Professional Documents

Culture Documents

Silcotech Internal Audit Procedure

Uploaded by

Quality Unit 1 Ajay PandeyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Silcotech Internal Audit Procedure

Uploaded by

Quality Unit 1 Ajay PandeyCopyright:

Available Formats

SILCOTECH BONNY PRODUCTS (INDIA) PVT. LTD.

AUTOMOTIVE QUALITY Date of Issue: 01/08/2017

MANAGEMENT SYSTEM PROCEDURE FOR INTERNAL Issue No. 02 .Rev. No. 01

IATF 16949:2016 AUDITING Date of Rev. :_01/12/2019_

(SBPIPL/OCP/06/00)

Procedure: Internal Auditing

1. SUMMARY

1.1. This procedure defines the process and methods for conducting internal quality management

system (QMS)/ Manufacturing process / Product audits.

1.2. The Management Representative is responsible for implementation and management of all

internal audits.

2. REVISION AND APPROVAL

Rev. Date Nature of Changes Approved By

0 01/08/2017 Original issue. Director

1 01/12/2019 Corrections in some documents numbers and names. Director

3. TERMS AND DEFINITIONS

Audit – Systematic and formal comparison of documentation and practice against

requirements, performed for the purpose of finding areas of nonconformity or opportunities

for improvement.

Evidence – Data or examples which can be proven true and verified for the purposes of

proving an audit finding.

Finding – Any summary of audit evidence; findings may be positive (reports of compliance)

or negative (reports of nonconformity)

Major Nonconformity – A nonconformity that shows an in clause or other requirement has

not been implemented at all, or has been implemented in such a way that the requirements

are not met at all.

Minor Nonconformity – A single instance or small set of single instance that shows a

requirement has not been met. At the Lead Auditor’s discretion, a large number of related

Minor Nonconformities may instead be filed as a single Major Nonconformity.

Nonconformity / noncompliance – Any instance where practice or evidence does not

comply with requirements.

4. PROCEDURE : CONDUCTING QMS / MANUFACTURING PROCESS / PRODUCT AUDITS

4.1. Internal quality audits are conducted to ensure ongoing compliance with requirements of the

QMS standards, Manufacturing process and Product, company’s policies and procedures. This

is accomplished by auditing against all processes, areas and shift and shift change over time

and by applying all applicable sections of the standard. Audit requirements include those of ISO

Issued By : QC Head 1 Approved By : Director

SILCOTECH BONNY PRODUCTS (INDIA) PVT. LTD.

AUTOMOTIVE QUALITY Date of Issue: 01/08/2017

MANAGEMENT SYSTEM PROCEDURE FOR INTERNAL Issue No. 02 .Rev. No. 01

IATF 16949:2016 AUDITING Date of Rev. :_01/12/2019_

(SBPIPL/OCP/06/00)

9001 / IATF 16949, the company’s quality system documentation, manufacturing process as

well as requirements of customers or regulatory authorities, as applicable.

4.2. QMS Audits are conducted by process, and each process must be audited at least once

annually.

4.3. Manufacturing Process audit and product audit shall be conducted once every year for every

part, yearly plan is maintained and part can be prioritized for audit taking into account the

maximum rejection % / PPM in that particular area and / or Maximum number of customer

complaints ( Process Audit Checklist/Report SBPIPL/MR/12, Product audit Report

SBPIPL/MR/13.

For Manufacturing process / product audit, In case Product is not under production during

planned interval, plan will be revised to reschedule / interchange audit with another running

product.

4.4. For QMS audit the applicable ISO 9001 / IATF 16949 standard clauses pertaining to each

process must be audited for each process; an auditor may audit any clause of the applicable

standard, and writing findings against them, depending on how the audit unfolds.

4.5. Additional processes of other activities or facilities, outside of the process model, may also be

scheduled. For example, this may include safety audits, configuration management audits, etc.

In such cases, unique audit forms may be developed for such non-process related audits.

4.6. The Management Representative plans audits according to need, management decision, or

customer requirements, and assigns a Lead Auditor for each, as well as any supporting auditor

team members if required from List of Internal Auditor SBPIPL/MR/14. Scheduling is recorded

in the Internal Audit Schedule portion of the Internal Audit Plan-SBPIPL/MR/06.

4.7. Auditors are independent of the area being audited; SILCOTECH BONNY PRODUCTS (INDIA)

PVT LTD may therefore use approved third-party contract auditors for its internal audit program;

the requirements for third party auditors are defined in the Quality Manual.

4.8. Employees selected as internal auditors for QMS will have attended at a minimum a 2 days

internal auditor training for IATF 16949. Auditors for Manufacturing process shall be qualified

internal auditor for IATF 16949 and must have knowledge and experience about process to be

audited. Auditors for Product audit shall be qualified internal auditor for IATF 16949 and must

have knowledge and experience about method, equipment and instrument utilized for

inspection.

Audit can be done by qualified internal auditor for IATF 16949 along with process expert if any

single person don’t have both the competency altogether.

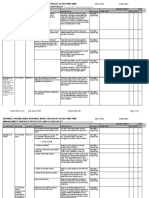

4.9. Using the Internal Audit Checklist – SBPIPL/MR/15 as a basic checklist, the Lead Auditor will

plan the scheduled audit with the appropriate departments and with any other audit team

Issued By : QC Head 2 Approved By : Director

SILCOTECH BONNY PRODUCTS (INDIA) PVT. LTD.

AUTOMOTIVE QUALITY Date of Issue: 01/08/2017

MANAGEMENT SYSTEM PROCEDURE FOR INTERNAL Issue No. 02 .Rev. No. 01

IATF 16949:2016 AUDITING Date of Rev. :_01/12/2019_

(SBPIPL/OCP/06/00)

members. The audit team will determine additional checklist items or requirements to verify,

and add these to the internal audit checklist portion.

4.10. Auditors will then conduct the audit by following the steps defined below:

4.10.1. Step One: Audit Planning – definition of the scope of the audit, dates of audit, auditors,

applicable clauses of affected standards, and documents to review.

4.10.2. Step Two: Document Review – a comparison of the quality system documentation

against the requirements of the applicable standard.

4.10.3. Step Three: Auditing – comparison of actual practice vs. the requirements of both the

company QMS documentation and the applicable standards.

4.10.4. Step Four: Verifying Effectiveness of the Process – general questions aimed at

verifying that the process being audited is effective and not prone to generating

nonconformities.

4.10.5. Step Five: Summarize Findings – a detailed list of the negative findings to be entered

into the Corrective Action Report system.

4.10.6. Step Six: Review of Report – a review by the Lead Auditor of all findings and evidence

to ensure the audit report is complete, clear, objective, and provides traceable objective

evidence.

4.11. Auditing shall be performed by obtaining objective evidence to support each requirement, or

indicate where non-conformances are found. All findings are recorded on the Internal Audit

Non-Conformity Report SBPIPL/MR/08.

4.12. When recording nonconformities, each negative finding must include three elements:

4.12.1. Indication of the Requirement – the document or clause of the applicable standard

which is thought to have been violated.

4.12.2. Objective Evidence – traceable indication of the evidence found which supports the

claim of nonconformity (e.g.: documents, products examined, interview results). In all

cases, objective evidence must be recorded in sufficient detail to ensure a third party can

find the exact evidence at a later date.

4.12.3. Details of the Disconnect – a brief statement on why the objective evidence shows

nonconformity against the requirement.

4.13. The nonconformities shall be rated as either “Major” or “Minor” per the requirements of

customers and some regulatory bodies. See definitions of Major and Minor Nonconformities in

section 3 above

4.14. Findings shall be rated by Type, whether Corrective, Preventive or Opportunity for

Improvement (OFI) for which Corrective Actions are filed.

4.15. Once Corrective Actions in SBPIPL/MR/08 are filed, the responsible managers or parties

shall ensure timely corrective action is taken to remedy any nonconformance found. During the

Issued By : QC Head 3 Approved By : Director

SILCOTECH BONNY PRODUCTS (INDIA) PVT. LTD.

AUTOMOTIVE QUALITY Date of Issue: 01/08/2017

MANAGEMENT SYSTEM PROCEDURE FOR INTERNAL Issue No. 02 .Rev. No. 01

IATF 16949:2016 AUDITING Date of Rev. :_01/12/2019_

(SBPIPL/OCP/06/00)

Corrective Action effectiveness review, the results of actions taken to address audit findings

are evaluated.

4.16. The MR shall update the audit schedule within the Internal Audit Summary SBPIPL/MR/07 to

reflect to closure of the audit, and enter a summary of audit findings. Based on the results of

the audits, and previous audits, the Management Representative will then schedule the next

audit of the particular process. Processes for which internal audits discover a high number of

findings, or critical findings of any number, should be audited more frequently until the process

is proven effective again.

4.17. The completed Internal Audit Non Conformity Report is then sent to the appropriate

managers of the areas audited, in order to report the findings and results. In this way, and in

conjunction with the submission of Corrective Actions, all necessary managers are notified of

the audit results and may make informed decisions for their departments based on those

results.

4.18. The results of internal audits are also gathered and summarized on the Audit Trend Analysis

Chart, generated, for review by top management during management review and by all

employees, through a general posting of the chart.

4.19. In all cases, auditees are expected to cooperate fully with the audit team.

Issued By : QC Head 4 Approved By : Director

You might also like

- TapRooT BriefDocument16 pagesTapRooT Briefmuhammadsuhaib100% (3)

- ISO 17025 Testing Laboratory Document KitDocument11 pagesISO 17025 Testing Laboratory Document KitSnehal Deshmukh100% (2)

- 04 Procedure For Internal QMS AuditDocument3 pages04 Procedure For Internal QMS AuditQualtic Certifications100% (4)

- Checklist Audit ISO 50001Document6 pagesChecklist Audit ISO 50001Ajai Srivastava100% (3)

- ISO 9001-2015 Supplier Audit Checklist SAMPLEDocument2 pagesISO 9001-2015 Supplier Audit Checklist SAMPLEFaisal0% (1)

- Control of Nonconforming Output ProcedureDocument4 pagesControl of Nonconforming Output Procedureandi wahyudin50% (2)

- Supplier Audit Check SheetDocument33 pagesSupplier Audit Check SheetMotive PostNo ratings yet

- Procedure - Management ReviewDocument2 pagesProcedure - Management Reviewiresendiz50% (2)

- Manufacturing Process Audit: Example ReportDocument25 pagesManufacturing Process Audit: Example ReportJawad rahmanaccaNo ratings yet

- Operating Procedure for Internal & External CommunicationDocument4 pagesOperating Procedure for Internal & External CommunicationnomanNo ratings yet

- BS en Iso 17034-2016Document36 pagesBS en Iso 17034-2016didi sudiNo ratings yet

- Internal Quality Audit: Ogive Technology LLP Quality System ProcedureDocument2 pagesInternal Quality Audit: Ogive Technology LLP Quality System Proceduretrivesh100% (1)

- ISO 9001 Internal Audit ProcedureDocument5 pagesISO 9001 Internal Audit ProcedureG RajasekharNo ratings yet

- Audit Checklist 1Document2 pagesAudit Checklist 1Jagi NikNo ratings yet

- QSP 8.3.1 Nonconforming Product - SampleDocument3 pagesQSP 8.3.1 Nonconforming Product - SampleGladys Calvo100% (2)

- 4 Context of The Organization 4.1 Understanding The Organization and Its ContextDocument5 pages4 Context of The Organization 4.1 Understanding The Organization and Its ContextkarthiksaadhanaNo ratings yet

- P018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Document9 pagesP018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Álvaro Martínez Fernández100% (1)

- INTERNAL AUDITS ENSURE QMS COMPLIANCEDocument2 pagesINTERNAL AUDITS ENSURE QMS COMPLIANCELuke J LandryNo ratings yet

- Management Review: ISO 9001:2015 GuidanceDocument3 pagesManagement Review: ISO 9001:2015 GuidanceMadan R HonnalagereNo ratings yet

- 15 (QSP-QA - 07) Process & Product AuditDocument3 pages15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- Continual Improvement ProcedureDocument6 pagesContinual Improvement ProcedureRonald Sarillana100% (1)

- SILCOTECH Management Review ProcedureDocument3 pagesSILCOTECH Management Review ProcedureQuality Unit 1 Ajay PandeyNo ratings yet

- Process Map–Internal AuditsDocument1 pageProcess Map–Internal AuditsNikhilesh NaikNo ratings yet

- Vendour Evaluation Report - JSL PDFDocument3 pagesVendour Evaluation Report - JSL PDFMitesh SinghNo ratings yet

- 9001 Planning Checklist - Production ProcessDocument14 pages9001 Planning Checklist - Production ProcessMowheadAdelNo ratings yet

- Quality ObjectivesDocument8 pagesQuality ObjectivesIqah Fauzi100% (1)

- Turtle Diagram & Its Usage in ISO 9001Document4 pagesTurtle Diagram & Its Usage in ISO 9001Gopalakrishnan100% (1)

- Happy Forgings EMS PerformanceDocument3 pagesHappy Forgings EMS Performancemool raj100% (1)

- Roles and Resposiblity-SampleDocument7 pagesRoles and Resposiblity-SampleELANTHENDRALNo ratings yet

- QP-004 Management Review ProcessDocument3 pagesQP-004 Management Review Processesraa asemNo ratings yet

- Guidance On INTERNAL AUDITSDocument7 pagesGuidance On INTERNAL AUDITSdhir.ankurNo ratings yet

- FSMS Stage 2 Audit of Cashew ProcessorDocument15 pagesFSMS Stage 2 Audit of Cashew ProcessorArpita TripathiNo ratings yet

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Document11 pagesISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351100% (1)

- Internal Quality Audit Checklist v. 01Document5 pagesInternal Quality Audit Checklist v. 01Mohd AzisNo ratings yet

- Recall Log Appendix-ADocument1 pageRecall Log Appendix-APharmacistNo ratings yet

- QP-55-03 Customer Complaint Suggestion Comment & SurveyDocument6 pagesQP-55-03 Customer Complaint Suggestion Comment & SurveySamsudin AhmadNo ratings yet

- Manufacturing Audit ChecklistDocument8 pagesManufacturing Audit Checklistgksp100% (1)

- QMS Record Control ProcedureDocument2 pagesQMS Record Control ProcedureHammad GhauriNo ratings yet

- QP Nonconforming Product Sample 2014Document2 pagesQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Initial Certification / Recertification: Audit ReportDocument14 pagesInitial Certification / Recertification: Audit ReportWhaOneNo ratings yet

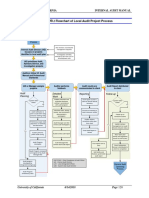

- 6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessDocument1 page6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessNiken RindasariNo ratings yet

- Komathi Engineering Works Performance Evaluation ProcedureDocument3 pagesKomathi Engineering Works Performance Evaluation ProcedurePINTU RAJNo ratings yet

- Turtle Diagram - Internal AuditDocument1 pageTurtle Diagram - Internal Auditsyahir etNo ratings yet

- Audit Check ListDocument7 pagesAudit Check Listtuan mai vanNo ratings yet

- Internal Audit Check Sheet MKTGDocument4 pagesInternal Audit Check Sheet MKTGRamdas PaithankarNo ratings yet

- Template - Management Review ReportDocument2 pagesTemplate - Management Review ReportIslam WayNo ratings yet

- FLVL-QHSE-SOP-F-006 Management Review MeetingDocument7 pagesFLVL-QHSE-SOP-F-006 Management Review MeetingmanjunathaNo ratings yet

- Auditor Observation Form MASTERDocument7 pagesAuditor Observation Form MASTERGavin JordanNo ratings yet

- Medford Fabrication Management Review Procedure SP-010Document2 pagesMedford Fabrication Management Review Procedure SP-010Bisma MasoodNo ratings yet

- Department Quality & FS Objective (Revision2015) - SampleDocument1 pageDepartment Quality & FS Objective (Revision2015) - SampleRachel YapNo ratings yet

- 7.6 Control of Monitoring and Measuring DevicesDocument2 pages7.6 Control of Monitoring and Measuring Devicesejub6447No ratings yet

- QS - F-136 List of (Iatf) Internal AuditorsDocument1 pageQS - F-136 List of (Iatf) Internal AuditorsShaili SharmaNo ratings yet

- Supplier Audit ChecklistDocument20 pagesSupplier Audit ChecklistSteven Singleton100% (1)

- TS 16949 Internal Audit Checklist - SectionsDocument42 pagesTS 16949 Internal Audit Checklist - SectionsLuongise LuongNo ratings yet

- Mandatory Documents and Records Required by ISODocument3 pagesMandatory Documents and Records Required by ISOAli AliNo ratings yet

- SOP-3-7045-337 REV S Document Control ProcedureDocument16 pagesSOP-3-7045-337 REV S Document Control ProcedureAbusaada2012No ratings yet

- IQA Checklist - SmpleDocument16 pagesIQA Checklist - SmpleHarits As Siddiq100% (1)

- Quality System Procedure: Corrective Action 1.0 PurposeDocument4 pagesQuality System Procedure: Corrective Action 1.0 PurposeNaveenkumar RNo ratings yet

- COMP-OPP-01 Procedure For Control and Validation of ProductionDocument4 pagesCOMP-OPP-01 Procedure For Control and Validation of ProductionISODCC DSPINo ratings yet

- ISO 9001 Internal Audit Checklist GuideDocument22 pagesISO 9001 Internal Audit Checklist GuidePCNo ratings yet

- Dilg r1 Management Review Minutes-SignedDocument8 pagesDilg r1 Management Review Minutes-SignedQuality Hosur100% (1)

- RP-IMS-P-17 Internal AuditDocument5 pagesRP-IMS-P-17 Internal AuditArul Prasaad100% (1)

- Quality Internal Audit ProcedureDocument5 pagesQuality Internal Audit ProcedureRohit VishwakarmaNo ratings yet

- GMP Guild For Cosmetic IngredientDocument48 pagesGMP Guild For Cosmetic IngredientLennon Tan Qin JiNo ratings yet

- Halal SecurityDocument8 pagesHalal SecurityNurul Azrianti AzizNo ratings yet

- N192 ISOCD 10001 Quality Management CustomerDocument30 pagesN192 ISOCD 10001 Quality Management CustomerLaboratorio Nacional de Ensayos SASNo ratings yet

- Doc10-16 BHHRL Qual ManDocument28 pagesDoc10-16 BHHRL Qual Manghadeer shaikhnaNo ratings yet

- GHTF Supplier Controlsg3final N17Document21 pagesGHTF Supplier Controlsg3final N17freelovefestNo ratings yet

- Mail Preparation Total Quality ManagementDocument105 pagesMail Preparation Total Quality Managementsram78153No ratings yet

- Certified Pharmaceutical Good Manufacturing Practices ProfessionalDocument20 pagesCertified Pharmaceutical Good Manufacturing Practices ProfessionalVarun ZotaNo ratings yet

- JCP Assessment ChecklistDocument2 pagesJCP Assessment ChecklistTanveerAliNo ratings yet

- 5-IsO 45001 - An Integrated Approach For QEHS Management Systems-Dr PeckDocument16 pages5-IsO 45001 - An Integrated Approach For QEHS Management Systems-Dr PeckNaliniRanjanMuduliNo ratings yet

- Руководство Учебного Центра SuperJet (Moscow)Document174 pagesРуководство Учебного Центра SuperJet (Moscow)olegprikhodko2809100% (2)

- Guidance Notes On Iso/Iec 17020: Aplac TC 006Document9 pagesGuidance Notes On Iso/Iec 17020: Aplac TC 006Anonymous TYGiADNo ratings yet

- Call Monitoring Feedback ProcedureDocument4 pagesCall Monitoring Feedback Procedureakeyz08No ratings yet

- Two Examples of TQM: - Texas TelecomDocument11 pagesTwo Examples of TQM: - Texas Telecomshru_87No ratings yet

- Working Sheet - Virtual TrainingDocument19 pagesWorking Sheet - Virtual TrainingPanchdev KumarNo ratings yet

- Iso 15189 Manual DocumentsDocument9 pagesIso 15189 Manual DocumentsyohannesNo ratings yet

- Accident Investigation 3Document33 pagesAccident Investigation 3grantNo ratings yet

- Model SOP Incident ReportDocument5 pagesModel SOP Incident ReportBALAJI0% (1)

- SOP-16 O M Reviewed Draft-1Document32 pagesSOP-16 O M Reviewed Draft-1Victoria GomezNo ratings yet

- Internal Audit ChecklistDocument14 pagesInternal Audit ChecklistRamesh KumarNo ratings yet

- Dust, Noise, Vibration Management PlanDocument9 pagesDust, Noise, Vibration Management PlanAnil PottekkatNo ratings yet

- Exercise No. IDocument3 pagesExercise No. Imonika rajani0% (1)

- Relevance of 8d MethodologyDocument5 pagesRelevance of 8d MethodologyR JNo ratings yet

- Procedure For Internal Audits: Consolidated Construction Consortium LTDDocument5 pagesProcedure For Internal Audits: Consolidated Construction Consortium LTDradhouaneNo ratings yet

- ADC-IMS-PR-18 Control of Non Conformance & Corrective ActionDocument3 pagesADC-IMS-PR-18 Control of Non Conformance & Corrective Actionsuhara hussainNo ratings yet

- FSSC 22000 V5 Fsma PCHF Addendum: (Geef de Tekst Op) (Geef de Tekst Op) (Geef de Tekst Op)Document25 pagesFSSC 22000 V5 Fsma PCHF Addendum: (Geef de Tekst Op) (Geef de Tekst Op) (Geef de Tekst Op)Ardhi Novrialdi GintingNo ratings yet

- NHAI Works Manual 2006 - NewDocument297 pagesNHAI Works Manual 2006 - NewSuniljpatil88% (8)