Professional Documents

Culture Documents

1CV. Agusman 2021

1CV. Agusman 2021

Uploaded by

fauzan alawy0 ratings0% found this document useful (0 votes)

26 views37 pagesOriginal Title

1CV. AGUSMAN 2021

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views37 pages1CV. Agusman 2021

1CV. Agusman 2021

Uploaded by

fauzan alawyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 37

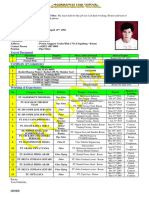

ri m vitae

Dear Prospective Employer

|lam Applying for the position of welder. My mainskill for this job are | am hard working Honest and keen to

progress it is to reach me by mobile phone

Personal Detail’s

Name AGUSMAN

Place, Date of Birth Palembang, August 18* 1983

Sex Male

Marital Stats Married

Religion Moslem

‘Nationality Indonesia oe

Last Education Senior High School

Address PerumKurniaDjayaAlam J Glatik 4No.07 Ru/004 Rw/005 =

Kel BelianKec Batam Kota

NK 2171121808839013

PW? No. 16.054,015,9-215.000

Contact Number +6253 6670 3381

Email Address agusman_weld@vahoo.com

Position pipe Welder Structural Welder GTAW.SMAW.FCAW

Travel of Document

1 Passport C.0316025 Balan, July 13 2018 July 13 2023

2 | Seaman's Book | G 049086 Palembang, Jul 06", 2021 | Jul 05%, 2024

Certificate Of Trainin;

For Workers (General Trade) | SS1CGI-1/4279 | Singapore, Nov 23°, 2019 - Nov 22™, 2021

2._| ForWork Trade) | SS1 152329 | Singapore, Nov, 23%, wv 22° 2024 |

SS-PLPROAE- ns

3 Confined Space Operation SSO Singapore, Dec 02, 2019

‘Working of Experiences

For JPTT at Jurong Port —

;_ | PT-SATRIAGLOBAL | Welders PT Rotary Engineering — | May 20.2021 | = ng o¢ project

PERSADA GTAWISMAW-CS | Indonesia—Tg. Uncang | Aug 20, 2021 i

Batam

2 |PI-KHOKONSTRUKSI | Welder 66R Formesa 2- PT SMOE | Nov25, 2020 Job

INDONE SIA ‘SNAW Indonesia—Kabil Batam | Apr 16, 2021_| Completed

3 | FT RATA | Welder FCAW-GS | PT. Delta Shipyard — Batam ie 63, 2020 | Finish Job

PT.IEGOILFIELD | , ; PT. IEG Oilfield Indonesia— | Aug Finished

4 INDONESIA Welder ERAS: Batam Nov 11,2019 | contract

s | ee Welder 66 Kaombo Project-Semcop | Nov 10,2017 | Contact

ul SMAWIFCAW-GS | Marine Singapore Pte. Lid | May 09, 2018 | Completion

Culzean ULO SOME 17 m

PT. DELIMAX Feb os", 2017-] Project

6 eee Welder SMAW DLxBTWoOT-PT. SMOE | TE Oem’ Sony | contted

ied 1

7 | PECITRATUBINDO | Welder FCAW.GS | Kaombo Project PT. Saipem | AUg27” Finish

ENGINEERING 6G Indonesia Karimun Branch | x44, 36° 2016 | Contract

Fabrication Boler and m

PT. PROFESIONAL Welder sep 16" 2015 | Contract

® | PRATAMA INDONESIA | SMAW/FCAW Gs | Pressure Vessel PROFAB | a0 15% 2915 | Completion

Indonesia-Batam Yard

PT.McCONELL | , ; F Aprilds" 2078 | Finish

9 | powelt services | Weller FCAW GS | Heorema Project-Batam Yard | EN Cim Sots | contact

go] ween ene Welder Modoc ProjectCaim Project | April21*2014 inish

NGINEERIN SMAWIFCAW GS Batam Yard Sept 20"2014 | Contract

Fabrication Boler and Oa "2013

PT.PROFESIONAL " Contract

41 | PRATAMAINDONESIA | W2lderSMAW | Pressure Vessel PROFAB | March 21 Completion

PT. GLOBAL Welder6G | PT Global Process Systems — | Marti", 2013 | Contract

12. | PROCESS SYSTEMS | GTAW/SMAW-CS Sekupang Batam Sep 10,2013 | Completion

13 PT. HANNINDO Welder 6G | PT Citta Tubindo Engineering | Aug 20” Finish

INTITRADA, GTAWISMAW-CS ~ Kabil Batam Contract,

Feb 19”. 2013

jards

n

publik

Indones

PERHATIAN

Re

#2 O53 cere 3351

INFORMASI PEMEGANG

IREORMATION ON BEARER

ie

0 F000 KDA Gerrtica ney

sore ran oe

saa 9a cre

PK IDNCKAGUSMANK <<< CK KK KEK KKK KEKE KKK KEKE KKK

€0316025<110N8308182M23071382171121808901368

‘Keverangan Pemegang / Description of Beerer \\

Tempat & Tanggal ahir_ PALEMBANG

{

Ener Oe CRUGR33EF BP 1

| pereomernn “emoerigas | | \ Tener 0109 /09/wu (Raat

Recent Om ALLEL a a

}

“Wana Rambst HITAM

Coto ef hat a

‘Wana Mota

“Go

“oo

“@

‘Surat Keterangon Vaksinasi COVID-19

locarabacraabenesaect

aaa 2 ibe 221

‘sich ddakutan vaained| COMD-1 unt deals perama

dectenc ONE-T9 an 8-218)

steni0l dengon Petotuzon Mentor Kesehatan Repub Indenet

for @ te Wile au

‘Surat Keterangan Vaksinasi COVID-7

Sorta ikon kepada:

Sax @ ger Witte

‘Surat Katerangen Vaksinasi COVID-19

Sertitkat il diberikon kepada

=

o enstemeassaeat

te tao 22

‘wi lalukan voksinat COVID-1 unt dels Kt

24 19a eo (tanh

‘e110 devgan Parotran Mantes Kesehatan Repu Indonesia

Sam © tor Wie aa

3:16.054.015.9-215,000

AGUSMAN

NIK= 2177121808639013

DA Se. OELATIC NO)

Teer MAGe a

pero

KPP PRATAMA BATA

fase en 14 GMALATING. MERGER, PASS

| SHIPYARD SAFETY INSTRUCTION COURSES

| FOR WORKERS (GENERAL TRADE)- CERTIFICATE

leNo: SSICGT-174279

aaniw2019

zeaaees

1 kty Conmect Ye La fe Ler Servier Prover ny Minmary of

Manpwer fo id extre overiel

hep not tran

Acad shal be retained ii has een tapered with aad or replaced

42:This card nthe property Salty Commer Pe Lad and mun be etre

Sound, pee return to Saety Conner Pe Lid # $00 Loe treet 1%

mer Rok Snyppene 427007

(For eagles conta Salty Comme Pe Ld 8 0862440 . e477

emergency TA: SCOF (905) Pls (99) . MONE COATHN,

gvsOud

|| ‘Gen We. | Code | Proces]ros] thk | ob | Fe | Verited

wc | AR] ean | ae| mee [3% eee] I

wa. | ans | Fear |

we Ore | Pee

ERLE 20N dd A

spam swore

sary coe),

26

caer

Sxconm € anes)

‘wea efor Wir n Cantina Space Operation

sae | ‘aousnean

° cancers

Serio umber 6 SS MEPRO-LTIESSIASFON

wauedoate = 272/209

WELDER IDENTIFICATION

PT. McConnell Dowell Services

Batam Indonesia

2 Heerema -Fabriention of

Chala Routing System

ES

Z2

Agusan

2171121808839053

Contes Poe Lad Ws Use ce Presider hy Miro

Mesper ered mee mck

2: pm nt trae

(Car salle retain as be amare with ned pa

Thi rd the property of aly Comme Pe Ld an mtb rete

Sd plese retaen to Salty Con ee Lad @ Sen Hee ST AOE

1 Paeer Bon, Spay S277

‘ter engair comet rainy Conners Pre weaning ses enn

‘Tiigeraency Ta TW (bo) Wace (QE ME

+e ofcard is govemed by terms and condition fsimly Safety Pe Ls

“Simpy Safey Pe Ltd a Singapore Werk fore ocy

“Aorovednning Organization the date of he Ssuance of Oe pass

“Thin eard isnot tansfenbe

filer of the cara Restoeen corte competent in the WSC Gourre onthe

‘ed ate as inca ont

“his eared wil pire 8 years for the dato se

“This ares the propery of Simpy Salty Pte Ltd and mast be retumed

en request

Card hal be retained tisha bewo tampered with, misused or repli

‘hs ar sad by Simply Safety Pte td. found plese return to

Shy Safety Pee Ltd at Ut Crescere 408-11 Encallbor Centre,

Singnpore #08571

‘sForenque, pease contac SptySalety Pie Ls ot 469-6264 4907

82640889

QUALIFICATION RANGE

| WPS PARAMETER RANGE

| WwW a PHERENA O8 Se RO, WPS LAMP (A)| VOLT (V) | ¥ see grey | Maat input

wasco WPS-We144 140-160 [22.08 130.200 1.54 MAX

Welder Identification Card | weewses[ivono| zor | wezm | 2irwax

| WARTSILA - KRAKEN FPSO ah wawise [reowo| ae | woos | 1a2max

| WPS-W-107 se021¢ 2328 75-58) O87 MAX

| wesw [160-1 | zeae | 165-97

| wrewse [sons] sas | 7595

| wwrewcim [veo | esas _| wot _|_anrnax

| Teles Ged poston bt Na ncaed Peston T.V Kio Confira

Welder Identification Card

jas hacen

a one 1

Seer:

ME

woh wesiiacn ya

Process SMAW-FCAW DS: ¥:

TEN DEVELOPMENT PROJECT

[rtiebgemuttbe return QA/OC Dep wan the nat ay of aries)

Feacess | SVAVFCAW DS RDO

mero Fuge Sm

arn rare united | ALL

ae a

jr _ ALL

PRECRESS UPHILL, onrare

pu] remore foam | Loe | aw

cre a

A mr ag 340 Ltt

{arson sTes To oo) ae

PT. SATRIA GLOBAL PERSADA

The Terrace House No. 28. Central Sukajadi

Phone : +62 (778) 4089 175. Email saa globalpersada@amail.com

rrassmiaauonal rensap, —_ Batam -Kepulauan Rig 00

SURAT PENGALAMAN KERJA

No. 372/HR-SGP/VIIU2021

Dengan ini menerangkan bahwa

This is certify that

Nama Agusman

Name

‘Nomor Karyawan_ DAIL

Employee Number

Klasifikasi Terakhir — : Welder

Pinal Classification

+ 20 May 2021 up to 20 August 2021

Service period of

Lokasi Kerja, : PT. Rotary Engineering Indonesia ~ Tanjung Uncang, Batam

Location of Work

Alasan Berhenti : End of Project

Reason of termination

We would ike (0 take this opportunity to thank you for your past efforts and contribution to

PL. Satria Global Persada and wish you every success in the future.

Kami. mengucapkan terima Kasih atas usaha dan jasa yang telsh Saudara sumbangkan kepada

PT. Satria Global Persada dan betharap semoga prestasi dan keberhasilan senantiasa menyertai

‘Saudara dimasa yang akan datang,

Batam, 31 August 2021

Hormat kami,

PT. SATRIA GLOBAL PERSADA

HR Manager

F-QAD-438

MANUFACTURER'S RECORD OF WELDER OR

WELDING OPERATOR QUALIFICATION TESTS

RS

ROTARY

Su

Jnane ‘AGUSMAN TWP he. 2i7iveiooBeIe013 TESTOATE 27-Aer-2024

pRGPOeCO PETROLEUN STORAGE AND HANDLING FACILITIES (DASE D) FOR WELDER gay wery2-p-096

pretats PTT AT JMRONG PORT STAMP care

ive.Bina PRocess(es) (ystaw weet) (MANUAL

(2) smaw (2) MANUAL

os Ws Grawnsman 166-210 x ODE: ASHE

east earentan weLoed Nios re ro ios Gre THICKNESS: «10 87mm

MANUAL Ano SeMI AUTOMATIC VARIABLES scrua ‘uvict QuaLIre®

laser wo 1 (ASME. Ne : ASMEP NG. Pt ASME P No 1 Town 015

[SACKING (HETAL,WELD MEAL, a rout at sWanvout

us, £16.) @ vans wi

PIPE OR PLATE: (DIA. IF MIRE) - PIPE (6) (0073.1 and Over

FILLER METAL SPEC. / AWS CLASS a SFA S18 7ER 7052 Ane

@ Sean /e70t8 itor

riLLeR METAL F-NO. sa a) ANS

a ritore

(Sumani insint FoR GTAW

JWELD DEPOSIT FOR EACH PROCESS a)

@

lweibine ncerriow (ic, 56 EC.

Jnocnession (ummiiivoOwNMAL) A)

@

Jeacians cas FoR GTAW,pAW, GMAW <_

WeLDins CURRENT TYPE/POLARTTY w

Report

s ree weirs

‘terete test nests: | :

live certity thot the’ stauements i this record are correct and that the test coupon was prepared, welded and vested in accordance with

ene requirements of Section 1X ofthe ASME

PT. KHO KONSTRUKSI INDONESIA

Kantor : Windsor Central Blok A No.11 - Batam 29444

Telp. (+62-778) 480 8570

CERTIFICATE OF EMPLOYMENT

SURAT KETERANGAN PENGALAMAN KERJA

NO :00033/HRD/KKI/2021

To Whom It May Concera

Dengan ini menerangkan

Name : Agusman.

Nama

Place/Date of birth : Palembang, August 18", 1983

Tempat/TanggalLahir

Employee Registration Number + KHO-EN-102

NomorKaryawan

Occupation : Welder SMAW 6GR

Jabatan

: November 25¢, 2020 until April 16%, 2021

MasaKerja

:JOB COMPLETED

AlasanBerhenti

‘We Would like to take this opportunity to thank you for your past effort and contribution to PT.

KHO KONSTRUKS! INDONESIA.

And to wish you every success in the future,

Kami mengucapkan banyak terima kasih atas usaha dan kerJasama yang telah saudara berikan

kepada PT. KHO KONSTRUKSI INDONESIA. Dan berharap semoga prestasi dan keberhasilan

senantiasa menyertai saudara di waktu yang akan datang,

Batam, April 20%, 2021

PT, KHO KONSTRUKSI INDONESIA

3 PT SMOE noe ann, PRIN 25A2

Mal Pal asicexicease

Welder Qualification Test Certificate

vecee SOE Wor oRMONA2-ns

secs rosteses

‘eh cis

erie ht

re were

pane rinse

Coli Avs Sc 20

Tame oi

ea sa aa

eneeea os mane

fate 7) eT

Ioron Tay ITT Gat Ba

= asx iia

om eam ee) a

na z aa

aman -

ie aestiea Ba moon na RC) ——

seta icine bm)

Tamm 307 am

Sen CTP ALL PP, PELE

eposed idknes am) Tam Seen CP ALL: PP, PULET

[oni means peor pte (esha) Pipe (10 me) - Unlined

Welaing poston cn All Position» Buca CIP on TRY Bos Tube

Weld elle ‘Gomve Weld Grane Kilt Wel

yer angle yer Mal ayer ‘Mi & Single layer

‘With or With

Bicking/Backgousng Witoae (Cr Jt fo Pige Box Te Shall Use Bacng or

Backgraing

Typ oft and canta Potemed wnt acpi Re regu Teron ante

saul examiration v WIT-VISSTRFORMOSA2.0119

Radiogapic eamnatior v WITRT-STRFORMOSA2-0119

Sica amiaton v

Macro eamiaton v

Frets oe T

Bed v

Aiaical te v

“Te conte by “Adi Attica

‘We cerfy tha the statements thinccord are caret and ht the el csupo were epee, wee

‘naccortance wth e regurement of AWS DI. Eon 2030

ATAMIK B

PT. BANYU ARTA SEGARA

General Contractor, Steel Construction, Structural, Piping, Firing Metal,

Ship Building, Ship Repair and Supply Man Power.

Perum, Taman Cipta Indah Blok, BI No.07 Batu Aji, BATAM— INDONESIA

Email : banyuartasegara@yaheo.com

CERTIFICATE OF EMPLOYMENT

SURAT PENGALAMAN KERJA

Nomor : SPK-03 1/SPK/BAS/IV/2020

This is to certify that :

Dengan ini menerangkan bahwa :

Name : AGUSMAN

Nama

Employee Number : DSS - 603465

NIK

Project Location : PT. DELTA SHIPYARD.

Lokasi Projek

Position : WELDER

Jabatan

Period of Service : February, 03°' 2020 up April, 032020

Masa Kerja

Reason of leavin; : Finish Jobs

Alasan berhenti

We would like to take this opportunity to thank you for your past effort and contributions to

company, and to wish you every success in the future.

Kami mengucapkan terima kasih atas jasa dan dedikasi yang telah saudara berikan kepada

perusahaan kami, dan berharap semoga prestasi dan keberhasilan senantiasa menyertai

saudara diwaktu yang akan datang.

MUTANDINEHt DA

HRD MANAGER

Welder Performance Qualification Record

AWS D1.1 Suuctural Welding Code - Steel: 2015

Weller's Name ‘AGUSMAN,

Stamp No ws 177

Cerificate No nsjaws/1a7/02/020

WPS No WS: PTO-FCAW.€09

Test Date £08 February 2020

ase Materis!Wolded MS Plate.1136 Thickness 30 mun

weredio 2M Mate,C1196 Thickness 20 mm

Welsing Variables

‘Actual Values (Quatfcation Range

Procete Fonw cs Foawas

type “Seri Automatic welding “Seni Automate WRG

Postion W735. TAMU

Progression Vertical uj Vertical Up.

‘ase Materiat ‘ons ‘Group 1

Thickness (plate)

Groowe 3.0 mm to Untimted.

Filet ‘unlimited

Thickness (pine / tbe)

Groove

Fatet

Pipe diameter

Electrode Single / multisle

‘Current / Polarity

Bachieg Material

Joins Deven

Filler Meal Spesifcation — AWSSFAS.20

FM

Gos/ Hue

Aeceatable Yesor No: Yes

Guided Bend Yost Result = MA

Best eosult

Fillet Test Rerilt

Appearance: 8 Filet Sic: a

Hrgeture Test soot renetvation Macrotch | NA

Test Number

Date

‘Radiographic Test Revue

teport No.

Radiographic Test Conducted by Geng Samudra Indonesta

We the undersigned, cetity thatthe statements ia this tecard are correct and that the test welds were prepared.

‘welted and tested, in accordance with the requirements of AWS DLT

ty:

Quality Contiat

PF. Delta Shiprocd

Panaran Daour 12. Sangal Pelnggut Saguiuny, Batam \pdonoel

‘Tolp, +62 778 36 8507, Fax 462778 736 8508 wwndeRaaMpyard com

=m PT. IEG Oilfield Indonesia

Kabil Integrated Industrial Estate, Jalan Mas ‘Surya Negara VI No. 2,

Batam, Kepulauan Riau, Indonesia, 29467

INTEGRATED ENGINEERING GROUP Tel. +62 778 7100056

CERTIFICATE OF EMPLOYMENT

SURAT PENGALAMAN KERJA

NO 1141EG/HR/X11/2019

This is certify that

Dengan ini menerangkan bahwa

Name AGUSMAN

Nama

Place/ Date of Birth PALEMBANG, 18 AUGUST 1983

‘Tempat/ Tg! Lahir

Employee No 190096

No Karyawan

Position WELDER

Jabatan

Department PRODUCTION

Departmen

Period of Service : 12 AUGUST 2019 — 11 NOVEMBER 2019

Masa Kerja

Reason for Termination FINISHED CONTRACT

Alasan Berhenti

We thank you for your service rendered to the Company during the period of your

employment

Kami mengucapkan terima kasih atas jasa — jasa saudara selama bekerja

Batam, 02 DECEMBER 2019

HR & GA Manager

TEL: +65 6261 0203; Fax: +65 62616 6163

NGINEERING Email: admin@sunmarine.com.se

Website: yww.sunmarine.com.sg

SUN MARINE ENGINEERING PTE LTD

Sun Marine 30, Tuas View Place, Singapore 637 876

TO WHOM IT MAY CONCERN

This is to certify that Mr. Agusman / A 8311828 has worked with Sun Marine

Engineering Pte. Ltd from November 10" 2017 to May 09% 2018 in the position of

Welder SMAW/FCAW.

Porject Kaombo / Location Sembcorp Marine Singapore Pte. Ltd.

He left our Company due to the completion of this employment Contract,

We appreciate his contribution tawards our achieving successful conclusion to the

projects and for his full suppor! to Sun Marine Engineering Pte. Lid

This cerlificate has been issued upon the request of the above employee for any

legal purposes it may serve him.

Singapore, May 122018

Respecttully Yous,

Sun Marine Engineering Pte. Ltd

Ge

Geopal Arikrishnan

Operation Manager

bi@SNE

STH RK

Komp. Ceatury Park

Blok D-3A, Batam Centre,

Batam Indonesia

Telp: 778-7418100

Ml PT. DELIMAX INDONESIA Fax: 7787418101

Es mk hoon/éctimax.com.s

SURAT KETERANGAN KERJA

OFFICIAL LETTER OF WORKING STATEMENT

PT. DELIMAX INDONESIA

No, 003/SKK-DLX/1I1/17

Dengan ini menerangkan bahwa,

This certify that,

Nama : AGUSMAN

Name

NIK 1-024

Employee No.

Jabatan ; WELDER

Job Title

Nama Project : CULZEAN ULQ SMOE 17DLXBTM001

Project Name

‘Tempat Project :SMOE YARD Kabil -Batam

Project Place

Masa Kerja :04 February to 08 March 2017

Working Period

Alasan Berhenti _: Project Completed

Reason for Leaving

Atas jasa-jasanya kami mengucapkan terima kasih dan semoga sukses selalu di masa yang akan datang.

We would like to express our thanks to him for services and cooperation and wish him always suecess in

the future endeavors,

Director

@ra PT. CITRA TUBINDO ENGINEERING

"EPG Unt S12, Kay ADF, Hang Kestrll 8 Lig iesalegled

Kati incisal Este, Batan 29467 - Indonesia

Tel. (62-778). 719433, Fax. (62-778) -791425

cledicte

#180 /TS-29001

CTE oe ae =,

CERTIFICATE OF EMPLOYMENT

SURAT PENGALAMAN KERJA

NO. : S14 /SPK/HR/CTE/ VII /2017

hhis is to certify that

Dengan ini menerangkan bahwa

Name : AGUSMAN

Nama

Emplovee Number :

Nomor Induk Karyawan TASH

has been employed by PT. Citra Tubindo Engineering Kabil - Batam |sland with the following data

telah bekerja PY. Citra Tubindo Engineering. Kabil - Pulau Batam dengan data sebagai

igineering. age

berikut

Job Classification 3S

: Welder FCAW GS 6G

Jabatan

Service Period + From _ 27 August 20

Masa Kerja * Dari * 27 Agustus 2016

~ Until ___ 26 November 2016

Sampai * 26 November 2016

Reason . Finish Contract

Alasan * Habis Konirak

Remark , Thank you for your services rendered to the Company during

Keterangan © the period of your employment

Alas pengahdian Saudara selama bekerja pada Perusahaan,

kami ucaphan terima kasih.

Batam, 02 September 2017

FM-HR-38 Page 10f1 Rev 01,19 Feb 17

A %) PT. PROFESIONAL PRATAMA INDONESIA

PROVIDING MANPOWER OUTSOURCING GENERAL TRADING etc.

CERTIFICATE OF EMPLOYMENT

‘No,01598/PPI/HRD/XIV/2015

To Whom It May Concern

This is certify that

Name : AGUSMAN

Employee Registration No. ; 21754

Dept /Job Cluification —: WELDER FCAW GS 6G.

Period of Services + 16Seprember 2015 To 15 December 2015

Project S Location » PT. Profub Indonesia

JL Bawal Kav. - Baru Merah

Batam

Reason of Leaving + Contract Completion

‘We would like to take this opportunity to thank you for your past effort and participation

to PT. Profesional Pratama Indonesia and we wish you every success in the future.

Batam, 16 December 2015

PT. Profesional Pratama Indonesia

Cendana Blok B1 No. 28 - Batam Centre Telp. Fax : +62 778 475 017 Email : ppi_cendana28@yahoo.com

— PT. PROFAB INDONESIA

AL _BAWALKAV. V BATUMERAH

PROrA3 seer

inponesia PHONE: 62776 413 250 FAX: €2 778 413260

Certificate no,: WP4244-M-1

‘QW-484A Weider Performance Qualification (WPQ)

(QW-301, Section IX, ASME Boller and Pressure Vessel Code)

Woks Nae: ‘AGUSMAN Foran Sure No: wre

\terteaten f WPS fone wremmanit

Spectoatn ct Bove meta): ‘API SD

esting Conditions and Qualfcation Limits

‘Welding Variabies (QW250)

Waking reese)

“ype ins raat vembaso) sad

aching rl wa sa due weed)

1D Me Pe erie caval Fon eubo)

‘Base metal Por S NurteroP-or Number

Fir Maa Elacrode ptr (SFA (roy)

Fler Weta Eecrode css) (in ry)

Fea Fr)

Conmunatl nse (GTAW or PAW)

‘ter ype (ert ac cocponse) STAN or PAN) Na, WA

‘Weld depot ticowes er exch weg proces

Proce 1: _SMAW Sayer min Yee

Proce 2 Slayesmhn Yes

Poston quad

‘Vertes Propescon oho Sore

‘rest as aching STAI, PANE. GMAW)

“Types FusiGas FW)

‘Traretr Mote (opayigeblarr puto sot cha GRAN)

GTAW waldo curt pfptety (AC, OCEP, OCEN)

a

at

Resuts

isu amotio ret (C024) 201

BendTet: CO. Rectandtine a Se (BConosn restart overt bane

Mar Tenttetaen

erp el mse OW. and W305) Pesses ___reperte.

frmctacaet pment tore Faacarni na conaby

‘eld Fre Tet NA Lang ard pacar dea

Mace ean wa Flltgdis ine

Fir spectner wali by ASNTLova 2 “Corpay

Wek supe by vei eerie Viresseey ———Sheeete

Mechanic et corti by aorta,

pionsio))

Yo

PT. PROFAB INDONESIA

\LBAWALKAV. V BATU MERAH

BATAM ISLAND, INDONESIA

PHONE: 62 778 413 250 FAX: 62 778413 260,

‘emalprofab@indosat.neLid

Certificate no.:Welder AWS-WP4244-FG1-6G

Walder! Welding Operator Performance Qualification (WPO)

‘AWS D1.4 Structural Welding Code — Stee!

via Ha: asuanes wre

WargPesante ace Sate

Wesices NPsanssroiRATw nn

— {Ae prgaeniope naan

at ae Teno Ged

awsome 1 ans oe cuaint

‘rela sai

a

retire

Tip. weer

‘ome sam

Pat. :

Pesaro ene a

Reaaiicacaita pais

Se mati onsooe asc1m) aa nde

cw ny see

wag Peston —_ . — _ee |

Pato aa ow Sine SS

Sock cl wes ei om le atl) Tnastone i sa ——

Fee gettin 83 Conan TERE aa

revere ny

(i etre wa

Swe cs =

Note: 4. Quid ss fol pil ont pextratin anny Dice ee

DOS 2ciprpesTuteshlie ung ecwaerbetggng hs

Veil waneinnee oat

Recon eene eae _eeve.__ aaa —

bon RO a rope ‘ao as

rsretteorssc)

— MA nS Pn

Fe Tod RosPerenton WA toons wa

Weary texcenacesty Wiig Superioce —WiresadBy GB Inapector

Metwialelcodidty :

We urged, cay tte store ca coe ar at eos wae we prepare wed anda

‘cco it regarmons Of Section ée ANSY AAS D1 200 Edt Sicha Wol Cate Sel

PT. PROFAB INDONESIA

-

‘JL_BAWAL KAV. V BATU MERAH

P20rA3 a Sot

raponesia PHONE: 62 78 413 250 FAX: 62778413 260

‘ematprotabGindosat.netid

Certificate no.: Welder AWS-WP4244-M1-6G

Welder / Welding Operator Performance Qualification (WPQ)

‘AWS 01.1 Structural Welding Code ~ Stee!

Webra Nene AGUSUAN ronaa Simp No:

Weary Pres) ‘sai Dee Hen _

WPS ised: ws.aw'

‘Base nal weed

AWSo

‘Treas iat,

‘Saar,

Flat,

‘Thidoess poe.

Caos.

het

Pe caret,

Wee sence Nea breach welina pce

‘Sigel mute ects

‘cure Pury

Wetng Potion

Progrssoe (uch dove)

Backing rea ald rt wt tom es, a.)

Fier Wet Specteation a

aopocanancaD030633IA

Gas! Tipe

toAws

Wo, be uncurigred carly Pa the satonart hr tisracar ar comet wed at et vals wore pena wae ard fst

sccorance wit ne equremets of Sect 4 ef ANSY AWS D1 2010 Ete Sucre Walhg Gade ~ Seal

MCCONNEL PT. McConnell Dowell Services

ee aamaeee

Neon iene

Batam 29424 ~ Riau land, Indonesia

+62 778 301 980

F062 778 391 985

Socuments

ao FT 73100 8K

srw. meconnelistowell. com

SURAT KETERANGAN KERJA

CERTIFICATION OF EMPLOYMENT

395/MCDIVIN2015

Dengan ini menerangkan bahwa:

This is to certify that

Nama : AGUSMAN

Name

No. Karyawan 2 BI141MO1

Badge No.

Proyek /Lokasi + 8283 -HEEREMA PROJECT

Project /Location Batam

JabatanTerakhir : STRUCTURAL WELDER 1ST CLASS

Last Position

Masa Kerja = APRIL 08th, 2015 - JUL 07th, 2015

Period of Service

Alasan Bethenti : FINISH CONTRACT

Reason of Leaving

Kami mengucapkan terima Kasih atas usaha dan jasa yang Saudara berikan kepada

PT.McCONNELL DOWELL SERVICES Batam. Semoga keberhasilan selalu menyertai

Saudara di masa mendatang.

We would like take this opportunity to thank you for your past efforts and contributions

PT.McCONNELL DOWELL SERVICES Batam. We wish you every success in the future.

Batam, JULY 16th, 2015

For PT_-McCONNELL DOWELL SERVICES

DRIVING PROGRESS

ee

a9 Record of Welder Qualification Test me ®,

017-F023-8383,

(CREATIVE CONSTRUCTION”

CLIENT : Heerema Marine Contractors Australia Pty. Ltd. JOB NO: 8383

PROJECT: Fabrication of Chain Routing System Certificate No: PTMCD/WC/1152

NAGE OF WELDER AGUSMAN TOCATION: PTMCD/BATAN | STAMP OR IDNo

bare: 90/03/2018 "| wcoasa

WELDING PROCESS) | TYPES) WPS No QUALIFICATION TEST No

roaw.cs semauromanc vascnse2s9s001 PORNo, NREVE3E801,02, 69.0

VARIABLES FOR EACH PROGESS(ES)(QW.250ORGW360) | ACTUAL VALUES ANGE QUALIFIED

Tipe of anand Wold Shalev at Wed tard Ft

Daking (rot wl tl welded boon, xen) | Beck ugg end Be was | WthBating (a Met or Back

Soo nora SeeR 32588 any Group oF Eur

Pla o Pipe NPSO.D and Thicoess Pate rm Met Tak Se Used

TANS BFANS (6) nd FO) FA, SFAS20.F8

Potion (86, Fe. Spada Poa) waa F.V.H oH

Presson (Upha/Oownhi ven pa

Shining Gaver) 8% Consonants) ean 02 conn coe

Fier rt fleets coors ere enme

Wecing Curen nd Peart coer DoEP

Space Resiion CLYes _CINo Or Ober Comment WA WA

"ADDITIONAL MAGHINE WELDING VARIABLES ACTUAL VALUES TANGE QUALIFIED

Diet or Renate Vue Corto Machine Orel Conto!___| Maine Ded Conta

Avaate Ae Votoge Corel Sate for FAW NA

‘eats Sort Tactig WA

Sil or pe Pate aba Pass

VISUAL AGCEPTANGE OF Name nage

Year cOuPoN Wek Hauer AMBARITA ra

TEST OONOUCTEDEY WA GERT No WA

(QUDE BEND TEETSPECMAEN TYPE RESULT "WA

RADIOGRAPHIC TET RESULTS

(FOR ALTERNATE GUALFICATION TEST CONDUCTED BY REPORT No mes

GroRGOvE WELDS BY RADIOGRAPHY) Urauaniy rnanawarioet ACCEPTABLE

TMBBWaTIOG2

FHLLET WELD TEST RESULTS

FRACTURE TEST DESCRIBE THE NATURE AND SCE

GFANY GRAGK OR TEARING OF THE SPECMEN NA

LENGTH ANO PERCENT OF DEFECTS: i

MACRO TEST-FUSION

APPEARANCE-FILLET SIZE(LEG); Mx MM.CONVEXITY MM.OR CONCAVITY: mm

TEST CONDUCTED BY LABTESTND

WE CERTIFY THAT THE STATEMENT IN THIS RECORD IS CORREGT AND THAT THE TEST WELDS WERE PREPARED, WELDED AND

TESTED IN ACCORDANCE WITH AWS DI.t 2010 STRUCTURE WELDING CODE - STEEL

TO BE SIGNED ON COMPLETION OF PROCEDURE.

CLIENT (applicable) CERTIFYING AUTHORITY

NAME/SIGNATURE NAME/SIGNATURE,

017-F023-8383 Revt 1Apr2014 Page 1 oft

MDT INSPECTION SOLUTIONS

Ny ee

Stondora NDT ~ Adkanceé NDT— Pipeline Construction

indonesia New Corstrucion Third Party Ingectlon /usting

Branch 1.1 17392,

Job No. 48.0018

RADIOGRAPHIC INSPECTION REPORT _ [Repatxes —[ersssworne

Test Date: 30-03-2015,

Page: Loft

CUENT Heerema Marine Contractors Australia Pty Ltd -

Job Destription Fabrication of Chain Routing System ie - ~

Job Location : Sagutung-Batam _ Requested By : QC Department

Order No. : Ra Work Instruction : 061

Cast Tab Nos 8383-3650 oun, Surface Condition : _AS WELDED

Material : Test Method SWS —~

NDT Procedure :

Acceptance Code +

Construction Code : Weld Specification +

‘Tea Speciation’: Film Type: _AGFA D7 Density :

Tecate: PARENT CERAM. Seren: _PbO.12Smm__—IQI Type: ASTM 1B

‘Test Restrictions / Source: Gamma Ray Ir-192___ _

‘Comments : ‘ a SFD/FFD : _457.2mm Flim Size; 4x10"

i a

A SeDebect ete er ‘Ths Cri inter Pe DIP Debris Pipe

ou FC elopiedety cr Garon HB How had

te TL Una Ini 10 Ose ncaen

" ke KL Longltel Crack

kr uy POHL) thomplae Ro Pesaran

uckOrRow Fossa 8 (ita)

Fras Gere Pipe me ate Party

Eisai Dreing sor PU Uanlorm Perey

Somer Mor or SMG Grading ark

Sater SUS Tore Surtce SRC Ron Casa

Erebe Pecirni Ded__WA___Worm oe SUCT__Unere ral

Ci Complies DNC: Does Not Comply NW: New Weld

Drawing Noz Nil

Spool / Hem No.: PLATE

Request No. RFLWOT-$383-RT-042

MAING | wetoeRNane [We1neRD| —wrsNe _[unom] Tax | WHERVAL | Wimmmrnmion [SS [conc

«6 AGUSMAN | McD—a8s | HMCAS36001/ 290mm | 25m0 | — A-B 4 2] e

— 1

Contractor Representative Client Representative ‘3 Party Representative

1) Aistobeee a

a

Ts a02c\2|

mainenorerine-it ame: Biba @

te: 31-03-2015 Pate ofoglis

Komplck Fal Spring. Bick D2 No, Batam 29436, Phone: (62 778148601 / 463275, Fax: (52-778) 464109, Web wwe alqualiy.com

NRTINSPECTION SOLUTIONS

ut ees fore arers

Indonesia ‘New Construction — Third Party Inspection /Auiting

Branch LD? To —

\ 48-0198

RTSEVWOTOR

30-43-2015

Loft

RADIOGRAPHIC INSPECTION REPORT

CUIENT: Heerema Marine Contractors Australia Pty Ltd iit =

‘ob Description + gaprication of Chain Ronting System . — ———

Job Location : Sagulung-Batarn ___ Requested By : QC Department i _

Order No. : WA Work Instruction : _062 —

Gamat ens 8385-3650 Surface Condition : _AS WELDED a

Material : S35SIR ___ Test Method : swst

NDT Procedure :

Acceptance Code + _A\

DI

Construction Code: Ws p1.1-2010 Weld Specifieation : _FCAW GAS

‘Test Specification: AWS D1-1-2010

_ Film Type: _AGFA DT Density: 2.2

Le DHENYCITRAM, Seren: _ Pb 0.125mm IQI Type: ASTM

‘Test Restrictions / Source : Gamma Ray Ir-192. eel =

Comments: Nil SED/ FFD ie

A No Dect Detected or Threw ‘Crater Pipe DIP Debs tnipe

DM biracion Mot EC Rlongated Cay Gutore HB Holm Bend

HC Copper cei {Lin tnion Indice 10 Oxierindion

TT Tans inden Ke Crane rach, ae Cock KL Lanperina Crack

KT Tranmere Crack LA OF tern Pon Incomple Rext LP(HL) Incomplete Root Peneration

LR Lack OF Row Fon LS LachOFSideFason PD Praca Dect (ign Low)

PGI Farge Gear a Pipe PL Line Poroty PSP Poor Sotse Profle PG LoeaiuedFoenty

SED Tacenve Drening SGI Incomplnty Pied Groove GS Shrinkage Grove PU Crem Poon

SMH amen Mark SMT ToetMark SPT Sones Ping SMG Grinding Mark

SSP Spater STS ToreSorfsr SUCE Unter Ester SRC RoniConaiy

SXP__LucesiveReseraton Bead WH Warm Hab WT Wagon Tracts SUC

(cz Comptes DNC {Does Not Compt RUD ¢_Repalr toe Repale3 NW t

TEST RESULT.

Drawing Noz Nil

Spool / item No.: PLATE cee HE

Request No, RFE-WOT-8383-RT-042

WELDING o

Position | WELDERNAME [WELDER ID | WrsNo, INTERPRETATION

G acusman | Mco—a88 | HMCARRE 36001

UT Quality Indonesia | Contractor Representative ‘Client Representative 37 Party Representative

@ :

Komik Paim Spring, Bok 0-2, No.8, Maram 29456, Phone: (62 778) 466915 ! 463278, Fx: (02-778) 464404, Web : wwe atgualiy com

Engineering Division Ww

wasco

IF EMPLOY!

523/WEI-HR/IX/2014

This is to certify that

Name : AGUSMAN

1.D. No, 2 02-1204

Position : WELDER

Department + PROJECT & OPERATIONS

Company Location 1 JL. BRIGJEN KATAMSO KM 5

TANJUNG UNCANG 29422

BATU AJI- BATAM

Period of Service April 21%, 2014 to September 20", 2014

Reason : FINISH CONTRACT

We would like to take this opportunity to thank for your past efforts and

contribution and wish you every success in the future.

Batam, September 22", 2014

PT. WASGO ENGINEERING INDONESIA

ER

HR Manager

PT. WASCO ENGINEERING INDONESIA

FCS8Re 3

wasco

—— ee MANUFACTURE’S RECORD OF WELDER,

mia Tanjung Uneang-Batan WELDING OPERATOR, TACKER WELDER |

indonecis

fone 062) 778 396212, Fx (+62) 778396211 QUALIFICATION TEST

Certificate No. ‘Wei WaR/AWs/1397 Tezue Date ia bec 2014

Welders Name ‘AGUSMAN | ieentifcation No. | 922

Type of Welder X | Welder__| | Welding Operator Tacker Welder

Welding Procedure Specification No. | WPS-W-130 | Rev.| 0 | Date Test | 11/12/2014

Record Actual Values Used in

Variables cuiiatee ‘Qualification Range

Process /Type [Table 4.12, item (2]) SMAW - FAW = |

Tlectrode (Single / Multiple) Table 4.12, ten (7) Single electrode SAW FAW |

Current /Polarity DCEP al

Position [Table 4.12, item (4)} 66 (Except, Y, K Configuration)

Welding Progression [Table 4.32, item ()] Uphill Uphi

Backing VES or NO) [Table 4.12, item (6)} No (SMAW), Yes (FCAW) ‘With/aithout (saw) — with (FCAW)

Material / Specification ‘APLSLX 52 ‘Any

Base Metal [Table 4.11]

Groove : 5mm to unlimited

Thickness (Plate) Fillet = ‘Any thickness

Groove Sch 80 ‘Simm to unlimited

Thickness (Pipe/Tube) — | EToe ~ Payee

Tiamat (Piel Groove Nese NPS 4 to above:

om Fillet = ‘Any size

Spec. ‘AS1-A5.20 F1-F3 with backing, F#

Filler Metal [Table 4.22] [AWS Class ‘#7018 = E7171 with/without backing & F6 with

F No. Table #12 (2)) Fa—F6 backing Allof No.6

Gas / Flux Type [Table 4.12] CO, (FCAW) |

other ‘ CO; (FAW)

Visual Examination of Complete Weld Results (48.1) | Acceptable

Guide Bend Test Results ee Seat ie Result

(4.30.5) : = : 5

Fillet Test Results (4.30.2.3 and 4.30.4.1)

‘Appearance 5 Fillet Size :

Fracture Test Root Penetration Macro etch 5

(Describe the location, nature, and size of ny rock, ing of the specimen)

‘Mechanical Test Conducted By Laboratory Test No =

Radiographic Test Results | Flim Identification No. | AT//Wei @swva7-war-ar-ass | Results meer |

(4,303.2) Fim interpreted By ‘ASNTLEVELII(NENORA) | Company | _PTASTANTESTING AINSPECTION

Welding Supervised By RAMS Company ‘WASCO ENGINEERING INDONESIA

We centfy that the statements in this record are correct and that the test welds were prepared, welded and tested in

conformance with the requirement of Section 4 of AWS D1.1/D1.1M-2010Structural Welding Code-Stee!

PT Wasco Engineering | PT Wasco Engineering

Organization Indonesia Indonesia

Pee ‘Checked By

sien [2 os \ s

\ ce) Fey ))

Name Kendy W Swiselip”

L Date 12/12/2014 12/12/2014 J

oc.o0se ney 3

es 2 reerino 7 MANUFACTURE’S RECORD OF WELDER,

iceman seeing toe WELDING OPERATOR, TACKER WELDER

Prov Kop ~Inonela

hora (S277 S002. ox (62) 78 386211 QUALIFICATION TEST

[ Cerificate No 1MS/WORTAWS/790 issue Date 6APRIL, 2014

Weilder’s Name ‘AGUSMAN identification No. 922

Type of Welder X | Welder Welding Operator Tacker Welder

‘Welding Procedure Specification No, | WPS-M-73. Rev, | 0 | Date Test 12 APRIL, 2014

Record Actual Values Used in

Variables ‘Qualification Qualification Range

Process/ Type [Table 4.12, item (1) SMAW - FCAW. 7

Electrode (Single / Multiple) [Table 4 12, em (7) SINGLE ELECTRODE ininghtsinial

Current? Polarity DCEP All

Position [Table 4.12, itern (4)] 6 (Except T, ¥, K Configuration)

Welding Progression (Table 4.12, item (5)) UPHILL UPHILL

Backing [YES of NO) [Table 4,12, tern (6)] NO (SMAW), YES (FCAW) eee

ateriai/ Specification ‘APLSL XSZ ‘Any

Base Metal [Table 4.11)

Groove z mm TO UNLIMITED

‘Thickness (Prete) Fillet - ANY THICKNESS

Groove SCH 80 (12.7mm) 4mm TO UNLIMITED

Thickness (Pipe/Tube) Sree 2 Sa SS

Groove tse NPS4TO ABOVE

Diameter (Pipe) Fillet 7 “ANY SIZE

Spec. ‘KS1-A520

Filler Metal [Table 4.12] AWS Class. £7018 ~ E7i1T La oe

F No. [Table 4.12 (2)) F4-F6

Gas / Flux Type [Table 4,12) CO; (FCAW)

[others ; 0, (FAW)

Visual Examination of Complete Weld Results (4.8.1) | ACCEPTABLE Too

Gilde end est tsuts |" fan Ties fest

(4.305) = = = ~

Fillet Test Results (4.30, 2.3 and 4.30.4.1)

Appearance = Tilet Sze z

Fracture Test Root Penetration = Macro etch z

(Describe the location, nature, dnd sizeof any Gach, tating of the specimen)

Mechanical Test Conducted By s Laboratory Test No. -

Radiographic est Results | Fim Wentication No, | —oounwe/calnywarrv/ia | Results cera

(4203.3) Film interpreted By ‘seruva.n | Company | PTAADINEY UrAMAINTERINEGS

Welding Supervised By RAMUS Company | __WASCO ENGINEERING INDONESIA

We certify that the statements in this record are correct and that the test welds were prepared, welded and tested in

conformance with the requirement of Section 4 of AWS D1.1/D1.1M-2010, Structural Welding Code-Stee!

WASCO ENGINEERING | WASCO ENGINEERING | WASCO ENGINEERING CAIRN

Prepared By Checked By ‘Approved By ‘Chant’: Representative

i

2 LOWE

‘Name Lariki Susanto Arif

Wiselin

(oe 16/04/2014 weley (710+ aoe

Organization

Py) PT PROFESIONAL PRATAMA INDONESIA

PROVIDING MANPOWER OUTSOURCING GENERAL TRADING etc.

CERTIFICATE OF EMPLOYMENT

No.0713/PPI/ARD/I1/2014

To Whom It May Concern

‘This is certify that +

Name

Employee Registration No. 20622

Dept / Job Clarification + WELDER SMAW 6G

Period of Services + 22 October 2013 To 21 March 2014

Project & Location + PT. Profab Indonesia

Jl, Bawal Kav. - Baru Merah

Baram

Reason of Leaving + Contact Completion

‘We would like to take this opportunity to thank you for your past effort and participation

to PT. Profesional Pratama Indonesia and we wish you every success in the future.

nine, 22 March 2014

PT. Profesional Pratama Indonesia

Cendana Blok B1 No. 28 - Batam Centre Telp. Fax : +62 778 475 017 Email : ppi_cendana28@yahoo.com

PROFA3 PT. PROFAB INDONESIA

JL BAWAL KAV.V BATU MERAH

BATAM ISLAND, INDONESIA

inpongsia PHONE: 62778 419 250 FAX: €2 778 443260

Certificate no.: WP4244-M-1

QW-484A Welder Performance Qualification (WPQ)

100.0, Section ASME Bor and Pressure Vessel ody)

Wonca re: orassonpo: _wraaee

"Test Descpton

erection of WPS fone 50 2 TestCagon 1 Protucooweld

‘Speceatan of Base meats): ‘APL XE Widnes samme.

—sona0 427m _

“Testing Conaitions and Qualification Limite

Welding Variables (@Wv-320) ‘Actual Values Renge Quatned

Wienges) — sew __

‘ypellenarual eri) aad Mas

‘acing (etal, wed mea obi wee)

2 Male 2 Pea(ertcanaarfipe cube)

‘Baseman or8-NunberioP-ocS-Narbar

ler Maar Ecos spectators) (SF rfoony)

‘lr etal Cero cafetons)efe.Ory

Fetus ta)

‘Cornus roet (STW or PA)

or ype gta rhc credponden (STAM or PAW)

Weiecepoa cess fr aac vel reese

Process: __SMAW 3lajenmin Yes No

Procas2: + Slaven Yor Ne

Poston quite

Vert Presse (ip or donb)

‘ner Backing STAW, PAV. GAN)

Typact Fu Gas OFM)

“Trantr Nee (opal e peo st chest GMAW) ——_ a a

(GTAOY wag caret Ypeky (AC, DOEP, DCEN) —doze,suam __ _neep satay

Rosuits

Vio arian ete (W302 Sd

BensTest: 1 Reandince a ae BP Cameson esstntoverybord

Mace Tetra

aarp et wets ( 0 a 305) Reporte, ——

Sracwestcandgennaniyere) Tagoprie at corna ye PEW Kiasttaa Ison

nev -Fracte Test NA gh a pct celecs

Mace wan vs Files nx on, Caenvoneay

Finecspacnenseaiatdty —___ASNTUne? "__Gimpary_Y. Be lata dein

Watoweninel by _“"watmaieniee _""Wieeisiy | __eruepetar

PT. PROFAB INDONESIA

—_

JL.BAWAL KAY. V BATU MERAH

PR0raA3 xine noes

indonesia PHONE: 62 778 419 250 FAX: €2 778 413 260,

‘emai:profab@indosat.netid

Certificate no.: Welder AWS-WP4244-M1-6G

‘Welder / Welding Operator Performance Qualification (WPQ)

AWS D1. Structural Welding Code ~Steel

Welders Name: roFaa Stamp No we4ase

Westng Processes) used Tee Men __

WPS use Wrs.AWS 20 Fev ° Tea Oat: 40ea013

Base maoral weld APIS XS 68mm OD (Thi

a” — ae

‘Actual Valves Range Qusifes

ANS Gow ans rout ‘Scop Lio

Tree pt, sw

Seooe rm : Smm=unieited

Filet Sa as

“Ticks pipe aioe

(Goo me Smm—unieitet

Flt rm

Pipe dancer, 21007mm dame

Wid depsttnckress foreach wen process

Sinjel mate lect rateaaten7 ‘Shale Single

Cron Polarty ——— a

‘Wang Poston eas2ton 6 ¥

Proyesson (ui down) ‘atest Uphl Yoh

‘Backing neta wold mata woe fom sda, fi) Taner Witteut Wit or wit

Fe Met Specfeaton st Cassicason__E7016-1 870764

Fe Met No. Fe Fitore

‘osooAocoNNCKaA WA

Gey RacType

Notes: 1. Qualified als for welding pati jintpenetraton on any thickness

‘Visual eaminaten results

RacograsicUrasonic txt resis

(eaaratesuatan spots ASR adoarasiclIT oot conticiod by

Filet TostRosuts 423445041

Areata NA Fret Soo NA

Frau Test Root Petron Ne Macroeen WA

Wisin est conducted by ___ Welding Supervicr —_ Wiresved By Cinapecie

Mecrani esiconaictod by NA Taboraterestre NA

‘We. tho endorse, cont thatthe satorarts this mcord ar carect andthe the ea welds ware prepared, welded and tested

‘aceardaree wa ne requremens of Section 4 of ANSV AWS 01.1 2010 Eaten Structural Weng Once — Seok

onaimonexa Form: QAF-225 Rev:

PT.Global Process Systems

Sckapeng Lagisic Bue

‘Block F, No.6, Martadinuta,

Telp 162778 322696

Fax 162.778 322695

SSS

CERTIFICATE OF EMPLOYMENT

Hi

DM/CERT/2491/1X/13

‘This is to certify that the following employee =

Name : Agusman

Employee No. 08578

Last Classification : Welder

Reason of Leaving + Contract Completion

Has been in the employment of PT. Global Process System, since 11-Mar-2013

thru 10-Sep-2013.

We would like to thank for the efforts and dedication during his service with our

company.

Batam, 10-Sep-2013

Pr, | Process Systems

HIR- Mgnager

Tol 162 778 522896 é wa

Fax +6278 322605, i]

srorw globalprocesssystems.com BS

WELDER QUALIFICATION TEST CERTIFICATE

Name Agusman

ono | 2471121908839013

WPS No | WPS-a31/9R2

Welding Variables

Welfing Process (es) GTAW/ SMAW GTAW/SMAW

‘Type (Manual, Auto, Semi Auto) MANUAL WANUAL

Weng Poston cy ALL

Weld Progression UPHILL UPHILL

Bactng Material /Gas NA NA

-Number to P-Number Pt toPt mt ba Pa

wet | Diameter "NPS ‘4° NPS to Unlimited

Thickness 127mm 254mm MAX

Classification ERT0S-6/ E7018-1 ER705-6/E7018-1

tt, [SFANunber ~_SFASIBISFAST SFAS16/SFAS.A

F-Number FoF F6/ FAF1,F2,F3 with Backing

Weld | Process 1 GTAW 63mm 13.8mm Max

Theness [Prowess? __ SMAW ‘mm Uniinited

Type of Gas /Flux

‘We certify thal the statements in ths record are corect and thatthe test coupons were prepared, welded ard tested in accordance

withthe requiromerts of ASNE Soc IX (ASME Boler and Pressure Vessel Code)

\ sh j

PT Global Process Systems

ENIOR INSPECTOR

PTSC

‘Beye iin

KEVIEWRIE AUTENOSGS NCPR TE

i) PT. Hanninno INTIT RADA

EMPLOYMENT TESTIMONIAL

No. : HIT/E-HRD/1788//2013

To Whom ft May Concern

- .

Dengan ini diterangkan bahwa

‘Name : AGUSMAN

‘Nama

Em i 07123972

‘Nomar Induk Karyawan

L WELDER GTAW/ SMAW

Dopt. Jabatan

CITRA TUBINDO ENGINEERING

August 20,2012 ~ February 19, 2013

‘Masa Kerja

Reason of Leaving : FINISH CONTRACT

Alasan Berhenti

‘The above said served well to meet all requirement and satisfaction as well as approved to have

‘|@ goog work discipline and best conducts. We thanks his heartiest and wish him all the success

in his future carreer

Yang tersebut diatas telah bekerja dengan baik untuk memenuhi semua persyaraten kerja untuk

mencapei hasil kerja yang baik dan juga telah mewujudkan disiplin kerja yang baik serta memiliki

penilaku yang terbaik. kami mengucapkan terima kasin yang setulus-tulusnya dan berharap

‘semoga mendapat kesuksesan dalam karr yang akan datang.

CC. File

Office ; Komplek Ruko Palm Spring BTC Blok A No.11, Batam Centre - Batam 29461, Indonesie

Phone : +62 778 469093 (Hunting) Fax : +62 778 460002, Email : stai¥@hannindo.com Website : www. hannindo.com

‘ PT, CITRA TUBINDO ENGINEERING

Walder / Welding Operator Performance Qualification (WPO)

(Section IX ASME Boilar and Pressure Vessel Code)

ome

Eater

Ears

Ere

a Rabo

fre Tene momen reyes

[Seinen =

WELDING VARABLISGm350)

ata cas ot

‘chapel wd ots cats ova

fg maa 9 enact

comme man amy mat

tt me Pane oe ares oun

ce S14 _ diay ei

Proce? S308 Sayen ren

‘een aes en sonra

et guatsng (STA, PAW, GLA)

(GTA coer we ay KOC, CEN)

Cmtiatioe

‘acomatc machine Welding Varta OW)

‘Atanas re vagal TAM)

‘nasa or a

ies mae nos Pe

Ourge on mama mare

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Foklore Project 1 CeritaDocument3 pagesFoklore Project 1 Ceritafauzan alawyNo ratings yet

- 5 PDFDocument1 page5 PDFfauzan alawyNo ratings yet

- Surat Dukungan Kegiatan FestifalDocument4 pagesSurat Dukungan Kegiatan Festifalfauzan alawyNo ratings yet

- Petunjuk Teknis FFPB2023 (Proses Editing)Document23 pagesPetunjuk Teknis FFPB2023 (Proses Editing)fauzan alawyNo ratings yet

- 3 PDFDocument1 page3 PDFfauzan alawyNo ratings yet

- 3Document1 page3fauzan alawyNo ratings yet

- Sea Safari Cruises - 2023 Sharing Trip PDFDocument6 pagesSea Safari Cruises - 2023 Sharing Trip PDFfauzan alawyNo ratings yet

- 4Document1 page4fauzan alawyNo ratings yet

- 2 PDFDocument1 page2 PDFfauzan alawyNo ratings yet

- 4 PDFDocument1 page4 PDFfauzan alawyNo ratings yet

- CV DODI Pipe FitterDocument26 pagesCV DODI Pipe Fitterfauzan alawyNo ratings yet

- 2Document1 page2fauzan alawyNo ratings yet

- 0 0 0 0 Cv. Hardiansyah 6gr TerbaruDocument14 pages0 0 0 0 Cv. Hardiansyah 6gr Terbarufauzan alawyNo ratings yet

- Trio OktabrianusDocument12 pagesTrio Oktabrianusfauzan alawyNo ratings yet

- 0 - CV - Irzad (April 2022)Document40 pages0 - CV - Irzad (April 2022)fauzan alawyNo ratings yet

- 203518Document25 pages203518fauzan alawyNo ratings yet