Professional Documents

Culture Documents

Aoac44.4.18a

Uploaded by

Adrián Rojas ÁvilaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aoac44.4.18a

Uploaded by

Adrián Rojas ÁvilaCopyright:

Available Formats

44.4.18A (2) Sofer procedure.

—Combustion tube: standard wall borosilicate

AOAC Official Method 998.12 glass (20 cm × 9 mm), sealed at one end. Before use, purge by heating ca

C-4 Plant Sugars in Honey 1 h at 550EC. To prepare CuO for Sofer procedure, crush CuO (wire

form) to pass through 1.5 mm sieve and heat 2 h at 750EC before use.

(b) Purification system (Craig).—Glass manifold intercon-

Internal Standard nected with combustion system including trap, collection tube, and

Stable Carbon Isotope Ratio Method manometer [see Figure 998.12A and Geochimica et Cosmochimica

First Action 1998

Acta 3, 54–55(1953)].

[Method is used to demonstrate C-4 (corn or cane) sugars in honey at (c) Mass spectrometer.—Instrument especially designed or

a concentration >7%.] modified for isotope ratio measurement at natural abundance and ca-

pable of accuracy of 0.01% of abundance at mass 45.

Results of the interlaboratory study supporting acceptance of the (d) Standards.—For calibration purposes (available every

method: 3 years in amount of 400 mg, except oil, 1 mL; graphite, 0.8 g; su-

Range = –0.30‰ (2.1%) to –1.9‰ (13.6%); sr = 1.25–2.69; crose, 1 g; from Office of Standard Reference Materials, National

sR = 11.25–2.69; RSDr = 9.22–90.0%; RSDR = 14.5–92.0% Institute of Standards and Technology, Gaithersburg, MD 20899,

USA): (1) NIST 19 Limestone.—*13C = –1.95‰ against Pee Dee

A. Principle

Belemnite. (2) NIST 22 Crude Oil.—*13C = –29.73 ± 0.09‰.

Stable carbon isotope ratio value for protein isolated from honey (3) ANU sucrose.—*13C = –10.47 ± 0.13‰. (4) USGS 24 Graph-

provides a standard to which stable carbon isotope ratio value of the

ite.—*13C = –15.9 ± 0.13‰. (5) PEFI polyethylene foil.—*13C =

whole honey is compared. The difference between these values (the

–31.77 ± 0.08‰.

ISCIRA index) is a measure of the C-4 sugar content of honey.

Both honey and protein must be analyzed on the same instrument. C. Preparation of Honey

(a) Craig procedure.—Place 20–50 mg test portion, weighed to

Honey nearest 0.1 mg, in ceramic boat, position boat in tube, and evacuate

system. Admit to 600 mm Hg, tank O purified over CuO at 700EC

followed by liquid N trap. Heat test portion to ≥850EC in manifold in

Alternative I—Batchwise Method tubular furnace, condensing CO2 in liquid N trap. Recirculate gases

Final Action 1979

over CuO 10–30 min at 850EC. Isolate collection trap and purifica-

B. Apparatus tion system from combustion system and Toepler pump by valves,

(a) Combustion system.—Use one of the following options: and pump off O. Cool purification trap with solid CO2–acetone; cool

(1) Craig procedure.—Vacuum-tight glass manifold including analyte tube with liquid N. Let collection trap warm, condensing im-

quartz combustion tube half-filled with CuO in tubular furnace, liquid purities in solid CO2 trap and CO2 in analyte tube.

N trap, automatic Toepler pump, and high-vacuum source. To prepare (b) Sofer procedure.—Use 9 in. (22.9 cm) Pasteur pipet to place

CuO for Craig procedure, purify CuO (wire form) by firing in electric 3–5 mg test portion on side wall of prepared combustion tube, spread-

furnace ca 1 h at 900°C. Store in closed bottle after cooling. ing as thin film in strip along axis of tube. Avoid placing material

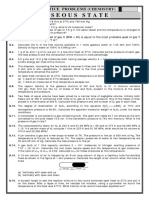

Figure 998.12A—Carbon combustion and purification system for Craig procedure.

© 2000 AOAC INTERNATIONAL

Figure 998.12B—Integrated system for continuous-flow method.

within 3–4 cm of open end. Cover test portion with 3–5 g CuO and let Alternative II—Continuous-Flow Method

tube remain horizontal ≥5 min. Place tube in drying oven at 60–65EC Final Action 1996

for ≥8 h. Remove tubes from oven, hold vertically, and tap firmly to A. Principle

dislodge CuO particles from wall area where seal will be made.

Test portion is burned by in-line automated Dumas combustion,

While tubes are still warm, place 1–6 analyte tubes on vacuum

with Cr3O3 catalyst and software-selected pulse of O3, purified and

manifold and evacuate by mechanical pump 3–4 min, then seal tubes

carried by He to ion source of mass spectrometer. Continuous-flow

with torch. Place tubes horizontally in oven with loose CuO cover-

combustion and purification process with on-line measurement by

ing test portion and bottom of each tube end-to-end. Combust test

single-inlet bench-top mass spectrometer is completely automated,

portions at 585–590EC for 1 h. Let tubes cool in oven at least 1 h at

under software control, with analyte *13C value obtained directly

<400EC. Attach tubes to vacuum purification line, and break seal or

from computer printout.

open with a tube cracker [see Anal. Chem. 48, 1652(1976)].

Purify and analyze CO2 as described in C(a). B. Apparatus

D. Determination Integrated system.—Equipped with automated Dumas combus-

Operate mass spectrometer according to manufacturer’s instruc- tion system with GC gas purification, mass spectrometer designed or

tions. Calibrate with ≥2 standards, B(d). Correct values obtained for modified for isotope ratio measurement at natural abundance, and

zero enrichment in inlet system, mixing between sampling and stan- IBM-compatible computer software control for combustion param-

dard valves, tailing of major onto minor peak signal, and combustion eters and calculation of results (PDZ Europa Service Centre, Europa

of 17O to mass 45 signal. House, Electra Way, Crewe, Cheshire CW1 62A UK; see Figure

Calculate: 998.12B).

C. Preparation of Test Portion

13 C /12 C test

*13C, ‰ = 13 12 − 1 × 1000 In triplicate, accurately weigh 3 mg undiluted honey, to nearest

C / C standard 0.1 mg, in 6 × 4 mm tin capsule, seal, and place on autosampler of

combustion unit. Place working standard reference sample [cali-

Convert laboratory analyses, relative to whatever standard was

brated against ≥2 reference standards as in Alternative I, B(d)] fol-

used, to PDB base with the following relationship:

lowing every 8 or fewer test portions.

*(X ! PDB) = *(X ! B) + *(B – PDB) + 10!3 *(X ! B) × *(B ! PDB) D. Determination

Operate system according to manufacturer’s instructions. Carrier

where *(X ! B) and *(X ! PDB) refer to analyses of test (X) relative to

flow rate is 60 mL/min, with computer-controlled 15 mL pulse of

standard (B) and relative to PDB, and (B ! PDB) is analysis of standard

high-purity O (99.999%) injected into oxidation tube at 1000EC. Set

(B) relative to PDB, and all *s are in parts per thousand.

reduction stage at 600EC and GC column at 150EC. Ion currents at

m/z 45, 46, 47 are simultaneously integrated, corrected for back-

ground, 17O contribution at mass 45, and any drift between refer-

ences. Because only one measurement can be made for each test

portion, precision is determined by measuring 5 test portions of

NIST 22 Crude Oil against itself as reference. Computer printout

may be in *13C units.

© 2000 AOAC INTERNATIONAL

Protein 3!5 mL H2O, mix, place in sac, tie 2 knots at end, and dialyze against

A. Apparatus running tap water for ≥16 h. Transfer contents of sac to 50 mL centri-

fuge tube, and centrifuge 5 min at 1500 × g. Decant supernate into

Centrifuge.—With horizontal 4-head rotor for 50 mL tubes, to

100 mL beaker, and discard pellet. Mix 6.0 mL 10% Na2WO4 and

provide 1500 × g.

6.0 mL 0.335M H2SO4, and add to dialysate. Heat on hot plate, stir-

B. Reagents ring until visible floc forms with clear supernate. Additional incre-

(a) Tungstic acid, sodium salt.—10% aqueous solution of ments of acid may be needed. Transfer to 50 mL centrifuge tube, and

Na2WO4⋅2H2O. centrifuge 5 min at 1500 × g. Discard supernate, disperse pellet thor-

(b) Sulfuric acid.—0.335M. Dilute 1.88 mL H2SO4 to 100 mL. oughly, fill tube with water, mix well, and centrifuge.

Place appropriate amount of protein in ceramic combustion boat

C. Determination

similar to that used for honey test portions. Combust protein by same

If appreciable amounts of solid matter are present, strain honey method used for honey. If necessary to hold for later isotope ratio

through 100!150 mesh (nylon stocking material is excellent); any analysis, either transfer (Pasteur pipet) washed pellet with minimum

insoluble material heavier than water will contaminate protein pre- amount of water to small vial, cap, and place in boiling water 2 min,

cipitate. or dry protein at least 3 h in ca 75EC oven.

Use one of the following options for protein isolation and purifi- Calculate apparent C-4 sugar content as follows:

cation:

(1) Repetitive washing procedure.—Add 4 mL H2O to 10–12 g δ13 CP − δ13 CH

C-4 sugars, % = × 100

honey in clear 50 mL centrifuge tube; mix well. Add 2.0 mL 10% δ13 CP − (−9.7)

NaWO4 solution and 2.0 mL 0.335M H2SO4 to small test tube, mix,

and immediately add to honey solution; mix well. Swirl tube in ca where *13CP and *13CH are *13C values, ‰, for protein and honey, re-

80EC water bath until visible floc forms with clear supernate. If no spectively, and !9.7 is the average *13C value for corn syrup, ‰. Re-

visible floc forms, or if supernate remains cloudy, add 0.335M port negative values from this calculation as 0%. Product is

H2SO4 in 2 mL increments, repeating heating between additions. considered to contain significant C-4 sugars (primarily corn or cane)

Fill tube with water, mix, centrifuge 5 min at 1500 × g, and decant only at or above a value of 7%.

supernate. Repeat washing, mixing, and centrifuging steps 5 times

with ca 50 mL portions of water, thoroughly dispersing pellet each References: JAOAC 61, 746(1978); 71, 88(1988); 72, 907(1989);

time. 74, 627(1991).

(2) Dialysis procedure.—Use cellulose dialysis tubing retaining J. AOAC Int. 75, 543(1992); 76, 140(1993).

proteins with mol wt >12 000, 25 mm (flat) × 30 cm (Sigma 250-9U Geochim et Cosmochim Acta 12, 133(1957).

is suitable). Hydrate tubing, closely tie 2 knots at one end. Heat Spectroscopy 4, 42(1989).

5!7 g honey to incipient boil (microwave oven is useful), add ca Anal. Chem. 48, 1651(1976); 52, 1389(1980).

© 2000 AOAC INTERNATIONAL

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- End of Respiration, Beginning of Reproduction TranscriptionDocument7 pagesEnd of Respiration, Beginning of Reproduction TranscriptionmarthafaragNo ratings yet

- The Role of Micro-OrganismsDocument64 pagesThe Role of Micro-OrganismsAmit Singh50% (2)

- NCSE 2007 Integrated ScienceDocument20 pagesNCSE 2007 Integrated SciencesweetestredsNo ratings yet

- SPECIAL REPORT: Identifying Sources Key To Detailed Troubleshooting of Amine FoamingDocument9 pagesSPECIAL REPORT: Identifying Sources Key To Detailed Troubleshooting of Amine FoamingAbhishek ChaudharyNo ratings yet

- Vallourec IPC-207Document4 pagesVallourec IPC-207zapspazNo ratings yet

- Lime Soda Ash SofteningDocument23 pagesLime Soda Ash SofteningNithi AnandNo ratings yet

- Asphyxiant PoisoningDocument47 pagesAsphyxiant PoisoningBenish AfzalNo ratings yet

- Iso 11265 1994Document8 pagesIso 11265 1994Adrián Rojas ÁvilaNo ratings yet

- Iso 11265 1994Document8 pagesIso 11265 1994Adrián Rojas ÁvilaNo ratings yet

- Nakajima 1993Document12 pagesNakajima 1993Adrián Rojas ÁvilaNo ratings yet

- Aoac971 27Document2 pagesAoac971 27Adrián Rojas ÁvilaNo ratings yet

- Analysis of Ethanol in Blood With The Agilent 7820A GC and 7697A Headspace SamplerDocument6 pagesAnalysis of Ethanol in Blood With The Agilent 7820A GC and 7697A Headspace SamplerAdrián Rojas ÁvilaNo ratings yet

- Shade Trees Reduce Building Energy Use and CO Emissions From Power PlantsDocument8 pagesShade Trees Reduce Building Energy Use and CO Emissions From Power PlantsEndah YulitaNo ratings yet

- The Effect of Monosaccharides Versus Disaccharides On The Rate of CO ProductionDocument4 pagesThe Effect of Monosaccharides Versus Disaccharides On The Rate of CO ProductionRyan LamNo ratings yet

- Cpp-Gaseous State - RGVDocument2 pagesCpp-Gaseous State - RGVGauri KabraNo ratings yet

- Effect of Synthesis Temperature On Catalytic Activity and Coke Resistance of Ni-Bio-Char During CO2 Reforming of TarDocument12 pagesEffect of Synthesis Temperature On Catalytic Activity and Coke Resistance of Ni-Bio-Char During CO2 Reforming of Tarabhishek_ictNo ratings yet

- AR700-68 - Compressed Gas StorageDocument103 pagesAR700-68 - Compressed Gas StoragetorolsoNo ratings yet

- Energy Scan Issue 51Document13 pagesEnergy Scan Issue 51Jai GuptaNo ratings yet

- Name: Marvin Batasinin BSRT-1C Deadline of Submission: April 21, 2020 Instructor: Ms. Jenessa C. Atibagos RatingDocument3 pagesName: Marvin Batasinin BSRT-1C Deadline of Submission: April 21, 2020 Instructor: Ms. Jenessa C. Atibagos RatingNikko AtabeloNo ratings yet

- Energy Production From Biomass (Part 1)Document10 pagesEnergy Production From Biomass (Part 1)36turkNo ratings yet

- J Tifs 2021 04 015Document12 pagesJ Tifs 2021 04 015deryl.baharudinNo ratings yet

- Fractional Ionization of A Monoprotic Weak Acid-Chpt 9Document40 pagesFractional Ionization of A Monoprotic Weak Acid-Chpt 9Dubu VayerNo ratings yet

- Global WarmingDocument4 pagesGlobal WarmingabdullahNo ratings yet

- Kcse 2023 Reflector Exams Series 1Document290 pagesKcse 2023 Reflector Exams Series 1micah isaboke100% (1)

- Smart Digital Dustbin: Dustbin (SDD) - Keywords-Incinerated Solid WastesDocument6 pagesSmart Digital Dustbin: Dustbin (SDD) - Keywords-Incinerated Solid WastesUma TamilNo ratings yet

- 2004.unit Conversions, Emissions Factors and Other Reference DataDocument16 pages2004.unit Conversions, Emissions Factors and Other Reference DataLalalalalalaNo ratings yet

- Solution 2.2: CHAPTER 2. The First Law and Other Basic ConceptsDocument8 pagesSolution 2.2: CHAPTER 2. The First Law and Other Basic ConceptsFelix LauwentoNo ratings yet

- 8 Lesson Plan Oxygen-IntegrationDocument6 pages8 Lesson Plan Oxygen-IntegrationDhen NacaNo ratings yet

- Eudiometry:: Ans. SolDocument2 pagesEudiometry:: Ans. Soltan jigNo ratings yet

- Record Breaking Savings in Operating Costs and CO EmissionsDocument2 pagesRecord Breaking Savings in Operating Costs and CO EmissionsmunhNo ratings yet

- Persiapan PSADocument11 pagesPersiapan PSAGoblin From Mars 2No ratings yet

- Benchmark ChecklistDocument5 pagesBenchmark ChecklistMagin Idelfonso TorreblancaNo ratings yet

- No Sun No Prob A New Process Might Soon Grow Plants in The Dark Science News ExploresDocument5 pagesNo Sun No Prob A New Process Might Soon Grow Plants in The Dark Science News Exploresziming linNo ratings yet

- AQA Chemistry GCSE Unit 1 Mark Scheme June 12Document16 pagesAQA Chemistry GCSE Unit 1 Mark Scheme June 12Fred Mate100% (1)

- Typha Charcoal SenegalDocument31 pagesTypha Charcoal SenegalGraschopf2No ratings yet