100% found this document useful (7 votes)

950 views128 pagesMachinery Alignment for Engineers

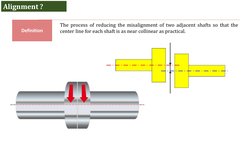

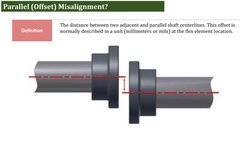

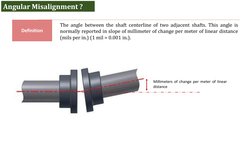

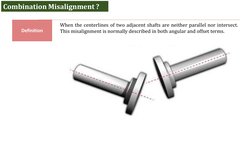

This document provides an overview of machinery alignment presented by Hesham M. Khalil. It defines different types of misalignment such as parallel, angular, and combination misalignment. It discusses the consequences of misalignment such as vibration, noise, and damage. It also describes alignment applications for couplings and motor sheaves/pulleys. Various alignment tools are introduced including dial indicators, brackets, shims, and lasers. Pre-alignment checks like coupling to shaft runouts are also covered.

Uploaded by

Ahmed AbdelwahabCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (7 votes)

950 views128 pagesMachinery Alignment for Engineers

This document provides an overview of machinery alignment presented by Hesham M. Khalil. It defines different types of misalignment such as parallel, angular, and combination misalignment. It discusses the consequences of misalignment such as vibration, noise, and damage. It also describes alignment applications for couplings and motor sheaves/pulleys. Various alignment tools are introduced including dial indicators, brackets, shims, and lasers. Pre-alignment checks like coupling to shaft runouts are also covered.

Uploaded by

Ahmed AbdelwahabCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction

- Misalignment Details

- Consequences of Misalignment

- Importance of Alignment

- Alignment Applications

- Couplings

- Sources of Misalignment

- Alignment Tools

- Pre-Alignment Checks

- Alignment Correction Planes

- Check of Sag

- Alignment Techniques

- Misalignment Tolerances

- Motor Sheave - Fan Pulley Alignment

- Conclusion