Professional Documents

Culture Documents

Electro-Pneumatic Intersystem TRANSMITER Type A201: Technical Details

Uploaded by

ANGEL FLORESOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electro-Pneumatic Intersystem TRANSMITER Type A201: Technical Details

Uploaded by

ANGEL FLORESCopyright:

Available Formats

ELECTRO-PNEUMATIC INTERSYSTEM

TRANSMITER type A201

ELECTRO-PNEUMATIC INTERSYSTEM TRANSMITTER type A201 IS

USED FOR CONVERSION THE STANDARD ANALOGUE ELECTRIC

SIGNAL ON STANDARD PNEUMATIC SIGANL AT RANGE 20...kPa OR

60..300kPa IN AUTOMATIC REGULATION SYSTEMS OR CONTROL

INDUSTRY SYSTEMS.

THIS TRANSMITTER POSSESES COOPERATION THE ELECTRONIC

AUTOMATION SYSTEMS WITH EXECUTIVE ELEMENTS.

THE TRANSMITTER’S WORKING IS BASED ON COMPARISON

MOMENT RULE OF FORCE MADE BY COIL WHICH WAS PUT IN

CONSTANT MAGNETIC FIELD PROPORTIONAL FOR INPUT SIGNAL,

WITH MOMENT OF FORCE MADE BY METALIC PRESSURE * pressure voltage 140±14 kPa

CAPSULE OF FEEDBACK, WHERE THE PNEUMATIC OUTPUT * protection degree IP 54

SIGNAL IS SUPPLIED. * spark-safety version acc. to ATEX directive

CHANGE OF DIRECT OF TRANSMITTER WORKING (”DIRECTLY” OR

“INVERSELY” WORKING) MIGHT BE REALIZED BY CHANGE

CURRENT FLOW DIRECTION BY COIL AND CORRECTION OF

TRANSMITTER REGULATION.

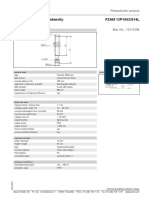

TECHNICAL DETAILS

- input standard signal 4...20 mA; 0...20 mA

- input inversion signal 20...4 mA; 20...0 mA

- output signal 20...100 kPa; 60...300 kPa

- pressure supply 140 ±14 kPa; 400 ±40 kPa

- input resistance ≤250W

- basis mistake 0,6%

- hysteresis 0,25%

- additional mistakes:

from changes of pressure supply by 10% max 0,5%

from change of ambient temperature max 0,8% on each 10OC

form vibrations in range:

10 ... 60 Hz, amplitude<0,35 mm

60 ... 500 Hz, acceleration 5g max 1%

form reaction the magnetic constant and commutative field

at intensity 100 A/m, 50 Hz (acc. to PN-EN 6100-4-8:1998) max 0,5 permissible basis mistake

form disturbances radiated magnetic field

at radio frequency 10 V/m., at frequency in range

80 MHz do 1 GHz (acc. to PN-EN 6100-4-3:2002) max 0,5 permissible basis mistake

from series of quick transient states made by voltage

at peak value 2 KV (acc. To PN-EN 6100-4-4:2002) max 0,5 permissible basis mistake

from surge at voltage 0,5 KV (acc. to PN-EN 6100-4-5:1998) max 0,5 permissible basis mistake

- working position optionally, subject to 0 correction in choosed position

- own air consumption max 0,35 kg/h at pz= 140 kPa

- max rate 7,5 kg/h at pz= 140 kPa

- spark-safety characteristic II 2 G EExia IICT6/T5/T4

- certificate KDB 04 ATEX 026X

- conditions of using in explosion-risk zone:

1. Electro-pneumatic system transmitter type A201-A2XX-XX-XX, ... may cooperate only with spark-safety circuit at parameters:

U1 = 28 V DC, I1 = 100 mA, P1 = 0,7 W

2. Transmitter connection with cooperating devices should be made by separate conductors pair or by cable, which OLNY spark-

safety circuits will be connected. L and C parameters of external circuit should be the same like for device cooperates with transmitter.

3. Acceptable ambient temperature - depending on temperature class

Temperature class of gases and steam T6 T5 T4

Acceptable ambient temperature(Ta) -400C ... +500C -400C ... +650C -400C ... +700C

- housing protection degree IP54 acc. to PN-EN 60529:2002

- mass 1,1 kg

- connectors:

Electric screw clamps for transmitter at diameter to 2,5 mm2

Pneumatic threaded holes St. B1/8” or connectors

CONTROLMATICA ZAP-PNEFAL Sp. z o.o. Page 1 of 2

ul. Krotoszynska 35; PL-63-400 Ostrow Wlkp., Poland

tel.: +48627372250, fax: +48627372724, e-mail: controlmatica@controlmatica.com.pl

www.controlmatica.com.pl

Electro-pneumatic intersystem transmitter type A201

WORKING CONDITIONS

Electro-pneumatic system transmitter type A201 is designed for working

in industry condition in little roof places, booths in the field, not heated and

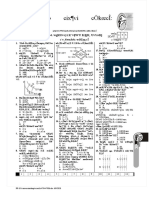

closed rooms or in control room base in conditions: DIMENSION DRAWINGS

- ambient temperature -40 0C ... +70 0C 57 .s

otwle 70

- relative humidity 100% 22 oh

9,5 6,5 8-

- sinusoidal vibrations 10 ... 60 Hz, amplitude< 0,35 mm,

8

60 ... 500 Hz, acceleration 5g

(class VH6 acc. to PN-EN 60654:1996)

- working position optionally, subject to 0 correction 14

in chosed position

- working medium air without dust, oil and aggressive pollution,

125

146

at relative humidity when dew temperature

should be lesser than ambient temperature

at the value not lesser than 10OC (10OK)

(PN-EN 60654-2:1999)

21 6,5

35 28.5

55 30 33

104 84

ORDERING METHOD

A201- Electro-pneumatic intersystem transmitter

CODE1 VERSION

1 standard

2 spark-safety with certificate ATEX II 2 G EExia IICT6/T5/T4

CODE 2 INPUT SIGNAL

0 4 ... 20 mA

1 0 ... 20 mA

5 20 ...4 mA (inversion signal)

6 20 ... 0 mA (inversion signal)

CODE 3 PNEUMATIC CONECTORS

1 connectors for copper or polyethylene pipes f

6x1 mm

OPTIONS:

CODE 4 INPUT OF ELECTRIC CABLE

-D1 standard cable key type M20x1,5 (metallic type covered zinc

coating - for standard and spark-safety version

-D2 polyamide cable key type M20x1,5 (for standard version)

-D3 polyamide cable key type M20x1,5 (for spark-safety version)

CODE 5 OUTPUT SIGNAL

-W1 range from 20...100 kPa

-W2* range from 60...300 kPa

* it doesn’t available in spark-safety Ex version

A201-A 1 0 1 - D1 EXAMPLE OF TRANSMITTER DENOTATION

REMARK: other versions of transmitter type A201 available aftr agreement with manufacturer

Example of ordering:

Electro-pneumatic intersystem transmitter type A201 in standard version with input signal 4...20 mA,

with connector for pipe f

6x1 mm with standard - metallic cable key and output signal from 20 ... 100 kP has denotation:

Electro-pneumatic system transmitter type A201-101 -D1-W1

The right of introducing design changes in the product, without deteriorating of its operation parameters, is reserved.

CONTROLMATICA ZAP-PNEFAL Sp. z o.o. Page 2 of 2

ul. Krotoszynska 35; PL-63-400 Ostrow Wlkp., Poland January 2012

tel.: +48627372250, fax: +48627372724, e-mail: controlmatica@controlmatica.com.pl

www.controlmatica.com.pl

You might also like

- Quantum SMR3000W SpecsDocument6 pagesQuantum SMR3000W Specsihsanju100% (1)

- Three-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ds-PmDocument12 pagesThree-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ds-PmSalaar AnsarNo ratings yet

- Abb Kent Taylor 504-505-506 TDocument6 pagesAbb Kent Taylor 504-505-506 TJulio RodriguezNo ratings yet

- sm2000 GBDocument4 pagessm2000 GBRikky ChaniagoNo ratings yet

- PM100 Series: FeaturesDocument2 pagesPM100 Series: FeaturesNattawut ZuesatNo ratings yet

- Pressure Transmitters: Type C-10Document6 pagesPressure Transmitters: Type C-10KaungMyint MyatNo ratings yet

- Zelio Control Relays - RM22TR33Document7 pagesZelio Control Relays - RM22TR33Dominic DomNo ratings yet

- Zelio Control Relays - RM22TR31-1Document3 pagesZelio Control Relays - RM22TR31-1GCN.MauricioNo ratings yet

- Schneider 3P Control Relay RM22TR33Document7 pagesSchneider 3P Control Relay RM22TR33Manuel RejanoNo ratings yet

- Zelio Control Relays - RM22TR33Document3 pagesZelio Control Relays - RM22TR33Tiago BalbinoNo ratings yet

- DRP 480 SpecDocument2 pagesDRP 480 SpecvrallamcitoNo ratings yet

- ABB A63-30-00 230-240V 50Hz - 240-260V 60Hz - Block Contactors - Contactors (Control Products)Document3 pagesABB A63-30-00 230-240V 50Hz - 240-260V 60Hz - Block Contactors - Contactors (Control Products)khairalla mohamedNo ratings yet

- WLC550 Industrial: Electrical SpecificationsDocument8 pagesWLC550 Industrial: Electrical SpecificationsNigel DsouzaNo ratings yet

- 320W Quad Output With PFC Function: SeriesDocument2 pages320W Quad Output With PFC Function: SeriesJulio César GuardiolaNo ratings yet

- Conlab Tansduser DatasheetDocument3 pagesConlab Tansduser Datasheetירדן רובינשטייןNo ratings yet

- Zelio Control Relays - RM22TU23Document7 pagesZelio Control Relays - RM22TU23aehque04No ratings yet

- Zelio Control Relays - RM22TU23Document7 pagesZelio Control Relays - RM22TU23abdul haseebNo ratings yet

- LED For Gas StationDocument3 pagesLED For Gas StationyahyaabedelrahmanNo ratings yet

- Zelio Control Relay RM4TR35Document7 pagesZelio Control Relay RM4TR35Abdul Majeed SurmawalaNo ratings yet

- Lufft Power Supply 24V 4ADocument2 pagesLufft Power Supply 24V 4AJose Luis IglesiasNo ratings yet

- AD694Document12 pagesAD694Asghar AliNo ratings yet

- Eaton 169234 DC1 12011NB A20N en - GBDocument7 pagesEaton 169234 DC1 12011NB A20N en - GBCele GomezNo ratings yet

- G2ba400v12a-4-20ma enDocument2 pagesG2ba400v12a-4-20ma enStipe CorakNo ratings yet

- Auxiliary RelayDocument5 pagesAuxiliary RelayVijayaganthaan VisvanatthanNo ratings yet

- DDP400 Sealed :: ROAL Living EnergyDocument8 pagesDDP400 Sealed :: ROAL Living EnergyroalscribdNo ratings yet

- InteliDrive Lite FPC Datasheet - 4Document4 pagesInteliDrive Lite FPC Datasheet - 4widiNo ratings yet

- Fisa TehnicaDocument7 pagesFisa TehnicaGherman GabrielNo ratings yet

- K8ab-Ph Ca csm1996 PDFDocument8 pagesK8ab-Ph Ca csm1996 PDFnl vinay kumarNo ratings yet

- Schneider Electric - Harmony-Control-Relays - RM4TR32Document10 pagesSchneider Electric - Harmony-Control-Relays - RM4TR32FOXX AHMNo ratings yet

- LCM 3000Document10 pagesLCM 3000Sina MehrabafiNo ratings yet

- MFA160 :: ROAL Living EnergyDocument4 pagesMFA160 :: ROAL Living EnergyroalscribdNo ratings yet

- Zelio Control Relays - RM22TR33Document7 pagesZelio Control Relays - RM22TR33SIVARAMANJAGANATHANNo ratings yet

- Fuente DC 440/24vdcDocument3 pagesFuente DC 440/24vdcINGWIRBONo ratings yet

- DC-DC Converter DS - T30 - 161005Document3 pagesDC-DC Converter DS - T30 - 161005AndreyNo ratings yet

- GNT400Document4 pagesGNT400Asad AhmedNo ratings yet

- 619 Amodel 619Document119 pages619 Amodel 619pNo ratings yet

- Datasheet DieboldDocument5 pagesDatasheet Dieboldconta enemNo ratings yet

- UHP 2500 Spec PDFDocument7 pagesUHP 2500 Spec PDFCristian BandilaNo ratings yet

- HBG 240 Spec 806072 PDFDocument10 pagesHBG 240 Spec 806072 PDFJuan Manuel JorqueraNo ratings yet

- Beck Climair - DatasheetDocument4 pagesBeck Climair - Datasheetboukhalfa.oman.muscatNo ratings yet

- MINT1400A: Medical - Universal Input Power SupplyDocument3 pagesMINT1400A: Medical - Universal Input Power SupplyRubén Pérez ArmasNo ratings yet

- 60W Triple Output Switching Power Supply: SeriesDocument3 pages60W Triple Output Switching Power Supply: SeriesMktg ChiragelectronicsNo ratings yet

- RM4TR32 DatasheetDocument9 pagesRM4TR32 DatasheetMinh HùngNo ratings yet

- JW - SF6 Gas LBS Catalog - 200210 (S)Document6 pagesJW - SF6 Gas LBS Catalog - 200210 (S)HopNo ratings yet

- SPKT0031D0Document2 pagesSPKT0031D0Rafael CruzNo ratings yet

- Zelio Control - RM22TR33Document7 pagesZelio Control - RM22TR33Mohamed ElBadryNo ratings yet

- Limit-Value Switch For Temperature Thermistor Input (NTC)Document2 pagesLimit-Value Switch For Temperature Thermistor Input (NTC)AlexanderNo ratings yet

- LaboomDocument4 pagesLaboomAndrei SpiridonNo ratings yet

- HBG-60P: 60W Constant Current Mode LED DriverDocument5 pagesHBG-60P: 60W Constant Current Mode LED DriverJuan Manuel JorqueraNo ratings yet

- Zelio Control Relays - RM35JA32MTDocument7 pagesZelio Control Relays - RM35JA32MTN_LocusNo ratings yet

- G2ba480v12a-010v enDocument2 pagesG2ba480v12a-010v enStipe CorakNo ratings yet

- A1500 Flyer E3 PDFDocument2 pagesA1500 Flyer E3 PDFrzgarNo ratings yet

- AS1440 Smart MeterDocument2 pagesAS1440 Smart MeterHamza AliNo ratings yet

- LP1100D 12mdaDocument1 pageLP1100D 12mdalucasmosnaNo ratings yet

- Zelio Control RM35JA32MRDocument7 pagesZelio Control RM35JA32MRVinh NguyenNo ratings yet

- 240W Single Output Switching Power Supply With PFC: SeriesDocument3 pages240W Single Output Switching Power Supply With PFC: SeriesMartinNo ratings yet

- DFI Power Supply UK - HIT - HVP103-120085 - DSDocument2 pagesDFI Power Supply UK - HIT - HVP103-120085 - DSjsw5mccmfgNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- KRAL Electronics BEM 300 y BEM PDF Descarga GratuitaDocument12 pagesKRAL Electronics BEM 300 y BEM PDF Descarga GratuitaANGEL FLORESNo ratings yet

- S CompDocument2 pagesS CompANGEL FLORESNo ratings yet

- Apr 2000galwDocument3 pagesApr 2000galwANGEL FLORESNo ratings yet

- Apr 2000GDocument3 pagesApr 2000GANGEL FLORESNo ratings yet

- PM 22Document1 pagePM 22ANGEL FLORESNo ratings yet

- Flanged Seals With Extended Diaphragm S-TDocument2 pagesFlanged Seals With Extended Diaphragm S-TANGEL FLORESNo ratings yet

- Chemical Flanged Seals With Flush Diaphragm S-CH: Diaphragm Seal Dimensions Acc. To DIN EN1092-1Document2 pagesChemical Flanged Seals With Flush Diaphragm S-CH: Diaphragm Seal Dimensions Acc. To DIN EN1092-1ANGEL FLORESNo ratings yet

- Flanged Seals With Flush Diaphragm S-PDocument2 pagesFlanged Seals With Flush Diaphragm S-PANGEL FLORESNo ratings yet

- Differential Pressure Transmitter For Low Ranges PR - G E50Document2 pagesDifferential Pressure Transmitter For Low Ranges PR - G E50ANGEL FLORESNo ratings yet

- LLC Series Conductivity Controller: Installation and Operation BulletinDocument2 pagesLLC Series Conductivity Controller: Installation and Operation BulletinANGEL FLORESNo ratings yet

- Water Leak Detectors: Battery or External Powered, SPST or DPDT RelaysDocument1 pageWater Leak Detectors: Battery or External Powered, SPST or DPDT RelaysANGEL FLORESNo ratings yet

- Compact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%Document1 pageCompact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%ANGEL FLORESNo ratings yet

- Conductivity Controller: Single Point or Differential Level Service, Compact Size, Up To 6 Ft. (1.82 M) ProbesDocument1 pageConductivity Controller: Single Point or Differential Level Service, Compact Size, Up To 6 Ft. (1.82 M) ProbesANGEL FLORESNo ratings yet

- 2261 19097 UsDocument2 pages2261 19097 UsANGEL FLORESNo ratings yet

- 100 MM Vane Thermo-Anemometer Test InstrumentDocument1 page100 MM Vane Thermo-Anemometer Test InstrumentANGEL FLORESNo ratings yet

- 2255 19090 UsDocument2 pages2255 19090 UsANGEL FLORESNo ratings yet

- Danfoss FC102 HVAC Data SheetDocument2 pagesDanfoss FC102 HVAC Data SheetANGEL FLORESNo ratings yet

- Reduce Energy Costs With Intelligent Heat ManagementDocument2 pagesReduce Energy Costs With Intelligent Heat ManagementANGEL FLORESNo ratings yet

- Baumer Laser Distance Sensors EN 20180101 TRDocument3 pagesBaumer Laser Distance Sensors EN 20180101 TRANGEL FLORESNo ratings yet

- Simply Intelligent Checking and ControllingDocument4 pagesSimply Intelligent Checking and ControllingANGEL FLORESNo ratings yet

- Economical Pressure Switch: Vacuum and Compound Ranges Available, Adjustable Set PointDocument1 pageEconomical Pressure Switch: Vacuum and Compound Ranges Available, Adjustable Set PointANGEL FLORESNo ratings yet

- FZAM 12P1002/S14L Diffuse Sensors With Intensity DifferenceDocument1 pageFZAM 12P1002/S14L Diffuse Sensors With Intensity DifferenceANGEL FLORESNo ratings yet

- Apc 2000alw PDFDocument5 pagesApc 2000alw PDFANGEL FLORESNo ratings yet

- Fzam 12 Diffuse Sensors With Intensity DifferenceDocument1 pageFzam 12 Diffuse Sensors With Intensity DifferenceANGEL FLORESNo ratings yet

- Lista de Fluidos para Las ValvulasDocument2 pagesLista de Fluidos para Las ValvulasANGEL FLORESNo ratings yet

- Pengenalan Portal ScrapperDocument18 pagesPengenalan Portal Scrapperzaki rafifNo ratings yet

- 1-Intro and First UnitDocument39 pages1-Intro and First Unitsahale sheraNo ratings yet

- Installation, Operation, and Maintenance Manual: 0 Series PumpDocument31 pagesInstallation, Operation, and Maintenance Manual: 0 Series PumpTim WorkmanNo ratings yet

- Roger Boscovich - The Founder of Modern Science: September 2015Document92 pagesRoger Boscovich - The Founder of Modern Science: September 2015Shann Aurelle RipaldaNo ratings yet

- Power System Analysis and Design 6th Edition Glover Test BankDocument14 pagesPower System Analysis and Design 6th Edition Glover Test BankMatthewGreenefgjtb100% (22)

- Chapter 1 NotesDocument12 pagesChapter 1 NotesLim Zhi EnNo ratings yet

- A-Isometer® Irdh275: Ground Fault Monitor / Ground Fault Relay For Ungrounded AC, DC, and AC/DC SystemsDocument80 pagesA-Isometer® Irdh275: Ground Fault Monitor / Ground Fault Relay For Ungrounded AC, DC, and AC/DC SystemsMauricio AguilarNo ratings yet

- Master Jee Classes: Kukatpally, HyderabadDocument42 pagesMaster Jee Classes: Kukatpally, HyderabadVLSISD23 KORRA NIKHILNo ratings yet

- 2016 NCSE Math Paper IIDocument15 pages2016 NCSE Math Paper IIDarryan Dhanpat0% (1)

- Ordering Information VOTANO 100: PackagesDocument6 pagesOrdering Information VOTANO 100: PackagesConstantNo ratings yet

- Type Tests On Disc Insulator Units & StringsDocument33 pagesType Tests On Disc Insulator Units & Stringssalsa222100% (8)

- Nanotechnology and Its ApplicationDocument28 pagesNanotechnology and Its ApplicationsorinamotocNo ratings yet

- Projectile MotionDocument46 pagesProjectile MotionAllen Espinosa100% (1)

- Chapter Three Velocity AnalysisDocument57 pagesChapter Three Velocity Analysismekete mulualemNo ratings yet

- The Steering System - SummaryDocument7 pagesThe Steering System - SummaryPagg Dē TygerNo ratings yet

- 5.QUSTEC IBM QE Quantum-Coherent Microwave-Optical Conversion PDFDocument1 page5.QUSTEC IBM QE Quantum-Coherent Microwave-Optical Conversion PDFisbro1788No ratings yet

- CAPE Physics U1 - Breakdown of SyllabusDocument24 pagesCAPE Physics U1 - Breakdown of SyllabusJevon SiddonNo ratings yet

- Code s4 Ques Ans Neet 2022Document41 pagesCode s4 Ques Ans Neet 2022proNo ratings yet

- Aviation Info BankDocument1,025 pagesAviation Info BankHI HILLSNo ratings yet

- Objective Question Bank (NDT)Document22 pagesObjective Question Bank (NDT)Syed FarhanNo ratings yet

- Grundfos Packaged Solutions: Grundfos Americas Brookshire, TX 77423 WWW - Grundfos.usDocument8 pagesGrundfos Packaged Solutions: Grundfos Americas Brookshire, TX 77423 WWW - Grundfos.usJhon Jairo Arango MarquezNo ratings yet

- Mechanical SpringDocument49 pagesMechanical SpringYeamlak SisayNo ratings yet

- Control System ModelingDocument88 pagesControl System Modelingcantik cuteNo ratings yet

- Febriana 2020 IOP Conf. Ser. Mater. Sci. Eng. 858 012047Document9 pagesFebriana 2020 IOP Conf. Ser. Mater. Sci. Eng. 858 012047mattNo ratings yet

- Mathematical Modeling 1Document68 pagesMathematical Modeling 1hermelaNo ratings yet

- GROWATT MIN 2500-5000 TL-XA DatasheetDocument2 pagesGROWATT MIN 2500-5000 TL-XA DatasheetErlangga SatyawanNo ratings yet

- Pioneer VSX Ax10ai G Service ManualDocument25 pagesPioneer VSX Ax10ai G Service ManualMaxima DemornayNo ratings yet

- 08a. Phy 2nd Paper Cadet TP (MCQ) 01Document19 pages08a. Phy 2nd Paper Cadet TP (MCQ) 01Mustafa Nabeel ZamanNo ratings yet

- Luo Chpt1Document38 pagesLuo Chpt1CharleneKronstedtNo ratings yet

- Alexander Binzel Schweisstechnik GMBH & Co. KG P.O. Box 10 01 53 D-35331 Gießen Phone: +49 (0) 64 08 / 59-0 Fax: +49 (0) 64 08 / 59-191Document8 pagesAlexander Binzel Schweisstechnik GMBH & Co. KG P.O. Box 10 01 53 D-35331 Gießen Phone: +49 (0) 64 08 / 59-0 Fax: +49 (0) 64 08 / 59-191Arda YazıcıNo ratings yet