Professional Documents

Culture Documents

Intro Paper Hank Solution

Uploaded by

Ademar Rodriguez D.Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intro Paper Hank Solution

Uploaded by

Ademar Rodriguez D.Copyright:

Available Formats

Corrosion of Intermetallics in Hank´s Solution

R. A. Rodriguez-Diaz1, S. Serna1,*, A. M. Ramirez-Arteaga1, 2, E. Diaz1, 2

1

Centro de Investigación en Ingeniería y Ciencias Aplicadas - UAEM, Av. Universidad 1001, Chamilpa 62209,

Cuernavaca Morelos, México.

2

Facultad de Ciencias Químicas e Ingeniería - UAEM, Av. Universidad 1001, Chamilpa 62209, Cuernavaca

Morelos, México.

3

Universidad Politécnica del Estado de Morelos, Boulevard Cuauhnáhuac 566, 62550 Jiutepec, MOR, México.

*E-mail: aserna@uaem.mx, rdiaz.unam@gmail.com

Abstract

Keywords:

1. Introduction

During various decades in the field of medical sciences including the biomedical engineering

and dentistry, various materials commonly named as biomaterials have been used aiming to

substitute or repair a tissue, body feature, organ or function. The proper functioning of

biomaterials that are in contact with living tissue is determined by the biocompatibility and

biofunctionality.

For the case of metallic biomaterials, one aspect that greatly influences the biocompatibility

behavior is the corrosion resistance and the corrosion products liberated onto the surrounding

tissue [1]. For example in dental sciences, the corrosion products of dental alloys possess

metal ions which may induce allergic reactions and some other diseases. In this sense, the

electrochemical behavior of non-precious alloys has been subject of various investigations

[2].

The corrosion resistance of the most common used metallic materials as austenitic stainless

steels, Co-Cr alloys, Ti and Ti-based implant alloys is determined by their passivation nature

which is at the same time controlled by a thin surface layer of oxide [3-6].

The ideal combination of properties of a metallic biomaterial, are as follows: A

biocompatible chemical composition to evade harmful tissue reactions. Excellent resistance

to degradation or corrosion, Appropriate strength to maintain cyclic loading supported by the

joint, elevated modulus to decrease the bone resorption, high wear resistance to minimize

wear waste generation [7].

The nature of physiological medium is extremely adverse and unfavorable to all external

materials and for that reason the effect of environment on metallic implant and the influence

of the metallic implant on its host tissue are a subject of main concern. It is worth noting that

the physiological environment contains an elevated concentration of chloride ions which

represents a very corrosive medium for metallic implants [8].

The intermetallic compounds based on aluminides of transition metals which possess an

ordered crystal structure are among the materials that can function properly as structural

materials, since the Al content of these compounds promotes the formation of a protective

layer of Al-oxide, which indices a good oxidation, corrosion, and sulfidation resistance at

room temperature or higher; besides these intermetallic compounds preserve a good strength

and stiffness at elevated temperatures [9-12].

During the last decades, the investigations related to the corrosion comportment of

Aluminides have been growing due to their interesting aqueous corrosion behaviors in acidic,

basic, chloride and sulfur-compound solutions. For these reasons, the iron aluminides are

among the materials that can be considered as substitutes of metallic biomaterials [13-15].

Hence, the object of this research is to report an assessment of the corrosion behavior of

intermetallic composition alloy by means of electrochemical techniques when the

intermetallic compounds are exposed to a hank´s solution for a short period of time.

2. Experimental Procedures

2.1. Materials

Cast ingots of ternary Fe-40AlX (X = 2.5 Ag, 2.5Cr) (at. %) alloys were fabricated employing

a high-frequency induction furnace at about 1500°C in air. High purity (99.9 %) Fe, Al, Cr

and Ag were put inside a SiC crucible in order to be induction melted. The molten ternary

Fe40Al based alloys were poured into a rectangular steel mold, then the alloys were

subsequently solidified during cooling until room temperature was reached, the ingots

produced in this way displayed a coarse grain microstructure.

2.2. Hank’s Solution

The previously produced alloys were exposed to the biomimetic solution, in this case, the

Hank’s solution was used as the corrosion medium, consisting of 8.0 g/L NaCl, 0.4 g/L KCl,

0.06 g/L KH2PO4, 1.0 g/L glucose (C6H6O6), 0.048 g/L Na2HPO4, 0.098 g/L MgSO47H2O,

0.14 g/L CaCl2 and 0.35 g/L NaHCO3 in distilled water. The pH 7.2 solution was prepared

with analytical grade chemical reagents

You might also like

- Metal Release From Stainless Steel in Biological Environments: A ReviewDocument18 pagesMetal Release From Stainless Steel in Biological Environments: A ReviewTiên TrầnNo ratings yet

- DAFLOU BATIS VpCI - 2Document6 pagesDAFLOU BATIS VpCI - 2Wr ArNo ratings yet

- Paper de Revision Modelo 3Document15 pagesPaper de Revision Modelo 3JulioNo ratings yet

- Introduction of Corrosion Science and Engineering-1Document26 pagesIntroduction of Corrosion Science and Engineering-1Dedsec DarloNo ratings yet

- Chemical Analysis of Dental Alloys: Name: Mahmoud Mohamed Owais ID:200043957 Subject: Prof. Dr. El-Zeiny Mousa EbeidDocument12 pagesChemical Analysis of Dental Alloys: Name: Mahmoud Mohamed Owais ID:200043957 Subject: Prof. Dr. El-Zeiny Mousa Ebeid3bdallah.mseNo ratings yet

- Biomaterials Journal: Corrosive Failure of Metals and Alloys in Dentistry: A ReviewDocument6 pagesBiomaterials Journal: Corrosive Failure of Metals and Alloys in Dentistry: A ReviewIstiak MahmoodNo ratings yet

- Additively Manufactured 316L Stainless Steel With Improved CorrosioDocument12 pagesAdditively Manufactured 316L Stainless Steel With Improved CorrosioMusfiqAtifNo ratings yet

- Materials 3 2 1 PDFDocument8 pagesMaterials 3 2 1 PDFAmaliNo ratings yet

- Dental Ceramics: Part II - Recent Advances in Dental CeramicsDocument8 pagesDental Ceramics: Part II - Recent Advances in Dental Ceramicsafsal latheefNo ratings yet

- Literature Review On Corrosion of Mild SteelDocument5 pagesLiterature Review On Corrosion of Mild Steelgw32pesz100% (1)

- Corrosion and Corrosion Inhibition of Pure Iron inDocument17 pagesCorrosion and Corrosion Inhibition of Pure Iron inKatNo ratings yet

- The Inhibitive Effect of Hexamethylenetetramine On The Acid Corrosion of SteelDocument10 pagesThe Inhibitive Effect of Hexamethylenetetramine On The Acid Corrosion of Steelhadi ebrahimfathNo ratings yet

- Agwanda's Full Proposal 26.1.2022prof.Document22 pagesAgwanda's Full Proposal 26.1.2022prof.Abdulfattah KhamisNo ratings yet

- Surface Characterization of Fe e10Ale25Mn Alloy For Biomaterial ApplicationsDocument7 pagesSurface Characterization of Fe e10Ale25Mn Alloy For Biomaterial ApplicationsRatna KartikasariNo ratings yet

- CORROSION RATE ANALYSIS ,, Assignment 1Document4 pagesCORROSION RATE ANALYSIS ,, Assignment 1Muhammad MustafaNo ratings yet

- 2016articleoncorrosionofmildsteel PDFDocument11 pages2016articleoncorrosionofmildsteel PDFsuryaNo ratings yet

- Corrosion Rates and Its Impact On Mild Steel in Some Selected EnvironmentsDocument11 pagesCorrosion Rates and Its Impact On Mild Steel in Some Selected EnvironmentsAdi SetiyawanNo ratings yet

- Metals 07 00043Document18 pagesMetals 07 00043hydromaniaNo ratings yet

- Review of Metal CastingDocument12 pagesReview of Metal CastingsonuNo ratings yet

- Types of Corrosion in BiomaterialsDocument47 pagesTypes of Corrosion in BiomaterialsYashNo ratings yet

- Inhibition of Microbial Corrosion of 304 Stainless Steel in Seawater by Some Novel BiocidesDocument12 pagesInhibition of Microbial Corrosion of 304 Stainless Steel in Seawater by Some Novel BiocidesBubai111No ratings yet

- Mechanism of Action and Applications of The Antimicrobial Properties of CopperDocument12 pagesMechanism of Action and Applications of The Antimicrobial Properties of CopperAninditaTrikusumaNo ratings yet

- 4 Eric PartingtonDocument4 pages4 Eric PartingtonmarroquinmeridaNo ratings yet

- Development of Ti-Mo Alloys For Biomedical Applications - Microestructure and Electrochemical CharacterizationDocument5 pagesDevelopment of Ti-Mo Alloys For Biomedical Applications - Microestructure and Electrochemical CharacterizationFelipe Cepeda SilvaNo ratings yet

- Iron Oxide NanoparticlesDocument25 pagesIron Oxide NanoparticlesGöksun GüvenNo ratings yet

- Electrochemical and Chemical Methods For Improving Surface Characteristics of 316LDocument12 pagesElectrochemical and Chemical Methods For Improving Surface Characteristics of 316Lmohammadreza hajialiNo ratings yet

- Biocompatibility of Aluminium Alloys and Anodic Al2O3Document6 pagesBiocompatibility of Aluminium Alloys and Anodic Al2O3Nícolas LaraNo ratings yet

- Emr 2201 Engineering Materials I Year 2 Bsc. Marine EngineeringDocument29 pagesEmr 2201 Engineering Materials I Year 2 Bsc. Marine EngineeringAhmed O MohamedNo ratings yet

- Chapter One, Introduction PDFDocument9 pagesChapter One, Introduction PDFOmar Abu MahfouthNo ratings yet

- Corrosion Science: Ramazan SolmazDocument10 pagesCorrosion Science: Ramazan SolmazkhalidNo ratings yet

- Role of Zirconium Conversion Coating in Corrosion Performance of Aluminum AlloysDocument27 pagesRole of Zirconium Conversion Coating in Corrosion Performance of Aluminum Alloysbmalki68No ratings yet

- Anti-Corrosion Ability of Surfactants: A Review: Int. J. Electrochem. Sci.Document22 pagesAnti-Corrosion Ability of Surfactants: A Review: Int. J. Electrochem. Sci.MarcTimNo ratings yet

- Gu Rappa 2002Document7 pagesGu Rappa 2002Deri Andika BangunNo ratings yet

- Equilibrium Phases in Cast AlloysDocument19 pagesEquilibrium Phases in Cast AlloysAkshayaa BalajiNo ratings yet

- Corrosion of Bio ImplantsDocument37 pagesCorrosion of Bio ImplantsDaniel de la CruzNo ratings yet

- Milos EvDocument27 pagesMilos EvMarioNo ratings yet

- Telfaria Occidentalis Extract - Mild Steel Acid Solution 2005Document6 pagesTelfaria Occidentalis Extract - Mild Steel Acid Solution 2005danish.hakeem251No ratings yet

- Sweet MelonDocument8 pagesSweet MelonAllia AsriNo ratings yet

- Research ArticleDocument10 pagesResearch ArticleNareshNo ratings yet

- On The Theory of CO2 Corrosion Reactions - Investigating Their Interrelation With The Corrosion Products and API-X100 Steel MicrostructureDocument14 pagesOn The Theory of CO2 Corrosion Reactions - Investigating Their Interrelation With The Corrosion Products and API-X100 Steel MicrostructureFaysal F. EliyanNo ratings yet

- Glass Coatings On Stainless Steels For High-Temperature Oxidation Protection MechanismDocument12 pagesGlass Coatings On Stainless Steels For High-Temperature Oxidation Protection MechanismJabbar AljanabyNo ratings yet

- Effect of 0.5Wt% CR Addition On The Mechanical Properties and Microstructure of Heat Treated Plain Carbon Low Alloy SteelDocument5 pagesEffect of 0.5Wt% CR Addition On The Mechanical Properties and Microstructure of Heat Treated Plain Carbon Low Alloy SteelhburitiNo ratings yet

- Ijrr0100 PDFDocument5 pagesIjrr0100 PDFAolNo ratings yet

- Reference 3Document12 pagesReference 3Junior CharlesNo ratings yet

- Ibrahim2017 PDFDocument62 pagesIbrahim2017 PDFMaxim MaximovNo ratings yet

- Implant MaterialsDocument16 pagesImplant MaterialsNikita AggarwalNo ratings yet

- A Review On Corrosion Scenario of Bio Implants in Human BodyDocument5 pagesA Review On Corrosion Scenario of Bio Implants in Human BodyJulioNo ratings yet

- Get 226 Lecture NoteDocument20 pagesGet 226 Lecture NoteRaphael GodfreyNo ratings yet

- Effect of 5, 5-Diphenylhydantoin On Corrosion of Mild Steel in 1M. Hydrochloric Acid SolutionDocument9 pagesEffect of 5, 5-Diphenylhydantoin On Corrosion of Mild Steel in 1M. Hydrochloric Acid SolutionIJRASETPublicationsNo ratings yet

- Synthesis and Characterization of A Novel Organic Corrosion Inhibitor For Mild Steel in 1â M Hydrochloric AcidDocument6 pagesSynthesis and Characterization of A Novel Organic Corrosion Inhibitor For Mild Steel in 1â M Hydrochloric AcidRoberta VasquesNo ratings yet

- Properties of Super Stainless Steels For Orthodontic ApplicationsDocument13 pagesProperties of Super Stainless Steels For Orthodontic ApplicationsDr.kaviyarasuNo ratings yet

- Corrosion in Titanium Dental Implants Literature ReviewDocument7 pagesCorrosion in Titanium Dental Implants Literature ReviewtotherethymNo ratings yet

- 1 - Chemistry For Civil Engineers-Lecture No. 1Document22 pages1 - Chemistry For Civil Engineers-Lecture No. 1Yusf ari jerjisNo ratings yet

- Environmental Cracking of Corrosion Resistant Alloys in The Chemical Process Industry - A Review PDFDocument15 pagesEnvironmental Cracking of Corrosion Resistant Alloys in The Chemical Process Industry - A Review PDFMarcos LeiteNo ratings yet

- Journal Pre-Proof: Surfaces and InterfacesDocument37 pagesJournal Pre-Proof: Surfaces and InterfacesNino AmigoNo ratings yet

- CAP2Document58 pagesCAP2ChriaAkaleziNo ratings yet

- Corrosion of Metallic Biomaterials A ReviewDocument92 pagesCorrosion of Metallic Biomaterials A ReviewSabrina RosoiuNo ratings yet

- 3,4-Dimethoxybenzaldehydethiosemicarbazone As CorrosionDocument11 pages3,4-Dimethoxybenzaldehydethiosemicarbazone As CorrosionFernando HenriqueNo ratings yet

- Intan DKK PisangDocument9 pagesIntan DKK PisangHISANA AFIFANo ratings yet

- PG BOTANY Research Methodology and Biostatistics CompleteDocument17 pagesPG BOTANY Research Methodology and Biostatistics CompleteSandeep PatilNo ratings yet

- Animal Enrichment Year 7 Integrated Learning TaskDocument7 pagesAnimal Enrichment Year 7 Integrated Learning Taskapi-350319898No ratings yet

- Glycolysis and Difference Between Aerobic and AnaeDocument12 pagesGlycolysis and Difference Between Aerobic and Anaepc usageNo ratings yet

- Respiratory System (Anatomy and Physiology)Document71 pagesRespiratory System (Anatomy and Physiology)Butch Dumdum100% (11)

- Impact Factor 2009Document55 pagesImpact Factor 2009Walter MoraesNo ratings yet

- Es Int 9a Eouth AspDocument6 pagesEs Int 9a Eouth AspHisokagenNo ratings yet

- 3.3 & 7.1 DNA Structure HL Caitlin WORDDocument4 pages3.3 & 7.1 DNA Structure HL Caitlin WORDCaitlin BarrettNo ratings yet

- Apologia Biology Class Module 6 NotesDocument4 pagesApologia Biology Class Module 6 Noteschickfilamom100% (2)

- SdarticleDocument13 pagesSdarticleapi-3700445No ratings yet

- EnzymeDocument9 pagesEnzymepooyenpengNo ratings yet

- Poisson IntervalDocument8 pagesPoisson Intervalaaro_oraalNo ratings yet

- зан.6 переведеноDocument7 pagesзан.6 переведеноРопннпгпNo ratings yet

- VET0816ra Mla eDocument23 pagesVET0816ra Mla eBibleBaptistYPSanRemNo ratings yet

- AQA Biology Organisation GraspIT GCSE - Reusable WorksheetDocument3 pagesAQA Biology Organisation GraspIT GCSE - Reusable Worksheetmaaa7No ratings yet

- Diaporthe 1 EF1-728FDocument9 pagesDiaporthe 1 EF1-728FDaniel Costas ImbernónNo ratings yet

- Glossary of Ayurvedic TermsDocument26 pagesGlossary of Ayurvedic TermsMaheish AyyerNo ratings yet

- CUMARINASDocument86 pagesCUMARINASMaria VieiraNo ratings yet

- Describing Variants: Recommendations For The Description of DNA ChangesDocument38 pagesDescribing Variants: Recommendations For The Description of DNA ChangesVasanthakumar rathinamNo ratings yet

- Body Mind Spirit Neural Web TheoryDocument21 pagesBody Mind Spirit Neural Web TheoryaaandradeNo ratings yet

- Lasercyte DX Message Codes enDocument1 pageLasercyte DX Message Codes enSpital Veterinar AndivetNo ratings yet

- NPQS A3-30 SoftscapeDocument32 pagesNPQS A3-30 SoftscapeWillisNo ratings yet

- Nephroprotective Effect of Vanillic Acid Againstcisplatin Induced Nephrotoxicity in Wistar Rats:a Biochemical and Molecular StudyDocument13 pagesNephroprotective Effect of Vanillic Acid Againstcisplatin Induced Nephrotoxicity in Wistar Rats:a Biochemical and Molecular StudyKavisa GhoshNo ratings yet

- Alcalase 2.4LDocument5 pagesAlcalase 2.4Lmarcola256No ratings yet

- Flower HybridDocument46 pagesFlower HybridAnirban MullickNo ratings yet

- Animal Tissues - Micro Notes by Seep PahujaDocument3 pagesAnimal Tissues - Micro Notes by Seep PahujaKazi AkibNo ratings yet

- Animal Phy Lec 3-7 DigestionDocument101 pagesAnimal Phy Lec 3-7 DigestionRaushanKumarNo ratings yet

- 1 Intro To Pharmacology 2023Document63 pages1 Intro To Pharmacology 2023Hussain RazaNo ratings yet

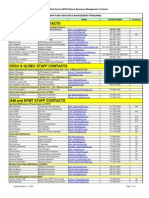

- MWR Park Resource MGMT PersonnelDocument5 pagesMWR Park Resource MGMT Personneldeborah_hastyNo ratings yet

- MK NR 01 en 1 PDFDocument213 pagesMK NR 01 en 1 PDFKLT63No ratings yet