Professional Documents

Culture Documents

20 KN Load Cell 21-23

20 KN Load Cell 21-23

Uploaded by

Debabrata Majhi0 ratings0% found this document useful (0 votes)

28 views2 pagesOriginal Title

20 Kn Load Cell 21-23

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views2 pages20 KN Load Cell 21-23

20 KN Load Cell 21-23

Uploaded by

Debabrata MajhiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

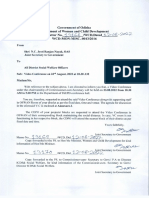

DRS ENGINEERING 8 CALIBRATION SERVICES

AN ISO/IEC-17025:2017/ ACCREDITED BY NABL_

cous oe, CONTACT US: (Gj 0120-4236630 © 8822229228 InfoGarstab.in

Ss

RVICES & A 82 SECTOR 65 NoIDA 201 301

€o3193

lIssued For MIS UNIQUE CALIBRATION JULR No, (6C319321000000597F

SOLUTIONS LLP \cai - |

611-P, SECTOR-38,GURGAON, joa cenmenteNe. _Florsovavssy _J

HARYANA-122001 RENEE De. prsisrri21266 |

Date of Calibration 11.09.2021

[bisiptine : Mechanical Force Proving Ring [Calibration Duo on 0.142028

Details of Unit Under Calibration Issue Date of Certificate 13.09.2021

Type Load Cet with incicator

Make MAKIN Date of Rec 70092024

Model 83 [Customer Ref. No. & Date: | BY HAND

Serial Numbor wwrz0151 [Conaition on receipt OK

Capacity 204N

Cable Length S5METER Environmental Condition

Details of Indicator JRoom Temperature mire

Indicator Type Dita Huriaty 400% RH

ee ma Mode of application of Force:

Serial Number 1226

Equipment kt ucsu.cios Compression

Resolution COUNTS

Accossories Set atgning Compression Pad

es, T0XN DEAD Wight Fore Calraion Nace (ORS/OWFON-GD)

200kN Fyeraue Caltaon Machine (ORSIMFCMO1)

Associated Uncertainty 0.044% at 22) 8 0.040% a 422)

trace

ity FRVOSI20}0WENV021 Dated [3708/2020 Vai upto 030972022

FRUDS2O;DWCWVO22A Dated 0310812020 Vali upto 03

|Principle/Methodology of Calibration and Calibration Procedure:

1. Work Instruction Number: DRS/SOPIOIF Based on IS 4169-2014 & ISO 375: 2011

2022

2. No Load Output: The digital Indicator was switched on for 30 minutes to warm up and stabilized for no lead output before the start of

[caltraton The no oad output was noted (before tarng) andthe calbration signal was noted.

3. Protoading : Before the aplication ofthe calibration forces, the instrument was preloaded tvice tos maximum capacity and Kept at fl

jad for about 90 seconds,

4. Calibration The sequence of applied calibration force in Compression ‘given below:

at 0° Two series of calitration forces in increasing values. At 120° and 240° postions: One series of calibration forces each increasing

values. Creep testis performed by calculating the ference in output 190 obtained at 308 and i300 obtained at 300s afer the removal ofthe

maximum calibration force and express this difference as percentage ofthe maximum defection. The calibration was made by using self

laigning Compression Pad provided along wih he instrument to ensure axial application ofthe force. Between each senes, the instrument was|

rated along its axis so as to occupy during calibration twee positions (0° 120",240") and the instrument was subjected to the fll load once fo

Jabout 90 seconds each tie before starting in a new pesiton. Between the loadings, readings corresponding to no load after waiting at least 20

lseconds forthe return to zero were noted

Se AS

ys > Qs

Gurdeep Singh KaUshal Kishore

3 (Technical Manager)

[FORWAT NO_-DRSICF/18.01 Page 1 of 2

ALIBRATION *TE

DRS ENGINEERING & CALIBRATION SERVICES <~

AN ISO/IEC-17025:2017/ ACCREDITED BY NABL

CONTACT US: @ 0120-4236630 ( 8822229228 & Into@drsiabin

SERVICE 2 A82 sector 65 NoIDa 201 301

CALIBRATION CERTIFICATE

03193

[Catibration Method : This Insrunent is Calbraied n Compression Modo as per] ULR No (60319521000000646F

ORS Engineering & Calibration Services Procedure No. DRSISOPIONF Based | orccesreae |

on 1s 4169-2014nS0 376-2011 cai comiteate no. | DRSIOE2H640

Result : Compression Mode

No Load Output 3 Counts [Galbration Signal Na :

sun ond rrcen] = Dato Coun)

iH ‘sition 0° | Position” | Position 120° | Postion 240° Average

series 4 series? | series 3 series 4 (sories 4.34)

7 3 ° o ° ° =

2 70 303 303 302 30 502

3 200 "ood 7005 7004 1003 7004

@ 500 2508 2506; 2505 2504 2506;

5 1000 ‘5005, ‘5000 ‘5003 ‘5000 7 5003.

5 7000 0024 0023 10020) 0005 70025

7 [4000 200s8 | 20028 2000 70022 20072

a 000 30025 30018 29998 30007 3000

3 0000) 50008 49968 49960 #0906) 43988 |

10 | 15000 74895) 74842 74832 “74860 74882

1 20000 ‘99727 99738 ‘99723 ‘99742 (99731

[12 0 0 co 1 0 =

[Greop ato Load

Reading After 20 Sec

Reading After 300 Sec

1 Counts

° Counts

Interpolation Equation:

= 0.000001 16482 + §.0091735719%

Viherox= Foc in Ys Average Reading in Couns

cinssteaion:

The Fore proving inant a fon a cmp wih he eure of 1:16.20 ssid a lows

ees Moae From To |___ Unser of ensure

Class 1 ‘Compression 20000 N 200N | 20.120%

ciass2 camresion | 200000 | 100N 20%

int is at coverage factor a2 which comesponde probably of approximately 85% for @ normal dtrbuton. Conssering

the relative deviation ofdference components such as creep, zero, rsliion, repeat rereducbily & combining wih the uncertainty of

applied tree

2 Caloraton nas boon permed using set-ingng Compression Pad proved bythe customer

3 Instruments has been calbatod as per case C cra,

“4 Rosult ite only the tom cairates

5 Creep measure at zo fad

16 This conteate shal not be reproduced expect in fi

Calbrated oy 1%

Gurceep nah SCA

oe ges (Techical Manager

& i Page Fo

FORMAT NO. DRSCHTEOT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Laboratory Name: Accreditation Standard Certificate Number Page No Validity Last Amended OnDocument35 pagesLaboratory Name: Accreditation Standard Certificate Number Page No Validity Last Amended OnDebabrata MajhiNo ratings yet

- 7990 8002Document8 pages7990 8002Debabrata MajhiNo ratings yet

- Instrument DetailsDocument2 pagesInstrument DetailsDebabrata MajhiNo ratings yet

- TSC - 22-23 - 5490-1 TachometerDocument2 pagesTSC - 22-23 - 5490-1 TachometerDebabrata MajhiNo ratings yet

- List of Instruments For CalibrationDocument2 pagesList of Instruments For CalibrationDebabrata MajhiNo ratings yet

- Scope CC 2795Document44 pagesScope CC 2795Debabrata MajhiNo ratings yet

- Edpdf PDF DEST L00103 2022 8 13168Document4 pagesEdpdf PDF DEST L00103 2022 8 13168Debabrata MajhiNo ratings yet

- Sub: Quotation For Lab Equipment: Pawan PaliwalDocument4 pagesSub: Quotation For Lab Equipment: Pawan PaliwalDebabrata MajhiNo ratings yet