Professional Documents

Culture Documents

PUMA M4.3 DHD 340 TD40 Maint June 2018

Uploaded by

Marco LeivaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PUMA M4.3 DHD 340 TD40 Maint June 2018

Uploaded by

Marco LeivaCopyright:

Available Formats

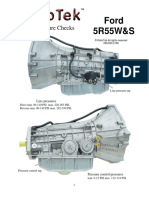

PUMA M4.

3 MAINTENANCE SHEET

DHD 340, TD40

EXPLODED VIEW DISASSEMBLY

WARNING!

• Use hammer disassembly bench.

Sub • Do not apply heat to any component

Backhead Assembly • Use wrenches in good condition

Backhead • Do not apply wrench on Inserts

• Apply clamps on recommended areas

O’Ring Wear DISASSEMBLY SEQUENCE

Sleeve

Check Valve 1 Move the piston to the bit side 5 Take out the Backhead and

Dart standing up the hammer remove its O’Ring

Position 2 Disassemble the hammer on the 6 Remove Check valve, Spring,

Spring bit side Compression Disk, Air guide,

Spacer

3 Extract the Chuck, Bit Retainer, and its O’ring

Compression

Disks Spacer / Bit Guide and Bit 7 Remove Piston and Cylinder

Make Up Ring 4. Flip the hammer, and loosen the

Shim Backhead side

Air Guide Chamfer

Towards

Backhead

Choke

B C C A

Spacer Bit Guide

O’Ring DHD 340 TD40

A B C

Cylinder Bit Side Back Head Side Clamp Location

O’Rings mm inch mm inch mm inch

161 6.3 270 10.6 50-100 2.0 – 3.9

Bit

Retainer

DHD 340 TD40 ASSEMBLY

Piston

O’Ring WARNING!

1 All components must be in 5 Check gap between Wear

Chuck good operating conditions Sleeve and Backhead is

2 Follow assembly sequence 0.9-1.4mm by manual pre-

DHD 340 TD40 shown in drawing torque if less than 0.7mm

3 Lubricate each component, add Make up ring shim

DHD 340 TD40 before installation 6 Apply recommended

Bit 4. Secure Compression Pre-torque

Disks position

Make

PRE-TORQUE up ring

shim Compression

ft-lbf kgf-m Disk position

DHD 340 TD40 2,500 – 2,700 346 - 374 T=Force x Arm

LUBRICATION MAINTENANCE

OIL GRADE SELECTION (cSt) STANDARD MAINTENANCE PROGRAM

Work TEMPERATURE ISO GRADE OPERATION CONDITIONS INSPECT EVERY:

Pressure Environment Discharge Dry With • Stable, non abrasive ground 200

Air Air Drilling Water • No water injection (operating hours)

100 – 150 -4°F to 86°F < 212°F 50 to 150 100 to 150

psig -20°C to 30°C < 100°C • Stable and abrasive ground 100

6.9 – 10.3 over 86°F • With or without water injection (operating hours)

> 212°F 150 to 220 150 to 220

barg over 30°C > 100°C • Unstable and abrasive ground 50

150 – 350 -4°F to 86°F < 212°F 100 to 220 220 to 320 • With or without water injection (operating hours)

psig -20°C to 30°C < 100°C

10.3 –24.1 over 86°F > 212°F 220 to 320 320 COMPONENT INSPECTION AND REPAIR.

barg over 30°C > 100°C All components must be washed thoroughly with

appropriate solvent, eliminating all accumulated dirt.

OIL CONSUMPTION L/h (q t/h) Use sand paper to smooth steel surfaces and friction

Drilling psig 150 200 250 300 350 marks , leaving all contact, sliding and threaded

Work pressure barg 10.3 13.8 17.2 20.7 24.1 surfaces in good smooth condition.

Consumption 0.7 1.0 1.3 1.6 2.0

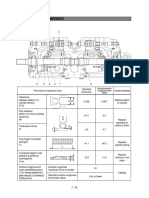

DIMENSIONS LIMITS mm (in)

COMPONENT DIMENSION DHD 340 TD 40

1 3 5

1 BACKHEAD ø External a 90 (3.54”)

2 AIR GUIDE ø Flute b 25.60 (1.007”)

3 CYLINDER ø Internal c 67.85 (2.671”)

Shoulder width c2 4 (0.16”)

4 WEAR SLEEVE ø External d 90 (3.54”)

ø Internal e 78.10 (3.074”)

2 4 6 7

5 PISTON ø Ext. Body f 77.78 (3.062”)

ø Ext. Tail g 67.52 (2.658”)

ø Int. Tail h 26.10 (1.028”)

ø Int. Body i 27.54(1.084”) 33.00(1.299”)

6 CHUCK ø External j 90 (3.54”)

External Length k 58 (2.28”)

Spline Width l 4 (0.16”)

7 BIT GUIDE ø Internal m ---- 68.(12.68”)

Check : 05/2018

PHONE: (56-2) 2431 2211; (56-2) 2431-2000 / www.drillco.com

You might also like

- PUMA M5.2EX maintenance and exploded viewsDocument1 pagePUMA M5.2EX maintenance and exploded viewsJORGE C. CHAO R.No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- 16 PRDocument10 pages16 PRlone_anarchistNo ratings yet

- Pressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2Document2 pagesPressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2ossoskiNo ratings yet

- Maintain Reciprocating Compressor ComponentsDocument21 pagesMaintain Reciprocating Compressor ComponentsAyub BashaNo ratings yet

- RH460 BrochureDocument24 pagesRH460 Brochurerigoberto otiniano100% (1)

- Input Drum Reinforcement Kit 77733-02KDocument2 pagesInput Drum Reinforcement Kit 77733-02KMichel Le DocteNo ratings yet

- Manual - Tong XQ6B RDCDocument26 pagesManual - Tong XQ6B RDCJavier Danilo Aranda PinzonNo ratings yet

- The Highest Level of Reloading PrecisionDocument3 pagesThe Highest Level of Reloading PrecisionToxophilus TheLuckyNo ratings yet

- Flo-Torq Propellor Installation ManualDocument7 pagesFlo-Torq Propellor Installation ManualTonyNo ratings yet

- Timing chain assembly guide for D20DT and D27DT diesel enginesDocument4 pagesTiming chain assembly guide for D20DT and D27DT diesel enginesMynor Witt100% (4)

- Timing Chain Assembly GuideDocument4 pagesTiming Chain Assembly GuideMynor WittNo ratings yet

- MBNZ-OM906LA-OM926LA MANUAL REPAIR - PDF Versión 13Document2 pagesMBNZ-OM906LA-OM926LA MANUAL REPAIR - PDF Versión 13Aron Emanuel Mendoza LopezNo ratings yet

- Transfer BoxDocument46 pagesTransfer BoxBob DesmetNo ratings yet

- Overhauling a Differential Step-by-StepDocument14 pagesOverhauling a Differential Step-by-StepHaris100% (2)

- John Deere 450CLC Excavator Service Repair Technical Manual (TM1925)Document14 pagesJohn Deere 450CLC Excavator Service Repair Technical Manual (TM1925)laopaodunNo ratings yet

- (Am-15) Format For Pump Maint ReportDocument2 pages(Am-15) Format For Pump Maint ReportShashankKumarNo ratings yet

- User's Manual for Hydraulic BreakersDocument34 pagesUser's Manual for Hydraulic BreakersClaudio VargasNo ratings yet

- Sandvik DTH Rock Drilling Tools.: This Way!Document12 pagesSandvik DTH Rock Drilling Tools.: This Way!jorgeNo ratings yet

- B70 Rock Breaker Care Operation Manual For TH86Document21 pagesB70 Rock Breaker Care Operation Manual For TH86Latifa EngineeringNo ratings yet

- Ford-Explorer 1998 EN US Manual de Taller Caja Automatica 0650ec0c6eDocument84 pagesFord-Explorer 1998 EN US Manual de Taller Caja Automatica 0650ec0c6eMono ArañaNo ratings yet

- Válvula Globo Tipo Placa - Spirax SarcoDocument2 pagesVálvula Globo Tipo Placa - Spirax SarcodgarciabNo ratings yet

- Shock Repair Repair Guide GuideDocument11 pagesShock Repair Repair Guide Guidebigblock3142No ratings yet

- Verado 200-275 Workshop-2Document90 pagesVerado 200-275 Workshop-2Servicios Luna LSNo ratings yet

- Workshop Manual: TBR SeriesDocument60 pagesWorkshop Manual: TBR Seriesfrankhil ramosNo ratings yet

- Shock Repair Guide 401 402 SeriesDocument11 pagesShock Repair Guide 401 402 Serieshcj920213No ratings yet

- Sure Cure Kit: Chrysler 41TE (A604), 42LE (A606)Document10 pagesSure Cure Kit: Chrysler 41TE (A604), 42LE (A606)carloaex23No ratings yet

- Toyota LC HZJ78 02 CL ClutchDocument4 pagesToyota LC HZJ78 02 CL Clutchyannis.spinnerNo ratings yet

- SONNAX 45rfeDocument2 pagesSONNAX 45rfefulltransmissionNo ratings yet

- kx80 Página 148Document1 pagekx80 Página 148PabloNo ratings yet

- clmt0365 0211Document2 pagesclmt0365 0211manuel paredesNo ratings yet

- Service Manual: For The HM40B and HM47B Rider Sweeper Sweeper For: Training Troubleshooting Adjustments JDocument39 pagesService Manual: For The HM40B and HM47B Rider Sweeper Sweeper For: Training Troubleshooting Adjustments JMiao MikeNo ratings yet

- CRV Valve AdjustmentDocument7 pagesCRV Valve AdjustmentJamieNo ratings yet

- Mantenimiento ScrollDocument33 pagesMantenimiento ScrollproyectosNo ratings yet

- Engine Hood DoorDocument113 pagesEngine Hood DoorJustin CosbyNo ratings yet

- A5hf1 Intro Part1Document41 pagesA5hf1 Intro Part1Huỳnh Minh ĐứcNo ratings yet

- Removal & Installation: Engine Cylinder Head Assembly - Service Information - HR VDocument13 pagesRemoval & Installation: Engine Cylinder Head Assembly - Service Information - HR VkavindaNo ratings yet

- 2010-2015 DHX RC4 - RC2 Rebuild - Bike Help Center - FOXDocument34 pages2010-2015 DHX RC4 - RC2 Rebuild - Bike Help Center - FOXYadi RomaNo ratings yet

- Manual 245 U140F 060Document6 pagesManual 245 U140F 060Nacho Arroyo100% (2)

- AS350 B2 - CH 04 - Main RotorDocument54 pagesAS350 B2 - CH 04 - Main RotorEX919No ratings yet

- 2010 - 11 - 08 General GX120 - 160 - 200 Engine Adjustment InformatDocument1 page2010 - 11 - 08 General GX120 - 160 - 200 Engine Adjustment InformatstacybriandNo ratings yet

- INSTALL HY-ROAD HYDRAULIC DISC BRAKEDocument2 pagesINSTALL HY-ROAD HYDRAULIC DISC BRAKETo KuNo ratings yet

- Operating Manual of XYQ6B TongDocument26 pagesOperating Manual of XYQ6B TongV.D. J.No ratings yet

- Stereo Turntable: Operating InstructionsDocument10 pagesStereo Turntable: Operating InstructionsBarbaraNo ratings yet

- Reverb Stealth Height Adjust Seatpost User ManualDocument128 pagesReverb Stealth Height Adjust Seatpost User ManualjackNo ratings yet

- Operating & Maintenance InstructionsDocument8 pagesOperating & Maintenance InstructionsVAN VIET NGONo ratings yet

- KATALOG Chain Conveyor OMEGA FINALDocument6 pagesKATALOG Chain Conveyor OMEGA FINALMilianto KwanNo ratings yet

- OFITE Calibration Kit For 6-Speed ViscosimetersDocument2 pagesOFITE Calibration Kit For 6-Speed ViscosimetersHenryNo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- Align AL CE500P ManualDocument15 pagesAlign AL CE500P Manualreginaldo020471No ratings yet

- Blower k430 Snh60 Overhaul ProcedureDocument39 pagesBlower k430 Snh60 Overhaul ProcedurejamiekuangNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument7 pagesGroup 2 Major Component: 1. Main PumpHậu MinhNo ratings yet

- Camshaft InstallDocument4 pagesCamshaft Installatorres611No ratings yet

- 538 270 Thomas Series DBZ, Sizes 50 451 Disc Couplings ManualDocument4 pages538 270 Thomas Series DBZ, Sizes 50 451 Disc Couplings ManualpelakupasarNo ratings yet

- K75 BellhousingDocument2 pagesK75 BellhousingFoster GibbonsNo ratings yet

- Hydraulic External Cutters Instruction Manual 5550 OEMDocument10 pagesHydraulic External Cutters Instruction Manual 5550 OEMTanzil100% (1)

- One Touch Hydraulic Punch Clamp Operator's ManualDocument21 pagesOne Touch Hydraulic Punch Clamp Operator's Manualtrung vothaiNo ratings yet

- R210LC-7 7-2Document10 pagesR210LC-7 7-2Krystian PalaciosNo ratings yet

- Cold Rolled Steel Sections - Specification: Kenya StandardDocument21 pagesCold Rolled Steel Sections - Specification: Kenya StandardPEng. Tech. Alvince KoreroNo ratings yet

- Thermal Analysis of An Ohmic Heater Applied To Mango Pulp Through CFD in Ansys ApdlDocument11 pagesThermal Analysis of An Ohmic Heater Applied To Mango Pulp Through CFD in Ansys ApdlOLANIYINo ratings yet

- Tips On Fatigue - NAVWEPS 00-25-559Document123 pagesTips On Fatigue - NAVWEPS 00-25-559Mark Evan SalutinNo ratings yet

- Family Nomenclature and Same-Name Divinities in Roman Religion and MythologyDocument17 pagesFamily Nomenclature and Same-Name Divinities in Roman Religion and MythologyhNo ratings yet

- STK6712BMK4: Unipolar Fixed-Current Chopper-Type 4-Phase Stepping Motor DriverDocument11 pagesSTK6712BMK4: Unipolar Fixed-Current Chopper-Type 4-Phase Stepping Motor DriverGerardo WarmerdamNo ratings yet

- Lecture 9: Exploration and Exploitation: David SilverDocument47 pagesLecture 9: Exploration and Exploitation: David Silver司向辉No ratings yet

- Python Programming For Mechanical EngineersDocument93 pagesPython Programming For Mechanical EngineerslucianoprocopioNo ratings yet

- GM Bluetooth Quick GuideDocument5 pagesGM Bluetooth Quick GuideTin_AmoNo ratings yet

- Kodak Miraclon Plate BrochureDocument2 pagesKodak Miraclon Plate BrochureQuinson Benson CoNo ratings yet

- Sehr I Time 2012 DelhiDocument1 pageSehr I Time 2012 DelhiVaibhav VermaNo ratings yet

- MEK 10103 ELECTRIC DRIVES AND APPLICATIONSDocument23 pagesMEK 10103 ELECTRIC DRIVES AND APPLICATIONSNazrul KocyNo ratings yet

- Sri Gopala Bhatta GoswamiDocument8 pagesSri Gopala Bhatta GoswamispshankarjpsNo ratings yet

- VCTA-S810 OnlineDocument3 pagesVCTA-S810 OnlineqwUENo ratings yet

- RTC Invoice 2965 Gj29es2223100505Document1 pageRTC Invoice 2965 Gj29es2223100505Alok PandeyNo ratings yet

- Agilent DSO5014A Oscilloscope Tutorial: EE105 Lab ExperimentsDocument6 pagesAgilent DSO5014A Oscilloscope Tutorial: EE105 Lab ExperimentshendraprimaNo ratings yet

- Industrial Coupling and HoseDocument57 pagesIndustrial Coupling and HoseCesar CoronelNo ratings yet

- WDCL Damaged-Control-Line Replacement Safety Valve SystemDocument4 pagesWDCL Damaged-Control-Line Replacement Safety Valve SystemDavid Pit FermiereNo ratings yet

- LESSON 1 Random-VariablesDocument29 pagesLESSON 1 Random-Variablesnica jane madrigalNo ratings yet

- Co Existence of Low and High Heat Flow Anomalies On The South Balearic Margin and Algerian Oceanic BasinsDocument19 pagesCo Existence of Low and High Heat Flow Anomalies On The South Balearic Margin and Algerian Oceanic BasinsmariaNo ratings yet

- Grove RT422 22T PDFDocument4 pagesGrove RT422 22T PDFJulio QuilarqueNo ratings yet

- Rajalakshmi Engineering CollegeDocument2 pagesRajalakshmi Engineering CollegebalaNo ratings yet

- Cengel FTFS 6e ISM CH 13Document83 pagesCengel FTFS 6e ISM CH 13Duck FernandoNo ratings yet

- Herman Pardamean Hutabarat: Mechanical EngineerDocument3 pagesHerman Pardamean Hutabarat: Mechanical EngineerHerman HutabaratNo ratings yet

- InglesDocument6 pagesInglesyarilisNo ratings yet

- WAVES FORM 5the diagram, identify the followingDocument52 pagesWAVES FORM 5the diagram, identify the followingHuda IdrisNo ratings yet

- BMW Inyeccion 320i-325i Motronic M31 PDFDocument2 pagesBMW Inyeccion 320i-325i Motronic M31 PDFIvoo ooNo ratings yet

- Reservoir SedimentationDocument20 pagesReservoir SedimentationKathlienNo ratings yet

- Sir James ChadwickDocument6 pagesSir James ChadwickMichael GuevarraNo ratings yet

- WEG Guia de Instalacao pws5610 Quick Guide English PDFDocument1 pageWEG Guia de Instalacao pws5610 Quick Guide English PDFÁgó AttilaNo ratings yet

- Prof (1) F P Kelly - ProbabilityDocument78 pagesProf (1) F P Kelly - ProbabilitycoolmohitNo ratings yet