Professional Documents

Culture Documents

Materials A Brief History Reflection

Uploaded by

Neel Nadpara0 ratings0% found this document useful (0 votes)

6 views2 pagesThis document summarizes and reflects on a paper by Dr. Ashby on the history of material development. It notes that Dr. Ashby outlines how materials have evolved over time, from stone and bone tools in prehistoric times to modern advanced materials like composites and semiconductors. It also discusses how Dr. Ashby uses charts to show how materials properties have changed and new materials have emerged to meet changing needs and challenges over history. The author relates their own experience in welding engineering selecting materials based on balancing multiple required properties.

Original Description:

Materials a Brief History Reflection

Neel Nadpara

Original Title

Materials a Brief History Reflection

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes and reflects on a paper by Dr. Ashby on the history of material development. It notes that Dr. Ashby outlines how materials have evolved over time, from stone and bone tools in prehistoric times to modern advanced materials like composites and semiconductors. It also discusses how Dr. Ashby uses charts to show how materials properties have changed and new materials have emerged to meet changing needs and challenges over history. The author relates their own experience in welding engineering selecting materials based on balancing multiple required properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesMaterials A Brief History Reflection

Uploaded by

Neel NadparaThis document summarizes and reflects on a paper by Dr. Ashby on the history of material development. It notes that Dr. Ashby outlines how materials have evolved over time, from stone and bone tools in prehistoric times to modern advanced materials like composites and semiconductors. It also discusses how Dr. Ashby uses charts to show how materials properties have changed and new materials have emerged to meet changing needs and challenges over history. The author relates their own experience in welding engineering selecting materials based on balancing multiple required properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Neel Nadpara

MSE 5336

HW Project 1

2/17/19

Task: After reading the paper reflect on the two points Dr. Ashby covers: material development with

time and how the data was presented. Consider your experience with materials and relate that in your

write-up.

Reflection on Dr. Ashby’s “Materials–a brief history”

Scientists have determined technological progress to be the key factor propelling the

advancement of human civilization. Materials have facilitated the creation and progress of civilizations

since the emergence of mankind. In 1819 Danish archeologist Christian J. Thomsen related the

classification of artifacts to technology by the materials the artifacts were comprised of (stone, bronze,

and iron). This, in turn, leads to materials becoming the defining characteristics of vast time periods

which became known as the three-age system which defined the: Stone Age, Bronze Age, and Iron Age.

Later, the Copper Age that occurred between the Stone and Bronze Ages was added to the three-age

system. Superior materials for tools and weapons permitted mankind to spread across the world and

conquer both other civilizations and problems. It is astonishing to think that materials have allowed

mankind’s advancement from the beginnings of time to the world we see today. To this day, innovations

in material development and material processing impact society such as ceramic matrix composites

allow for more efficient gas turbine engines and improved continuous casting processes in steel rolling

mills improve quality and efficacy.

Dr. Ashby begins by highlighting Figure 1 which is essentially a timeline of materials from the

beginning at the Stone Age (100,000 BC) and going up to the Nano-Age (1980-Present). The Stone age

encompassed mostly natural materials such as bone and stone. The materials were shaped into tools

such as flaking flint and quartz into sharp edges. Then the Age of Copper (5000 BC) came to be since it

was a metal that could be found in its native form in nature. Copper could be smelted and cold worked

to form complex geometries while also hardening the material. Then by 3000 BC, accidental inclusion of

tin into copper allowed the formation of Bronze. The alloy bronze was much harder allowing for the

production of better tools such as knives that could hold an edge for much longer. However, by 1450 BC

a way to reduce ferrous oxides to make iron made bronze obsolete. Iron offered much greater stiffness,

strength, and hardness which made it far superior when making tools. The development of processing

had to evolve significantly to make iron and eventually the Bessemer process allowed the commercial

production of steel in 1856.

By following Dr. Ashby’s history of materials development, we realize that over time more

materials, processing techniques, and strengthening techniques were determined and exploited. Also, it

becomes clear that as humanity has better materials, the challenges change. After the Iron Age, the

problem is no longer survival and instead, humanity is able to thrive. Iron leads to the advent of better

plows and agriculture lead to a better quality of life. The advent of steel allows for the construction of

large buildings such as skyscrapers and initiates the birth of the magnificent city skylines we know today.

As humanity moves forward, the challenges become more complex and demanding. Flight transitioned

from the aluminum-copper (precipitation hardened light alloy) block reciprocating engine on the Wright

Brother’s plane to the jet turbines of today that require nickel and cobalt superalloys due to the extreme

temperatures in the hot section. It is a similar story for other materials such as polymers and

semiconductors where a need drives innovation in achieving new materials with better performance

characteristics. Dr. Ashby presents this progress by means of material-property charts in Figure 2.

Material properties limit the performance of most designs. However, it is rare that the performance of a

component is limited by just one property. Most of the time, it is a combination or even several

combinations of properties that matter to the performance of a component. Such combinations could

be the strength to weight ratio as seen in Figure 2 which is important in the design of lightweight

components. Dr. Ashby presents possible material choices by way of material property charts. By

plotting one property against another and creating fields in property space a large amount of

information can be packed into a compact accessible form. This form can reveal correlations between

material properties and eventually allows for the selection of materials based on the component

relevant properties. Thus, by analyzing Figure 2 it can be seen that many materials were developed for

lightweight applications over time such as foams for packaging fragile products where lightweight

materials would same money during transportation. Moreover, materials within each family were

developed over time such as aluminum and titanium alloys within the metals family to allow for strong

lightweight materials for specific applications.

My experience with materials has shown exactly what Dr. Ashby has described. First, that

materials evolve over time to serve additional performance requirements. Second, those materials are

rarely selected for one property and that careful consideration of numerous properties is required for

material selection. Currently, I am working as a Welding Engineer at Electric Boat and one of the projects

I work on is on steam turbines. Steam turbines tend to use older materials compared to their gas turbine

counterparts. However, steam turbines still have great demands in performance and materials must

exhibit good yield strength, corrosion resistance, fatigue life, resistance to cavitation erosion, good

machinability, and good weldability. It is difficult to find materials that exhibit all of these properties,

thus in many cases, we use combinations of materials such as cladding martensitic stainless steel with

an Inconel alloy to gain additional heat and corrosion resistance while minimizing cost. Also, materials

may be developed over time such as high strength low alloy steels that have good strength, toughness,

ductility, and weldability for pressure vessel applications. Overall, I agree with Dr. Ashby’s message and

am pleased to work in a field that helps further the reach of mankind.

Sources:

Ashby, M. F. Materials Selection in Mechanical Design. Butterworth-Heinemann, 2017.

Ashby, Mike. “Materials–a Brief History.” Philosophical Magazine Letters, vol. 88, no. 9-10, 2008, pp.

749–755., doi:10.1080/09500830802047056.

Valiulis, Algirdas Vaclovas. “A History of Materials and Technologies Development.” 2014.

You might also like

- Material Science (IISc Bangalore)Document272 pagesMaterial Science (IISc Bangalore)Suresh Khangembam100% (9)

- XXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkFrom EverandXXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkNo ratings yet

- Material Science Multiple ChoiceDocument946 pagesMaterial Science Multiple ChoiceMs. D. Shruthi Keerthi100% (1)

- 2D Metal Carbides and Nitrides (MXenes) - BookDocument530 pages2D Metal Carbides and Nitrides (MXenes) - BookChannarith Be100% (1)

- Composite Pressure Vessel Term PaperDocument35 pagesComposite Pressure Vessel Term PaperNeel NadparaNo ratings yet

- Hydrogen Embrittlement: Jump To Navigation Jump To SearchDocument10 pagesHydrogen Embrittlement: Jump To Navigation Jump To SearchCarlos BustamanteNo ratings yet

- High-Speed Steel - The Development, Nature, Treatment, and use of High-Speed Steels, Together with Some Suggestions as to the Problems Involved in their UseFrom EverandHigh-Speed Steel - The Development, Nature, Treatment, and use of High-Speed Steels, Together with Some Suggestions as to the Problems Involved in their UseNo ratings yet

- Welding Workshop ManualDocument28 pagesWelding Workshop ManualMADHAV GUPTA 10814-07No ratings yet

- MCQ Metallurgy Question PaperDocument11 pagesMCQ Metallurgy Question PaperAshutosh AvasekarNo ratings yet

- Chapter 1 Introduction On Material ScienceDocument33 pagesChapter 1 Introduction On Material ScienceZjian Wai100% (1)

- Bme Project ReportDocument16 pagesBme Project ReportAditya RanjanNo ratings yet

- Handbook of Ceramic Hard Materials, 3527299726Document1,089 pagesHandbook of Ceramic Hard Materials, 3527299726Hozefa TinwalaNo ratings yet

- SA Refractory MarketDocument16 pagesSA Refractory MarketCharles CoetzeeNo ratings yet

- An Introduction to Metallic Glasses and Amorphous MetalsFrom EverandAn Introduction to Metallic Glasses and Amorphous MetalsRating: 5 out of 5 stars5/5 (1)

- Ganesh Balasubramanian (Eds.) - Advances in Nanomaterials - Fundamentals, Properties and Applications-Springer International Publishing (2018)Document181 pagesGanesh Balasubramanian (Eds.) - Advances in Nanomaterials - Fundamentals, Properties and Applications-Springer International Publishing (2018)Jesus Moreno Castillo100% (1)

- PPR Konf 08Document4 pagesPPR Konf 08faris026No ratings yet

- 1 IntroductionDocument10 pages1 IntroductionrevanthkumarreddybNo ratings yet

- Assignment No-02: (Document Subtitle)Document18 pagesAssignment No-02: (Document Subtitle)Mah NoorNo ratings yet

- Materials Science: Design For Engineering Unit 8 Material Science and Engineering Annette Beattie August 15, 2006Document18 pagesMaterials Science: Design For Engineering Unit 8 Material Science and Engineering Annette Beattie August 15, 2006يحيى عياشNo ratings yet

- Material Science NptelDocument225 pagesMaterial Science NptelchandankrdumkaNo ratings yet

- Material ScienceDocument16 pagesMaterial ScienceELIAN JOSUE FUENTES LOPEZNo ratings yet

- Full Download Book High Entropy Alloys 2Nd Edition PDFDocument41 pagesFull Download Book High Entropy Alloys 2Nd Edition PDFrichard.lamar761100% (19)

- Metallic MicrolatticeDocument3 pagesMetallic MicrolatticeAnonymous AMvlXRW3TsNo ratings yet

- Adoremos, 3a, Me323, Intro and Scope of Materials Science and EngineeringDocument10 pagesAdoremos, 3a, Me323, Intro and Scope of Materials Science and EngineeringMECHANICAL ENGINEERINGNo ratings yet

- Materials - Science 15ME32 - Module 1 PDFDocument25 pagesMaterials - Science 15ME32 - Module 1 PDFDevaraj ENo ratings yet

- CBR Material TeknikDocument11 pagesCBR Material TeknikTV SHOWNo ratings yet

- STS18 - Module 6 L4P2 Chech in ActivityDocument4 pagesSTS18 - Module 6 L4P2 Chech in ActivityMarriane Tangi100% (1)

- Lecture 1 IntroductionDocument21 pagesLecture 1 IntroductionKelvin Ken WitsNo ratings yet

- 202 Introduction To Materials ScienceDocument435 pages202 Introduction To Materials ScienceRK SinghNo ratings yet

- ch3 AshbylecturesDocument21 pagesch3 AshbylecturesUtku Orçun GeziciNo ratings yet

- Intro To Material Science & EngineeringDocument16 pagesIntro To Material Science & EngineeringAnkur Yash100% (1)

- Material Science IISc BookDocument810 pagesMaterial Science IISc BookSoumyadeep MannaNo ratings yet

- Materials Science: Course Motivation and HighlightsDocument4 pagesMaterials Science: Course Motivation and Highlightskh_gallardoNo ratings yet

- Material ScienceDocument265 pagesMaterial Sciencevenkatesh198910No ratings yet

- Materials Science & Engineering Lecture Notes (Unit 1)Document19 pagesMaterials Science & Engineering Lecture Notes (Unit 1)baakaruopdeng50No ratings yet

- Materials Selection in Mechanical Design Michael Ashby: Chapter 1. IntroductionDocument21 pagesMaterials Selection in Mechanical Design Michael Ashby: Chapter 1. IntroductionpetronashscribdidNo ratings yet

- Af5 2077430Document6 pagesAf5 2077430Lesly Michell Rubio CanobbioNo ratings yet

- NP 1Document12 pagesNP 1Soumya BullaNo ratings yet

- Unit I IV PPTs DR Satheesh Engineering Materials Lectures 2021Document463 pagesUnit I IV PPTs DR Satheesh Engineering Materials Lectures 2021Nilanjan KunduNo ratings yet

- 1A Introduction To MaterialsDocument26 pages1A Introduction To MaterialsAhmed AliNo ratings yet

- Introduction To Material Science Rev1Document36 pagesIntroduction To Material Science Rev1Blessings James BwalyaNo ratings yet

- Topik 1 - Introduction-Ilmu Bahan PDFDocument10 pagesTopik 1 - Introduction-Ilmu Bahan PDFUmar Putra SyahrudinNo ratings yet

- Test Examen - Année 2019/2020 Anglais Technique : Prof. Mr. El FadlDocument5 pagesTest Examen - Année 2019/2020 Anglais Technique : Prof. Mr. El FadlFaris YosefNo ratings yet

- Research Paper On Iron OreDocument7 pagesResearch Paper On Iron Orekquqbcikf100% (3)

- Biomateriales General.Document9 pagesBiomateriales General.qcmyskr7y5No ratings yet

- 2016 Book OxideMaterialsAtTheTwo-DimensiDocument403 pages2016 Book OxideMaterialsAtTheTwo-DimensipedroNo ratings yet

- Nanomaterials: Boxuan Gu and David McquillingDocument31 pagesNanomaterials: Boxuan Gu and David McquillingVenkata Ganesh GorlaNo ratings yet

- MastermyrDocument5 pagesMastermyrnofunclub100% (1)

- Material ScienceDocument810 pagesMaterial ScienceNikhil Batham67% (3)

- Materials ScienceDocument368 pagesMaterials ScienceHarinderpal Singh Pannu100% (1)

- Capili Jefferson 1Document6 pagesCapili Jefferson 1Christian Al EncarnacionNo ratings yet

- Features CarbonDocument2 pagesFeatures CarbonrpodilaNo ratings yet

- MaterialogyDocument181 pagesMaterialogyrajraj3550No ratings yet

- Mse215 Full-BirleştirildiDocument352 pagesMse215 Full-BirleştirildiyagmurdeniiizzzNo ratings yet

- Classification of Materials: October 2017Document17 pagesClassification of Materials: October 2017HAFIZ MUGHEEZ ALI ZAHID SHEHZAD ALINo ratings yet

- Recent Advancements in The Metallurgical Engineering and Electrodeposition (Dhanasekaran Vikraman (Editor) Etc.)Document209 pagesRecent Advancements in The Metallurgical Engineering and Electrodeposition (Dhanasekaran Vikraman (Editor) Etc.)Monseñior Melcacho AramburuzabalaNo ratings yet

- The Metallurgy of Anodizing Aluminum: Connecting Science to PracticeFrom EverandThe Metallurgy of Anodizing Aluminum: Connecting Science to PracticeNo ratings yet

- Lab 4 - DMFCDocument11 pagesLab 4 - DMFCNeel NadparaNo ratings yet

- Lab 5 - Fluid Flow MeasurementDocument8 pagesLab 5 - Fluid Flow MeasurementNeel NadparaNo ratings yet

- Lab 8 - Latent Heat vs. Sensible HeatDocument15 pagesLab 8 - Latent Heat vs. Sensible HeatNeel NadparaNo ratings yet

- Lab 9 - Thermal Energy StorageDocument14 pagesLab 9 - Thermal Energy StorageNeel NadparaNo ratings yet

- Lab 2 - Vibrations of A Cantilever BeamDocument11 pagesLab 2 - Vibrations of A Cantilever BeamNeel NadparaNo ratings yet

- Lab 7 - Estimation of Internal Pressure of A Soda CanDocument10 pagesLab 7 - Estimation of Internal Pressure of A Soda CanNeel NadparaNo ratings yet

- Lab 3 - Heat ExchangerDocument8 pagesLab 3 - Heat ExchangerNeel NadparaNo ratings yet

- Bridgeport Lab - Lab 4Document8 pagesBridgeport Lab - Lab 4Neel NadparaNo ratings yet

- Lab 1 - Heat EngineDocument9 pagesLab 1 - Heat EngineNeel NadparaNo ratings yet

- Intro To Sensors and Data: Lab 1 Summary: AbstractDocument2 pagesIntro To Sensors and Data: Lab 1 Summary: AbstractNeel NadparaNo ratings yet

- Lab 6 - Heat PipeDocument12 pagesLab 6 - Heat PipeNeel NadparaNo ratings yet

- Lab 2Document4 pagesLab 2Neel NadparaNo ratings yet

- Intro To Sensors and Data: Lab 3: AbstractDocument4 pagesIntro To Sensors and Data: Lab 3: AbstractNeel NadparaNo ratings yet

- Lab 6: Beam Natural Frequencies: AbstractDocument4 pagesLab 6: Beam Natural Frequencies: AbstractNeel NadparaNo ratings yet

- Lab 4Document6 pagesLab 4Neel NadparaNo ratings yet

- HW 2Document7 pagesHW 2Neel NadparaNo ratings yet

- Effects of Lubrication and Cooling - Lab 1Document11 pagesEffects of Lubrication and Cooling - Lab 1Neel NadparaNo ratings yet

- AFM in The Preparation of Hydrophobic Aluminum SurfacesDocument4 pagesAFM in The Preparation of Hydrophobic Aluminum SurfacesNeel NadparaNo ratings yet

- HW 4Document6 pagesHW 4Neel NadparaNo ratings yet

- Powder Processing by Melt AtomizationDocument11 pagesPowder Processing by Melt AtomizationNeel NadparaNo ratings yet

- VLM PaperDocument3 pagesVLM PaperNeel NadparaNo ratings yet

- HW 1Document5 pagesHW 1Neel NadparaNo ratings yet

- HW 5Document5 pagesHW 5Neel NadparaNo ratings yet

- HW 2Document13 pagesHW 2Neel NadparaNo ratings yet

- ME 3227 Shaft ProjectDocument31 pagesME 3227 Shaft ProjectNeel NadparaNo ratings yet

- Investigating The Quench Sensitivity of 2219 Aluminum Alloy: Transmission Electron Microscopy (TEM) SummaryDocument5 pagesInvestigating The Quench Sensitivity of 2219 Aluminum Alloy: Transmission Electron Microscopy (TEM) SummaryNeel NadparaNo ratings yet

- Examination of Selective Laser Melted Aluminum Alloy by SEMDocument5 pagesExamination of Selective Laser Melted Aluminum Alloy by SEMNeel NadparaNo ratings yet

- DSC Analysis of Solute Clustering Behavior in 6082 Aluminum AlloyDocument5 pagesDSC Analysis of Solute Clustering Behavior in 6082 Aluminum AlloyNeel NadparaNo ratings yet

- Vamsi 2018Document7 pagesVamsi 2018neel gajNo ratings yet

- The ABC's of Arc Welding: Weld DecayDocument4 pagesThe ABC's of Arc Welding: Weld DecayLakshmi KanthNo ratings yet

- Chapter 3Document47 pagesChapter 3eiman bataNo ratings yet

- Anealing TypesDocument29 pagesAnealing TypesPratheep AddrinNo ratings yet

- Notes, MetalsDocument7 pagesNotes, MetalsindaiNo ratings yet

- Improving Cylindrical Inconel 718 Ingots Produced at PAO RuspolimetDocument5 pagesImproving Cylindrical Inconel 718 Ingots Produced at PAO RuspolimetJH ShinNo ratings yet

- SAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKDocument15 pagesSAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKFerry SiegersNo ratings yet

- Experiment No. 6 Pit Furnace Melting Practice: Aim TheoryDocument3 pagesExperiment No. 6 Pit Furnace Melting Practice: Aim TheoryDhananjay ShimpiNo ratings yet

- Standards MaterialDocument1 pageStandards MaterialFarzad MirzavandNo ratings yet

- Technical Materials Ii. Metals: Ferrous Metals - Iron AlloysDocument4 pagesTechnical Materials Ii. Metals: Ferrous Metals - Iron AlloysAlexis Vicente SandulacheNo ratings yet

- Protective Coating On MetalsDocument18 pagesProtective Coating On MetalsHarshit joshiNo ratings yet

- 13480-2 2017 EN-MaterialsDocument83 pages13480-2 2017 EN-MaterialsPaulo VidasinhaNo ratings yet

- An Investigation Into Microstructure and MechanicaDocument10 pagesAn Investigation Into Microstructure and MechanicaGowri Shankar WuritiNo ratings yet

- Material Spec Chart 1Document1 pageMaterial Spec Chart 1mr.dennis73No ratings yet

- PRT 203 - Metal Forming and FabricationDocument130 pagesPRT 203 - Metal Forming and FabricationNiyonase OlivierNo ratings yet

- Metallurgy: Applied Failure Analysis MetallurgyDocument19 pagesMetallurgy: Applied Failure Analysis MetallurgyAndiNo ratings yet

- Improvement of Mechanical Properties of Alloy Steel Type (40x) by Using Heat TreatmentsDocument11 pagesImprovement of Mechanical Properties of Alloy Steel Type (40x) by Using Heat Treatmentsyared sitotawNo ratings yet

- Duaplate D80 Weld Overlay: ManufactureDocument1 pageDuaplate D80 Weld Overlay: ManufactureImmalatulhusnaNo ratings yet

- Effect of Cryogenic Heat Treatment On Metallic MaterialDocument6 pagesEffect of Cryogenic Heat Treatment On Metallic MaterialSahil NegiNo ratings yet

- Special WeldingDocument20 pagesSpecial WeldingNallappan Rajj ANo ratings yet

- Service DetailsDocument2 pagesService DetailsApr MarNo ratings yet

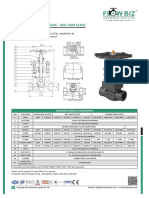

- FlowBiz Forged Steel Globe Valve 1500 ClassDocument2 pagesFlowBiz Forged Steel Globe Valve 1500 ClassFlowBiz Exports Pvt. Ltd.No ratings yet

- Sultan Al-Baqami Est. For Trading: TEL: +966 11 292 1883 FAX: + 966 11 292 1883Document10 pagesSultan Al-Baqami Est. For Trading: TEL: +966 11 292 1883 FAX: + 966 11 292 1883salman KhanNo ratings yet

- Sop 091-13Document2 pagesSop 091-13m_armoutiNo ratings yet

- 6082 Aluminium AlloyDocument3 pages6082 Aluminium AlloyWeiso ChenNo ratings yet

- Case Hardening Heat TreatmentDocument15 pagesCase Hardening Heat TreatmentHazrat BelalNo ratings yet

- Composite Materials: N. Rajesh MathivananDocument13 pagesComposite Materials: N. Rajesh MathivanantrishulNo ratings yet