Professional Documents

Culture Documents

(Brochure) Live - DPN

Uploaded by

Johanes GigihOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Brochure) Live - DPN

Uploaded by

Johanes GigihCopyright:

Available Formats

Digital Pulsed Neutron

LIVE PL digital slickline production logging services

APPLICATIONS As the latest addition to LIVE PL* digital slickline production logging services, digital pulsed neutron

■ Locate oil, water, and gas contacts (DPN) service provides crucial information, such as fluid contact monitoring and fluid identification

■ Identify known formations in behind casing, to inform wellsite decision making for optimizing reservoir management and

development wells production in mature fields.

■ Conduct time-lapse logging of reservoir DPN pairs the field-proven Schlumberger small-diameter high-output pulsed neutron generator (PNG)

fluid interfaces with dual scintillation gamma ray detectors to provide real-time sigma measurement in mixed-

■ Guide perforating by identifying salinity cased hole environments. Dual neutron burst with adaptive timing is performed to ensure

gas contacts the measurement’s insensitivity to borehole conditions and eliminate the need for environmental

■ Evaluate gravel-pack placement correction. Measurement precision is further honed by using the available job planner.

■ Correlate from well to well

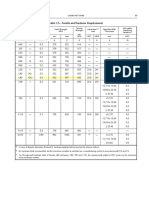

Measurement Specifications Digital Pulsed Neutron

BENEFITS Output Sigma, apparent porosity, gas indicator

■ Leverage the efficiency and simplicity Logging speed 1,800 ft/h [549 m/h]

of slickline operations with the accurate Range of measurement 0 to 60 cu

depth control, digital capabilities, and Vertical resolution 2.5 ft [0.76 m]

real-time measurement quality of Precision <±2% cu

Borehole fluid or formation water salinity >50,000 ppm

wireline-conveyed services

Mechanical Specifications Digital Pulsed Neutron

■ Easily conduct operations with a short tool Temperature rating 302 degF [150 degC]

where rig-up height is constrained Pressure rating 15,000 psi [103 MPa]

or space is limited Casing size—min. 41/2 in

■ Avoid the typical memory limitations of Casing size—max. 95/8 in

slickline logging with a high-performance Outside diameter 1.72 in [4.37 cm]

lithium ion battery providing up to Weight 37 lbm [17 kg]

15 hours of continuous operation

Conventional wireline and slickline

■ Improve operational efficiency

with tool combinability and Pressure

Traditional way

Electric Power control Slickline Power

multipurpose deployments line unit pack equipment unit pack

PCE skid

(PCE) skid

■ Reduce risk in wax or debris Wireline + Slickline

accumulations by running with D-Jar*

digital downhole adjustable jar Electric Electric Slickline Slickline

line toolbox line PCE toolbox PCE

FEATURES

■ Full compatibility with LIVE* digital DPN with digital slickline: 1 unit, 1 crew, 1 rig-up

slickline services

■ Short, 111/16-in-OD tool for through-tubing LIVE Power

PCE skid

LIVE

service Slickline

service pack

conveyance and negotiating restrictions toolbox PCE

■ Deployment on 0.108- or 0.125-in

digital slickline Conventional LIVE DSL

Sigma Logging and

Slickline wear sleeve run Slickline wear sleeve retrieval

■ Sigma, apparent porosity, and gas Plugback Comparison

Slickline gauge ring run Slickline gauge ring run Equipment required reduced

indicator measurements ■

by factor of two

Slickline rig-down and electric line rig-up LIVE service sigma run

■ Sourceless pulsed neutron generator Electric line sigma LIVE Perf* digital slickline perforating services

■ Simplified PCE

■ Reduction in crew size

■ Accurate real-time onsite depth control Electric line plug run Remove wear sleeve ■ Two pressure tests eliminated

Electric line rig-down and slickline rig-up ■ Two conveyance

■ Logging speed up to 1,800 ft/h Slickline wear sleeve retrieval changes eliminated

Faster, simpler, reduced risk

No memory limitations

■

■

The efficiency and simplicity of using DPN service on digital slickline with only one unit,

* Mark of Schlumberger one crew, and one rig-up save significant operational time over intervention operations

Copyright © 2020 Schlumberger. All rights reserved. 19-PR-553591 that switch from slickline to electric wireline line for logging and back to slickline. slb.com/LIVE

You might also like

- 534fef10e34e24c71e53baf5Document2 pages534fef10e34e24c71e53baf5sandeep naikNo ratings yet

- Pinnacle 45: Long-Range Self-Contained & Real-Time ADCPDocument2 pagesPinnacle 45: Long-Range Self-Contained & Real-Time ADCPAlan BerryNo ratings yet

- General Specifications: Model DY Model DYA Vortex FlowmetersDocument24 pagesGeneral Specifications: Model DY Model DYA Vortex FlowmetersSayed Ibrahim GhanemNo ratings yet

- TOPAS PS 120 Data SheetDocument2 pagesTOPAS PS 120 Data SheetmasmoohNo ratings yet

- Conventional Slickline With Real-Time Data: One Crew. One System. One Rig-UpDocument7 pagesConventional Slickline With Real-Time Data: One Crew. One System. One Rig-UpKoray YilmazNo ratings yet

- DAC80 CB1 V DatasheetDocument10 pagesDAC80 CB1 V DatasheetsunhuynhNo ratings yet

- Industrial Robot Controller: Key BenefitsDocument2 pagesIndustrial Robot Controller: Key BenefitsPhúc Lê HoàngNo ratings yet

- Medium Pressure SensorsDocument2 pagesMedium Pressure SensorsLoic TrocmeNo ratings yet

- Brookfield Brings Full Compliance To Stand-Alone InstrumentsDocument2 pagesBrookfield Brings Full Compliance To Stand-Alone InstrumentsGESTION ASMETROLOGYNo ratings yet

- SAGE Prime Mass Flow MeterDocument2 pagesSAGE Prime Mass Flow MeterLeo@spNo ratings yet

- Advanced High-Tech Coil Winding SolutionsDocument8 pagesAdvanced High-Tech Coil Winding Solutionsswapnil kapaseNo ratings yet

- Ds Irg 4000 Baur En-GbDocument3 pagesDs Irg 4000 Baur En-Gbrupesh kumarNo ratings yet

- spinNXG-P2Document1 pagespinNXG-P2Mohammd EssaNo ratings yet

- 2-D Electrophoresis SolutionsDocument6 pages2-D Electrophoresis SolutionsAhmet Selim ÇağinNo ratings yet

- Dac 80Document10 pagesDac 80sunhuynhNo ratings yet

- Dvnext Cone/Plate Rheometer: Ametek Brookfield'S Latest Rheometer For Measuring Small Sample SizesDocument2 pagesDvnext Cone/Plate Rheometer: Ametek Brookfield'S Latest Rheometer For Measuring Small Sample Sizeskyaw nyiNo ratings yet

- PTS Slick E Line Brochure 2018 PDFDocument5 pagesPTS Slick E Line Brochure 2018 PDFfelipeNo ratings yet

- Sulky DX20-30 ENDocument24 pagesSulky DX20-30 ENAleksandar DautovicNo ratings yet

- Pressure Gravity Tool DatasheetDocument1 pagePressure Gravity Tool DatasheetHendri HaryantoNo ratings yet

- 1D-miniLDV Brochure 201611 PDFDocument1 page1D-miniLDV Brochure 201611 PDFmanikandan RNo ratings yet

- Edb 1590910 GBR enDocument7 pagesEdb 1590910 GBR enwahyualprianto.fgiNo ratings yet

- DS - Cable Fault Location System - Syscompact 4000 - BAUR - En-GbDocument3 pagesDS - Cable Fault Location System - Syscompact 4000 - BAUR - En-GbTri Ari WibowoNo ratings yet

- Model 760P: Dual Channel Hour Meter & Maintenance Monitor ModuleDocument3 pagesModel 760P: Dual Channel Hour Meter & Maintenance Monitor ModuleEwerton BianchiNo ratings yet

- LL Vortexmaster en C PRDocument2 pagesLL Vortexmaster en C PRjmmwaterdogNo ratings yet

- DMM 7510 7 - Digit Graphical Sampling Multimeter: DatasheetDocument27 pagesDMM 7510 7 - Digit Graphical Sampling Multimeter: DatasheetFranco MelidoniNo ratings yet

- Tool Specifications Pulsed Neutron NeutronDocument2 pagesTool Specifications Pulsed Neutron NeutronCarlos Alberto Aguilera MendezNo ratings yet

- PNG7000 Datasheet REV2Document4 pagesPNG7000 Datasheet REV2meinalitaminamiNo ratings yet

- Cable Status Indicator MkiiDocument2 pagesCable Status Indicator MkiiMohammed HassanNo ratings yet

- Spesifikasi Detail & Jual Total Station Topcon GTS-102N (081297551995)Document2 pagesSpesifikasi Detail & Jual Total Station Topcon GTS-102N (081297551995)Rina Wahyuni100% (1)

- GTS 102N PDFDocument2 pagesGTS 102N PDFSaepullohNo ratings yet

- Absolute and Gauge Pressure Ceraphant PTP31BDocument3 pagesAbsolute and Gauge Pressure Ceraphant PTP31BAntônio PimentaNo ratings yet

- Hands On 1986 01 02Document100 pagesHands On 1986 01 02RAUL RENDONNo ratings yet

- Bran Luebbe Powermon Natriometer 164 01 GBDocument2 pagesBran Luebbe Powermon Natriometer 164 01 GBaelbaroudy390No ratings yet

- Series 21/22: - Up To 1270 PPR With Marker - Compact 2.25" Cube Shape - Economical DesignDocument4 pagesSeries 21/22: - Up To 1270 PPR With Marker - Compact 2.25" Cube Shape - Economical DesigndgfjkhNo ratings yet

- Image StabilizationDocument3 pagesImage StabilizationDiego CNo ratings yet

- Data Sheet Mercury 1500VDocument9 pagesData Sheet Mercury 1500VBala MuruganNo ratings yet

- RIEGL VQ-580: Waveform Processing Airborne Laser Scanning SystemDocument6 pagesRIEGL VQ-580: Waveform Processing Airborne Laser Scanning System李旭No ratings yet

- Nuts Volts 200601Document100 pagesNuts Volts 200601akounaNo ratings yet

- DS Time Domain Reflectometer IRG 2000 BAUR En-GbDocument2 pagesDS Time Domain Reflectometer IRG 2000 BAUR En-GbgoomiNo ratings yet

- Ds Irg 2000 Baur En-GbDocument2 pagesDs Irg 2000 Baur En-Gbwinston11No ratings yet

- ND20 network parameter meterDocument2 pagesND20 network parameter meterSpardha GuptaNo ratings yet

- PS Platform: Production Logging With ConfidenceDocument6 pagesPS Platform: Production Logging With ConfidenceMelisa JuradoNo ratings yet

- Bae - Artisan DatasheetDocument2 pagesBae - Artisan DatasheetTasnikNo ratings yet

- PROBE Petrol StationDocument9 pagesPROBE Petrol StationΣακης ΜυλωναςNo ratings yet

- DLC CoatingDocument2 pagesDLC CoatingFernando Tapia GibsonNo ratings yet

- R&S NRP-Power-MeterDocument40 pagesR&S NRP-Power-MeterSeven PinkNo ratings yet

- Cat#761r0 Rex451 PDFDocument4 pagesCat#761r0 Rex451 PDFdeepak_singla227No ratings yet

- CS5490 F3Document57 pagesCS5490 F3iqbalNo ratings yet

- Astm Compression Tester Accessories: ADR Advanced Digital ReadoutDocument7 pagesAstm Compression Tester Accessories: ADR Advanced Digital ReadoutJorge SanchezNo ratings yet

- Steam ProDocument2 pagesSteam ProMoisés A. LoboNo ratings yet

- SteamPro PDFDocument2 pagesSteamPro PDFMoisés A. LoboNo ratings yet

- Load-Line 2 digital weight indicator optimized for floor scales, truck scales and industrial applicationsDocument2 pagesLoad-Line 2 digital weight indicator optimized for floor scales, truck scales and industrial applicationskafi piyalNo ratings yet

- Conductivity Sensor 4019Document2 pagesConductivity Sensor 4019Dietrich ThomysNo ratings yet

- HiokiDocument8 pagesHiokibajarlibroselectroNo ratings yet

- AVV-701 Pro Laser Alignment (Brochure)Document2 pagesAVV-701 Pro Laser Alignment (Brochure)Ahmed El-ShafeiNo ratings yet

- d407 Aanderaa Wave and Tide Sensor 5218 5218rDocument2 pagesd407 Aanderaa Wave and Tide Sensor 5218 5218rhoved20185No ratings yet

- Radio MagazineDocument84 pagesRadio MagazineJoão Almeida100% (1)

- P-625 Computerized Welding Machine: CRC-Evans Automatic WeldingDocument4 pagesP-625 Computerized Welding Machine: CRC-Evans Automatic Weldingyasi heeruNo ratings yet

- API SPEC 5CT 10TH 2018 Table C5Document1 pageAPI SPEC 5CT 10TH 2018 Table C5Johanes GigihNo ratings yet

- Elite Magna-Range Bridge PlugDocument2 pagesElite Magna-Range Bridge PlugJohanes GigihNo ratings yet

- API SPEC 5CT 10TH 2018 Table C4Document1 pageAPI SPEC 5CT 10TH 2018 Table C4Johanes GigihNo ratings yet

- Icruise - BrochureDocument2 pagesIcruise - BrochureJohanes GigihNo ratings yet

- Poro MaxDocument9 pagesPoro MaxJohanes GigihNo ratings yet

- FLYER - Drilling Bit Selection Rev1Document2 pagesFLYER - Drilling Bit Selection Rev1Johanes GigihNo ratings yet

- Technology Readiness Level Assessment of Composites RecyclingDocument12 pagesTechnology Readiness Level Assessment of Composites RecyclingJohanes GigihNo ratings yet

- Lawrence&Pasternack Chapter03Document80 pagesLawrence&Pasternack Chapter03Johanes Gigih100% (1)

- Investasi Lampiran1 ManningandRaoulac (2001)Document52 pagesInvestasi Lampiran1 ManningandRaoulac (2001)Johanes GigihNo ratings yet

- Investasi Lampiran1 ManningandRaoulac (2001)Document52 pagesInvestasi Lampiran1 ManningandRaoulac (2001)Johanes GigihNo ratings yet

- Brick AssDocument12 pagesBrick AssInaf NafiNo ratings yet

- Naemi Root Crop Rat Killer ResearchDocument3 pagesNaemi Root Crop Rat Killer ResearchJerome BumagatNo ratings yet

- The Declaration of Alma-Ata at 40Document19 pagesThe Declaration of Alma-Ata at 40Nicole MedinaNo ratings yet

- CA Prostate by Dr. Musaib MushtaqDocument71 pagesCA Prostate by Dr. Musaib MushtaqDr. Musaib MushtaqNo ratings yet

- All India Integrated Test Series: JEE (Main) - 2022Document17 pagesAll India Integrated Test Series: JEE (Main) - 2022Beyond ur imagination100% (1)

- Diagnostic Test Science 5Document7 pagesDiagnostic Test Science 5Rex Russel SalemNo ratings yet

- Aprinnova Simply Solid One Page SummaryDocument2 pagesAprinnova Simply Solid One Page SummaryPatrick FlowerdayNo ratings yet

- ReportDocument1 pageReportRanjan Mano100% (1)

- UG TRB Physical Education Study MaterialDocument17 pagesUG TRB Physical Education Study Materialசண்முக சுந்தரம் குருசாமி100% (2)

- Parasitic Draw ChartDocument9 pagesParasitic Draw Chartlionellin83No ratings yet

- Dycaico Vs SssDocument1 pageDycaico Vs SssGladys Bustria OrlinoNo ratings yet

- PFC Katalog PPDocument128 pagesPFC Katalog PPbmsinghNo ratings yet

- Dating Questions and AnswersDocument13 pagesDating Questions and AnswersFelicia Babrant98% (49)

- ENA SEAL low viscosity dental sealantDocument1 pageENA SEAL low viscosity dental sealantRicky NicholsonNo ratings yet

- Guide To Rural England - ShropshireDocument54 pagesGuide To Rural England - ShropshireTravel Publishing100% (2)

- CH 2Document123 pagesCH 2Caitlin HurleyNo ratings yet

- Directorate of Education, GNCT of Delhi: Term-II (Session 2021-22)Document4 pagesDirectorate of Education, GNCT of Delhi: Term-II (Session 2021-22)Anjli KulshresthaNo ratings yet

- Euphoria Special Edition Rue ScriptDocument24 pagesEuphoria Special Edition Rue ScriptMoldovan EdithNo ratings yet

- Can You Distinguish Neutral, Formal and Informal Among The Following Groups of WordsDocument3 pagesCan You Distinguish Neutral, Formal and Informal Among The Following Groups of WordsВікторія РудаNo ratings yet

- Expert swimming coach with over 30 years experienceDocument3 pagesExpert swimming coach with over 30 years experienceSHAHRUL SHAFIQUE BIN. HAMIDON (KEJORA)No ratings yet

- Crystal-Phase Transitions and Photocatalysis in Supramolecular Scaffolds (2017)Document8 pagesCrystal-Phase Transitions and Photocatalysis in Supramolecular Scaffolds (2017)Louis Peronet VergaraNo ratings yet

- AISC Design Guide 27 - Structural Stainless SteelDocument159 pagesAISC Design Guide 27 - Structural Stainless SteelCarlos Eduardo Rodriguez100% (1)

- Chemical Manual L PDFDocument160 pagesChemical Manual L PDFИгорьNo ratings yet

- Roofing Section Guide for QCS 2014Document5 pagesRoofing Section Guide for QCS 2014Galfarqatar MEPNo ratings yet

- Introduction To CommerceDocument30 pagesIntroduction To Commerceapi-24690719591% (11)

- PNLE III For Care of Clients With Physiologic and Psychosocial AlterationsDocument10 pagesPNLE III For Care of Clients With Physiologic and Psychosocial AlterationsANGELINE PALATINO100% (1)

- Manitowoc Cff-90 PartsDocument13 pagesManitowoc Cff-90 PartsDaren FerreiraNo ratings yet

- KR1100 2Document1 pageKR1100 2Byron Xavier Lima CedilloNo ratings yet

- A Study On Employee Absenteeism at TVS Sundaram Fasteners Limited, Chennai, TamilnaduDocument7 pagesA Study On Employee Absenteeism at TVS Sundaram Fasteners Limited, Chennai, TamilnaduIJRASETPublicationsNo ratings yet

- Standards.: General Fastener Standards BS OrderDocument33 pagesStandards.: General Fastener Standards BS OrderamdarvishvandNo ratings yet