown. Tiered-outboard mounting configuration similar.)

the clamp bolts at the coupling immediately

above the handle are securely tightened.

Then securely tighten the set screw. Refer

to coupling photo on previous page.

k. Fasten the free end of the grounding strap

to the lowest vertical-operating-pipe section

a few inches above the operating-handle

assembly with the U-bolt connector provided

for this purpose. Then connect the lower

end of the strap to a suitable earth ground,

using the grounding connector provided at

the end of the strap. See Figure 7 on page 15.

Proceed to Step 10.

NOTICE

The grounding recommendations herein

may differ from the standard operating and

safety procedures of certain electric utility

companies. Where a discrepancy exists, the

operating procedures of the electric utility

apply.

18 S&C Instruction Sheet 765-505

Installation

Installing the Vertical Operating Pipe

and Operating Handle (Switches

provided with 1¹⁄₄-inch IPS Operating

Pipe)

Step 9

NOTICE

Step 9 is a Standard Mounting Arrangement

for which 1¹⁄₄-inch IPS vertical operating pipe

is furnished, as signified by the addition of the

Standard Minor Modification Suffix “‑S15” to

the erection drawing (ED) number.

NOTICE

Installing Piercing Set Screws

This equipment uses piercing set screws

to couple the operating mechanism to the

operating pipe, and to provide stability to

couplings joining one or more lengths of

pipe.

Before assembling a coupling, back the

piercing set screw out of the coupling so that

the tip does not protrude into the body of the

coupling. This ensures that the coupling’s

clamp screws can be fully tightened.

After tightening the clamp bolts to their

final torque, tighten the set screws to pierce

and/or crip the pipe.

When installing the vertical operating pipe, it is

advisable to completely make up each coupling

as work progresses. When installing operating

pipe in a rod-guide coupling, make certain that

the cutting tip of the piercing set screw does

not protrude through the body of the coupling.

Torque the clamp bolt to final tightness. Then,

securely tighten the associated piercing set

screw.

Proceed as follows:

a. Make sure that the switch poles are fully

closed. Install the uppermost section of

vertical operating pipe by clamping an

unthreaded pipe section to the coupling at

the switch drive lever.

b. Use the vertical operating pipe as a plumb

line to locate the adjustable rod guide radi-

ally to the pole—see Section B-B of the

erection drawing. Then, drill two ¹¹⁄₁₆-inch

diameter holes at the locations indicated

on the erection drawing, and mount the rod

guide using ⁵⁄₈-inch bolts (not furnished).

S&C Instruction Sheet 765-505 19

Installation

c. Slip the lower end of the vertical operating

pipe into the coupling on the driven arm of

Positioning bolt

the adjustable rod guide, with the rod-guide Piercing

(remove when

arm pointing upward at a 45-degree angle. directed in Step 5) set screw

See Figure 11. A positioning bolt holds the

Driven arm

rod-guide arm at 45 degrees. Securely tighten

the rod-guide clamp bolt. Then, securely

tighten the associated piercing set screw.

d. If only one rod guide is used, proceed to (e).

If more than one rod guide is used, install

the next section of operating pipe onto the

Pipe

lower coupling of the adjustable rod guide. coupling

Securely tighten the rod-guide clamp bolt.

Then, securely tighten the associated pierc-

ing set screw. Repeat (b) and (c) using a

non-adjustable rod guide. Install additional

operating-pipe sections and rod guides in the

same manner.

NOTICE

When the last rod guide has been installed,

proceed to (e) for instructions on installing Adjustable rod guide

the last section of operating pipe. (install in uppermost position)

e. Install the lowest vertical-operating-pipe Positioning bolt

section by threading one end of the pipe (remove when

into the coupling on the operating handle. directed in Step 5)

Approximately ¹⁄₄ inch of thread should

extend through the coupling. See Figure 8

on page 16. Tighten the locknut. Attach the

upper end of the pipe to the lowest rod-guide

coupling. Then, tighten the coupling clamp

bolts but do not tighten the associated set

screw at this time.

Nonadjustable rod guide

(install in intermediate and lowest position)

Figure 11. Rod-guide assemblies for use with 1¹⁄₄ IPS vertical operating

pipe, furnished with Standard Minor Modification Suffix “-S15.”

20 S&C Instruction Sheet 765-505

Installation

f. Make sure that the switch poles are fully

closed and that the operating handle is held Grounding

strap Locknut Vertical

in its closed position by means of the locking

bar. See Figure 12. operating

pipe

Use the vertical operating pipe as a plumb

line to locate the operating handle radially to Pipe

the pole—see Section D-D on the erection coupling

drawing. Then, drill two ¹¹⁄₁₆-inch diameter

holes at the locations indicated on the erec-

tion drawing, and mount the handle using

⁵⁄₈-inch threaded rod or through-bolts (not-

furnished). At the same time, use one of the

operating-handle mounting bolts to attach

one end of the grounding strap (the end with Operating

the grounding connector attached) to the handle

handle mounting plate. See Figure 12.

Locking bar

NOTICE

The grounding recommendations herein

may differ from the standard operating and

safety procedures of certain electric utility

companies. Where a discrepancy exists, the

Grounding connector (for earth

operating procedures of the electric utility ground connection—see text)

apply.

Without key interlock

g. Now remove the temporary 45-degree posi-

tioning bolt from each rod guide. See Fig-

ure 11. Remove the locking bar and loosen

the clamp bolt on the lowest rod-guide

coupling. Then, while holding the handle

approximately 20 degrees from the closed

position, retighten the rod-guide clamp bolts.

Do not tighten the associated set screw.

Finally, move the handle to the fully closed

position. A definite resistance should be

Blocking screw

felt at the end of the stroke, indicating that to be located

all slack in the operating linkage has been opposite locked

taken up. position

If this is not the case, the above procedure

should be repeated except that the operat-

ing handle should be moved more than 20

degrees in the opening direction before

tightening the clamp bolt on the lowest rod-

guide coupling. Conversely, if it is necessary

to use considerable force to move the handle Key interlock with zero bolt

to the fully closed position or if the operating projection and ³⁄₄ bolt travel

handle does not swing 180 degrees to the

With key interlock

fully open position, loosen the clamp bolt

on the lowest rod-guide coupling and then Figure 12. Operating handle assembly.

retighten it with the operating handle at less

than the 20-degree position.

S&C Instruction Sheet 765-505 21

Installation

h. With the operating handle adjusted for full

180-degree travel as described in (g), open

and close the interrupter switch slowly to see

that no operational difficulties are encoun-

tered due to undetected damage in shipping.

Ç WARNING

This applies only when checking for

alignment and complete closure; when in

service, the interrupter switch should be

opened or closed vigorously through its

full travel without hesitation at any point.

Be prepared to apply additional force to

maintain full speed when operating effort

increases as the switch blades engage the

interrupters.

Check to be sure that the following condi-

tions exist:

• When the operating handle is completely

closed (and over center), all main contacts

of the interrupter switch are in the fully

closed position.

• When the operating handle is completely

open, the switch blades are 90 degrees from

the closed position.

In the unlikely event that the conditions

described in (h) above are not met, more

switch-blade travel is required. Proceed as

follows:

i. Move the operating handle to its mid-position

to take the strain off the operating-pipe link-

age. Secure the handle in that position by

inserting a ³⁄₈-inch bolt or metal pin into the

hole provided. See Figure 9 on page 17.

j. Then, loosen the two clamp bolts on the

adjustable switch drive lever. Shorten the

drive lever one “step” (¹¹⁄₃₂ inch) and retighten

the bolts. (Shortening the lever increases the

amount of switch travel.) Remove the bolt.

Then readjust for full operating-handle and

switch-blade travel as described above.

Repeat this procedure, shortening the drive

lever in one-step increments, until full

switch-blade travel is attained. See Figure

10 on page 18.

k. When satisfactory travel adjustment of

handle and switch is attained, make sure that

the clamp bolts at the coupling immediately

above the handle are securely tightened.

Then securely tighten the set screw.

22 S&C Instruction Sheet 765-505

Installation

1. Fasten the free end of the grounding strap

to the lowest vertical-operating-pipe section

a few inches above the operating-handle

assembly with the U-bolt connector provided

for this purpose. Then connect the lower end

of the strap to a suitable earth ground, using

the grounding connector provided at the end

of the strap.

Extension link

NOTICE assemblies

The grounding recommendations herein

may differ from the standard operating and

safety procedures of certain electric utility

companies. Where a discrepancy exists, the

operating procedures of the electric utility

apply.

Dead-end brackets

Dead-Ending Conductors

Dead-ending provisions are standard on

Omni-Rupter switches having tiered-outboard

mounting configurations.d When dead-ending

to these brackets, extension-link assemblies and

pole bandsl are required. See Figure 13.

Maximum dead-end loading for S&C dead- Figure 13. Dead-ending bracket (triangular mounting configuration

ending brackets on switches with steel bases: shown).

a. 2000 pounds per conductor where pull-off

forces are applied to only one side of the

switch.

b. 8000 pounds per conductor where equal

pull-off forces are applied to both sides of

the switch.

Maximum dead-end loading for S&C dead-

ending brackets on switches with insulated

bases:

a. 750 pounds or 500 pounds per conductor,

14.4-kV and 25-kV respectively, where pull-

off forces are applied to both sides of the

switch.

b. 8000 pounds per conductor for 14.4-kV and

25-kV switches, where equal pull-off forces

are applied to both sides of the switch.

d Dead ending not available for switches in the vertical

mounting configuration.

l Pole band can be specified by adding suffix “-P1” to

the catalog number. Extension-link assemblies can be pro-

vided by adding suffix “-D” to the catalog number of the

switch, or equivalent user-furnished extension means may

be used.

S&C Instruction Sheet 765-505 23

Installation

Connecting High-Voltage

Conductors

Step 10

Ç DANGER

Conductors must be de-energized and

grounded in accordance with standard

system operating practice.

Failure to do so can can result in

serious injury or death.

The Omni-Rupter terminal pads are silver plated

and do not require abrasive cleaning as a part

of their preparation. Wipe any dirt or grease

from the surface, and apply a thick coating of

Penetrox A or other appropriate conductor

preparation compound. DO NOT wire-brush

the terminal pads.

Step 11

Ç CAUTION

DO NOT apply excessive load to the terminal

pads.

The jumper connections should be in-line

with and level to the terminal pad bolt holes

before securing the jumper fasteners to the

terminal pad. Large pull-off forces may mis-

align the blades with the stationary contacts

or prevent proper closing.

Misaligned contacts may overheat

causing arcing and damage to the

switch. Injury to operating personal

may result.

When high-voltage conductors are to be con-

nected using aluminum-alloy connectorsa, the

following procedures should be employed:

a. Thoroughly wire-brush the current-transfer

surfaces of each connector and immedi-

ately apply a liberal coating of Penetrox®

A (available from Burndy Corporation) or

another appropriate conductor preparation

compound to the brushed surfaces.

b. Prepare the conductors using established

procedures and clamp them in their respec-

tive connectors.

For other types of connector, follow the

manufacturer’s recommended preparation

procedure before connecting to Omni-Rupter

terminal pads.

a “Mass anode” type connectors, such as the Catalog

Number 5300 series offered by S&C, which have been

designated by the connector manufacturer as being suit-

able for direct attachment to copper alloy terminal pads.

24 S&C Instruction Sheet 765-505

Installation

Step 12

Attach the jumper connectors to their respec-

tive terminal pads using flexible-conductor

connections. When attaching connectors to Conductor

Connector

the Omni-Rupter terminal pads, the connectors

should be parallel to the terminal pad. Attach

and form the conductors so that no significant

loading pressure is applied to the terminal pads.

See Figure 14. Terminal pad

Locking the Operating Handle

Step 13

With Padlock:

The operating-handle assembly includes

provisions for padlocking the interrupter switch

in either the open or closed position.

With Key Interlock: Figure 14. Connect jumper connector parallel to terminal pad.

A key interlock (Superior or equivalent),

supplied with the interrupter switch when

the erection drawing (ED) number includes

Standard Minor Modification Suffix “-S6,”

will be mounted on the operating handle (see

Figure 15). One of the two slots in the operating

handle will be blocked to provide either a

locked-open or locked-closed arrangement.

If the interrupter switch is supplied with

provision for the addition of a key interlock,

(Standard Minor Modification Suffix “-S6L”)

the operating handle will have an interlock-

mounting plate attached to the base. Install

interlock as follows:

a. Attach interlock to mounting plate so that

interlock bolt, when extended, will engage

a slot in the operating handle. A Superior Blocking screw

(Type B4003-1) key interlock with zero bolt to be located

projection and ¾-inch bolt travel is required. opposite locked

position

b. Block one of the two slots in the operating

handle with the blocking screw provided.

The slot to be blocked will be determined

by whether a locked-open or locked-closed

arrangement is required.

NOTICE

Key interlock with zero bolt

Key interlocks are intended for proper projection and ³⁄₄ bolt travel

sequencing of switching operations; they

are not intended to provide security. With key interlock

The operating-handle assembly includes Figure 15. Key interlocks.

provisions for padlocking the interrupter

switch in either the open or closed

position.

S&C Instruction Sheet 765-505 25

Installation

Checking Operation

Step 14

Open and close the interrupter switch by swing-

ing the handle slowly through its full travel.

Check to be sure that the following conditions

exist:

a. With the operating handle as far as it will go

in the closing direction, all main contacts of

the interrupter switch are in the fully-closed Blade

position. contacts

b. With the operating handle as far as it will go Bumper stop

in the opening direction, the switch blades

are 90° from the closed position.

Jaw contact

If adjustment is required, loosen the hinge-

end bolts that fasten the blade assembly to its

insulator and move the switch blade until it is in Figure 16. Make sure the jaw contact is fully-centered between the blade

contacts and that the blade contacts are against the bumper stop.

the fully-closed position with the blade against

the bumper stop; then re-tighten the bolts mak-

ing sure the blade remains in the fully closed

position. (Cypoxy insulators—torque the C\,–16

hardware to 22 ft-lbs; Porcelain insulators—

torque the Z\x–13 hardware 55 ft-lbs.) See Fig-

ures 16 and 17.

If adjustment is required beyond that provided

by moving the switch-blade assembly, loosen the

two clamping bolts and set screw that fasten

the coupling to the interphase rod and rotate

the switch blade until it is in the fully closed

position. Re-tighten the clamping bolts and

set screw, making sure the interrupter switch

remains in the fully-closed position.

Step 15

For 14.4-kV switches. Check the following on

Figure 17. Loosen the blade hardware if necessary and move blade to

each phase. the fully-closed position against the bumper stop.

a. Open and close the switch and examine the

interrupter and blade alignment. The inter-

rupter must be parallel to the sweep of the

blade.

b. Partially open the switch. The following

conditions should be met:

• A Z\cx0 minimum clearance between the

top of the opening cam and the bottom

of the closing lever, at their closest point.

• A Z\cx0 minimum clearance between the

top of the opening lever and the bottom

of the closing cam.

c. Open the switch and place the blade in the

position shown in Figure 18, View A. The

following conditions should be met:

• A Z\nv0 minimum clearance between the

opening cam and the opening lever.

26 S&C Instruction Sheet 765-505

Installation

• A clearance between C\cx0 and M\cx0 between

the shunt contact and the interrupter

housing at the beginning of the closing

sweep. Main contact

d. Place the switch in the fully-closed position. ¹⁄₆₄ min.

The following conditions should be met: Opening cam

• A clearance of Z\zn0– >\cx0 between the

closing cam and the closing lever. Opening lever

• A Z\x0 minimum clearance between the

blade shunt contact and the interrupter

housing contact. C\cx to ⁷⁄₃₂

Closing

e. Slowly open the switch. As the blade moves lever

in the opening direction, the blade shunt Interrupter

contact must firmly engage the interrupter housing

housing contact before the blade disengages Closing cam

from the jaw contact. Bend and reform the

shunt contact if necessary to attain the

proper contact.

f. Slowly close the switch. At the start of the

closing stroke, the interrupter housing should

be at the distance checked in STEP 12c and

should continue to make contact with the

shunt contact during the duration of the

closing stroke. This will ensure that the shunt

contact and interrupter housing contact stay

in the circuit long enough for the interrupter

to break the circuit during the opening View A

stroke. See Figure 18, View B.

g. If adjustment is required, loosen the bolts Opening cam Jaw contact

that fasten the jaw-contact casting to its insu- casting

lator and slightly rotate the casting in order to Blade shunt contact

achieve the necessary clearances. Re-tighten

the bolts, making sure that the blade engages

the stationary contact on-center.

NOTICE Closing

lever

If any of the conditions described above

cannot be achieved, it is likely that damage Closing

was sustained during shipping or storage. cam

¹⁄₂ min.

Contact the nearest S&C Sales Office for

Opening lever

assistance.

Interrupter housing

contact ¹⁄₁₆ to ⁹⁄₃₂

NOTICE

View B

Omni-Rupter switches specified with the

optional harsh environment contacts (Cata- Figure 18. Operating checkpoints for switches rated 14.4 kV.

log Number Suffix “-C”) have graphite

impregnated blades which are greaseless

and self-lubricating. DO NOT apply grease

to the blade contacts.

S&C Instruction Sheet 765-505 27

Installation

If any of the conditions described in this step

cannot be achieved, it is likely that damage was

sustained during shipping. Contact the nearest

S&C Sales Office for assistance.for 14.4-kV Main contact

switch. There should also be ¹⁄₃₂ minimum

¹⁄₆₄ min.

clearance between the top of the opening lever

Opening lever

and the bottom of the closing cam.

Opening cam

Step 16

For 25 kV switches. Check the following on

each phase: Interrupter

a. Examine the interrupter and blade alignment. housing Closing

The interrupter must be parallel to the sweep cam

Closing ⁵⁄₃₂ to ⁷⁄₃₂

of the blade.

lever

b. Partially open the switch. The following

conditions should be met:

• A Z\cx0 clearance between the bottom of

the opening cam and the top of the clos-

ing lever.

• A Z\cx0 minimum clearance between the

bottom of the closing lever and the top

of the blade.

c. Open the switch and place the blade in the

position shown in Figure 19, View A. The

following conditions should be met:

• A Z\nv0 minimum clearance between the View A

opening cam and the opening lever.

• A clearance between B\cx0 and M\cx0 between

the shunt contact and the interrupter Opening cam

housing at the beginning of the closing

Jaw contact

sweep. Blade shunt contact

casting

Closing

lever

Z\x0 min.

Closing

Opening

cam

lever

Interrupter

housing contact Z\,0–C\,0

View B

Figure 19. Operating checkpoints for switches rated 25 kV.

28 S&C Instruction Sheet 765-505

Installation

d. Place the switch in the fully-closed position.

The following conditions should be met:

• A clearance of Z\,0 – C\,0 between the clos-

ing cam and the closing.

• A Z\x0 minimum clearance between the

blade shunt contact and the interrupter

housing contact.

e. Slowly open the switch. As the blade moves

in the opening direction, the blade shunt

contact must firmly engage the interrupter

housing contact before the blade disengages

from the jaw contact. Bend and reform the

shunt contact if necessary to attain the

proper contact.

f. Slowly close the switch. At the start of

the closing stroke, the interrupter housing

should be at the distance checked in Step 13c

and should continue to make contact with

the shunt contact during the duration of the

closing stroke. This will ensure that the shunt

contact and interrupter housing contact stay

in the circuit long enough for the interrupter

to break the circuit during the opening

stroke. See Figure 19, View B.

g. If adjustment is required, loosen the bolts

that fasten the jaw-contact casting to its insu-

lator and slightly rotate the casting in order to

achieve the necessary clearances. Re-tighten

the bolts, making sure that the blade engages

the stationary contact on-center.

NOTICE

If any of the conditions described above

cannot be achieved, it is likely that damage

was sustained during shipping. Contact the

nearest S&C Sales Office for assistance.

S&C Instruction Sheet 765-505 29

Printed in U.S.A.

You might also like

- CompTIA Linux+ Certification Study Guide (2009 Exam): Exam XK0-003From EverandCompTIA Linux+ Certification Study Guide (2009 Exam): Exam XK0-003No ratings yet

- S&C Omni-Rupter Switches Outdoor DistributionDocument25 pagesS&C Omni-Rupter Switches Outdoor DistributionluggerNo ratings yet

- PIC Microcontroller Projects in C: Basic to AdvancedFrom EverandPIC Microcontroller Projects in C: Basic to AdvancedRating: 5 out of 5 stars5/5 (10)

- Aduty - Instruction Sheet 761 500Document33 pagesAduty - Instruction Sheet 761 500Enrique MirandaNo ratings yet

- 440G-LZ Guardmaster Guard Locking Switch: User ManualDocument62 pages440G-LZ Guardmaster Guard Locking Switch: User ManualMateus Rodolfo DiasNo ratings yet

- Cortina de Luz 445l-Um001Document72 pagesCortina de Luz 445l-Um001ulliisseessNo ratings yet

- Powerflex 755Ts Products With Totalforce Control: Hardware ServiceDocument198 pagesPowerflex 755Ts Products With Totalforce Control: Hardware Serviceabner kaiberNo ratings yet

- Lennox MinisplitDocument46 pagesLennox MinisplitUbaldo PérezNo ratings yet

- Multi Vision: 2020TG For Gauge Pressure and Level 2020TA For Absolute PressureDocument24 pagesMulti Vision: 2020TG For Gauge Pressure and Level 2020TA For Absolute PressureHectorNo ratings yet

- Panelview Plus 7 Standard Terminals: User ManualDocument156 pagesPanelview Plus 7 Standard Terminals: User ManualMarcos MouraNo ratings yet

- Cr30 Allen BradleyDocument190 pagesCr30 Allen BradleyOziel Medina AlvaradoNo ratings yet

- Powerflex® 6000 Medium Voltage Variable Frequency Drive Commissioning ManualDocument98 pagesPowerflex® 6000 Medium Voltage Variable Frequency Drive Commissioning ManualSGQNo ratings yet

- U Series Manual (N00 809 03)Document125 pagesU Series Manual (N00 809 03)Roberto NajeraNo ratings yet

- Manual Panelview 5310 2Document114 pagesManual Panelview 5310 2Ignacio VillaNo ratings yet

- Guardmaster Configurable Safety Relay: User ManualDocument190 pagesGuardmaster Configurable Safety Relay: User ManualAgnaldo JuniorNo ratings yet

- Iqan-Lx - Uk - Ed0707 - InstruçãoDocument29 pagesIqan-Lx - Uk - Ed0707 - InstruçãoAxicelNo ratings yet

- Panelview Plus 7 Standard Terminals: User ManualDocument156 pagesPanelview Plus 7 Standard Terminals: User ManualWaseem AhmedNo ratings yet

- Guardmaster Configurable Safety Relay: User ManualDocument188 pagesGuardmaster Configurable Safety Relay: User ManualautoNo ratings yet

- Itraxr PRX Module: Customer Product Manual Part 1078355-05Document49 pagesItraxr PRX Module: Customer Product Manual Part 1078355-05Bob YahyaNo ratings yet

- Ethernet/Ip Absolute Encoders: Standard and Cip Safety ModelsDocument104 pagesEthernet/Ip Absolute Encoders: Standard and Cip Safety ModelsEfrain Paricahua QuispeNo ratings yet

- Heraeus (Manual)Document28 pagesHeraeus (Manual)Fernando OliveiraNo ratings yet

- RA PanelView 5310 User ManualDocument104 pagesRA PanelView 5310 User ManualMelvis MellNo ratings yet

- Powerflex 6000 Medium Voltage Variable Frequency Drive: Installation InstructionsDocument88 pagesPowerflex 6000 Medium Voltage Variable Frequency Drive: Installation InstructionsTomas BorosNo ratings yet

- Kaco Blueplanet 20.0 Tl3 IntDocument96 pagesKaco Blueplanet 20.0 Tl3 IntManuel Urdaneta100% (1)

- Guard I/O Ethernet/Ip Safety Modules: User ManualDocument176 pagesGuard I/O Ethernet/Ip Safety Modules: User ManualEdison MalacaraNo ratings yet

- Brief Operating Instructions - Tank Side Monitor NRF590 - KA01070FEN - 1515Document40 pagesBrief Operating Instructions - Tank Side Monitor NRF590 - KA01070FEN - 1515andytonuiNo ratings yet

- Panelview 5510 Terminals: User ManualDocument116 pagesPanelview 5510 Terminals: User ManualFernando BravoNo ratings yet

- W347-E1-06 c200hw cqm1-drt drt1Document381 pagesW347-E1-06 c200hw cqm1-drt drt1Vũ MinhNo ratings yet

- Micropilot M FMR245: Brief Operating InstructionsDocument36 pagesMicropilot M FMR245: Brief Operating InstructionsImad Eddine AbidNo ratings yet

- Symac CQM1 Omron Operation ManualDocument155 pagesSymac CQM1 Omron Operation ManualsunhuynhNo ratings yet

- CENTERLINE 2100 Low Voltage Motor Control Centers: Installation InstructionsDocument136 pagesCENTERLINE 2100 Low Voltage Motor Control Centers: Installation InstructionsreinaldomdNo ratings yet

- Manual Instrucciones TX Nivel Ultrasonico FMU40-42-43 - FFDocument36 pagesManual Instrucciones TX Nivel Ultrasonico FMU40-42-43 - FFHeiner PalaciosNo ratings yet

- U-Series Manual (N00-809-01)Document132 pagesU-Series Manual (N00-809-01)Rizal FahmiNo ratings yet

- Dynamix 1443 Series Sensors: User ManualDocument28 pagesDynamix 1443 Series Sensors: User ManualCVONo ratings yet

- Tai Lieu AbDocument326 pagesTai Lieu AbMinh Nhut LuuNo ratings yet

- ACS580 01drivesHW RevC Screen A5Document218 pagesACS580 01drivesHW RevC Screen A5Zhen Xing HengNo ratings yet

- Manual Variador POWERFLEX527 PDFDocument178 pagesManual Variador POWERFLEX527 PDFGerardo LozanoNo ratings yet

- Ba00401g08en06 14Document160 pagesBa00401g08en06 14NunoFigueiredoNo ratings yet

- 80116-134 Erbejet2 ServiceDocument32 pages80116-134 Erbejet2 ServiceAxl RamirezNo ratings yet

- N Series Manual (N00 808 01)Document144 pagesN Series Manual (N00 808 01)Thành CôngNo ratings yet

- SE9763 Ringmaster O&M Manual Web PDFDocument137 pagesSE9763 Ringmaster O&M Manual Web PDFNemitha Lakshan0% (1)

- E-Series Manual (N00-807-01)Document119 pagesE-Series Manual (N00-807-01)M Cristian MorenoNo ratings yet

- Instructions For Use: ContactorDocument38 pagesInstructions For Use: ContactorHanh TranNo ratings yet

- Optilift RPC Manual RockwellDocument462 pagesOptilift RPC Manual RockwellPantau Pembangunan DuriNo ratings yet

- Abb LMT100 200 NivelDocument84 pagesAbb LMT100 200 NivelWilmar salgado cañateNo ratings yet

- CUTLER HAMMER ACB - Bobguns TVDocument52 pagesCUTLER HAMMER ACB - Bobguns TVMelchie Bob GunayanNo ratings yet

- W236-E1-07 C200HS Installation - GuideDocument221 pagesW236-E1-07 C200HS Installation - GuidechrisalexoNo ratings yet

- Workman® 200 Spray System: For Heavy-Duty Workman VehiclesDocument56 pagesWorkman® 200 Spray System: For Heavy-Duty Workman VehiclesJoaquim Filipe GanhaoNo ratings yet

- 440c Um001 - en PDocument204 pages440c Um001 - en Plouiswang1964No ratings yet

- Instruction Sheet 451-500 PDFDocument18 pagesInstruction Sheet 451-500 PDFJuanNo ratings yet

- Tek P6022 Current ProbeDocument48 pagesTek P6022 Current Probelaser0185No ratings yet

- Cassette Toshiba Mmu-AP 4hp-E enDocument28 pagesCassette Toshiba Mmu-AP 4hp-E enplacide nkusiNo ratings yet

- ABB Drives ACS580 Manual 2017Document278 pagesABB Drives ACS580 Manual 2017rrebollarNo ratings yet

- Grundfosliterature 6014711Document62 pagesGrundfosliterature 6014711YAR SOLUTIONSNo ratings yet

- Operating Manual: Measuring Amplifier For Instrument Panel MountingDocument68 pagesOperating Manual: Measuring Amplifier For Instrument Panel Mountingrmdoucet100% (1)

- 857 Protection System For Feeder and Motor Protection, Bulletin 857, Series ADocument38 pages857 Protection System For Feeder and Motor Protection, Bulletin 857, Series ABairon AlviraNo ratings yet

- Guard I/O Ethernet/Ip Safety Modules: User ManualDocument142 pagesGuard I/O Ethernet/Ip Safety Modules: User ManualdanielNo ratings yet

- Pacv D PDFDocument61 pagesPacv D PDFUmen AryanNo ratings yet

- Micropilot M FMR250: Brief Operating InstructionsDocument36 pagesMicropilot M FMR250: Brief Operating InstructionsJosué Hadid CastilloNo ratings yet

- Variador de Frecuencia Yask.616G5Document114 pagesVariador de Frecuencia Yask.616G5yoyo50100% (1)

- Short Road To Great PresentationsDocument338 pagesShort Road To Great PresentationsGizella Hernandez PairazamanNo ratings yet

- Writing in The Technical FieldsDocument271 pagesWriting in The Technical FieldsGizella Hernandez PairazamanNo ratings yet

- 2014 Burndy Master CatalogDocument1,002 pages2014 Burndy Master CatalogGizella Hernandez PairazamanNo ratings yet

- 07 Rotating Machines DiagnosticDocument79 pages07 Rotating Machines DiagnosticGizella Hernandez PairazamanNo ratings yet

- Bongiglioli - Manual A - enDocument54 pagesBongiglioli - Manual A - enRifatAlAhmedNo ratings yet

- 60Hz MV MHDocument48 pages60Hz MV MHAxl RoseNo ratings yet

- Timken ADAPT Bearing Installation GuideDocument16 pagesTimken ADAPT Bearing Installation GuideAlvaroNo ratings yet

- MMTMDocument44 pagesMMTMRookie AustralianNo ratings yet

- S6 Mech CAD Lab Model Exam Question PaperDocument8 pagesS6 Mech CAD Lab Model Exam Question PaperKailas Sree ChandranNo ratings yet

- Single Hoist Crane Inspection Report 02-1008027 - J1607552 - NQC1108 - PDFDocument3 pagesSingle Hoist Crane Inspection Report 02-1008027 - J1607552 - NQC1108 - PDFAnonymous N2Se0bYNo ratings yet

- Installation Instruction G400 Online 3Document16 pagesInstallation Instruction G400 Online 3jose manuel gonzalez alonsoNo ratings yet

- Bipex Kaplin ÖlçüleriDocument7 pagesBipex Kaplin ÖlçüleriSERDAR CEREZNo ratings yet

- 1HP5 - 2012 Camuflado Parts ManualDocument89 pages1HP5 - 2012 Camuflado Parts ManualCharles SignoreNo ratings yet

- Bawn 004Document4 pagesBawn 004sike1977No ratings yet

- Maintenance Scheduling For Mechanical Equipment PDFDocument111 pagesMaintenance Scheduling For Mechanical Equipment PDF郭允超No ratings yet

- 7029120023Document1 page7029120023Roderick Pinto100% (1)

- Machinery Coupling Guard Oil Leakage Design Solutions 1595104444Document13 pagesMachinery Coupling Guard Oil Leakage Design Solutions 1595104444Alexander Rodriguez SarmientoNo ratings yet

- ROTALIGN PRO Manual Part 2 PDFDocument86 pagesROTALIGN PRO Manual Part 2 PDFTheerayoot Poomchai67% (3)

- Astm c1461Document4 pagesAstm c1461Júlio RosaNo ratings yet

- Bhel Guide: Hydro GeneratorsDocument29 pagesBhel Guide: Hydro GeneratorsDeepen SharmaNo ratings yet

- Centrifugal Pump API 686 Key RecommendationsDocument1 pageCentrifugal Pump API 686 Key RecommendationsAniekanNo ratings yet

- User's Guide: Torque TransducerDocument18 pagesUser's Guide: Torque TransducerAris WijayaNo ratings yet

- Mud Hog 1 1-Manual-Rev2Document19 pagesMud Hog 1 1-Manual-Rev2Ali Ali0% (1)

- Coupling 2Document14 pagesCoupling 2dsadasdasdasNo ratings yet

- Cema Design BookDocument59 pagesCema Design BookBapu612345No ratings yet

- Api 674 DSDocument19 pagesApi 674 DSjayaram432100% (1)

- Sauter Valve 1763170steam Reg. ValveDocument24 pagesSauter Valve 1763170steam Reg. ValveSergei GovorkoNo ratings yet

- Dayton Superior Bar-Lock Coupler SystemDocument4 pagesDayton Superior Bar-Lock Coupler SystemJosh ReynoldsNo ratings yet

- Hub City Beveal Gear DrivesDocument5 pagesHub City Beveal Gear DrivesJuan CaceresNo ratings yet

- Grundfos CRCRNDocument73 pagesGrundfos CRCRNsmile4hariNo ratings yet

- Dome PDFDocument7 pagesDome PDFADARSH S DNo ratings yet

- Timken Quick Flex Catalog PDFDocument64 pagesTimken Quick Flex Catalog PDFRickson PhilipNo ratings yet

- Manual For Multipump - TSM Viking PumpsDocument116 pagesManual For Multipump - TSM Viking PumpsMarcosNo ratings yet

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersFrom EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersRating: 4.5 out of 5 stars4.5/5 (2)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerFrom EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo ratings yet

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)

- Practical Methods for Analysis and Design of HV Installation Grounding SystemsFrom EverandPractical Methods for Analysis and Design of HV Installation Grounding SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Global Landscape of Renewable Energy FinanceFrom EverandGlobal Landscape of Renewable Energy FinanceNo ratings yet

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977From EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977No ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Recent Advances in Electrical Engineering: Applications OrientedFrom EverandRecent Advances in Electrical Engineering: Applications OrientedNo ratings yet

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)