Professional Documents

Culture Documents

A Low Cost High Tension Lead Tester

Uploaded by

TIMOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Low Cost High Tension Lead Tester

Uploaded by

TIMCopyright:

Available Formats

A Low Cost High

Tension Lead Tester

By Thomas K. Eismin, Professor testing defective leads (i.e., the current ponents to a 1/4" plywood base which

Aviation Technology has traveled through the low resistance will later be placed inside the case. This

Purdue University of the lead's defective insulation). plywood mounting will help eliminate

West Lafayette, IN 47907 the possibility of short circuits. For final

Unit Construction case assembly see Detail B.

Electrical: As indicated by the

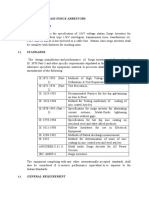

Mechanical: The electrode gap is schematic and parts lists in Detail C,

Have you priced a Bendix ignition definitely the most critical part of the the unit's electrical system is quite sim-

harness high tension lead tester lately? lead tester. The electrodes I recom- ple, and all components are readily

If you have, you know why I was de-

mend are constructed from two 1-1/2", available. The 120 volt AC power is di-

termined to produce a low cost substi-

number 10 brass machine screws filed rected through a transformer and a full

tute. The theory of operation of any igni- wave rectifier to allow 12 volt DC power

to a point. The screws are then

tion lead tester is simple. The tester mounted to a clear plastic housing and to be used by the ignition coil. A master

must produce a high voltage low cur- adjusted to a 7mm gap (see Detail A). switch is used to control the AC current

rent, DC signal, send that signal to the The electrode assembly was then to the lead tester.

ignition lead positive conductor and de- placed in the tester case near a 1" A second normally open switch, the

tect any current leakage from the lead punched hole. This placement allows lead test switch, controls the current to

positive conductor to the lead ground or the operator to view the electrode gap the ignition coil primary winding. This

shielding. during lead testing. switch is manually operated during lead

My initial thought was to study the The tester case can be made of virtu- testing. The secondary circuit of the ig-

Bendix lead tester and build a similar ally any material, although plastic and nition coil is directly connected to the

"black box". This sounds simple; how- aluminum boxes are commercially 7mm electrode gap in parallel with the

ever, the Bendix tester utilizes two available. An 8" x 6" x 4-1/2" case will test lead alligator clips. It should be

specially made transformers which I allow sufficient room for easy assembly noted that high voltage wire must be

found virtually impossible to purchase. used in the secondary circuit to prevent

of all components. If a metal case is

I knew there had to be a better solution, used, I recommend mounting all com- unwanted arcing.

and there was. A solution so simple the

entire lead tester can be built for under

$30.

My lead tester was built using a typi- Detail A

cal automotive ignition coil to generate

a 6000 volt output. The output of a typ-

ical production model high tension lead

tester was determined to be between I I'M'LP"

5500 and 6000 volts. Therefore, the au-

tomotive coil was perfect.

The ignition coil can be powered di-

rectly from a self-contained battery, the TOP VIEW

onboard aircraft battery, or from a 120

volt AC source. I chose the 120 volt AC

source for two major reasons: (1) the

self-contained batteries (8-D cells), al-

though simplest, required replacement 1V 2 "#10

#10 Brass 7 mm gap

much too often, and (2) the use of the /~ brass machine

nut, 4 ea.

aircraft battery was eliminated because 4 I-eri'iiM-i.

•iii'in'i'fn>

>' screw, 2 ea.

aircraft are often 24 volt, and often

leads are tested after the battery has

been removed from the aircraft. Thus, #10 Brass

the solution is a 120 volt AC power washer, 6 ea \_ electrical

source. crimp connectors,

2ea.

Similar to production models, my de-

sign uses a 7mm electrode gap to allow

a maximum voltage of approximately

5600 volts available for lead testing. I — — 3/ie" or

The high voltage generated in the tester thicker plexiglass

has a choice of two current paths: (1)

across the electrode gap, or (2) through

the ignition lead insulation. Since cur-

rent always takes the path of least resis-

tance, a spark will appear across the FRONT VIEW

electrode gap when testing good igni-

tion leads. No spark will appear when

42 JULY 1985

Unit Operation: The basic operation

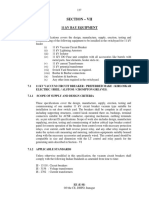

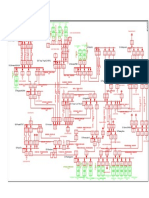

DetaMB of this lead tester is similar to that of

production models. To test the insula-

A.C. power cord grommet tion of high tension leads:

(1) Attach one test lead alligator

clip to the aircraft ignition lead ferrule

(i.e. the outer wire of the ignition lead).

f.-\ (2) Attach the other test lead al-

-f I —

ligator clip to the ignition lead positive

T, - Step down —— wire (i.e., the inner wire of the ignition

transformer I J coil lead).

W (3) Connect the test instrument as

Primary & secondary a 120 volt AC source and turn on the

R, - Rectifier

v S~ negative connection unit's master switch.

w **y

assembly -»//Tb t ———— t- __ / Primary positive (4) Depress the spring loaded lead

(4 diodes & / connection test switch and release rapidly. This will

1 capacitor) ^—~^« ^ofnnHiri/ rvi*^iti\/P

activate the high voltage source and

connection test the ignition lead.

Electrode

assembly

^ —— C2 - Capacitor (5) While releasing the lead test

switch, view the electrode gap through

*] the case viewing window. If a spark oc-

curs across the gap, the lead insulation

S, - Master — si *. , ^ 1\—— S2 - Test is airworthy. If no spark is viewed

switch Test lead grommets switch across the electrode gap, the ignition

TOP VIEW lead should be rejected.

(6) Repeat steps one through five

for each ignition lead to be tested.

Other Operation Notes:

(1) Always check your lead tester

prior to operation. This can be done by

separating the alligator clips approxi-

viewing ^\

/ window \v

mately one inch, then depress and

Negative r master test N rapidly release the lead test switch. For

Test Lead ^ Positive a correctly operating tester, a spark

Test Lead should appear across the electrode

gap. Next, connect the alligator clips to-

gether and repeat the test. No spark

FRONT VIEW should appear across the electrode

gap. If this sequence does not occur,

retest and identify any problems prior to

ignition lead testing.

(2) When testing leads which are

Detail C installed on the engine, be sure to keep

the tester alligator clips and test leads

well Jear of any grounded metal parts

of the aircraft. If the test leads and al-

ligator clips come in physical contact

with grounded metal parts, the tester

may falsely reject good leads.

(3) On some engines, leakage may

C»2 occur through the magneto distributor

to the magneto coil. Therefore, before

rejecting any leads which are tested

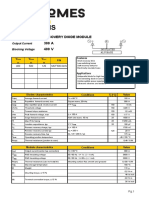

Parts List while connected to the magneto, turn

P, - A.C. power plug, 3A the engine (magneto) slightly and re-

S, - SPST 120 V.A.C., 5A switch peat the test.

T, - 120 V.A.C. input, 3 AMP 12 volt output, (4) Remember, insulation leakage

transformer is not the only cause of defective leads.

R, - Rectifier Assembly — Each lead should also be tested for con-

4 Diodes, 3 AMP 50 volt; tinuity of the positive conductor. A typi-

Diodes are mounted to an Experi- cal ohmmeter or continuity light may be

menter Gird Board 2%" x 3%"

C, - Capacitor 35V, 1000 uF used for this test.

S2 - Normally open SPST 5A D.C. switch This high tension lead tester will offer

C2 - Typical automotive ignition capacitor 12 many years of faithful service to any

V.D.C., 1000 uF technician. But keep in mind, the quality

T2 - Typical automotive 12 volt ignition coil of any tool is only as good as the work-

W, & W2 - 35 KV, 18 gage stranded wire manship used during construction.

(all other wires are stranded 20 Please take your time and assemble

gage wire) your lead tester carefully and accu-

G, - 7mm electrode gap rately. If you have any questions con-

A, & A2 - Alligator dip

cerning this item, please feel free to

contact me.

SPORT AVIATION 43

You might also like

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusFrom EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusRating: 3 out of 5 stars3/5 (1)

- BEKO K5 ChassisDocument46 pagesBEKO K5 Chassisf17439No ratings yet

- Chassis C7-C8 PDFDocument69 pagesChassis C7-C8 PDFAouadi AbdellazizNo ratings yet

- Test terminal blocks safely calibrate energy metersDocument4 pagesTest terminal blocks safely calibrate energy metersAsim Ali GardeziNo ratings yet

- 33kv-plug-in-termination-kit-raychemDocument7 pages33kv-plug-in-termination-kit-raychemArdhendu Sekhar BhanjaNo ratings yet

- Voltage Surges Caused by Contactor CoilsDocument6 pagesVoltage Surges Caused by Contactor CoilsRajuNo ratings yet

- Passive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2From EverandPassive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2No ratings yet

- TH 32 C 400 DDocument58 pagesTH 32 C 400 DAnonymous nIcSGEwNo ratings yet

- Technical Specifications and Block Diagram of a TV ReceiverDocument22 pagesTechnical Specifications and Block Diagram of a TV Receiverdancalin64No ratings yet

- Haier Model - 21F7A-P TVDocument26 pagesHaier Model - 21F7A-P TVGiovanny Enrique Gonzalez CastroNo ratings yet

- 12.3 Beko Service ManualDocument21 pages12.3 Beko Service ManualCaptain444No ratings yet

- Beko Chassis 14.2 SMDocument31 pagesBeko Chassis 14.2 SMbardhi2322No ratings yet

- 14.2 Service ManualDocument30 pages14.2 Service ManualALCATRAZNo ratings yet

- Panasonic+Th 46pz85u+Service+ManualDocument128 pagesPanasonic+Th 46pz85u+Service+Manuala1electronicsNo ratings yet

- 12.7 Service ManualDocument20 pages12.7 Service Manualadi_samaNo ratings yet

- Module 4: Substation Equipment's Details and Operations: July 2021Document14 pagesModule 4: Substation Equipment's Details and Operations: July 2021Gundeboyina GopiNo ratings yet

- Texas AM MV SpecificationDocument11 pagesTexas AM MV SpecificationDavid BurgessNo ratings yet

- File 2501230505230Document56 pagesFile 2501230505230alkingfrhatNo ratings yet

- Testing Cables for Electrical SafetyDocument8 pagesTesting Cables for Electrical SafetyDiwakar DiwakarNo ratings yet

- KR21N7N Service ManualDocument16 pagesKR21N7N Service ManualBogdan DorofteyNo ratings yet

- Panasonic TH-50PZ80U Service ManualDocument132 pagesPanasonic TH-50PZ80U Service ManualMoto0524No ratings yet

- Protect 11kV systems with metal oxide surge arrestorsDocument16 pagesProtect 11kV systems with metal oxide surge arrestorsSandip AhireNo ratings yet

- Prelim Exam JOPIADocument4 pagesPrelim Exam JOPIAGABRIEL ABRAM JOPIANo ratings yet

- E1 Chassis Service Manual Technical Specs and Safety InstructionsDocument34 pagesE1 Chassis Service Manual Technical Specs and Safety InstructionsDanNo ratings yet

- Cooper Deadbreak Elbow 55010Document4 pagesCooper Deadbreak Elbow 55010denzil_1000No ratings yet

- Chasis TelevisorDocument49 pagesChasis TelevisorReynaldo MarcaNo ratings yet

- Chassis CX-B29FB Manual de Servicio-1 PDFDocument49 pagesChassis CX-B29FB Manual de Servicio-1 PDFReynaldo MarcaNo ratings yet

- Samsung Yp-K3Document56 pagesSamsung Yp-K3Wagner PrudenteNo ratings yet

- TH 50px80uDocument106 pagesTH 50px80unaso150No ratings yet

- TC 37lz800 PDFDocument61 pagesTC 37lz800 PDFPedro SandovalNo ratings yet

- Bobinas HansenDocument4 pagesBobinas HansenJose Ignacio Figueroa CortesNo ratings yet

- Panasonic Tc-l47wt50 Chassis La35Document99 pagesPanasonic Tc-l47wt50 Chassis La35mitchel taylorNo ratings yet

- Testing of BushingDocument8 pagesTesting of BushingAmir Ali khanNo ratings yet

- Panasonic TX32A400 Service ManualDocument27 pagesPanasonic TX32A400 Service ManualJan Kowalski100% (1)

- Panasonic TC P42S1Document115 pagesPanasonic TC P42S1Vicente EsquerreNo ratings yet

- 29Q (PAL) Service ManualDocument58 pages29Q (PAL) Service ManualElectronica MeizaNo ratings yet

- 7 Hitachi - Energy - 145kV - Dry - Plug-In - GIS - Transformer - TerminationDocument4 pages7 Hitachi - Energy - 145kV - Dry - Plug-In - GIS - Transformer - TerminationMonisha S.No ratings yet

- Service Manual: Color TelevisionDocument16 pagesService Manual: Color TelevisionYoyneer SalinasNo ratings yet

- 11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesDocument61 pages11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesHemant KumarNo ratings yet

- Specification of Lightening ArrestersDocument12 pagesSpecification of Lightening ArrestersS BalasubramaniamNo ratings yet

- K15BD Manual ServicioDocument55 pagesK15BD Manual ServiciomarcellobbNo ratings yet

- Panasonic tc-l55dt50 CH La35Document71 pagesPanasonic tc-l55dt50 CH La35Marko MatićNo ratings yet

- Module 4: Substation Equipment's Details and Operations: July 2021Document21 pagesModule 4: Substation Equipment's Details and Operations: July 2021Gundeboyina GopiNo ratings yet

- TC-L32E6H: 32 Inch Class 1080p LCD HDTVDocument30 pagesTC-L32E6H: 32 Inch Class 1080p LCD HDTVJosé Ivan Bonillas GranadosNo ratings yet

- Haier: Color Television & DVDDocument29 pagesHaier: Color Television & DVDWilinton PissoNo ratings yet

- SUN2000 - (2KTL-6KTL) - L1 Quick GuideDocument22 pagesSUN2000 - (2KTL-6KTL) - L1 Quick GuideNicolae ChirilaNo ratings yet

- TC-42X1 Part 1Document50 pagesTC-42X1 Part 1Pedro SandovalNo ratings yet

- Service Manual: Colour TelevisionDocument21 pagesService Manual: Colour TelevisionTecnico GenioNo ratings yet

- Panasonic Tc-p50s1 Chassis Gpf12duDocument118 pagesPanasonic Tc-p50s1 Chassis Gpf12dumanuel_robalinoNo ratings yet

- Voltgage Prof Odf Eelecterolyric CapaivueortsDocument6 pagesVoltgage Prof Odf Eelecterolyric CapaivueortsbhaskaaNo ratings yet

- Basic Electronics Laboratory LatestDocument54 pagesBasic Electronics Laboratory LatestBhargobi RoyNo ratings yet

- Panasonic Tc-50px14Document111 pagesPanasonic Tc-50px14AnibalNo ratings yet

- 11 KV Bay EquipmentDocument22 pages11 KV Bay EquipmentSudhir ShindeNo ratings yet

- TC-P42X1: 42 Inch Class 720p Plasma HDTVDocument108 pagesTC-P42X1: 42 Inch Class 720p Plasma HDTVGeovanny SanJuanNo ratings yet

- CANCK1122Document3 pagesCANCK1122ztmp1No ratings yet

- Panasonic Lx7 Service ManualDocument101 pagesPanasonic Lx7 Service Manualmofared100% (1)

- Aiaa 1990 3198 784Document11 pagesAiaa 1990 3198 784TIMNo ratings yet

- Aiaa 1984 2163 828Document13 pagesAiaa 1984 2163 828TIMNo ratings yet

- NASA Langley Technical Report TM-2000-210646Document20 pagesNASA Langley Technical Report TM-2000-210646spikebusterNo ratings yet

- Single or Twin EngineDocument15 pagesSingle or Twin EngineTIMNo ratings yet

- Magneto Fundamentals & Ignition Req (1-22)Document22 pagesMagneto Fundamentals & Ignition Req (1-22)TIMNo ratings yet

- Magneto Early Ignition Systems (23-31)Document9 pagesMagneto Early Ignition Systems (23-31)TIMNo ratings yet

- NASA Report Details Simplified Theory of Magneto InductionDocument18 pagesNASA Report Details Simplified Theory of Magneto InductionTIMNo ratings yet

- Magneto Service Practices (49-64)Document16 pagesMagneto Service Practices (49-64)TIMNo ratings yet

- 977 Sample PDFDocument6 pages977 Sample PDFAdrianNo ratings yet

- Physics Note Dynamic Force 02Document30 pagesPhysics Note Dynamic Force 02Tapendra BistNo ratings yet

- Dieless Wire DrawingDocument16 pagesDieless Wire DrawingRohit GothwalNo ratings yet

- Gasoline electronic Direct Injection SystemDocument34 pagesGasoline electronic Direct Injection Systemloganathanpalani100% (1)

- GIS 8DQ1 DS eDocument18 pagesGIS 8DQ1 DS esachinkudachiNo ratings yet

- Kia Sportage 2001 G 2.0 DOHC ECM Terminal Voltage ChartDocument6 pagesKia Sportage 2001 G 2.0 DOHC ECM Terminal Voltage ChartJorge Luis Espino Cruz50% (2)

- MCF300.04IS: Insulated Fast Recovery Diode Module 300 A 400 VDocument4 pagesMCF300.04IS: Insulated Fast Recovery Diode Module 300 A 400 VAnonymous nC9gpUWPNo ratings yet

- Pure Substance Model and Two-Phase Flow Basics: - Fall 2010 Problem Set 6Document3 pagesPure Substance Model and Two-Phase Flow Basics: - Fall 2010 Problem Set 6pstgouveiaNo ratings yet

- Cs563e 2Document2 pagesCs563e 2Gilberto Morales Caldas100% (2)

- Module 3 - Fire SafetyDocument5 pagesModule 3 - Fire SafetyvonsonNo ratings yet

- R7 AuraMarine Preheating UnitDocument4 pagesR7 AuraMarine Preheating UnitRodrigo CastroNo ratings yet

- Astm d5682Document4 pagesAstm d5682Ernesto Morales100% (1)

- SOP For Diesel Generator Set (DG)Document2 pagesSOP For Diesel Generator Set (DG)PADCL100% (4)

- Vetting Inspectors.Document5 pagesVetting Inspectors.Pavel ViktorNo ratings yet

- Baudouin - PowerKit Brochure - EN - 02.17Document8 pagesBaudouin - PowerKit Brochure - EN - 02.17storkbNo ratings yet

- Strategy Evaluation Toyota Motor CorportationDocument7 pagesStrategy Evaluation Toyota Motor CorportationGayathri KumarNo ratings yet

- EUROPA REFERENCE BOOKS For Automotive Te PDFDocument20 pagesEUROPA REFERENCE BOOKS For Automotive Te PDFLaércio LaercioNo ratings yet

- Gerotor Pump: Application Briefs From FluentDocument2 pagesGerotor Pump: Application Briefs From FluentahmedNo ratings yet

- 1TGC902030B0201 MNS System GuideDocument34 pages1TGC902030B0201 MNS System GuideSubhroSenNo ratings yet

- Adafruit Mics5524 Gas Sensor BreakoutDocument12 pagesAdafruit Mics5524 Gas Sensor BreakoutWerliock MorlorumNo ratings yet

- As SystemDocument18 pagesAs Systemkr_abhijeet72356587No ratings yet

- NCF3 PDFDocument311 pagesNCF3 PDFShivNo ratings yet

- Model Divison Musa PakDocument6 pagesModel Divison Musa PakSania AliNo ratings yet

- gg1 Engineer S Controls Classic TrainsDocument1 pagegg1 Engineer S Controls Classic Trainsbaron mNo ratings yet

- Hillbrandt Axel CV AH-PC E 1216Document4 pagesHillbrandt Axel CV AH-PC E 1216HillbrandtNo ratings yet

- SLD Bali NormalDocument1 pageSLD Bali NormalHamam PrigelNo ratings yet

- Door Frame Cutout and Wire Transfer Installation GuideDocument1 pageDoor Frame Cutout and Wire Transfer Installation Guiderodney_massieNo ratings yet

- MFL67477506 - English + HindiDocument38 pagesMFL67477506 - English + HindiFarhanNo ratings yet

- El Tanque TorricelliDocument4 pagesEl Tanque TorricelliMelanie RebourNo ratings yet

- South Pasadena AP Chemistry Nuclear Chemistry Practice TestDocument2 pagesSouth Pasadena AP Chemistry Nuclear Chemistry Practice Testerice12No ratings yet