Professional Documents

Culture Documents

Icruise - Brochure

Uploaded by

Johanes GigihOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Icruise - Brochure

Uploaded by

Johanes GigihCopyright:

Available Formats

LEVEL 1 CAPABILITY

DIRECTIONAL | Level

DRILLING | Rotary

2 Capability

Steerable

(if applicable)

Systems

iCruise® Intelligent Rotary

Steerable System

SMART, FAST, AND RELIABLE SYSTEM TO REDUCE WELL

TIME AND PLACE WELLS ACCURATELY

OVERVIEW

Controlling the direction and deviation of the wellbore while drilling is essential for

achieving the planned well trajectory and hitting the target on time and on budget.

In today’s drilling environment, operators are looking for ways to drill longer laterals

faster to lower costs per BOE. The iCruise® intelligent rotary steerable system

(RSS) is automation-enabled for precise steering and accurate well placement,

helping operators to reduce well time through faster drilling, reliable performance,

HAL123554

and predictable results.

HIGH MECHANICAL SPECIFICATIONS ENABLE FASTER DRILLING

Simple and rugged, the iCruise intelligent RSS is engineered with some of the highest FEATURES AND BENEFITS

mechanical specifications on the market, helping operators reduce well time and »» Unrivaled intelligence for accurate

maximize the rate of penetration (ROP) in unconventionals, mature fields, and well placement:

deepwater environments. The modular bottomhole assembly (BHA) can be configured − Six high-speed processors

to drill a long lateral section fast, or to drill a vertical, curve, and lateral in a single run. − Three distinct survey packages

− 1,000 measurements per second

MODERN ELECTRONICS ALLOW FOR ACCURATE STEERING »» High mechanical specifications

AND IMPROVED RELIABILITY (6.75 in. tool size) to reduce well time:

The iCruise intelligent RSS is designed with the latest technology to enable accurate − 400 RPM

well placement and complex downhole calculations. The RSS can accurately steer − 65,000 lbf (28,913 daN) weight on

the well up to 400 RPM while measuring the tool face 1,000 times per second. bit (WOB)

Sophisticated algorithms and proprietary digital control electronics for self-diagnostics − 18,500 ft-lbf (2,508 daN.m) of torque

and self-prognostics monitor the health of the equipment in real time, thus increasing − Doglegs of up to 18°/100 feet (30 meters)

reliability by minimizing repair time, and allowing for fast tool turnarounds. »» Simple, modular BHA design

»» Engineered GeoTech (GTi) drill bit

The RSS is matched with the GeoTech® (GTi) drill bit, engineered in Direction by »» Proprietary self-diagnosis and

Design® (DxD) software to predict the side-cutting efficiency (SCE) of the bit for self-prognosis electronics

improved steerability and drilling performance. »» Real-time vibration management and

directional control

AUTOMATED DRILLING DELIVERS PREDICTABLE RESULTS »» Automation-enabled to reduce risks,

The iCruise intelligent RSS is integrated with automated drilling advisory commands nonproductive time (NPT) and to provide

based on physics-based models, a BHA digital twin, and machine learning from predictable results

real-time data analytics: »» Integrated high performance

measurement-while-drilling system:

»» Steering advisory commands help plan, project the well path, optimize wellbore

− Flow off survey

trajectory, and avoid hazards and collisions

− Azimuthal gamma ray

»» Vibration advisory commands advise on optimal RPM ranges to manage − PWD

downhole vibration and allow for better directional control − Vibrations

By automating the drilling process, Halliburton Sperry Drilling can help operators

maximize asset value through reduced well time, fewer rigsite personnel, lower costs

per BOE, while delivering predictable, dependable, and consistent results.

LEVEL 1 CAPABILITY

DIRECTIONAL | Level

DRILLING | Rotary

2 Capability

Steerable

(if applicable)

Systems

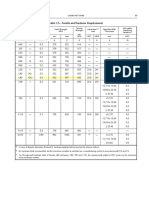

Technical Specifications: iCruise® Intelligent Rotary Steerable System

Nominal Tool OD 4.75 in. (121 mm) 6.75 in. (171 mm) 8.00 in. (203 mm) 9.50 in. (241 mm)

5.875 in. (149 mm) to 8.375 in. (213 mm) to 12.25 in. (311 mm) to 16 in. (406 mm) to

Nominal Hole Size

6.75 in. (171 mm) 9.5 in. (241 mm) 14.75 in. (375 mm) 26 in. (660 mm)

17.5 in. Hole Size: 9.63 in. (244 mm)

Maximum Housing OD 5.125 in. (130 mm) 6.750 in. (171 mm) 8.00 in. (203 mm)

26 in. Hole Size: 11.50 in. (292 mm)

No Flex: 34.9 ft (10.64 m) No Flex: 26.45 ft (8.06 m) No Flex: 26.75 ft (8.15 m)

Length 33.7 ft (10.27 m)

Super Flex: 40.8 ft (12.44 m) Flex/SuperFlex: 34.7 ft (10.59 m) Flex/SuperFlex: 35.0 ft (10.67 m)

Inside Diameter 1.40 in. (36 mm) 1.88 in. (48 mm) 2.530 in. (64 mm) 3.250 in. (82 mm)

No Flex: 1953 lb (886 kg) No Flex: 2,344 lb (1,063 kg) No Flex: 3,800 lb (1,723.6 kg)

Nominal Tool Weight 7,985 lb (3,622 kg)

With Flex: 2115 lb (959 kg) With Flex: 2,759 lb (1,251 kg) With Flex: 4,400 lb (1,995.5 kg)

Top Collar Connection 3-1/2-in. IF Box (with crossover) NC-50 Box API 6-5/8-in. REG Box API 7-5/8 REG Box (with crossover)

Bottom Collar Connection 3-1/2-in. REG Box 4-1/2-in. REG Box API 6-5/8-in. REG Box 7-5/8-in. REG Box

Minimum Steering

0° 0° 0° 0°

Inclination

No Flex: 21°/100 ft (30.5 m)

Maximum Dogleg Severity No Flex: 30°/100 ft (30.5 m) No Flex: 14°/100 ft (30.5 m)

Flex: 21°/100 ft (30.5 m) 14°/100 ft (30.5 m)

(Non-Rotating) SuperFlex: 30°/100 ft (30.5 m) Flex: 14°/100 ft (30.5 m)

SuperFlex: 21°/100 ft (30.5 m)

No Flex: 6°/100 ft (30.5 m)

Maximum Dogleg Severity No Flex: 5°/100 ft (30.5 m) No Flex: 4°/100 ft (30.5 m)

Flex: 12°/100 ft (30.5 m) 3°/100 ft (30.5 m)

Capability SuperFlex: 10°/100 ft (30.5 m) Flex: 8.5°/100 ft (30.5 m)

SuperFlex: 15°/100 ft (30.5 m)

Maximum Drilling or

10,000 ft-lbf (1,356 daN.m) 18,500 ft-lbf (2,508 daN.m) 45,000 ft-lbf (6,100 daN.m) 80,000 ft-lbf (10,846 daN.m)

Operating Rotary Torque

Bit Makeup Torque 8,000 ft-lbf (1,085 daN.m) 16,000 ft-lbf (2,169 daN.m) 43,000 ft-lbf (5,830 daN.m) 68,000 ft-lbf (9,220 daN.m)

Maximum Overpull 340,000 lbf (151,240 daN) 822,684 lbf (365,948 daN) 1,088,000 lbf (483,966 daN) 1,500,000 lbf (667,233 daN)

RPM Range 30–400 RPM 30–400 RPM 30–400 RPM 30–400 RPM

Maximum Weight on Bit 35,000 lbf (15,569 daN) 65,000 lbf (28,913 daN) 100,000 lbf (44,482 daN) 100,000 lbf (44,482 daN)

Maximum RPM 400 RPM 400 RPM 400 RPM 400 RPM

Vibration As Per the Sperry Drilling Logging-While-Drilling (LWD) Vibration Limits (Available Upon Request)

Mud Type Compatible with All Fluid Systems Including: WBM, OBM, SBM, and Silicates.

Maximum Sand Content 1% 1% 1% 1%

Pressure Loss Through

145 psi (275 GPM) 150 psi (575 GPM) 87 psi (@ 900 GPM) 88 psi (@1,500 GPM)

Tool in Water

Maximum LCM Limit TIER-1 50 lb/bbl / TIER-2 84 lb/bbl – WAL-NUTT Medium

®

Maximum Operating

302°F (150 °C) 302°F (150 °C) 302°F (150 °C) 302°F (150 °C)

Temperature

Survival Temperature 329°F (165 °C) 329°F (165 °C) 329°F (165 °C) 329°F (165 °C)

Maximum Pressure 20,000 psi (137.9 MPa) 20,000 psi (137.9 MPa) 20,000 psi (137.9 MPa) 20,000 psi (137.9 MPa)

Power Supply Turbine Turbine Turbine Turbine

Flow Range 150–350 GPM 250–750 GPM 585–1,300 GPM 1,200–1,800 GPM

11–12 kft-lb 30–33 kft-lb 48.5–51.5 kft-lb 77-80 kft-lb

Makeup Torque Range

(1,491–1,627 daN) (4,067.4–4,474.2 daN) (6,576–6,982 daN) (10,440-10,847 daN)

Geo-Span® Downlink Surface pulser provides rapid communication and confirmation via InSite® control screen; independent manual control backup

Service system via pumps and rotary on-off signals rated 10,000 psi (69 MPa) MPa operating H2S service suitable for zones 1, IIA, and T3.

Uplink LWD System LWD System LWD System LWD System

Surface Software InSite® Rig Information Management System

Inclinometer Accuracy ± 0.1° ± 0.1° ± 0.1° ± 0.1°

Inclinometer Span 10 G (x and y) and 5 G (z) 10 G (x and y) and 5 G (z) 10 G (x and y) and 5 G (z) 10 G (x and y) and 5 G (z)

For more information, contact your local Halliburton representative

or visit us on the web at www.halliburton.com

Sales of Halliburton products and services will be in accord solely with the terms and conditions

contained in the contract between Halliburton and the customer that is applicable to the sale.

H013142 11/20 © 2020 Halliburton. All Rights Reserved.

You might also like

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Subsea Tree design considerationsDocument47 pagesSubsea Tree design considerationsWilliam EvansNo ratings yet

- Procedure to pick up 12 1⁄4Document2 pagesProcedure to pick up 12 1⁄4adrsneadNo ratings yet

- Evo-Trieve® EB0 Retrievable Straddle - HalliburtonDocument2 pagesEvo-Trieve® EB0 Retrievable Straddle - HalliburtonYovaraj KarunakaranNo ratings yet

- Top Drive - Lessons LearnedDocument8 pagesTop Drive - Lessons LearnedRuslan ZakirovNo ratings yet

- 09 Icruise Best Practice v2Document45 pages09 Icruise Best Practice v2Nelson RamirezNo ratings yet

- Technical and Economic Evaluation of Compact Drill Rigs for Deep Geothermal WellsDocument82 pagesTechnical and Economic Evaluation of Compact Drill Rigs for Deep Geothermal WellsKolawole Adisa100% (2)

- 013 Wireline Tool StringDocument1 page013 Wireline Tool StringSoon Han CheanNo ratings yet

- Archer Modular TractorDocument2 pagesArcher Modular TractorYovaraj KarunakaranNo ratings yet

- JarPro Jarring Analysis SoftwareDocument4 pagesJarPro Jarring Analysis Softwareeleceron7919No ratings yet

- Pipe Body Performance PropertiesDocument118 pagesPipe Body Performance Propertieshamid nobakhtNo ratings yet

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDocument8 pagesBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNo ratings yet

- Velesto Energy Berhad Naga 3Document2 pagesVelesto Energy Berhad Naga 3فؤاد ابوزيدNo ratings yet

- SLB PowerPak Handbook 2004Document216 pagesSLB PowerPak Handbook 2004casda73No ratings yet

- Kuster K10 Gauge Software ManualDocument12 pagesKuster K10 Gauge Software Manualfarhad2004No ratings yet

- Dynomax Operations Manual - Third Edition - 3!22!2019Document360 pagesDynomax Operations Manual - Third Edition - 3!22!2019Chinyere NkereNo ratings yet

- Rig Components & Equipment ReviewDocument19 pagesRig Components & Equipment Reviewking ghNo ratings yet

- 14P220 Triplex Mud Pump Spec SheetDocument1 page14P220 Triplex Mud Pump Spec SheetWHWENNo ratings yet

- IADC DDR Codes 2 13 2019Document4 pagesIADC DDR Codes 2 13 2019txcrudeNo ratings yet

- Cement Retainer 103387896 PDFDocument1 pageCement Retainer 103387896 PDFhitesh kumarNo ratings yet

- Auto DrillerDocument2 pagesAuto DrillersrpadronNo ratings yet

- Santrol Pocket Guide InternationalDocument2 pagesSantrol Pocket Guide Internationalintoyou2007No ratings yet

- PPS Catalogue 2016v4 (English)Document44 pagesPPS Catalogue 2016v4 (English)Kamry AhmadNo ratings yet

- West Oberon 87263Document3 pagesWest Oberon 87263Arturo Treviño MedinaNo ratings yet

- QWS2500 SD, Or67658, Line 1 - Service ManualsDocument108 pagesQWS2500 SD, Or67658, Line 1 - Service ManualsmaciekziebaNo ratings yet

- Rs User ManualDocument332 pagesRs User ManualShafar FareethNo ratings yet

- Advanced Subsea Engineer Program (ASSEP) : Lloyd's Register Energy - Drilling Training AcademyDocument2 pagesAdvanced Subsea Engineer Program (ASSEP) : Lloyd's Register Energy - Drilling Training AcademyShraddhanand More100% (1)

- Top Drive Electric ManualDocument97 pagesTop Drive Electric ManualJohancy Cordero100% (1)

- Parker Drilling Rig 258Document2 pagesParker Drilling Rig 258Nathan Thillai100% (2)

- Presentation2 Rotary Steerable System and Deepwater Operations BSU Symposium 19 Oct 2019Document82 pagesPresentation2 Rotary Steerable System and Deepwater Operations BSU Symposium 19 Oct 2019Lemuel Violante100% (1)

- BOP Dimensions 13stackDocument3 pagesBOP Dimensions 13stackSasan AbbasiNo ratings yet

- MPD Brochure BeyondDocument10 pagesMPD Brochure BeyondIRLANDA100% (1)

- Concept of Operations For Directional Drilling On AmphionDocument11 pagesConcept of Operations For Directional Drilling On AmphionTaymoor MalekNo ratings yet

- 6923 PDFDocument5 pages6923 PDFMEHDINo ratings yet

- GTSC Simulator Profile Offers 10 Training OptionsDocument14 pagesGTSC Simulator Profile Offers 10 Training OptionsDurga PrasadNo ratings yet

- Production Dual Caliper (X-Y) : DescriptionDocument1 pageProduction Dual Caliper (X-Y) : DescriptionKarim IsmailNo ratings yet

- Well CommanderDocument8 pagesWell Commanderice_PLNo ratings yet

- Drilling SupervisorDocument2 pagesDrilling Supervisoreng7mohamed7hashimNo ratings yet

- KB200C Drill Specifications and Manufacturer ContactDocument8 pagesKB200C Drill Specifications and Manufacturer ContactMarcel StavreNo ratings yet

- Detail Specification of Rig Sagar Gaurav: Ongc Videsh Ltd. Out Line Drilling Unit SpecificationDocument25 pagesDetail Specification of Rig Sagar Gaurav: Ongc Videsh Ltd. Out Line Drilling Unit SpecificationMohitNo ratings yet

- 10017Document2 pages10017Alex RamirezNo ratings yet

- Case Hole PDFDocument11 pagesCase Hole PDFyazidNo ratings yet

- W5D2 - DE - Introduction To Well Trajectory PlanningDocument54 pagesW5D2 - DE - Introduction To Well Trajectory PlanningFernandoNo ratings yet

- Packer Testing Program Design and Management: August 2013Document7 pagesPacker Testing Program Design and Management: August 2013wily784No ratings yet

- Managed Pressure Drilling Modeling & Simulation (A Case Study)Document8 pagesManaged Pressure Drilling Modeling & Simulation (A Case Study)Mejbahul SarkerNo ratings yet

- Powerstroke Drilling Jar: Instruction Manual 4250Document24 pagesPowerstroke Drilling Jar: Instruction Manual 4250Foros IscNo ratings yet

- AXON 005 Drilling Products Top Drives BrochureDocument16 pagesAXON 005 Drilling Products Top Drives BrochureJuan Pablo Villazon Richter100% (1)

- Benefits of Top Drive DrillingDocument7 pagesBenefits of Top Drive DrillingAndrea Pappada'No ratings yet

- Reducing Nonproductive Time: Pipe Recovery ServicesDocument8 pagesReducing Nonproductive Time: Pipe Recovery ServicesWaleed Barakat Maria100% (1)

- Drillmec HH220 Rig Package Technical SpecsDocument2 pagesDrillmec HH220 Rig Package Technical SpecsFernando OstoichNo ratings yet

- Specs ZJ 30 2Document1 pageSpecs ZJ 30 2fatehul alamNo ratings yet

- Wire Line ch-2Document35 pagesWire Line ch-2Ammar HrzNo ratings yet

- Cougar DLLG Solutions FaqDocument5 pagesCougar DLLG Solutions FaqLenis CeronNo ratings yet

- Blackstar II Dual Telemetry MWD Tool Spec Sheet PDFDocument4 pagesBlackstar II Dual Telemetry MWD Tool Spec Sheet PDFDani HpNo ratings yet

- Efficient Drilling Techniques for Geothermal Projects in KenyaDocument20 pagesEfficient Drilling Techniques for Geothermal Projects in Kenyazouke2002No ratings yet

- Wireline 3Document154 pagesWireline 3William EvansNo ratings yet

- H10 SpecificationsDocument2 pagesH10 SpecificationsBorysNo ratings yet

- 245 - 41000e Casing Drive System WebDocument8 pages245 - 41000e Casing Drive System WebBepdj100% (1)

- Globaltops Wellsite Reference BookDocument438 pagesGlobaltops Wellsite Reference BookJho DiNo ratings yet

- Programmable Hydraulic Cutter APC-61 SB: APC-61IISB Major Specifications Machine DimensionsDocument4 pagesProgrammable Hydraulic Cutter APC-61 SB: APC-61IISB Major Specifications Machine DimensionsCh StoneNo ratings yet

- API SPEC 5CT 10TH 2018 Table C4Document1 pageAPI SPEC 5CT 10TH 2018 Table C4Johanes GigihNo ratings yet

- Elite Magna-Range Bridge PlugDocument2 pagesElite Magna-Range Bridge PlugJohanes GigihNo ratings yet

- API SPEC 5CT 10TH 2018 Table C5Document1 pageAPI SPEC 5CT 10TH 2018 Table C5Johanes GigihNo ratings yet

- Poro MaxDocument9 pagesPoro MaxJohanes GigihNo ratings yet

- (Brochure) Live - DPNDocument1 page(Brochure) Live - DPNJohanes GigihNo ratings yet

- Lawrence&Pasternack Chapter03Document80 pagesLawrence&Pasternack Chapter03Johanes Gigih100% (1)

- FLYER - Drilling Bit Selection Rev1Document2 pagesFLYER - Drilling Bit Selection Rev1Johanes GigihNo ratings yet

- Technology Readiness Level Assessment of Composites RecyclingDocument12 pagesTechnology Readiness Level Assessment of Composites RecyclingJohanes GigihNo ratings yet

- Investasi Lampiran1 ManningandRaoulac (2001)Document52 pagesInvestasi Lampiran1 ManningandRaoulac (2001)Johanes GigihNo ratings yet

- Investasi Lampiran1 ManningandRaoulac (2001)Document52 pagesInvestasi Lampiran1 ManningandRaoulac (2001)Johanes GigihNo ratings yet

- GE Fuji AF 300 VFD ManualDocument44 pagesGE Fuji AF 300 VFD ManualAnderson GonçalvesNo ratings yet

- Tips For Use Cube Uk 1Document4 pagesTips For Use Cube Uk 1LucasNo ratings yet

- Cisco System Managing de Supply ChainDocument7 pagesCisco System Managing de Supply ChainNorberto VarasNo ratings yet

- Replacement AlgoDocument13 pagesReplacement AlgoTejaswi SuryaNo ratings yet

- Android Log Events CapturedDocument16 pagesAndroid Log Events Capturedsaqlain aNo ratings yet

- HP 1980A Operations ManualDocument522 pagesHP 1980A Operations ManualKyle NahasNo ratings yet

- EyeQueue User Guide Version 8.0.8Document318 pagesEyeQueue User Guide Version 8.0.8Jeff EdstromNo ratings yet

- Oppo Pricelist As of July 01, 2021Document1 pageOppo Pricelist As of July 01, 2021Sophia Jane SabaterNo ratings yet

- Airline Benchmarking and Performance ImprovementDocument27 pagesAirline Benchmarking and Performance ImprovementJatin ParmarNo ratings yet

- Backup RelayDocument3 pagesBackup RelayTinashe MupayaNo ratings yet

- Automatic Weather StationDocument8 pagesAutomatic Weather StationMyat Tun OoNo ratings yet

- CBR500R Owner'S Manual: 32MKPF10 00X32-MKP-F100Document134 pagesCBR500R Owner'S Manual: 32MKPF10 00X32-MKP-F100edwinNo ratings yet

- Dolphin Wallpapers On WallpaperDogDocument1 pageDolphin Wallpapers On WallpaperDogHannah Ding (Qtps)No ratings yet

- Brocade ICX 6610 Switches: Chassis-Like Capabilities in A Stackable Form FactorDocument11 pagesBrocade ICX 6610 Switches: Chassis-Like Capabilities in A Stackable Form FactorjscerNo ratings yet

- Assessment of Small Reciprocating Engine Manufacturers and Generator Set PackagersDocument66 pagesAssessment of Small Reciprocating Engine Manufacturers and Generator Set PackagersAnonymous zfmlsb2GjA100% (1)

- Features: CC CC IN PeakDocument3 pagesFeatures: CC CC IN PeakRobson DiasNo ratings yet

- LTE Planning Optimization FeaturesDocument6 pagesLTE Planning Optimization FeaturessgrajNo ratings yet

- Lampiran SpesifikasiDocument7 pagesLampiran SpesifikasiLede HidrofarmNo ratings yet

- Overall Equipment EffectivenessDocument12 pagesOverall Equipment EffectivenessAbdul RashidNo ratings yet

- Lycoming Engine Order Form: (If Different)Document2 pagesLycoming Engine Order Form: (If Different)Michel LefebvreNo ratings yet

- Specifications For Concrete Construction ACI 301-20: Field Reference ManualDocument6 pagesSpecifications For Concrete Construction ACI 301-20: Field Reference ManualIRFAN NAZIR50% (2)

- Battery StorageDocument46 pagesBattery StorageKishore MuluguNo ratings yet

- Print Purch Order-Foreign Lang. - PO23000201Document1 pagePrint Purch Order-Foreign Lang. - PO23000201Aicha AbounasrNo ratings yet

- JSP: Overview of lifecycle, architecture, elements, implicit objects and exception handlingDocument73 pagesJSP: Overview of lifecycle, architecture, elements, implicit objects and exception handlingRushikesh YadavNo ratings yet

- TSA 1000XEn112 PDFDocument83 pagesTSA 1000XEn112 PDFJoseph BoshehNo ratings yet

- Simulation of SOI PIN Diode for Space Radiation DetectionDocument12 pagesSimulation of SOI PIN Diode for Space Radiation Detectionzuraixoz7967No ratings yet

- Chapter - 00 Course Policy & Organization-1Document7 pagesChapter - 00 Course Policy & Organization-1Minjae LeeNo ratings yet

- A Presentation On: Status of Construction Procedures of Nepal & E-Bidding For Contract DocumentationDocument27 pagesA Presentation On: Status of Construction Procedures of Nepal & E-Bidding For Contract DocumentationShankar KhanalNo ratings yet

- Service Bulletin: PurposeDocument3 pagesService Bulletin: PurposejussmeeeNo ratings yet

- CR 300Document128 pagesCR 300Francisco José Fontelles ObelenisNo ratings yet