Professional Documents

Culture Documents

Ranpelen PP Random Copolymer General Information: Description

Uploaded by

TRUONGOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ranpelen PP Random Copolymer General Information: Description

Uploaded by

TRUONGCopyright:

Available Formats

January, 2013

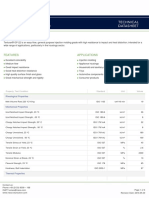

RANPELEN J-560S PP RANDOM COPOLYMER

General Information

Description

J-560S is a nucleated random copolymer for injection molding applications.

This grade is designed to be processed in conventional injection molding equipment and

offers super excellent transparency, good stiffness/impact strength balance, high gloss, high

hinge property and low smell.

Applications

Cosmetics container & cap, Food container, Transparency case, Stationery

Disposable syringe, CD/DVD case

Physical Properties1

Physical Test Method Nominal Values

Melt Flow Index ASTM D1238 18 g/10min

Density ASTM D792 0.9 g/cm 3

Mechanical

Tensile Stress (Yield) ASTM D638 300 kgf/cm2 29 MPa

Tensile Strain (Break) ASTM D638 >100 % >100 %

Flexural Modulus ASTM D790 12,000 kgf/cm2 1,180 MPa

Rockwell Hardness ASTM D785 95 R

Impact

Notched Izod Impact Strength (23℃) ASTM D256 5.5 kgf∙cm/cm 54 J/m

Notched Izod Impact Strength (-10℃) ASTM D256 3.0 kgf∙cm/cm 29 J/m

Thermal

Heat Deflection Temperature (4.6kgf/cm2) ASTM D648 95 ℃

Additional Properties

Haze ASTM D1003 20 %

NOTE ISO 9001, 14001, /TS 16949

1 Physical Properties : these are not to be construed as specifications

www.lottechem.com

※ 본 문서는 "롯데케미칼" 보안문서로 무단 복사/반출을 금지합니다.

January, 2013

RANPELEN J-560S PP RANDOM COPOLYMER

General Information

Description

J-560S is a nucleated random copolymer for injection molding applications.

This grade is designed to be processed in conventional injection molding equipment and

offers super excellent transparency, good stiffness/impact strength balance, high gloss, high

hinge property and low smell.

Applications

Cosmetics container & cap, Food container, Transparency case, Stationery

Disposable syringe, CD/DVD case

Physical Properties1

Physical Test Method Nominal Values

Melt Flow Index ISO 1133 18 g/10min

Density ISO 1183 0.9 g/cm 3

Mechanical

Tensile Stress (Yield) ISO 527-1 270 kgf/cm2 26 MPa

Tensile Strain (Break) ISO 527-1 >100 % >100 %

Flexural Modulus ISO 178 9,900 kgf/cm2 970 MPa

Impact

Notched Izod Impact Strength (23℃) ISO 180 5.0 kgf∙cm/cm 49 J/m

Notched Izod Impact Strength (-10℃) ISO 180 2.5 kgf∙cm/cm 24 J/m

Thermal

Heat Deflection Temperature (4.6kgf/cm2) ISO 75-1 85 ℃

Additional Properties

Haze 20 %

NOTE ISO 9001, 14001, /TS 16949

1 Physical Properties : these are not to be construed as specifications

www.lottechem.com

※ 본 문서는 "롯데케미칼" 보안문서로 무단 복사/반출을 금지합니다.

You might also like

- Ranpelen PP Random Copolymer: DescriptionDocument2 pagesRanpelen PP Random Copolymer: DescriptionVu Thanh ThuongNo ratings yet

- 150601 J-560M 물성 (영문 ASTM 단위통합)Document2 pages150601 J-560M 물성 (영문 ASTM 단위통합)Vu Thanh ThuongNo ratings yet

- PP RANDOM Lotte - Ranpelen - J590K MI 44Document1 pagePP RANDOM Lotte - Ranpelen - J590K MI 44Luis LOZANONo ratings yet

- Description: Hivorex High Density Polyethylene General InformationDocument1 pageDescription: Hivorex High Density Polyethylene General InformationLuca GuadagnoNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- kopelen jh-350 (1)Document2 pageskopelen jh-350 (1)AthonioMourinhoNo ratings yet

- Honam Honam: DescriptionDocument1 pageHonam Honam: DescriptionChampion PaltánNo ratings yet

- Kopelen PP Block Copolymer: DescriptionDocument2 pagesKopelen PP Block Copolymer: DescriptioncentroNo ratings yet

- ImpactosIngles7600Document2 pagesImpactosIngles7600casillasfigjcNo ratings yet

- Achieve™ Advanced PP8285E1: Polypropylene Impact CopolymerDocument2 pagesAchieve™ Advanced PP8285E1: Polypropylene Impact CopolymermosesNo ratings yet

- Technical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticDocument1 pageTechnical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticarmandoNo ratings yet

- Nghi Son Refinery And Petrochemical Llc: Công Ty Tnhh Lọc Hóa Dầu Nghi SơnDocument1 pageNghi Son Refinery And Petrochemical Llc: Công Ty Tnhh Lọc Hóa Dầu Nghi SơnJimmy NguyenNo ratings yet

- High Density Polyethylene Properties and ApplicationsDocument2 pagesHigh Density Polyethylene Properties and ApplicationsLuca GuadagnoNo ratings yet

- RADILON A CP300K 333 BK Product InfoDocument4 pagesRADILON A CP300K 333 BK Product InfomuthuNo ratings yet

- PE LL6201 Series DatasheetDocument1 pagePE LL6201 Series DatasheetmaheshgupteNo ratings yet

- Hostacom G3 N01 102297Document2 pagesHostacom G3 N01 102297Sumit BishtNo ratings yet

- Lotte Chemical HDPE 7000FDocument1 pageLotte Chemical HDPE 7000FGogoseanu PaulNo ratings yet

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- Nghi Son Refinery And Petrochemical Llc: Công Ty Tnhh Lọc Hóa Dầu Nghi SơnDocument1 pageNghi Son Refinery And Petrochemical Llc: Công Ty Tnhh Lọc Hóa Dầu Nghi SơnJimmy NguyenNo ratings yet

- Channel Prime Alliance 5R2 Polypropylene Data SheetDocument1 pageChannel Prime Alliance 5R2 Polypropylene Data SheetdianaNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- tds-hd5403pdfDocument2 pagestds-hd5403pdfAthonioMourinhoNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Zytel® 73G15L NC010-gbDocument12 pagesZytel® 73G15L NC010-gbzoxxxnNo ratings yet

- Plexiglas Satinice Df21 8n - enDocument3 pagesPlexiglas Satinice Df21 8n - enjonathan6657No ratings yet

- TDS Hpr1018ha AstmDocument2 pagesTDS Hpr1018ha AstmOsamah JoubsenNo ratings yet

- Sabic® Ldpe 2201H0Document2 pagesSabic® Ldpe 2201H0Berkosan BalkansNo ratings yet

- High Flow Polystyrene for Thin Wall PackagingDocument2 pagesHigh Flow Polystyrene for Thin Wall Packagingdrmohamed120No ratings yet

- Tds Tasnee HD b1258Document2 pagesTds Tasnee HD b1258أبو أميرNo ratings yet

- Adflex Q100FDocument2 pagesAdflex Q100FAna Maria MuresanNo ratings yet

- PP Mosten EH 501: Technical DatasheetDocument2 pagesPP Mosten EH 501: Technical DatasheetBanupriya BalasubramanianNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Exceed™ XP 8318MJ: Performance PolymerDocument2 pagesExceed™ XP 8318MJ: Performance PolymerMaram YasserNo ratings yet

- Polypropylene CP 741: Sub-GroupDocument1 pagePolypropylene CP 741: Sub-GroupAnonymous m4MucCNo ratings yet

- Ficha Tecnica Paxon As55003Document2 pagesFicha Tecnica Paxon As55003Eleannys GarciasNo ratings yet

- Technical Data Sheet ADFLEX F 500Document2 pagesTechnical Data Sheet ADFLEX F 500leftpowtaNo ratings yet

- Exceed™ XP 8656ML: Performance PolymerDocument2 pagesExceed™ XP 8656ML: Performance PolymerCristian RodriguezNo ratings yet

- Exxonmobil Lldpe LL 1002ay CastDocument2 pagesExxonmobil Lldpe LL 1002ay CastOscar Tan IIINo ratings yet

- SABIC® LLDPE - 118WM - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118WM - Global - Technical - Data - Sheethafidz 35No ratings yet

- ABS Technical Data SheetDocument1 pageABS Technical Data SheetarmandoNo ratings yet

- Exceed™ XP 8358 Series: Performance PolymerDocument2 pagesExceed™ XP 8358 Series: Performance PolymerMaram YasserNo ratings yet

- RADILONAESL128100NTDocument4 pagesRADILONAESL128100NTRicardoNo ratings yet

- Zytel® 101 NC010-gbDocument11 pagesZytel® 101 NC010-gbalejandrocharlescollNo ratings yet

- Datasheet SaphirAF 2016 EN v1Document2 pagesDatasheet SaphirAF 2016 EN v1André CardosoNo ratings yet

- Globalene 7011: Polypropylene Impact copolymer 聚丙烯耐衝擊共聚合物Document1 pageGlobalene 7011: Polypropylene Impact copolymer 聚丙烯耐衝擊共聚合物medo.k016No ratings yet

- Radiflam A Rv250 Af 375 BK: Product InformationDocument3 pagesRadiflam A Rv250 Af 375 BK: Product InformationLucas Valentim MendesNo ratings yet

- P O L Y P R O P Y L E N E: Reliance Industries LimitedDocument1 pageP O L Y P R O P Y L E N E: Reliance Industries LimitedSiddheshNo ratings yet

- Exceed™ XP 6026 Series: Performance PolymerDocument2 pagesExceed™ XP 6026 Series: Performance PolymerMaram YasserNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- PP ARPP200-1 Black 14 Melt HomoDocument1 pagePP ARPP200-1 Black 14 Melt HomocountzeroaslNo ratings yet

- Styrolution PS 1290/1291: General Purpose Polystyrene (GPPS)Document2 pagesStyrolution PS 1290/1291: General Purpose Polystyrene (GPPS)DiegoTierradentroNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Reach-99 0623 00 07Document1 pageReach-99 0623 00 07TRUONGNo ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- GPPS Moplen HP520J HPDocument2 pagesGPPS Moplen HP520J HPTRUONGNo ratings yet

- 2021.04.30 PGM8010F BK (SH2104299) - PP BK GF30 V0Document1 page2021.04.30 PGM8010F BK (SH2104299) - PP BK GF30 V0TRUONGNo ratings yet

- Radel® R-5900 - SolvayDocument3 pagesRadel® R-5900 - SolvayTRUONGNo ratings yet

- Component - Plastics: PP-130GTADocument1 pageComponent - Plastics: PP-130GTATRUONGNo ratings yet

- Pa66-R10g25 Tds-Iso-EngDocument2 pagesPa66-R10g25 Tds-Iso-EngTRUONGNo ratings yet