Professional Documents

Culture Documents

Scope:: Property of "Oil & Gas Inspection Services"

Uploaded by

Asem AbdelazizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scope:: Property of "Oil & Gas Inspection Services"

Uploaded by

Asem AbdelazizCopyright:

Available Formats

ASNT LEVEL-II / ULTRASONIC TESTING / PROCEUDRE / OIL & GAS INSPECTION SERVICES

1. Scope:

• This procedure defines the criteria and general requirements to carry out ultrasonic examination on ferritic

welded joints.

• This procedure applicable to most geometric configurations and materials encountered in fabrication

under normal conditions. However, special configuration and materials may require modified methods and

techniques. In this case, special procedure shall be demonstrated prior to use to the satisfaction of the Authorized

Inspector in accordance with the requirements of T-150, ASME Code Sec. V. The procedure qualification record shall

be attached to this procedure

2. Reference:

2.1 This Procedure refers to the following:

• ASME Code Section V (Non-Destructive Examination), applicable edition/addenda

• ASME Code Section I, for acceptance criteria

• ASME Code Section VIII, Div 1 for acceptance criteria

• ANSI/ASME B31.1, applicable edition/addenda, for acceptance criteria

• ANSI/ASME B31.3, applicable edition/addenda, for acceptance criteria

• National Board Inspection Code, NBIC-23, applicable edition

• AWS D1.1- applicable edition

• Clients’ specification requirements for acceptance criteria

3. Definitions:

• ASME: American Society for Mechanical Engineers

• DAC: Distance Amplitude Correction

• NDE: Non-Destructive Examination

• IIW: The International Institute of Welding

4. Responsibilities:

• The NDE Examiner shall be responsible for conducting and reporting the results of examination in

accordance with the applicable Code and Client’s specifications, whichever is more restrictive

5. Personnel Qualifications:

• All personnel involved in Ultrasonic Examinations shall be qualified to Level II in accordance with the

requirements of ANST, Written Practice (Training, Qualification & Certification for NDE Personnel)

• When the written practice is revised, the certification of NDE personnel remains valid to the requirements

of the previous revision until the expiry date of the personnel qualification certificate; then, recertification to the

requirements of the new revision is required

• The certification of personnel shall be checked by the QA/QC Manager or NDE Level III prior to work

commencement.

6. Procedure:

6.1 Equipment:

Property of “Oil & Gas Inspection Services”

ASNT LEVEL-II / ULTRASONIC TESTING / PROCEUDRE / OIL & GAS INSPECTION SERVICES

6.1.1 Ultrasonic examination equipment shall be of the pulse echo type utilizing “A” scan

presentation, capable of generating and receiving frequencies between 1 and 5 MHz as a minimum

and shall be capable of recording UT data including the scanning positions

6.1.2 The flaw detector shall be calibrated in accordance with the relevant calibration procedure. A

certificate of conformance shall accompany each flaw detector

6.1.3 The ultrasonic instrument shall provide linear vertical presentation within ± 5% of the full

screen height (FSH) for 20% to 80% FSH and to be recorded in Screen Height Linearity Record Form

No. TNE-UT-Doc-02 Rev ‘0.’ The procedure for evaluating screen height linearity is carried out as per

ASME section V, article 4, appendix I (and or AWS D1.1-6.30)

6.1.4 The ultrasonic instrument shall utilize an amplitude control accurate over its useful range to

20% of the nominal amplitude ratio, to allow measurement of indications beyond the linear range of

the vertical display on the screen. The procedure for evaluating amplitude control linearity shall be

performed as per ASME section V, Article 4, appendix II

6.1.5 The requirements of 6.1.3 and 6.1.4 above; shall be met at intervals not to exceed three

months for analogue type instruments and one year for digital type instrument, or prior to first use

thereafter

6.1.6 When any part of the examination system is changed, a calibration check shall be made on the

basic calibration block to verify that distance range points and sensitivity setting (s) satisfy the

requirements of ASME section V, T-466.3

6.1.7 A calibration check on at least one of the reflectors in the basic calibration block shall be

performed at the completion of each examination or series of similar examinations, and when

examination personnel are changed. The distance range and sensitivity values recorded shall satisfy

the requirements of ASME section V, T-466.3

6.1.8 If during any check, it is determined that the examination equipment is not functioning

properly, all the product that has been examined since the last valid equipment calibration shall be

re-examined

6.2 Materials:

6.2.1 Search units shall be electrically matched to the flaw detector

6.2.2 Search units shall be in the frequency range 1 MHz to 5 MHz and be free of noise and internal

reflections. Twin or single transducer elements may be used dependent upon the configuration of

weld under examination

6.2.2.1 In case of AWS D1.1

• Straight-beam Search unit transducers shall have an active area of not less than

1/2in² nor shall more than 1 in². The transducer must be a round shape or square

shape

• Angle-Beam Search Units shall consist of a transducer and an angle wedge. The

unit may be comprised of the two separate elements or may be an integral unit.

Search Units shall be square or rectangular and may vary from 5/8in to 1in in width

and from 5/8in to13/16in in height. The search unit shall produce a sound beam in

the material being tested within±2 o̊ f one of the following proper angles:70 ,̊ 60 ,̊ or

45 .̊ The transducer frequency shall be between 2 and 2.5 MHz

6.2.3 Search units with contoured contact wedges may be used to aid the ultrasonic coupling.

Calibration shall be done with the contact wedges used during the examination

Property of “Oil & Gas Inspection Services”

ASNT LEVEL-II / ULTRASONIC TESTING / PROCEUDRE / OIL & GAS INSPECTION SERVICES

6.2.4 Each flaw detector shall have a full set of search units with cables; the search units shall be of

type, size and frequency, as required by the governing specification. 6.2.5 Calibration blocks shall

include but not be limited to “IIW –V2” UT reference Block. The operator shall also have access to

IIW-V1, and such others that may be required to ensure compliance regarding calibration of flaw

detector and probe characteristics, e.g. beam angle, beam profile, exit point (index). etc.

6.2.5 In case of AWS D1.1 the “IIW” UT reference block shall be the standard used for both distance

and sensitivity calibration

6.2.6 Basic Calibration Block Material shall be of the same product form, and material specification

or equivalent P-Number grouping as one of the materials being examined. For this procedure P-

Numbers 1, 3, 4, and 5 materials are considered equivalent. The calibration block shall have the

same heat treatment specification for the type and grade and have the same surface finish

6.2.7 Measurements of beam spread for scan indexing limits shall be taken only when required by a

referencing code section. Beam spread angles shall be measured once for a search unit wedge

combination in the calculated far field at the beginning of each period of extended use, or every 3

months, whichever is less.

6.2.8 Search units with worn faces shall not be used.

6.2.9 Couplant shall be used to give the maximum acoustic transmission between the probe face and

the material under examination. The couplant shall be cellulose paste, liquid soap, oil, or grease. In

all cases the couplant including additive, shall not be detrimental to the material being examined

6.3 Surface Condition:

6.3.1 Welds that are being examined using ultrasound shall be prepared to provide a sufficiently

smooth and regular area for scanning to be undertaken. The area shall extend at least the full skip

distance required, and shall be free of any irregularities such as spatter, grinding or chipping marks

scale, etc., which may hinder the scanning pattern or cause confusion in the interpretation of the

resultant display i.e. excessive surface noise.

6.4 Technical Information:

6.4.1 Prior to commencement of examination, the following information shall be obtained: Type of

material. Joint configuration. Welding Process. Other information that may have a bearing on the

inspection e.g. post weld heat treatment, etc.

6.5 Examination Procedure:

6.5.1 For examinations in materials where the examination surface diameter is greater than 20 in.

(508 mm), a block of essentially the same curvature shall be used, or alternatively, a flat basic

calibration block, may be used, if, gain correction shall be adjusted as described in code section V,

Article 4, Appendix B.

6.5.2 For examination in materials where the examination surface diameter is 20 in. (508 mm), or

less, the calibration block shall be curved. Except where otherwise stated in the reference code, a

single curved basic calibration block may be used to calibrate the examination on surfaces in the

range of curvature from 0.9 to 1.5 times the basic calibration block diameter.

6.5.3 The scanning shall be 100%. The entire volume shall be examined with a 10% overlap of the

probe. The rate of search unit movement for examination shall not exceed 6 inches per second

(152mm/sec) unless calibration is verified at scanning speed

6.5.4 For reflectors oriented transverse to the weld the scanning shall be done parallel to the weld

axis. If the weld is not ground flushed the probe shall be controlled such that it faces nearly parallel

to the weld body. The search unit shall be manipulated so that the ultrasonic energy passes through

the required volume of weld and adjacent base material. The search unit shall be rotated 180 deg

Property of “Oil & Gas Inspection Services”

ASNT LEVEL-II / ULTRASONIC TESTING / PROCEUDRE / OIL & GAS INSPECTION SERVICES

and the examination repeated. If the weld cap is not ground flat, the examination shall be

performed from the base metal on both sides of the weld cap in both weld axis directions

6.5.5 Calibration:

6.5.5.1 Straight Beam Calibration (0° Probe):

(A) The equipment is calibrated using a straight beam probe for a suitable range for the

thickness of material being examined. A minimum of two back wall echoes from the material

under test be noted during the examination.

(B) A Distance Amplitude Correction curve (DAC curve) shall be produced using the

appropriate calibration block. The gain control is adjusted to produce a response of 80% full

screen height and the screen is marked. Then the probe is re-positioned to give the

maximized response for each of the remaining holes. At each maximized position, mark the

position of maximum response on the screen. Connect the screen marks to produce the DAC

curve. This gain setting is primary reference level.

6.5.5.2 Angle Beam Calibration:

(A) The equipment is calibrated for a suitable range for the beam path length required to

satisfactorily complete the examination, (i.e. Full Skip Distance)

(B) Produce a DAC curve in accordance with paragraph 6.5.5.1(B)

6.5.5.3 System calibration shall be carried out at the commencement of and at 4 hourly

intervals during, the inspection and on completion of an inspection

If during the calibration confirmation the sweep range of the DAC curve has changed by the

following tolerances:

Sweep Range: If a point of the DAC curve has moved on the time base by more than 10% of

its original time base position.

DAC Curve: If a point on DAC curve has changed by ± 20% or 2 dB from its original

amplitude.

Then the following action shall be taken:

Sweep Range:

The calibration shall be corrected with a note of the correction being made on the report. If

any signals have been recorded, all recorded indications shall be re-examined with the

corrected calibration and their values corrected accordingly on the report

DAC Curve:

If any point on the DAC curve has decreased by 20% or 2 dB all recorded data since the last

valid calibration shall be marked void. A new DAC curve shall be produced with a note to this

effect on the report and the voided are as shall be re-examined. If any point on the DAC

Curve has increased following the production of the new DAC curve. A note of this shall be

made on the report

6.5.6 Inspection Technique:

6.5.6.1 Parent Metal Examination, Prior to any examination of the weldments, the parent

material shall be examined. A compression wave 0 examination will be carried out for a

minimum of 3 in. (75 mm) either side of the weld to locate any flaws in the parent material

and to determine its thickness.

6.5.6.2 Weld Examination. Plate and Pipe Welds:

Property of “Oil & Gas Inspection Services”

ASNT LEVEL-II / ULTRASONIC TESTING / PROCEUDRE / OIL & GAS INSPECTION SERVICES

A critical root scan shall be carried out from both sides of the weld, with at least one

angle probe directed essentially perpendicular to the weld axis to distinguish between root

variations and the existence of root cracks or crack-like defects. This may be done where

practicable with the aid of a magnetic strip placed so that the distance from the probe index

to the root will be constant. The body and fusion faces of the weld shall then be examined

using a continuous scanning raster from both sides of the weld between the weld center line

or the cap edge whichever is appropriate and full skip plus the cap width using at least two

probes of differing angles

6.5.7 Scanning:

6.5.7.1 A Datum reference point shall be clearly marked on the work-piece and shall

be marked with the weld identification. The datum shall be used for a reference for

locating defects, and the reporting of defects.

6.5.7.2 The weld and base metal shall be scanned, where required by the

referencing code section to the extent possible with the straight beam search unit.

6.5.7.3 Angle beam scanning shall be performed at a gain setting at least two times

the primary reference level. Evaluation shall be performed with respect to the

primary reference level.

6.5.7.4 The angle beam shall be directed at approximate right angles to the weld axis

from two directions where possible to detect discontinuities oriented parallel to the

weld axis.

6.5.7.5 The angle beam shall be directed essentially parallel to the weld axis and

shall be manipulated so that the angle beam passes through the required volumes of

weld and adjacent base metal specified by the referencing code to detect

discontinuities oriented transverse to the weld axis. The search unit shall be rotated

180º and the examination shall be repeated.

6.5.7.6 The rate of search unit movement for examination shall not exceed 6”/sec.

unless calibration is verified at scanning speed

6.5.8 In case of AWS D1.1 The testing angle and scanning procedure shall be in conformance with

those in AWS D1.1 Table 6.7. The Indication Rating “d” represents the algebraic difference in

decibels between the indication level and the deference level with correction for attenuation as

indicated in the following expression. Instruments with gain in dB: a - b – c = d 6.6 Defect

Evaluation and Sizing

6.6.1 Any imperfection which causes an indication more than 20% DAC shall be investigated

to the extent that it can be evaluated in terms of the acceptance standards of the

referencing code section

The indication shall be investigated to:

Confirm its existence. Determine its location regarding the established datum points.

Determine its size. Determine its nature. This investigation may require scanning from other

positions and with different probes. It is highly subjective in its nature and should be carried

out with extreme care. The recommended sizing techniques are as follows: Defect Length

Use the 6 dB drop technique, marking the probe center at the defect end points.

Through Thickness Dimension:

Use the 20-dB technique in conjunction with an adjustable flaw location slide. The recording

levels and rejection levels shall be in accordance with the referencing Code or standard. All

Property of “Oil & Gas Inspection Services”

ASNT LEVEL-II / ULTRASONIC TESTING / PROCEUDRE / OIL & GAS INSPECTION SERVICES

defects shall be assessed in accordance with the requirements of the applicable referencing

Code Section

6.6.2 In case of AWS D1.1, Each weld discontinuity shall be accepted or rejected based on its

indication rating and its length, in conformance with AWS D1.1 Table 6.2 for statically loaded

structures or Table 6.3 for cyclically loaded structures. The length of such indication shall be

determined by measuring the distance between the transducer centerline locations where

the indication rating amplitude drops 50%(6 dB) below the rating for the applicable

discontinuity classification. This length shall be recorded under “discontinuity length”

6.7 Acceptance Standards

6.7.1 ASME Code, Sec. I Paragraph PW-52 : For Power Boilers

6.7.2 ASME Code, Sec. VIII Div 1 (Mandatory Appendix 12) : For Pressure Vessels

6.7.3 ASME B31.1 Paragraph (136.4.6) : For Process Piping

6.7.4 AWS D1.1, Clause 6. Table 6.2 and 6.3 : For Steel Structures

6.8 Reporting

6.8.1 Upon completion of the examination the examiner shall prepare an examination report, for

each weld or area of weld examined, all restrictions which limit the effectiveness of the test must be

recorded.

6.8.2 All reflectors greater than 50% of the reference level shall be reported and shall be described

regarding size, shape, location and probable identity/classification

6.8.3 In addition, sketches and drawings shall be prepared to support written descriptions

Property of “Oil & Gas Inspection Services”

You might also like

- UT ProcedureDocument6 pagesUT ProcedureMurali YNo ratings yet

- Sop UtDocument6 pagesSop UtEddy Dwi CahyonoNo ratings yet

- SC Ut Sop - Upto 70 DiaDocument11 pagesSC Ut Sop - Upto 70 DiaSrinu GrandhalayamNo ratings yet

- Ultrasonic Testing Procedure SampleDocument10 pagesUltrasonic Testing Procedure SamplePrashant PuriNo ratings yet

- Ultrasonic Testing Procedure GuideDocument8 pagesUltrasonic Testing Procedure GuideShailendra GhaisasNo ratings yet

- Krishna Engineering: 1. ScopeDocument8 pagesKrishna Engineering: 1. Scopegaurav shrimaliNo ratings yet

- Property of "Oil & Gas Inspection Services"Document1 pageProperty of "Oil & Gas Inspection Services"Mahmoud AlwasifNo ratings yet

- ScopeDocument9 pagesScoperaghbirNo ratings yet

- Property of "Oil & Gas Inspection Services"Document1 pageProperty of "Oil & Gas Inspection Services"Mahmoud AlwasifNo ratings yet

- Ultrasonic Testing Procedure for Metallic WeldsDocument9 pagesUltrasonic Testing Procedure for Metallic WeldsMajdi JerbiNo ratings yet

- 05 Ultrasonic Test Procedure 500405Document11 pages05 Ultrasonic Test Procedure 500405Sefa KasapogluNo ratings yet

- Ultrasonic TestDocument11 pagesUltrasonic TestHarry DobleNo ratings yet

- PAUT AWS d1 1Document17 pagesPAUT AWS d1 1Jeganeswaran100% (8)

- Ultrasonic ProcedureDocument31 pagesUltrasonic ProcedureChristopher Jones100% (1)

- QUSE PA Crack Sizing Test Procedure API UT 11 May 2017Document12 pagesQUSE PA Crack Sizing Test Procedure API UT 11 May 2017solrac4371100% (2)

- ULTRASONIC TESTING PROCEDUREDocument14 pagesULTRASONIC TESTING PROCEDUREshifa0% (1)

- Ultrasonic Examination ProcedureDocument10 pagesUltrasonic Examination ProcedureJake SparrowNo ratings yet

- 1744 - UT PROCEDURE (For Final) PDFDocument27 pages1744 - UT PROCEDURE (For Final) PDFpvdang8453100% (1)

- Ultrasonic Inspection Procedure For Complete Joint Penetration (CJP) Welds in A T-JointDocument9 pagesUltrasonic Inspection Procedure For Complete Joint Penetration (CJP) Welds in A T-JointPierpaolo AparoNo ratings yet

- Ansaldo NDT Specifications 22GRKW v1 0Document117 pagesAnsaldo NDT Specifications 22GRKW v1 0pvssrh9929No ratings yet

- 11 Ut ProcedureDocument11 pages11 Ut ProcedureSajeesh KrishnanNo ratings yet

- Procedure For UT TestingDocument13 pagesProcedure For UT TestingKarrar TalibNo ratings yet

- UT PROCEDURE TITLEDocument40 pagesUT PROCEDURE TITLEShyam Singh100% (3)

- Product Type and Name: AAR Axle Process Document: AAR Axle Ultrasonic Detection Procedure Process Document No. GY (11) TY-024Document13 pagesProduct Type and Name: AAR Axle Process Document: AAR Axle Ultrasonic Detection Procedure Process Document No. GY (11) TY-024gueridiNo ratings yet

- UT Procedure Rev.8Document15 pagesUT Procedure Rev.8kalaiselvanNo ratings yet

- Appendix F Phased Array Ultrasonic Testing: 1.0 PurposeDocument17 pagesAppendix F Phased Array Ultrasonic Testing: 1.0 PurposeThananon Chomcherd100% (2)

- procedure pa-draftDocument20 pagesprocedure pa-draftmahmoud naviddoustNo ratings yet

- Ut ProcedureDocument12 pagesUt ProcedurerohithNo ratings yet

- UT Equipment Calibration ProcedureDocument14 pagesUT Equipment Calibration ProcedureSantanu Saha100% (4)

- UT MIS AWS Rev 00 TKYDocument27 pagesUT MIS AWS Rev 00 TKYSantanu Saha100% (2)

- Ut-001 Rev 0 Ultrasonic Testing ProcedureDocument5 pagesUt-001 Rev 0 Ultrasonic Testing ProcedureBen Buys100% (1)

- Specification For Ultrasonic Inspection of Al-Alloy Plate For Pressure VesselsDocument6 pagesSpecification For Ultrasonic Inspection of Al-Alloy Plate For Pressure Vesselsmarkieboy36No ratings yet

- PAUT Model Procedure PDFDocument12 pagesPAUT Model Procedure PDFநந்த குமார் சம்பத் நாகராஜன்81% (16)

- Saep 1146Document8 pagesSaep 1146Ronanki RaviNo ratings yet

- Ultrasonic Testing ProcedureDocument15 pagesUltrasonic Testing ProcedureZulaiha Abdul Rahman100% (1)

- PAUT Procedure for Bridge Girder WeldsDocument14 pagesPAUT Procedure for Bridge Girder Weldsteopan PanNo ratings yet

- P-003 Ultrasonic Testing ProcedureDocument24 pagesP-003 Ultrasonic Testing ProcedureSaheb Yadav100% (2)

- Prosedur UTG Asu AnjingDocument15 pagesProsedur UTG Asu Anjingyusuf akbarNo ratings yet

- PAUT General Work ProceduresDocument16 pagesPAUT General Work Proceduresdiaccessltd_1717296188% (8)

- Welding Inspection For Boiler Pressure Vessel (BPV) in Biomass Power Plant Using Phased Array Ultrasonic Technique (PAUT)Document5 pagesWelding Inspection For Boiler Pressure Vessel (BPV) in Biomass Power Plant Using Phased Array Ultrasonic Technique (PAUT)roseNo ratings yet

- Is 7666 1988Document9 pagesIs 7666 1988chepurthiNo ratings yet

- UT PROCEDURE NewDocument10 pagesUT PROCEDURE NewMeet Patel100% (3)

- Penetration TEst - 2-material-2023-JAN-3Document21 pagesPenetration TEst - 2-material-2023-JAN-3viyfNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationnmclaughNo ratings yet

- ASNT Level-II Visual & Optical Testing ProcedureDocument5 pagesASNT Level-II Visual & Optical Testing ProcedureFadil WimalaNo ratings yet

- API 650 12th Edition 2013 PTDocument2 pagesAPI 650 12th Edition 2013 PTRonel John Rodriguez CustodioNo ratings yet

- PAUT Procedure for Butt Weld JointsDocument22 pagesPAUT Procedure for Butt Weld Jointsrupam100% (5)

- Straight-Beam Ultrasonic Examination of Steel Plates': Standard SpecificationDocument2 pagesStraight-Beam Ultrasonic Examination of Steel Plates': Standard SpecificationRegis KoroivaNo ratings yet

- Ultrasonic Test Procedure1Document8 pagesUltrasonic Test Procedure1MHDNo ratings yet

- Ut Procedure OnsDocument10 pagesUt Procedure OnsPARTHNo ratings yet

- Is 4260 2004Document10 pagesIs 4260 2004Mehmet SoysalNo ratings yet

- AWS D1.1 Phased Array GuidelineDocument40 pagesAWS D1.1 Phased Array GuidelineMario Perez100% (1)

- Ultrasonic Examination Procedure: Doc. No.: QUAL/UT/001: of 10 Revision: 00 Date: 25.04.05 1.0Document10 pagesUltrasonic Examination Procedure: Doc. No.: QUAL/UT/001: of 10 Revision: 00 Date: 25.04.05 1.0smsunil12345No ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- Sensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesFrom EverandSensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesNo ratings yet

- LG AnalysisDocument4 pagesLG AnalysisAnkit MishraNo ratings yet

- Stolle Cupping Systems: ConnectingDocument2 pagesStolle Cupping Systems: ConnectingHieu NguyenNo ratings yet

- Coal PDFDocument36 pagesCoal PDFurjanagarNo ratings yet

- PDF Vertical Axis Wind Turbines DDDocument38 pagesPDF Vertical Axis Wind Turbines DDKunal AhiwaleNo ratings yet

- Contoh Kurikulum Vitae PDFDocument8 pagesContoh Kurikulum Vitae PDFANDI2lusNo ratings yet

- Dual-band patch antenna for 5G applicationsDocument3 pagesDual-band patch antenna for 5G applicationsHarini VemulaNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Media Palnning ProcessDocument3 pagesMedia Palnning ProcessSrinivas KumarNo ratings yet

- User Manual Rish Insu 10Document10 pagesUser Manual Rish Insu 10Manoj TyagiNo ratings yet

- Chapter 3 - Excel SolutionsDocument8 pagesChapter 3 - Excel SolutionsHalt DougNo ratings yet

- Superior Drummer 2 ManualDocument38 pagesSuperior Drummer 2 ManualEmmanuel MarcosNo ratings yet

- United States Government and PoliticsDocument21 pagesUnited States Government and PoliticsTony BuiNo ratings yet

- Free V Bucks Generator Vbucks1Document2 pagesFree V Bucks Generator Vbucks1Paula BoulesNo ratings yet

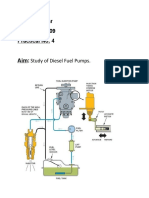

- Study of Diesel Fuel Pumps ComponentsDocument6 pagesStudy of Diesel Fuel Pumps ComponentsPro GamerssNo ratings yet

- ACCO 20073 Backflush CostingDocument2 pagesACCO 20073 Backflush CostingMaria Kathreena Andrea AdevaNo ratings yet

- Topology Optimization of Automotive Brake PedalDocument5 pagesTopology Optimization of Automotive Brake PedalNizam Sudin Dan KhatijahNo ratings yet

- Sterotex SheetDocument2 pagesSterotex SheetHemant DangarNo ratings yet

- Mid 185 - Pid 70 - Fmi 2Document3 pagesMid 185 - Pid 70 - Fmi 2Akbar100% (1)

- Department of Civil Engineering, Semester 7th: Different Types of BridgesDocument39 pagesDepartment of Civil Engineering, Semester 7th: Different Types of BridgesSiddhartha SahaNo ratings yet

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniNo ratings yet

- The Delta-Sigma Modulator: A Circuit For All SeasonsDocument6 pagesThe Delta-Sigma Modulator: A Circuit For All SeasonsSohaib AkhtarNo ratings yet

- Citroen C4 Picasso/Grand Picasso BilmetropolenDocument5 pagesCitroen C4 Picasso/Grand Picasso BilmetropolenAlberto Miglino100% (1)

- BABOK V3 10. Glossary PDFDocument16 pagesBABOK V3 10. Glossary PDFAakash ChhibberNo ratings yet

- AI Story WritermnfyaDocument2 pagesAI Story Writermnfyafrenchrugby98No ratings yet

- Razwan Iqbalcv1Document3 pagesRazwan Iqbalcv1razwaniqbalNo ratings yet

- 20NCT2 1784 SampleDocument12 pages20NCT2 1784 Samplekimjohn dejesusNo ratings yet

- Sas Clinical Data Integration Fact SheetDocument4 pagesSas Clinical Data Integration Fact SheetChandrasekhar KothamasuNo ratings yet

- Datasheet - CI 7432Document5 pagesDatasheet - CI 7432Alexandre NettoNo ratings yet

- Australia vs. France ReportDocument5 pagesAustralia vs. France ReportammeNo ratings yet

- Study of Altman's Z ScoreDocument8 pagesStudy of Altman's Z ScoreKatarina JovanovićNo ratings yet