Professional Documents

Culture Documents

Turtle Diagram & Its Usage in ISO 9001

Uploaded by

Gopalakrishnan100%(1)100% found this document useful (1 vote)

193 views4 pagesOriginal Title

Turtle Diagram & its usage in ISO 9001

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

193 views4 pagesTurtle Diagram & Its Usage in ISO 9001

Uploaded by

GopalakrishnanCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

Using Turtle Diagram in ISO 9001

What is a turtle diagram?

“Turtle Diagram” is a great tool for visualizing process characteristics. Processes

are made up of inputs, outputs, criteria, etc, and a Turtle Diagram visualizes a

process to assist in their effective execution and improvement. The diagram looks

like the body of a turtle, with components as body, legs, head, and tail.

Benefits of Using Turtle Diagrams

Turtle Diagrams allow you to look at the entire process, as well as the

communication and mapping of interrelated processes with relevant functions and

levels within the organization. Turtle Diagrams can help both management and the

workforce better understand the process. The diagram helps layout the framework

in an easy to follow fashion, and can identify gaps in the organization’s structure.

Where do you use a Turtle Diagram?

They can be used for any process, anywhere in the ISO 9001 does not require a

turtle diagram, but the turtle diagram can help you understand your processes as

well as define the criteria for measuring process effectiveness. There are several

clauses within the ISO 9001 requirements that may benefit from using a turtle

diagram. These clauses are:

4.1 Understanding the Organization and its Context

4.2 Interested Parties

5.2 Quality Policy

6.1 Risk Management

7.2 Competence

7.3 Awareness

7.4 Communication

8.4 Control of External Providers

8.7 Nonconforming Products

10.2 Nonconformity and Corrective Action

10.3 Continual Improvement

Download a Turtle Diagram Word Document

So how do you use a Turtle Diagram?

Using a turtle diagram is simple. The Turtle Diagram is made up of 6 areas, all

surrounding the process, which is considered the turtle body. The 6 areas are:

inputs, materials & equipment (what), support processes, procedures & methods

(how), outputs, competence skills & training (whom), and finally performance

indicators (results).

Process: The center of the diagram is titled “process”. This box address the value

adding step, and any sequence that fall within the scope of the process. A process

may involve many employees and multiple departments within your organization.

Inputs: This category should define the details of the actual process including:

documents, materials, information, requirements, etc.

Outputs: Should include details of the process such as products, documents, etc.

Support processes, Procedures & Methods: Support material includes,

procedures, instructions, specific methods, etc.

Whom: This section is dedicated to finding all the employees whose roles within

the organization have the responsibility to value adding steps within the process.

What: This section is dedicated to finding the resources needed to perform the

process

How: This section is dedicated to identifying any specific documents within the

management system that tell the people responsible for completing the value

added steps how to successfully complete them within the organization’s best

practice.

Results: This section looks at the measures the organization has at its disposal to

monitor how well the procurement process is performing. If the measures align to

the organization’s plan, policies goals and objectives, the the measures should be

able to tell management if the procurement process is fulfilling or needs to be

adjusted or improved.

You might also like

- Cracking the Case of ISO 9001:2015 for Manufacturing: A Simple Guide to Implementing Quality Management in ManufacturingFrom EverandCracking the Case of ISO 9001:2015 for Manufacturing: A Simple Guide to Implementing Quality Management in ManufacturingNo ratings yet

- Turtle Diagram: (4) by What (5) WhoDocument1 pageTurtle Diagram: (4) by What (5) WhoNNo ratings yet

- Quality Management - ISO 9001 - 2015 Mandatory Documented Information - Documents and RecordsDocument6 pagesQuality Management - ISO 9001 - 2015 Mandatory Documented Information - Documents and RecordsSithanandan GanapathyNo ratings yet

- Documented - Information para Iso9001-2015Document5 pagesDocumented - Information para Iso9001-2015jrodangarNo ratings yet

- ISO 9001 Requirements WorkbookDocument27 pagesISO 9001 Requirements WorkbookMahkota Jaya Raya KarawangNo ratings yet

- ISO 9001 Key Process Turtle TemplateDocument1 pageISO 9001 Key Process Turtle TemplateShirleyNo ratings yet

- Quality Manual 9001-2008 Elsmar 1Document13 pagesQuality Manual 9001-2008 Elsmar 1luis miguel perez cruzNo ratings yet

- Roles and Resposiblity-SampleDocument7 pagesRoles and Resposiblity-SampleELANTHENDRALNo ratings yet

- Quality Manual ExampleDocument32 pagesQuality Manual ExamplesaiaviNo ratings yet

- ISO 9001:2015 To IATF 16949:2016 - QMS Transition Checklist: Blue FontDocument3 pagesISO 9001:2015 To IATF 16949:2016 - QMS Transition Checklist: Blue FontPratik Ardhapurkar100% (1)

- Komathi Engineering Works Performance Evaluation ProcedureDocument3 pagesKomathi Engineering Works Performance Evaluation ProcedurePINTU RAJNo ratings yet

- Process Turtle Diagram - Assignment EngineeringDocument1 pageProcess Turtle Diagram - Assignment EngineeringShara Jane DelmoNo ratings yet

- Turtle Diagram - Internal AuditDocument1 pageTurtle Diagram - Internal Auditsyahir etNo ratings yet

- Process Map–Internal AuditsDocument1 pageProcess Map–Internal AuditsNikhilesh NaikNo ratings yet

- C4 Turtle Diagram Process Design ProcessDocument1 pageC4 Turtle Diagram Process Design Processcao thanh quocNo ratings yet

- P018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Document9 pagesP018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Álvaro Martínez Fernández100% (1)

- How Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementDocument3 pagesHow Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementPavan MujawdiyaNo ratings yet

- Quality Manual 9001-2015 06-10-2021Document27 pagesQuality Manual 9001-2015 06-10-2021Geoff EricksonNo ratings yet

- Control of RecordsDocument3 pagesControl of Recordschahi100% (1)

- Management Review: ISO 9001:2015 GuidanceDocument3 pagesManagement Review: ISO 9001:2015 GuidanceMadan R HonnalagereNo ratings yet

- ISO Check List IADocument3 pagesISO Check List IAParesh ChopraNo ratings yet

- Alabama Specialty Products, Inc.Document24 pagesAlabama Specialty Products, Inc.qmicertificationNo ratings yet

- Product Safety ProcessDocument4 pagesProduct Safety Processdhir.ankurNo ratings yet

- ISO 9001 Evidence ChecklistDocument40 pagesISO 9001 Evidence ChecklistsanrexiNo ratings yet

- MRF Management ReviewDocument4 pagesMRF Management ReviewhastinkakaNo ratings yet

- Mandatory Documents and Records RequiredDocument2 pagesMandatory Documents and Records Requiredaldi_dudulNo ratings yet

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Document11 pagesISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351100% (1)

- Sampling plan for elastomer parts inspectionDocument1 pageSampling plan for elastomer parts inspectionLOGANATHAN V100% (1)

- Mgt Review MinutesDocument6 pagesMgt Review Minutesmgamal1080100% (1)

- 01 Documented Information 1Document11 pages01 Documented Information 1Noor Muddassir KhanNo ratings yet

- CS Customer - Plant Turtle Diagram 07Document1 pageCS Customer - Plant Turtle Diagram 07Alex100% (1)

- QS - F-136 List of (Iatf) Internal AuditorsDocument1 pageQS - F-136 List of (Iatf) Internal AuditorsShaili SharmaNo ratings yet

- ISO-TS 16949 IQA Course MaterialDocument31 pagesISO-TS 16949 IQA Course Materialazadsingh1No ratings yet

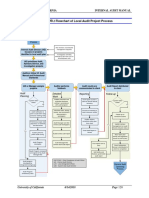

- 6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessDocument1 page6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessNiken RindasariNo ratings yet

- Audit Checklist 1Document2 pagesAudit Checklist 1Jagi NikNo ratings yet

- IQA Checklist - SmpleDocument16 pagesIQA Checklist - SmpleHarits As Siddiq100% (1)

- 2 Handout IATF 16949 Clause Map 2016 To 2009 PDFDocument5 pages2 Handout IATF 16949 Clause Map 2016 To 2009 PDFMohini Marathe100% (2)

- QMS Audit Report Sample IatfDocument39 pagesQMS Audit Report Sample IatfMANGESH100% (2)

- Q2-760-01-Control of Monitoring and Measuring DevicesDocument5 pagesQ2-760-01-Control of Monitoring and Measuring DevicesAlineNo ratings yet

- 7.6 Control of Monitoring and Measuring DevicesDocument2 pages7.6 Control of Monitoring and Measuring Devicesejub6447No ratings yet

- Appendix 1 - Quality Objectives: Zanzibar Bureau of StandardsDocument3 pagesAppendix 1 - Quality Objectives: Zanzibar Bureau of StandardsMariel GentilesNo ratings yet

- What Is A Document?: Tips On ISO 9001 Quality Management System DocumentationDocument5 pagesWhat Is A Document?: Tips On ISO 9001 Quality Management System DocumentationMohammad Jaid AlamNo ratings yet

- Quality Manual: ISO/TS 16949:2009 Quality Management SystemDocument47 pagesQuality Manual: ISO/TS 16949:2009 Quality Management Systemluismi081300No ratings yet

- QMS Audit Checklist On FFS Rev2 1Document8 pagesQMS Audit Checklist On FFS Rev2 1Xion100% (1)

- 9001 ExcerciseDocument5 pages9001 ExcerciseMohamed Fouad100% (1)

- DCC-FO-040 Turtle Diagram FormatDocument3 pagesDCC-FO-040 Turtle Diagram FormatMaricris Napigkit SerranoNo ratings yet

- Process Name: Process Owner: Instructions: Date: Risk Identification Risk Analysis Risk# Description Likelihood Impact Risk LevelDocument15 pagesProcess Name: Process Owner: Instructions: Date: Risk Identification Risk Analysis Risk# Description Likelihood Impact Risk LevelJustformedia JustformediaNo ratings yet

- Iso 9001 2015 Quality Manual-ExposedDocument23 pagesIso 9001 2015 Quality Manual-ExposedJobair Alam100% (1)

- Blank Turtle DiagramDocument1 pageBlank Turtle Diagrammrtelephone1100% (2)

- ISO 9001 Internal Audit ChecklistDocument14 pagesISO 9001 Internal Audit ChecklistEsterNTNo ratings yet

- Basic Principles of GMP: Complaints and RecallsDocument20 pagesBasic Principles of GMP: Complaints and Recallshardik_20No ratings yet

- Manufacturing Process Audit for Factory ABCDocument18 pagesManufacturing Process Audit for Factory ABCmakubuya nasser100% (1)

- 01 Quality Objectives SummaryDocument1 page01 Quality Objectives SummaryDenny Dagger100% (1)

- QP-004 Management Review ProcessDocument3 pagesQP-004 Management Review Processesraa asemNo ratings yet

- Initial Certification / Recertification: Audit ReportDocument14 pagesInitial Certification / Recertification: Audit ReportWhaOneNo ratings yet

- Iso 9001 10 Clauses InterpretationDocument34 pagesIso 9001 10 Clauses InterpretationJojo DollolasaNo ratings yet

- Clause Applicability MatrixDocument14 pagesClause Applicability MatrixPramod Bodne100% (1)

- Documented InformationDocument5 pagesDocumented InformationripacNo ratings yet

- VE DMAIC: A Six Sigma Approach to Value EngineeringDocument7 pagesVE DMAIC: A Six Sigma Approach to Value EngineeringGopalakrishnanNo ratings yet

- Enth Being This &@an Bnalyds: To Return Owrating Ism$t.mentDocument1 pageEnth Being This &@an Bnalyds: To Return Owrating Ism$t.mentGopalakrishnanNo ratings yet

- The Whole The: PartsDocument2 pagesThe Whole The: PartsGopalakrishnanNo ratings yet

- Vava 1191Document14 pagesVava 1191GopalakrishnanNo ratings yet

- Value Engineering: Vol: 2 No: 1 June 1969Document68 pagesValue Engineering: Vol: 2 No: 1 June 1969GopalakrishnanNo ratings yet

- C:/scanned/1150.tif Page 1Document39 pagesC:/scanned/1150.tif Page 1GopalakrishnanNo ratings yet

- VE Journal April 1979 Issue HighlightsDocument53 pagesVE Journal April 1979 Issue HighlightsGopalakrishnanNo ratings yet

- C:/scanned/1150.tif Page 1Document39 pagesC:/scanned/1150.tif Page 1GopalakrishnanNo ratings yet

- C:/scanned/501 TIFDocument1 pageC:/scanned/501 TIFGopalakrishnanNo ratings yet

- Fluorescrnt Capacitor: Value SISDocument28 pagesFluorescrnt Capacitor: Value SISGopalakrishnanNo ratings yet

- Paco Group of Restaurants - Case StudyDocument1 pagePaco Group of Restaurants - Case StudyGopalakrishnanNo ratings yet

- The Whole The: PartsDocument2 pagesThe Whole The: PartsGopalakrishnanNo ratings yet

- Fluorescrnt Capacitor: Value SISDocument28 pagesFluorescrnt Capacitor: Value SISGopalakrishnanNo ratings yet

- C:/scanned/501 TIFDocument1 pageC:/scanned/501 TIFGopalakrishnanNo ratings yet

- Production Riser Life Extension: Guidance Notes OnDocument24 pagesProduction Riser Life Extension: Guidance Notes OnGopalakrishnanNo ratings yet

- 100 years of Quality management evolutionDocument1 page100 years of Quality management evolutionGenGyan Global Business Solutions Pvt LtdNo ratings yet

- VE Journal April 1979 Issue HighlightsDocument53 pagesVE Journal April 1979 Issue HighlightsGopalakrishnanNo ratings yet

- Recommended Sequence: Describe: 1. Process Name 2. Inputs & Outputs 3. Criteria 4. Finish The RemainderDocument1 pageRecommended Sequence: Describe: 1. Process Name 2. Inputs & Outputs 3. Criteria 4. Finish The RemainderGopalakrishnanNo ratings yet

- Failure Mode and Effect Analysis On Base Frame - Case StudyDocument6 pagesFailure Mode and Effect Analysis On Base Frame - Case StudyGopalakrishnanNo ratings yet

- Lean Six-Sigma Applications in Aircraft Assembly (PDFDrive)Document62 pagesLean Six-Sigma Applications in Aircraft Assembly (PDFDrive)GopalakrishnanNo ratings yet

- Sjet34b413 418Document6 pagesSjet34b413 418suranatanuj007No ratings yet

- Managing Cost of Quality in the Chemical IndustryDocument82 pagesManaging Cost of Quality in the Chemical IndustryGopalakrishnanNo ratings yet

- Using Cost of Quality To Improve Business ResultsDocument4 pagesUsing Cost of Quality To Improve Business ResultsMiguel BradshawNo ratings yet

- Cost of Quality For Automobile Industry: A ReviewDocument7 pagesCost of Quality For Automobile Industry: A Reviewrcbcsk cskNo ratings yet

- Cost of Quality (Coq) : Which Collection System Should Be Used?Document7 pagesCost of Quality (Coq) : Which Collection System Should Be Used?Muhammad NasrullahNo ratings yet

- Cost of Quality PDFDocument3 pagesCost of Quality PDFGopalakrishnan100% (1)

- Aiag-Vda Process Fmea PDFDocument18 pagesAiag-Vda Process Fmea PDFsharif1974No ratings yet

- SAVE Certification Exam Study Guide - July 2016 FinalDocument15 pagesSAVE Certification Exam Study Guide - July 2016 FinalGopalakrishnanNo ratings yet

- TNA (Training Need Analys)Document6 pagesTNA (Training Need Analys)Sahman WiparnaNo ratings yet

- Value AnalysisDocument32 pagesValue Analysisbrijkishor2017No ratings yet

- Responsibility AccountingDocument4 pagesResponsibility AccountingEllise FreniereNo ratings yet

- Survey of Portland Cement Consumption by of Portland Cement Consumption 1stDocument45 pagesSurvey of Portland Cement Consumption by of Portland Cement Consumption 1stHimerozNo ratings yet

- Zain Ufone Best 1 Strategic Management ProjectDocument50 pagesZain Ufone Best 1 Strategic Management Projectzain_lion2009372280% (10)

- Andhra Pradesh Board Fee Payment FormDocument1 pageAndhra Pradesh Board Fee Payment FormM JEEVARATHNAM NAIDUNo ratings yet

- Advertising & Promotion Chapter 2 Powerpoint ReviewDocument4 pagesAdvertising & Promotion Chapter 2 Powerpoint ReviewCOREY DAVISNo ratings yet

- Differences between startups and spinoffsDocument4 pagesDifferences between startups and spinoffsRafael CavalcanteNo ratings yet

- Terminate Utilities AccountDocument1 pageTerminate Utilities AccountVimal FranklinNo ratings yet

- Deposits in Transit and Outstanding Checks PDFDocument1 pageDeposits in Transit and Outstanding Checks PDFAaliyah Joize LegaspiNo ratings yet

- Developing Lean and Agile Automotive Suppliers ManDocument12 pagesDeveloping Lean and Agile Automotive Suppliers ManLia Nurul MulyaniNo ratings yet

- Factory Accounting RulesDocument61 pagesFactory Accounting RulesMitthu KumarNo ratings yet

- Quiz Manajemen Pengadaan - Nisrina Zalfa Farida - 21B505041003Document5 pagesQuiz Manajemen Pengadaan - Nisrina Zalfa Farida - 21B505041003Kuro DitNo ratings yet

- 2021 Remaining Ongoing CasesDocument2,517 pages2021 Remaining Ongoing CasesJulia Mar Antonete Tamayo AcedoNo ratings yet

- Accounting Postulates, Concepts and PrinciplesDocument4 pagesAccounting Postulates, Concepts and PrinciplesKkaran ShethNo ratings yet

- Equity CrowdfundingDocument13 pagesEquity CrowdfundingantonyNo ratings yet

- Nike PresentationsDocument54 pagesNike PresentationsSubhan AhmedNo ratings yet

- BGC Internship Job Description On LetterheadDocument4 pagesBGC Internship Job Description On Letterheadgadija ishahNo ratings yet

- M&ADocument27 pagesM&ArinacharNo ratings yet

- ABS ISPS Company - Vessel Audit ChecklistDocument1 pageABS ISPS Company - Vessel Audit ChecklistredchaozNo ratings yet

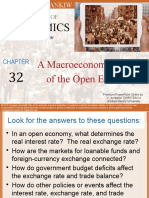

- CH 32 A Macroeconomic Theory of The Open EconomyDocument45 pagesCH 32 A Macroeconomic Theory of The Open EconomyveroirenNo ratings yet

- Cbse Cost Accounting NotesDocument154 pagesCbse Cost Accounting NotesMANDHAPALLY MANISHANo ratings yet

- Nabanita Das - Senior Integration (Software AG Webmethods) Consultant 03242023Document12 pagesNabanita Das - Senior Integration (Software AG Webmethods) Consultant 03242023vipul tiwariNo ratings yet

- PPM02 Project Portfolio Prioritization Matrix - AdvancedDocument5 pagesPPM02 Project Portfolio Prioritization Matrix - AdvancedHazqanNo ratings yet

- Chapter 9 Intercompany Bond Holdings and Miscellaneous Topics-Consolidated Financial StatementsDocument45 pagesChapter 9 Intercompany Bond Holdings and Miscellaneous Topics-Consolidated Financial StatementsAchmad RizalNo ratings yet

- Your Results For "Quick Quiz (Open Access) "Document2 pagesYour Results For "Quick Quiz (Open Access) "Manuel CornejoNo ratings yet

- MSc Sales & Marketing Statement of PurposeDocument1 pageMSc Sales & Marketing Statement of PurposeDaud LawrenceNo ratings yet

- LABOR STANDARDS REVIEW MCQDocument5 pagesLABOR STANDARDS REVIEW MCQLiza MelgarNo ratings yet

- Designing The Perfect Procurement Operating Model: OperationsDocument9 pagesDesigning The Perfect Procurement Operating Model: Operationspulsar77No ratings yet

- PEST AnalysisDocument7 pagesPEST AnalysisWaqas Ul HaqueNo ratings yet

- Growth Hacking Decoded Grow Your BusinessDocument18 pagesGrowth Hacking Decoded Grow Your BusinessmeghaaNo ratings yet

- Experienced Hospitality Professional Seeking New OpportunitiesDocument2 pagesExperienced Hospitality Professional Seeking New OpportunitiesValeria SpasovaNo ratings yet

- The Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverFrom EverandThe Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverRating: 4.5 out of 5 stars4.5/5 (186)

- Scaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0From EverandScaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0Rating: 5 out of 5 stars5/5 (1)

- The First Minute: How to start conversations that get resultsFrom EverandThe First Minute: How to start conversations that get resultsRating: 4.5 out of 5 stars4.5/5 (55)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Spark: How to Lead Yourself and Others to Greater SuccessFrom EverandSpark: How to Lead Yourself and Others to Greater SuccessRating: 4.5 out of 5 stars4.5/5 (130)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The 4 Disciplines of Execution: Revised and Updated: Achieving Your Wildly Important GoalsFrom EverandThe 4 Disciplines of Execution: Revised and Updated: Achieving Your Wildly Important GoalsRating: 4.5 out of 5 stars4.5/5 (48)

- How the World Sees You: Discover Your Highest Value Through the Science of FascinationFrom EverandHow the World Sees You: Discover Your Highest Value Through the Science of FascinationRating: 4 out of 5 stars4/5 (7)

- The 12 Week Year: Get More Done in 12 Weeks than Others Do in 12 MonthsFrom EverandThe 12 Week Year: Get More Done in 12 Weeks than Others Do in 12 MonthsRating: 4.5 out of 5 stars4.5/5 (411)

- Billion Dollar Lessons: What You Can Learn from the Most Inexcusable Business Failures of the Last Twenty-five YearsFrom EverandBillion Dollar Lessons: What You Can Learn from the Most Inexcusable Business Failures of the Last Twenty-five YearsRating: 4.5 out of 5 stars4.5/5 (52)

- How to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobFrom EverandHow to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobRating: 4.5 out of 5 stars4.5/5 (36)

- How to Lead: Wisdom from the World's Greatest CEOs, Founders, and Game ChangersFrom EverandHow to Lead: Wisdom from the World's Greatest CEOs, Founders, and Game ChangersRating: 4.5 out of 5 stars4.5/5 (95)

- The Introverted Leader: Building on Your Quiet StrengthFrom EverandThe Introverted Leader: Building on Your Quiet StrengthRating: 4.5 out of 5 stars4.5/5 (35)

- The 7 Habits of Highly Effective PeopleFrom EverandThe 7 Habits of Highly Effective PeopleRating: 4 out of 5 stars4/5 (2564)

- Work Stronger: Habits for More Energy, Less Stress, and Higher Performance at WorkFrom EverandWork Stronger: Habits for More Energy, Less Stress, and Higher Performance at WorkRating: 4.5 out of 5 stars4.5/5 (12)

- The 7 Habits of Highly Effective People: 30th Anniversary EditionFrom EverandThe 7 Habits of Highly Effective People: 30th Anniversary EditionRating: 5 out of 5 stars5/5 (336)

- The Power of People Skills: How to Eliminate 90% of Your HR Problems and Dramatically Increase Team and Company Morale and PerformanceFrom EverandThe Power of People Skills: How to Eliminate 90% of Your HR Problems and Dramatically Increase Team and Company Morale and PerformanceRating: 5 out of 5 stars5/5 (22)

- Get Scalable: The Operating System Your Business Needs To Run and Scale Without YouFrom EverandGet Scalable: The Operating System Your Business Needs To Run and Scale Without YouRating: 5 out of 5 stars5/5 (1)

- Leadership Skills that Inspire Incredible ResultsFrom EverandLeadership Skills that Inspire Incredible ResultsRating: 4.5 out of 5 stars4.5/5 (11)

- Sustainability Management: Global Perspectives on Concepts, Instruments, and StakeholdersFrom EverandSustainability Management: Global Perspectives on Concepts, Instruments, and StakeholdersRating: 5 out of 5 stars5/5 (1)

- Summary: Choose Your Enemies Wisely: Business Planning for the Audacious Few: Key Takeaways, Summary and AnalysisFrom EverandSummary: Choose Your Enemies Wisely: Business Planning for the Audacious Few: Key Takeaways, Summary and AnalysisRating: 4.5 out of 5 stars4.5/5 (3)

- Unlocking Potential: 7 Coaching Skills That Transform Individuals, Teams, & OrganizationsFrom EverandUnlocking Potential: 7 Coaching Skills That Transform Individuals, Teams, & OrganizationsRating: 4.5 out of 5 stars4.5/5 (27)

- 7 Principles of Transformational Leadership: Create a Mindset of Passion, Innovation, and GrowthFrom Everand7 Principles of Transformational Leadership: Create a Mindset of Passion, Innovation, and GrowthRating: 5 out of 5 stars5/5 (51)

- Business Made Simple: 60 Days to Master Leadership, Sales, Marketing, Execution, Management, Personal Productivity and MoreFrom EverandBusiness Made Simple: 60 Days to Master Leadership, Sales, Marketing, Execution, Management, Personal Productivity and MoreRating: 5 out of 5 stars5/5 (58)

- The E-Myth Revisited: Why Most Small Businesses Don't Work andFrom EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andRating: 4.5 out of 5 stars4.5/5 (708)