Professional Documents

Culture Documents

Zytel® 73G15L NC010-gb

Uploaded by

zoxxxnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zytel® 73G15L NC010-gb

Uploaded by

zoxxxnCopyright:

Available Formats

Zytel® 73G15L NC010

NYLON RESIN

Common features of Zytel® nylon resin include mechanical and physical properties such as high mechanical strength, excellent balance of stiffness

and toughness, good high temperature performance, good electrical and flammability properties, good abrasion and chemical resistance. In

addition, Zytel® nylon resins are available in different modified and reinforced grades to create a wide range of products with tailored properties for

specific processes and end-uses. Zytel® nylon resin, including most flame retardant grades, offer the ability to be coloured.

The good melt stability of Zytel® nylon resin normally enables the recycling of properly handled production waste. If recycling is not possible, we

recommend, as the preferred option, incineration with energy recovery (-31kJ/g of base polymer) in appropriately equipped installations. For

disposal, local regulations have to be observed.

Zytel® nylon resin typically is used in demanding applications in the automotive, furniture, domestic appliances, sporting goods and construction

industry.

Zytel® 73G15L NC010 is a 15% glass fiber reinforced polyamide 6 resin for injection moulding.

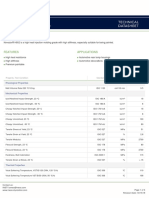

Product information

Resin Identification PA6-GF15 ISO 1043

Part Marking Code >PA6-GF15< ISO 11469

ISO designation ISO 16396-PA6,GF15,M1GNR,S14-060

Rheological properties dry/cond.

Viscosity number 139 / * cm³/g ISO 307, 1628

Moulding shrinkage, parallel 0.3 / - % ISO 294-4, 2577

Moulding shrinkage, normal 0.8 / - % ISO 294-4, 2577

Typical mechanical properties dry/cond.

Tensile modulus 6000 / 3500 MPa ISO 527-1/-2

Tensile stress at break, 5mm/min 140 / 70 MPa ISO 527-1/-2

Tensile strain at break, 5mm/min 4 / 10 % ISO 527-1/-2

Flexural modulus 5100 / 3100[DS] MPa ISO 178

Flexural strength 190 / 90[DS] MPa ISO 178

Charpy impact strength, 23°C 50 / 95 kJ/m² ISO 179/1eU

Charpy impact strength, -30°C 45 / 54 kJ/m² ISO 179/1eU

Charpy notched impact strength, 23°C 7 / 15 kJ/m² ISO 179/1eA

Charpy notched impact strength, -30°C 6 / 14 kJ/m² ISO 179/1eA

Charpy notched impact strength, -40°C 6/- kJ/m² ISO 179/1eA

Izod notched impact strength, 23°C 6 / 12 kJ/m² ISO 180/1A

Izod notched impact strength, -30°C 5/- kJ/m² ISO 180/1A

Izod notched impact strength, -40°C 5/- kJ/m² ISO 180/1A

Izod impact strength, 23°C 45 / - kJ/m² ISO 180/1U

Izod impact strength, -40°C 40 / - kJ/m² ISO 180/1U

Ball indentation hardness, H 961/30 210 / 123 MPa ISO 2039-1

Poisson's ratio 0.35 / 0.37

[DS]: Derived from similar grade

Printed: 2024-02-07 Page: 1 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

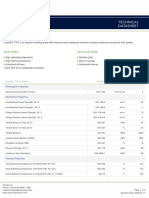

NYLON RESIN

Thermal properties dry/cond.

Melting temperature, 10°C/min 221 / * °C ISO 11357-1/-3

Glass transition temperature, 10°C/min 55 / 15 °C ISO 11357-1/-3

Temperature of deflection under load, 1.8 MPa 200 / * °C ISO 75-1/-2

Temperature of deflection under load, 0.45 MPa 220 / * °C ISO 75-1/-2

Vicat softening temperature, 50°C/h 50N 220 / * °C ISO 306

Coeff. of linear therm. expansion, parallel, -40-23°C 34 / * E-6/K ISO 11359-1/-2

Coeff. of linear therm. expansion, parallel 37 / * E-6/K ISO 11359-1/-2

Coeff. of linear therm. expansion, parallel, 55-160°C 15 / * E-6/K ISO 11359-1/-2

Coeff. of linear therm. expansion, normal, -40-23°C 80 / * E-6/K ISO 11359-1/-2

Coefficient of linear thermal expansion (CLTE), 109 / * E-6/K ISO 11359-1/-2

normal

Coefficient of linear thermal expansion 100 / * E-6/K ISO 11359-1/-2

(CLTE), normal, 55-160°C

Thermal conductivity of melt 0.19 W/(m K) Internal

Specific heat capacity of melt 2470 J/(kg K) Internal

RTI, electrical, 1.5mm 65 °C UL 746B

RTI, impact, 1.5mm 65 °C UL 746B

RTI, strength, 1.5mm 65 / * °C UL 746B

Flammability dry/cond.

Burning Behav. at 1.5mm nom. thickn. HB / * class UL 94

Thickness tested 1.5 / * mm UL 94

UL recognition yes / * UL 94

Burning Behav. at thickness h HB / * class UL 94

Thickness tested 1.5 / * mm UL 94

UL recognition yes / * UL 94

Oxygen index 21 / * % ISO 4589-1/-2

Glow Wire Flammability Index, 1.0mm 725 / - °C IEC 60695-2-12

Glow Wire Flammability Index, 2.0mm 725 / - °C IEC 60695-2-12

Glow Wire Flammability Index, 3.0mm 725 / - °C IEC 60695-2-12

Glow Wire Ignition Temperature, 1.0mm 725 / - °C IEC 60695-2-13

Glow Wire Ignition Temperature, 2.0mm 725 / - °C IEC 60695-2-13

Glow Wire Ignition Temperature, 3.0mm 725 / - °C IEC 60695-2-13

FMVSS Class B ISO 3795 (FMVSS 302)

Burning rate, Thickness 1 mm 25[DS] mm/min ISO 3795 (FMVSS 302)

[DS]: Derived from similar grade

Physical/Other properties dry/cond.

Humidity absorption, 2mm 2.5 / * % Sim. to ISO 62

Water absorption, 2mm 7.6 / * % Sim. to ISO 62

Density 1230 / - kg/m³ ISO 1183

Density of melt 1070 kg/m³ Internal

Printed: 2024-02-07 Page: 2 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

NYLON RESIN

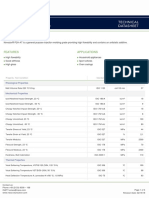

VDA Properties dry/cond.

Odour 4[DS] class VDA 270

Fogging, G-value (condensate) 0/* mg ISO 6452

[DS]: Derived from similar grade

Injection

Drying Recommended yes

Drying Temperature 80 °C

Drying Time, Dehumidified Dryer 2-4 h

Processing Moisture Content ≤0.2 %

Melt Temperature Optimum 270 °C Internal

Min. melt temperature 260 °C

Max. melt temperature 280 °C

Screw tangential speed ≤0.2 m/s

Mold Temperature Optimum 100 °C

Min. mould temperature 70 °C

Max. mould temperature 120 °C

Hold pressure range 50 - 100 MPa

Hold pressure time 3 s/mm

Characteristics

Additives Release agent

Printed: 2024-02-07 Page: 3 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

NYLON RESIN

Stress-strain (dry)

200

-40 °C

-20 °C

0 °C

23 °C

B 40 °C

60 °C

80 °C

120 °C

B 150 °C

150 B B - Break

Y - Yield

B

Stress in MPa

100

Y

Y

50

Y

0

0 2 4 6 8

Strain in %

Printed: 2024-02-07 Page: 4 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

NYLON RESIN

Stress-strain (cond.)

150

-20 °C

Y 0 °C

23 °C

40 °C

60 °C

80 °C

120 °C

150 °C

Y - Yield

Y

100

Stress in MPa

Y

50

Y

Y

0

0 2 4 6

Strain in %

Printed: 2024-02-07 Page: 5 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

NYLON RESIN

Secant modulus-strain (dry)

8000

-40 °C

-20 °C

0 °C

23 °C

40 °C

60 °C

80 °C

120 °C

150 °C

6000

B - Break

Y - Yield

B

B

Secant modulus in MPa

4000

2000

Y Y Y

0

0 2 4 6 8

Strain in %

Printed: 2024-02-07 Page: 6 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

NYLON RESIN

Secant modulus-strain (cond.)

8000

-20 °C

0 °C

23 °C

40 °C

60 °C

80 °C

120 °C

150 °C

Y - Yield

6000

Secant modulus in MPa

4000

2000

Y

Y Y

Y

Y Y

0

0 2 4 6

Strain in %

Printed: 2024-02-07 Page: 7 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

NYLON RESIN

Specific volume-temperature (pvT)

0.8

0.1 MPa

40 MPa

80 MPa

120 MPa

160 MPa

200 MPa

Spec. volume in E-3 m³/kg

0.75

0.7

0.65

0 100 200 300

Temperature in °C

Printed: 2024-02-07 Page: 8 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

NYLON RESIN

Tensile modulus-temperature (dry)

1E4

Tensile modulus in MPa

1E3

-50 0 50 100 150

Temperature in °C

Printed: 2024-02-07 Page: 9 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

NYLON RESIN

Tensile modulus-temperature (cond.)

1E4

Tensile modulus in MPa

1E3

-50 0 50 100 150

Temperature in °C

Printed: 2024-02-07 Page: 10 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

NYLON RESIN

Chemical Media Resistance

Acids

Acetic Acid (5% by mass), 23°C

Citric Acid solution (10% by mass), 23°C

Lactic Acid (10% by mass), 23°C

Hydrochloric Acid (36% by mass), 23°C

Nitric Acid (40% by mass), 23°C

Sulfuric Acid (38% by mass), 23°C

Sulfuric Acid (5% by mass), 23°C

Chromic Acid solution (40% by mass), 23°C

Bases

Sodium Hydroxide solution (35% by mass), 23°C

Sodium Hydroxide solution (1% by mass), 23°C

Ammonium Hydroxide solution (10% by mass), 23°C

Alcohols

Isopropyl alcohol, 23°C

Methanol, 23°C

Ethanol, 23°C

Hydrocarbons

n-Hexane, 23°C

Toluene, 23°C

iso-Octane, 23°C

Ketones

Acetone, 23°C

Ethers

Diethyl ether, 23°C

Mineral oils

SAE 10W40 multigrade motor oil, 23°C

SAE 10W40 multigrade motor oil, 130°C

SAE 80/90 hypoid-gear oil, 130°C

Insulating Oil, 23°C

Standard Fuels

ISO 1817 Liquid 1 - E5, 60°C

ISO 1817 Liquid 2 - M15E4, 60°C

ISO 1817 Liquid 3 - M3E7, 60°C

ISO 1817 Liquid 4 - M15, 60°C

Standard fuel without alcohol (pref. ISO 1817 Liquid C), 23°C

Standard fuel with alcohol (pref. ISO 1817 Liquid 4), 23°C

Diesel fuel (pref. ISO 1817 Liquid F), 23°C

Diesel fuel (pref. ISO 1817 Liquid F), 90°C

Diesel fuel (pref. ISO 1817 Liquid F), >90°C

Printed: 2024-02-07 Page: 11 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

Zytel® 73G15L NC010

NYLON RESIN

Salt solutions

Sodium Chloride solution (10% by mass), 23°C

Sodium Hypochlorite solution (10% by mass), 23°C

Sodium Carbonate solution (20% by mass), 23°C

Sodium Carbonate solution (2% by mass), 23°C

Zinc Chloride solution (50% by mass), 23°C

Other

Ethyl Acetate, 23°C

Hydrogen peroxide, 23°C

DOT No. 4 Brake fluid, 130°C

Ethylene Glycol (50% by mass) in water, 108°C

1% nonylphenoxy-polyethyleneoxy ethanol in water, 23°C

50% Oleic acid + 50% Olive Oil, 23°C

Water, 23°C

Water, 90°C

Phenol solution (5% by mass), 23°C

Symbols used:

possibly resistant

Defined as: Supplier has sufficient indication that contact with chemical can be potentially accepted under the intended use conditions and

expected service life. Criteria for assessment have to be indicated (e.g. surface aspect, volume change, property change).

not recommended - see explanation

Defined as: Not recommended for general use. However, short-term exposure under certain restricted conditions could be acceptable (e.g.

fast cleaning with thorough rinsing, spills, wiping, vapor exposure).

Printed: 2024-02-07 Page: 12 of 12

Revised: 2022-12-21 Source: Celanese Materials Database

NOTICE TO USERS: Values shown are based on testing of laboratory test specimens and represent data that fall within the standard range of properties for natural material. These values alone do

not represent a sufficient basis for any part design and are not intended for use in establishing maximum, minimum, or ranges of values for specification purposes. Colourants or other additives may

cause significant variations in data values. Properties of moulded parts can be influenced by a wide variety of factors including, but not limited to, material selection, additives, part design,

processing conditions and environmental exposure. Other than those products expressly identified as medical grade (including by MT® product designation or otherwise), Celanese’s products are

not intended for use in medical or dental implants. Regardless of any such product designation, any determination of the suitability of a particular material and part design for any use contemplated

by the users and the manner of such use is the sole responsibility of the users, who must assure themselves that the material as subsequently processed meets the needs of their particular product

or use. To the best of our knowledge, the information contained in this publication is accurate; however, we do not assume any liability whatsoever for the accuracy and completeness of such

information. The information contained in this publication should not be construed as a promise or guarantee of specific properties of our products. It is the sole responsibility of the users to

investigate whether any existing patents are infringed by the use of the materials mentioned in this publication. Moreover, there is a need to reduce human exposure to many materials to the lowest

practical limits in view of possible adverse effects. To the extent that any hazards may have been mentioned in this publication, we neither suggest nor guarantee that such hazards are the only ones

that exist. We recommend that persons intending to rely on any recommendation or to use any equipment, processing technique or material mentioned in this publication should satisfy themselves

that they can meet all applicable safety and health standards. We strongly recommend that users seek and adhere to the manufacturer’s current instructions for handling each material they use, and

entrust the handling of such material to adequately trained personnel only. Please call the telephone numbers listed for additional technical information. Call Customer Services for the appropriate

Materials Safety Data Sheets (MSDS) before attempting to process our products.

© 2023 Celanese or its affiliates. All rights reserved. Celanese®, registered C-ball design and all other trademarks identified herein with ®, TM, SM, unless otherwise noted, are trademarks of

Celanese or its affiliates. Fortron is a registered trademark of Fortron Industries LLC. KEPITAL is a registered trademark of Korea Engineering Plastics Company, Ltd.

Powered by TCPDF (www.tcpdf.org)

You might also like

- Narrow Fabrics: G.Maheswaran Assistant Professor Department of Textile Technology PSG College of Technology CoimbatoreDocument22 pagesNarrow Fabrics: G.Maheswaran Assistant Professor Department of Textile Technology PSG College of Technology Coimbatoremahes_tex100% (2)

- Zytel® 101 NC010-gbDocument11 pagesZytel® 101 NC010-gbalejandrocharlescollNo ratings yet

- Zytel® 103HSL NC010-gbDocument15 pagesZytel® 103HSL NC010-gbFaustoNo ratings yet

- Zytel® 101L NC010-gbDocument21 pagesZytel® 101L NC010-gbRamiro PredassiNo ratings yet

- Zytel® 45HSB NC010-gbDocument14 pagesZytel® 45HSB NC010-gbJuan Fernando CampuzanoNo ratings yet

- 5.0.aspa Axial Uv Antiestatica-1Document16 pages5.0.aspa Axial Uv Antiestatica-1Ventilación Minera S.A.SNo ratings yet

- Zytel FR50 NC010 ADocument9 pagesZytel FR50 NC010 ADario de SantiagoNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Zytel 70 G13 HS1 LBK031Document3 pagesZytel 70 G13 HS1 LBK031vikram goralNo ratings yet

- Campus® Datasheet: Zytel® St801 Bk010A - Pa66-I Dupont Engineering PolymersDocument7 pagesCampus® Datasheet: Zytel® St801 Bk010A - Pa66-I Dupont Engineering Polymersavinashchauhan2695No ratings yet

- Campus® Datasheet: Zytel® 70G30L Nc010 - Pa66-Gf30 Dupont Engineering PolymersDocument5 pagesCampus® Datasheet: Zytel® 70G30L Nc010 - Pa66-Gf30 Dupont Engineering PolymersVinayak ImadiNo ratings yet

- Delrin® 100 NC010-enDocument14 pagesDelrin® 100 NC010-enshahin_723No ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Advanced-PP 1102LQ - 0Document1 pageAdvanced-PP 1102LQ - 0Narender RawatNo ratings yet

- NORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFDocument3 pagesNORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFbhushansalunkeNo ratings yet

- Flow Elem. Makrolon 2467 - en - 56977450 00003066 15285551Document4 pagesFlow Elem. Makrolon 2467 - en - 56977450 00003066 15285551Guilherme Dos Santos SouzaNo ratings yet

- Zytel80g14ahsnc010 EnDocument8 pagesZytel80g14ahsnc010 EnMILORADNo ratings yet

- Makrolon 2407 - en - 56977361 00009645 19213223Document4 pagesMakrolon 2407 - en - 56977361 00009645 19213223vaibhav ShindeNo ratings yet

- Advanced PP 1102KDocument1 pageAdvanced PP 1102KLaxman AhirNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Makrolon 3206 - en - 56817747 00003433 19231690Document4 pagesMakrolon 3206 - en - 56817747 00003433 19231690noto.sugiartoNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- ULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Document2 pagesULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Luis Enrique Ramos PérezNo ratings yet

- Akulon Ultraflow KFKGS6 Ben SIDocument2 pagesAkulon Ultraflow KFKGS6 Ben SISrini VasanNo ratings yet

- CELANEX® 1600a-EnDocument4 pagesCELANEX® 1600a-EnleftpowtaNo ratings yet

- Arkema Rilsan MB 3000 NAT TDSDocument5 pagesArkema Rilsan MB 3000 NAT TDSstartionlilNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Makrolon 6557 - TDSDocument4 pagesMakrolon 6557 - TDSCassianNo ratings yet

- RilsamidAesnoMed TDS 201811Document2 pagesRilsamidAesnoMed TDS 201811Satish KumarNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Makrolon AL2447 - en - 56978848 00009654 19215151 2Document4 pagesMakrolon AL2447 - en - 56978848 00009654 19215151 2optoyhamelNo ratings yet

- CELCON® M90-EnDocument8 pagesCELCON® M90-EnJosue OrtizNo ratings yet

- Makrolon 6265 X - en - 83439336 05122261 16125443Document4 pagesMakrolon 6265 X - en - 83439336 05122261 16125443solar4meNo ratings yet

- Makrolon 2407 - en - 86286874 00009645 19213223Document4 pagesMakrolon 2407 - en - 86286874 00009645 19213223fernandoincesaNo ratings yet

- Makrolon 6485 - en - 56978635 00009652 18539090Document4 pagesMakrolon 6485 - en - 56978635 00009652 18539090Lin DanNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- Dupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinDocument11 pagesDupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinTomGaliciaNo ratings yet

- Crastin S600 F40 NC010Document11 pagesCrastin S600 F40 NC010TomGaliciaNo ratings yet

- Grivory GVX 5h Nat - Mds - enDocument5 pagesGrivory GVX 5h Nat - Mds - enJohn KingNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueErnesto Cheguavara100% (1)

- Ultrason E3010 NATDocument7 pagesUltrason E3010 NATDaniel Lack PendásNo ratings yet

- Technical Sheet Extruded AcrylicDocument1 pageTechnical Sheet Extruded AcrylicG GutierrezNo ratings yet

- CAMPUS® Datasheet: Rilsan® BZM 30 BLACK TL - PA11-GF30 ArkemaDocument2 pagesCAMPUS® Datasheet: Rilsan® BZM 30 BLACK TL - PA11-GF30 ArkemaRavindraNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Li NNOTAMDocument1 pageLi NNOTAMricva_rjNo ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Datasheet CX02-81Document2 pagesDatasheet CX02-81jprodriguezNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- POLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetDocument2 pagesPOLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetscribdNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- 202-Covestro Makrolon RX1805 Technical Data Sheet 03-12-2018Document3 pages202-Covestro Makrolon RX1805 Technical Data Sheet 03-12-2018obeckoneNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- NEGA bonding pad test results optimize glass fiber lengthDocument5 pagesNEGA bonding pad test results optimize glass fiber lengthNatarajan KrishnanNo ratings yet

- Comparative Study of Deflocculation Mechanisms in Colloidal Clay SuspensionsDocument18 pagesComparative Study of Deflocculation Mechanisms in Colloidal Clay SuspensionsJOSE FRANCISCO RAMIREZ RODRIGUEZNo ratings yet

- Catalog TS Transformer IndDocument56 pagesCatalog TS Transformer Indfourris258No ratings yet

- Water Quality AnalysisDocument100 pagesWater Quality AnalysisSuhil IrshadNo ratings yet

- Orca Share Media1554262372568Document8 pagesOrca Share Media1554262372568Ivy Mendoza PagcaliwanganNo ratings yet

- 2-Storey Residential HouseDocument49 pages2-Storey Residential HouseAngel Joy NicolasNo ratings yet

- Is 4990Document17 pagesIs 4990AnuradhaPatraNo ratings yet

- Hydrocarbons (Alkanes and Alkenes)Document16 pagesHydrocarbons (Alkanes and Alkenes)Soham NagNo ratings yet

- Chemistry Salt AnalysisDocument42 pagesChemistry Salt AnalysisVATSAL KHANDALNo ratings yet

- International Indian School, Dammam. Boys Middle Section Class: Viii Social Science Geo. Lesson - 5 IndustriesDocument4 pagesInternational Indian School, Dammam. Boys Middle Section Class: Viii Social Science Geo. Lesson - 5 IndustriesShaheem MuhammedNo ratings yet

- ASTM D2394-83 (1999) Simulated Service Testing of Wood and Wood-Base Finish FlooringDocument10 pagesASTM D2394-83 (1999) Simulated Service Testing of Wood and Wood-Base Finish FlooringĐỗ Thanh TùngNo ratings yet

- Proposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)Document2 pagesProposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)John Axl LajomNo ratings yet

- Construction of Pipelines, Tunnels and Ancillary WorkDocument26 pagesConstruction of Pipelines, Tunnels and Ancillary Workpopperoo00No ratings yet

- KEIM StucasolDocument2 pagesKEIM StucasolgunelNo ratings yet

- Design Example ASD GirderDocument12 pagesDesign Example ASD GirderEdward van MartinoNo ratings yet

- Type 06011 - Gastight: Safety ValvesDocument2 pagesType 06011 - Gastight: Safety ValvesMohamed RaafatNo ratings yet

- MSDS XW15Document8 pagesMSDS XW15mk7718No ratings yet

- FLOW 3D General BrochureDocument12 pagesFLOW 3D General BrochurehhadNo ratings yet

- Microbiology A Laboratory Manual 10th Edition Cappuccino Solutions ManualDocument3 pagesMicrobiology A Laboratory Manual 10th Edition Cappuccino Solutions Manualzeldaguinevereiur100% (28)

- PORON 4790-92-25041 P Extra SoftSlow ReboundSupportedDocument2 pagesPORON 4790-92-25041 P Extra SoftSlow ReboundSupportedkarpagsNo ratings yet

- AssignmentDocument2 pagesAssignmentmnzNo ratings yet

- FAILUREDocument20 pagesFAILUREMarcharlie PadillaNo ratings yet

- Qualify Trico Rod Buster Sucker Wrench and Combination Tap and Die SetDocument1 pageQualify Trico Rod Buster Sucker Wrench and Combination Tap and Die SetSharay VillanovaNo ratings yet

- PlaxisDocument16 pagesPlaxisSUNDARAVELNo ratings yet

- Conbextra GP 1011Document4 pagesConbextra GP 1011Srinivasan ReddyNo ratings yet

- Aislador Polimérico - Sediver - IECDocument6 pagesAislador Polimérico - Sediver - IECdaniel carhuamacaNo ratings yet

- Saudi Aramco Inspection Checklist: Plumb Drainage System Lay-Out SAIC-S-4040 30-Apr-13Document13 pagesSaudi Aramco Inspection Checklist: Plumb Drainage System Lay-Out SAIC-S-4040 30-Apr-13khurram ijazNo ratings yet

- Hardtop Optima Alu: Technical Data SheetDocument5 pagesHardtop Optima Alu: Technical Data SheetBiju_PottayilNo ratings yet

- 45m Square Tower - DryFoot 100KPADocument13 pages45m Square Tower - DryFoot 100KPAAhmed ShabanNo ratings yet