Professional Documents

Culture Documents

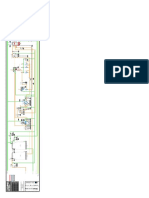

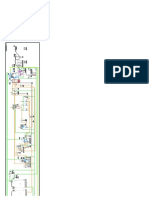

Complete Line, 1907 FFE - 705510 - 001 - 06

Uploaded by

ELSAYED KhalfOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Complete Line, 1907 FFE - 705510 - 001 - 06

Uploaded by

ELSAYED KhalfCopyright:

Available Formats

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

flame treater

271, 281, 291, 215 2 321 214 1 334 326 331 336 565 347 347 340 371 exhaust ozone exhaust 391 395 244

main extruder, co#extrusion, casting raw material feeding heating / cooling units auxiliary machine direction auxiliary coater heat recovery unit external airing transverse direction pull roll system level +4500 level +4500 winder winder loading slitter edge trim

die unit, co#extr. feed syst. machine main extrusion system machine direction orienter winder 1 orienter winder 2 fan for level u0 syst. assy, for TDO level +4500 orienter trolley recycling

M corona station M

1 5000

1' 5000

2 6000

3 8000

4 8000

5 8000

6 8000

7 8000

8 8000

9 8000

10 8000

11 8000

12 8000

13 8000

14 8000

15 8000

16 8000

17 8000

18 8000

19 8000

20 8000

21 8000

22 8000

23 8000

24 10000

25 8000

26 8000

27

990 9610 4040 14360 4000 88500 8700 12051 7100

A D

C (±0.00)

SLITTER TRIM

F.F.L.

(+2.25)

F.F.L. HEAT EXCHANGER / RECOVERY ROOM

MDO PUMP ROOM

L

500 L

CONTROL ROOM-2

7700

FILTER ROOM COMPRESSOR ROOM ENGINEERING STORE PLANT OFFICE SAMPLE ROOM LABORATORY

1500

#2000

GLASS WINDOW

B

+SY

1000

+SE1 +SE2 +SEU1 +SMU

12

Supply Supply Supply

12 13 34

CONTROL ROOM

5467

#1200

K K

#1600

6385,5

5000

pits for exhaust pipes of

flame and corona

pit oil piping

+SEV

#1500 treatment

C

+SR 2

first level on tower

B190 1200

13200

OS

O 260 +SE +SE +SE

+SW

31

0 51 51 51

5000

+SE

61

1500

Supply

Supply

18

16

J J

50 m³

+ LKF

D

Supply

35

+SK

+SM +SM

11

11 21

4400

+SM +SM

B180

12 22

Supply

33

Fl

+SC

4200

2

+SEF

CL

12

28400

Supply

+SWU

19

F11

+S

CL

E

200 m³

E

+SWU

5400

1000

H +SD11 +SD12

waste film H

4200

Supply

B170

29

#1800 #1500 a

F 200 m³ 5 layer

+PP1

+SP

324

11

1200 7000

O

+S +SX +SX

future

460

DS

X 12 32

15200

22

5400

extension

5000

cooling units casting

+SW

+S

11

X +SW +SW +SW

22

21 22 23

Supply

B160

23

+SX

Gas mixture generator

21

+LPQ +LPF 1 +LPF 2 +LPF3 +LPF4

G +SX

11

Supply

+SX

31

Supply

24

G

G

22

#1500

6385,5

200 m³ concrete platform CU chain cooling FOK 8.8 electric pit #2200

cellar #4500 pit for edge trim conveying

5000

#1500

5400

1500

#1500

B150

A A

#1000

Supply

H

31

Supply Supply

45 46

+SC

1 +SF +SF +SF +SF +SPQ +SPQ

GLASS WINDOW TT3

11 12 13 14 11 12

GLASS WINDOW

F 200 m³ blower room +SY +SY +SPU +SPU

F

2600

Supply

soundproofed 12 11 11 12

B

10

+S

switchboard room

+SR +SR

3100

11400

R

2800

12 13

HCU's for

6000

11

N

flame

2500 PRAYER ROOM cooling PRAYER ROOM

coater

Supply

50

500 air knife fan

MB Container Hex COATING ROOM 22000 cellar #5000

EREMA

+LR1

2650

H'

5500

MECH. ROOM CANTINE

B140 pit #2000

1000 m³ blowers water removal SBR on ±0 q 4000

E

casting unit 215 1 DRUM STORAGE

CANTINE 2200 E

5000

MB Container Coex

CORRIDO

CORRIDO

CORRIDO

LT PANEL ROOM 17000

resin supply ROOM

co#extrusion RECYCLING AREA Gesamtfundamentplan siehe Mat. Nr. 1907_1224

R

I TFH AREA

general foundation plan see mat. no. 1907_1224

#2250

241 Für die Abstandmaße der Referenzpunkte zueinander gilt die Baumaßtoleranz DIN 18202 (siehe WB 49.0)

8600

TOILETS TRANSFORMERS ROOMS 3400 CHANGE ROOM/ For the distance between reference points, the building standards DIN 18202 are applicable. (see also WB 49.0)

5000

blower pit LOCKER ROOM edge trim grinder

soundproofed level #5000 Transporthinweis (Autokran) siehe Gesamtfundamentplan

4200

+SF

23

D D

For the entrance of equipments and mobile crane # see instructions on general foundation drawing

Supply

+SF +SF

1600

22

51

B130

J

21

1000 m³ #2250

O 7800 COMP ROOM Schnitt A#A, B#B, C#C, D#D, E#E: siehe Blatt 2/2

2000

2300

section A#A, B#B, C#C, D#D, E#E: see sheet 2/2

211 1/ 2/ 3

5000

5300

raw material reception TOILETS Note :

General Layout Plan does not indicate Seller´s or Buyer´s Scope of Supply !

K

8600

C #2500 #3000 C

1700

# x 06 66913 09.05.2019 YSEB WAJ Werksblatt / company spec

L

Y

no. Index Änd.#Nr./version#no. Datum / date designer checked # # # #

R

Werkstückkanten / work edges DIN ISO 13715 Oberflächenbeschaffenheit / surface texture DIN ISO 1302 Geheimhaltung / secret status

Bezugspunkt / reference point

3050

A

B120 B

Tolerierungsgrundsatz / tolerancing principle DIN ISO 8015

IN

1000 m³ automatic bag emptying CL Anlagen # Mitte / machine centerline

M Allg.#Toleranzen / general tolerances DIN ISO 2768 cL Thermisches Schneiden / thermal cutting DIN EN ISO 9013 #

M

Fl Folienlauf / film direction # #

I

Allg.#Tol. Schweißkonstr. / general tol. weldment DIN EN ISO 13920 Schweißnaht#Bewertungsgruppe / weld inspect DIN EN ISO 5817

L

OS Bedienseite / operator side Toleranzen für Bauwerke / tolerances in buildings DIN 18202 # # #

E E

E

5250

B B

Maßstab / scale Gewicht / weight Material Nr. / material no.:

R

DS Antribsseite / drive side The reproduction, distribution and utilization of this

1 : 100 0,999 KG

document as well as the communication of its contents to

137417

713 D

P

8600

CR Kontrollraum / control room others without explicit authorization is prohibited. Offenders

252 374 251 2 251 1 251 3

/

will be held liable for the payment of damages. All rights

N cooling unit SB Schaltschrankraum / switchboardroom reserved in the event of the grant of a patent, utility model Datum / date Name / name Dokument Nr. / document no.: Blatt / sheet:

B

exhaust or design.

cooling water re#granulating heating / cooling units fluff silos waste film designer 03.08.2018 APE

705510 001 / 002

213

A

pull roll system grinder filter CU Kühlaggregat / cooling unit DIN ISO 16016 checked 09.08.2018 WAJ

level +10000

R

DOCK LEVELER

B110 C level #4500 level #4500 level +9500 BR Gebläseraum / blower room Bezeichnung:

O

raw material FOR 2 NOS. TRUCK Gesamtanlage, 1907 FFE

V

A availability 1000 m³ DOCK LEVELLER AB / Arbeitsbreite zwischen den Kluppen / A

WW working width between the clips description:

D#83313 Siegsdorf

B von Brückner / seller's supply

vom Kunden / buyer's supply Ursprung / origin mat.137417 Stückliste / parts list S

complete line, 1907 FFE

Ersatz für / replacement for: # Ersetzt durch / replaced by: # 2x A0

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 erstellt mit: Solid Edge ST8

You might also like

- Electrical System C7 Industrial Engine: Harness and Wire Electrical Schematic SymbolsDocument4 pagesElectrical System C7 Industrial Engine: Harness and Wire Electrical Schematic SymbolsCésar Pérez100% (3)

- SNAKE EATER-ContrabassDocument1 pageSNAKE EATER-ContrabassPepe GonzalezNo ratings yet

- Alabox - TromboneDocument1 pageAlabox - TromboneCoro YopNo ratings yet

- 164642-1 A Betriebsanleitung en-US PDFDocument34 pages164642-1 A Betriebsanleitung en-US PDFHadj Ahmed SaoudiNo ratings yet

- Queen Opener TBN 2Document2 pagesQueen Opener TBN 2PqrhelionNo ratings yet

- Harness Main Tripac Evolution: A REV List of MaterialDocument2 pagesHarness Main Tripac Evolution: A REV List of MaterialBroks ArriagaNo ratings yet

- July 2022Document1 pageJuly 2022Create UsernaNo ratings yet

- July 2022Document1 pageJuly 2022Create UsernaNo ratings yet

- A Mensagem Da Cruz: ComposerDocument1 pageA Mensagem Da Cruz: ComposerPedro ViniciusNo ratings yet

- HEY BROTHER-Clarinete en Sib 1Document1 pageHEY BROTHER-Clarinete en Sib 1diego sanchezNo ratings yet

- Sentenced - MournDocument3 pagesSentenced - Mournamin bakiNo ratings yet

- Game of Thrones Theme ViolinDocument1 pageGame of Thrones Theme ViolinJulio Duarte BatistaNo ratings yet

- Perfect Life - Violin I PDFDocument1 pagePerfect Life - Violin I PDFleijocNo ratings yet

- Perfect Life - Double BassDocument1 pagePerfect Life - Double BassleijocNo ratings yet

- Nothing Else Matters: Metallica MetallicaDocument3 pagesNothing Else Matters: Metallica MetallicaMiguel RuedaNo ratings yet

- Vehicle Ides of March TenorsaxDocument1 pageVehicle Ides of March TenorsaxPim van HartenNo ratings yet

- Vehicle Ides of March TromboneDocument1 pageVehicle Ides of March TrombonePim van HartenNo ratings yet

- Fuerzas Diagonales PDFDocument1 pageFuerzas Diagonales PDFEdwin EnriquezNo ratings yet

- January 2022Document1 pageJanuary 2022Create UsernaNo ratings yet

- January 2022Document1 pageJanuary 2022Create UsernaNo ratings yet

- Burlesque-Saxofón Alto 1Document1 pageBurlesque-Saxofón Alto 1jhojanNo ratings yet

- التحليل العددي ماتلابDocument230 pagesالتحليل العددي ماتلابlazhorlazhorNo ratings yet

- JFN01 05 028 BDocument1 pageJFN01 05 028 Bluca.laniNo ratings yet

- GUARDIANS - Bombardino - SolDocument1 pageGUARDIANS - Bombardino - SolFelype SilvaNo ratings yet

- Stand by Me: Ben E KingDocument1 pageStand by Me: Ben E KingnatttalyNo ratings yet

- Kessler Reach Stacker HysterDocument5 pagesKessler Reach Stacker HysterHumberto Augusto de Borba100% (1)

- Dhamm-Ho Bisogno Bass DamidiDocument3 pagesDhamm-Ho Bisogno Bass Damidikris bandiniNo ratings yet

- TRMB Melodias TarijeñasDocument2 pagesTRMB Melodias TarijeñasAlvaroNo ratings yet

- Alto Sax Horn 2 Transcription MARIO BROS 2Document4 pagesAlto Sax Horn 2 Transcription MARIO BROS 2Kaden DayogNo ratings yet

- P3LA-MEC-DST-007-Rev2 Data Sheet For Gate ValveDocument6 pagesP3LA-MEC-DST-007-Rev2 Data Sheet For Gate ValveMr. AlferditomaNo ratings yet

- LandUseMapFigure22 PDFDocument1 pageLandUseMapFigure22 PDFIlaria BonviniNo ratings yet

- Stationary RequisitionDocument1 pageStationary Requisitionapplyhr.asgNo ratings yet

- SAN LORENZO Marcha - Trumpet 1Document2 pagesSAN LORENZO Marcha - Trumpet 1Alfredo PalaciosNo ratings yet

- Treasure Fantasy MapDocument1 pageTreasure Fantasy MapArnav ChakrabortyNo ratings yet

- Children's March: "Over The Hills and Far Away": B Trumpet 1Document5 pagesChildren's March: "Over The Hills and Far Away": B Trumpet 1Billan LiaoNo ratings yet

- Sway (Quien Sera) - Trompeta 1Document2 pagesSway (Quien Sera) - Trompeta 1jhojanNo ratings yet

- Kanye West Hallelujah DrumsDocument2 pagesKanye West Hallelujah DrumsDaise SIlveira de AndradeNo ratings yet

- Grande É o Senhor - FagoteDocument1 pageGrande É o Senhor - FagoteAlves Esdras EmanuelNo ratings yet

- In Bicicletta: Tema Del Film IL POSTINODocument1 pageIn Bicicletta: Tema Del Film IL POSTINOGianluca GregantiNo ratings yet

- AehnlichkeitserinnerungDocument15 pagesAehnlichkeitserinnerungMatthew Lee KnowlesNo ratings yet

- Saltarello 2 PDFDocument2 pagesSaltarello 2 PDFDarwin Paul Otiniano LuisNo ratings yet

- Tinh Thoi Xot Xa - Strings-GuitarDocument3 pagesTinh Thoi Xot Xa - Strings-Guitarson anhNo ratings yet

- LSA46.2 ManualDocument24 pagesLSA46.2 ManualDaniel ArdilaNo ratings yet

- Mudarra FantharpatranscriptieDocument4 pagesMudarra FantharpatranscriptieJulian SterneNo ratings yet

- San Lorenzo Marcha - BassDocument2 pagesSan Lorenzo Marcha - BassAlfredo PalaciosNo ratings yet

- A Holiday Celebration-Bassoon 1Document1 pageA Holiday Celebration-Bassoon 1jorge farquezNo ratings yet

- A HOLIDAY CELEBRATION-Bassoon 1 PDFDocument1 pageA HOLIDAY CELEBRATION-Bassoon 1 PDFjorge farquezNo ratings yet

- Children's March: "Over The Hills and Far Away": B Trumpet 2Document5 pagesChildren's March: "Over The Hills and Far Away": B Trumpet 2Billan LiaoNo ratings yet

- H2O2 Soap: Agitator 2 Drum Pulper VatDocument1 pageH2O2 Soap: Agitator 2 Drum Pulper VatMatsumura SokonNo ratings yet

- Answer Sheet Answer SheetDocument2 pagesAnswer Sheet Answer Sheetyannie isananNo ratings yet

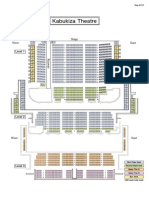

- Kabukiza Seat ChartDocument1 pageKabukiza Seat ChartpatrickvillelaNo ratings yet

- Tien An Men-PianoDocument2 pagesTien An Men-PianoggodetNo ratings yet

- EngineerDocument25 pagesEngineersmjang49No ratings yet

- GE Renewal Parts: Ac Motor Models 5Geb20B4A Thru 5Geb20B4FDocument7 pagesGE Renewal Parts: Ac Motor Models 5Geb20B4A Thru 5Geb20B4Flei songNo ratings yet

- Attendance List of TrainingDocument1 pageAttendance List of TrainingPuji LNo ratings yet

- Answer Sheet Daw HahahahhaDocument4 pagesAnswer Sheet Daw HahahahhaBeverly RoqueNo ratings yet

- H2O2 Soap: Agitator 2 Drum P Ulper VatDocument1 pageH2O2 Soap: Agitator 2 Drum P Ulper VatMatsumura SokonNo ratings yet

- Call It English: The Languages of Jewish American LiteratureFrom EverandCall It English: The Languages of Jewish American LiteratureNo ratings yet

- 7 Principles of Auditing Management SystemDocument3 pages7 Principles of Auditing Management SystemELSAYED KhalfNo ratings yet

- Before.. After..: © Open Source Six Sigma, LLCDocument9 pagesBefore.. After..: © Open Source Six Sigma, LLCELSAYED KhalfNo ratings yet

- 5S Manual PDFDocument72 pages5S Manual PDFSudhagarNo ratings yet

- 5S Implementation at Work Place Complete PresentationDocument16 pages5S Implementation at Work Place Complete PresentationELSAYED KhalfNo ratings yet

- Muda, Mura, Muri: #KME - LessonsDocument3 pagesMuda, Mura, Muri: #KME - LessonsELSAYED KhalfNo ratings yet

- Excel Tips Tricks Ebook DLDocument30 pagesExcel Tips Tricks Ebook DLSiamNo ratings yet

- Overview of Incorporation in CambodiaDocument3 pagesOverview of Incorporation in CambodiaDavid MNo ratings yet

- Introduction To Pharmacology by ZebDocument31 pagesIntroduction To Pharmacology by ZebSanam MalikNo ratings yet

- Catalogo HydronixDocument68 pagesCatalogo HydronixNANCHO77No ratings yet

- Chapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsDocument27 pagesChapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsEdwin ChuenNo ratings yet

- Gifted Black Females Attending Predominantly White Schools Compressed 1 CompressedDocument488 pagesGifted Black Females Attending Predominantly White Schools Compressed 1 Compressedapi-718408484No ratings yet

- Forensic My Cology Mcgraw HillDocument8 pagesForensic My Cology Mcgraw HillJayanti RaufNo ratings yet

- A Vision System For Surface Roughness Characterization Using The Gray Level Co-Occurrence MatrixDocument12 pagesA Vision System For Surface Roughness Characterization Using The Gray Level Co-Occurrence MatrixPraveen KumarNo ratings yet

- DISTRICT CENSUS HANDBOOK North GoaDocument190 pagesDISTRICT CENSUS HANDBOOK North Goants1020No ratings yet

- Drawbot 1Document4 pagesDrawbot 1SayanSanyalNo ratings yet

- EPSS 627: DescriptionDocument2 pagesEPSS 627: DescriptionudayakumartNo ratings yet

- Ultrasonic Based Distance Measurement SystemDocument18 pagesUltrasonic Based Distance Measurement SystemAman100% (2)

- Abacus 1 PDFDocument13 pagesAbacus 1 PDFAli ChababNo ratings yet

- Brachiocephalic Artery: AnteriorDocument37 pagesBrachiocephalic Artery: AnteriorFarah FarahNo ratings yet

- Crown BeverageDocument13 pagesCrown BeverageMoniruzzaman JurorNo ratings yet

- Resolution: Owner/Operator, DocketedDocument4 pagesResolution: Owner/Operator, DocketedDonna Grace Guyo100% (1)

- Topic 6 Nested For LoopsDocument21 pagesTopic 6 Nested For Loopsthbull02No ratings yet

- The Global Entrepreneurship and Development Index 2014 For Web1 PDFDocument249 pagesThe Global Entrepreneurship and Development Index 2014 For Web1 PDFAlex Yuri Rodriguez100% (1)

- QuerySurge Models Mappings DocumentDocument28 pagesQuerySurge Models Mappings Documentchiranjeev mishra100% (1)

- Computerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting MachineDocument61 pagesComputerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting Machine Computerized Flat Knitting MachineAmira's ClothesNo ratings yet

- B2B Marketing: Chapter-8Document23 pagesB2B Marketing: Chapter-8Saurabh JainNo ratings yet

- CAMEL Model With Detailed Explanations and Proper FormulasDocument4 pagesCAMEL Model With Detailed Explanations and Proper FormulasHarsh AgarwalNo ratings yet

- NDT HandBook Volume 10 (NDT Overview)Document600 pagesNDT HandBook Volume 10 (NDT Overview)mahesh95% (19)

- Propp Function's Types:: 1-Absentation: One of The Members of A Family Absents Himself From HomeDocument10 pagesPropp Function's Types:: 1-Absentation: One of The Members of A Family Absents Himself From HomeRohith KumarNo ratings yet

- Grammar Practice #2Document6 pagesGrammar Practice #2Constantin OpreaNo ratings yet

- Presentation No. 3 - Songs and ChantsDocument44 pagesPresentation No. 3 - Songs and Chantsandie hinchNo ratings yet

- Growing Onion Management and Water NeedsDocument25 pagesGrowing Onion Management and Water NeedsKATE NAVAJANo ratings yet

- Chanakya: For The Indian Television Series Based On His Life, SeeDocument11 pagesChanakya: For The Indian Television Series Based On His Life, SeeTrinadh CrazyguyNo ratings yet

- When I Was A ChildDocument2 pagesWhen I Was A Childapi-636173534No ratings yet

- Micronet TMRDocument316 pagesMicronet TMRHaithem BrebishNo ratings yet

- Anabolic Steroid-Dynamics, Kinetics, Mechanisms, Adverse Effects and AbuseDocument6 pagesAnabolic Steroid-Dynamics, Kinetics, Mechanisms, Adverse Effects and AbuseArvin DiNozzoNo ratings yet