Professional Documents

Culture Documents

Dmyi 000060

Uploaded by

mohammadfarsiinfoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dmyi 000060

Uploaded by

mohammadfarsiinfoCopyright:

Available Formats

Description of DM:

Propeller cone fit procedure

All rights reserved. Nothing from this publication may be reproduced, or disclosed without prior written approval of Wärtsilä Propulsion Netherlands B.V

System code Info code System variant Issue Date Page Doc. no. Rev.

110 271 FPP propeller 2001-10-16 1/2 DMYI000060 04

1.1 Propeller cone fit procedure

- For installation sufficient space is needed.

- Hoisting facilities must be arranged.

1.1.1 Documents

- Instruction “General warnings and cautions”.

- Drawing “Propeller boss”.

1.1.2 Required conditions

- The shaft hole in the propeller boss is either pre-machined to a scraping tolerance or is finish

machined.

- When the shaft hole is finish machined by WPNL, a blue fit test on the propeller shaft hole has

been carried out. A classification surveyor has witnessed the result of this test.

- In most cases the yard has to perform the blue fit test for a local classification surveyor, even

when WPNL already obtained approval of the fit.

- The contract indicates whether the propeller cone is delivered pre- or finish machined.

1.1.3 Preparations

Pay attention to instruction “General warnings and cautions”.

• Prepare required tools and blue fit paste.

• Sufficient space.

• Cleaning material.

1.1.4 Procedure; Fitting of propeller by means of scraping

The shaft hole in the boss is pre-machined to a specified scraping tolerance on the inner diameter.

For an accurate fit between propeller and shaft cone an additional scraping shall be carried out.

The result of scraping has to be checked by means a blue fit test.

- In order to reduce the possibility of a premature oil leak it is important to avoid linear grooves

to the extreme forward and aft ends of the propeller bore. See drawing “Propeller boss”.

- The effect of the scraping shall be regularly checked, by means of a template, cone or shaft fit.

1.1.5 Blue fit test

A classification representative shall witness and approve the results of the blue fit test.

The propeller is not pushed up the shaft cone. For the purpose of contact area determination only

the shaft shall be put into the propeller shaft hole.

When the blue fit test is carried out in a machine shop, it is advised to position the propeller

(exactly) horizontal on the floor. The shaft is lifted in vertical position above the propeller shaft hole.

1. Clean the shaft or gauge and the propeller cone hole with solvent cleaner.

2. Apply a thin layer of blue fit paste on the shaft or gauge cone.

File name:DMYI000060_05, Last printed 17-03-03 9:37

Document title

Propeller cone fit procedure

Doc. no. DMYI000060 Rev. 04 Page 2/2

3. Gently insert the shaft or gauge cone into the propeller. Do not force the shaft or gauge. Only

the own shaft or gauge weight is applied during the fit test. If the propeller has to be fitted in

horizontal position (for instance behind the ship), the propeller must be pushed onto the shaft

using the hydraulic nut. Use in this case the start point load as an alternative for the shaft

weight that is used in case of vertical fitting.

4. Protect the propeller blades to prevent damaging.

When the cone is completely in the shaft hole, hit one of the propeller blades with a soft

hammer. These vibrations will lead to a reliable marking.

5. Check the markings at the propeller cone hole.

The fit is acceptable when markings are obtained over a 50 mm band at the extreme forward

and aft ends of the propeller cone and on at least 70% of the total cone surface.

6. In case the fit is not acceptable, scrape the propeller cone surface where required.

7. Continue with point 1 and repeat this procedure until satisfactory result.

8. Check the linear grooves to the extreme forward and aft ends of the propeller bore.

9. After approval, clean all cone surfaces and protect all cones against any dirt and damage.

17-03-03 DMYI000060_05 2

You might also like

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Dmyi 000025Document4 pagesDmyi 000025Sandeepa NimansithNo ratings yet

- ASI Lab Record - StudentsDocument24 pagesASI Lab Record - StudentsAVINASH SINGHNo ratings yet

- Wood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsDocument4 pagesWood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsPOUETNo ratings yet

- Repair Manual MP 1Document11 pagesRepair Manual MP 1Tiffany DacinoNo ratings yet

- c9 PDFDocument23 pagesc9 PDFAnjaana PrashantNo ratings yet

- Sensenich Ground Adjustable Propeller Log BookDocument12 pagesSensenich Ground Adjustable Propeller Log BookFaisNo ratings yet

- Fifth Wheel MTD-WI-06Document10 pagesFifth Wheel MTD-WI-06vinothNo ratings yet

- Procedure For Ship Propeller RenewalDocument24 pagesProcedure For Ship Propeller RenewalJORGENo ratings yet

- 412 Tuning Tips 2Document7 pages412 Tuning Tips 2nikola parlovNo ratings yet

- FSO 300 Thru 700 FSO 750 Thru 1027 FS 750 Thru 1027: Installation InstructionsDocument6 pagesFSO 300 Thru 700 FSO 750 Thru 1027 FS 750 Thru 1027: Installation InstructionsEzequiel CeccarelliNo ratings yet

- Qa-Lhb-Draft Gear & CouplingDocument4 pagesQa-Lhb-Draft Gear & CouplingSriram SubramanianNo ratings yet

- Top Co Operating Manual Type 505 506 Float EquipmentDocument5 pagesTop Co Operating Manual Type 505 506 Float EquipmentjalalNo ratings yet

- LrbollpullDocument5 pagesLrbollpullzufi110No ratings yet

- Pocket Guide For PavingDocument48 pagesPocket Guide For PavingТракия Билд100% (1)

- Multiflo W: Horizontal Multistage PumpsDocument14 pagesMultiflo W: Horizontal Multistage Pumpsbayu enasoraNo ratings yet

- Outline Activities, Needed: Sequence Method, ResourcesDocument10 pagesOutline Activities, Needed: Sequence Method, ResourcesNasrul HakimNo ratings yet

- Mos Driven Pile 11Document4 pagesMos Driven Pile 11Laila AzreenNo ratings yet

- Practical Assignment (Nurridzman)Document3 pagesPractical Assignment (Nurridzman)Naufal NasirNo ratings yet

- HDLDS 0036 UsDocument6 pagesHDLDS 0036 UsDaniel BahamondeNo ratings yet

- Von Klip Tip 10 Commandments of Prop CareDocument16 pagesVon Klip Tip 10 Commandments of Prop CareaviationMYNo ratings yet

- Pro 151 5001Document38 pagesPro 151 5001jdpardoNo ratings yet

- Sensenich Composite Propeller Installation InstructionsDocument4 pagesSensenich Composite Propeller Installation InstructionsrobertoNo ratings yet

- 100 CC Manual RC PlaneDocument39 pages100 CC Manual RC PlaneNeeleshGuptaNo ratings yet

- FM Patterson Driveshaft IOMDocument22 pagesFM Patterson Driveshaft IOMeaywdjw2070No ratings yet

- SelfEducting Foam Nozzles RevADocument10 pagesSelfEducting Foam Nozzles RevARaúl Manuel Espinoza RetamozoNo ratings yet

- 30cc Yak 55 Redwing PDFDocument23 pages30cc Yak 55 Redwing PDFaero oranNo ratings yet

- General Purpose Overrunning Clutches FRB 400 Through 800: Installation InstructionsDocument4 pagesGeneral Purpose Overrunning Clutches FRB 400 Through 800: Installation InstructionsPedro AbregúNo ratings yet

- Centrifuga Refrigerada Component R Manual de UsuarioDocument23 pagesCentrifuga Refrigerada Component R Manual de Usuarioleonard perezNo ratings yet

- ES-238 Compression Pump Shimming Field Instruction PDFDocument10 pagesES-238 Compression Pump Shimming Field Instruction PDFKeivin AriasNo ratings yet

- Thakur Institute of Aviation TechnologyDocument10 pagesThakur Institute of Aviation TechnologyAshwini ChaurasiaNo ratings yet

- Pilot 53in Sbach 342 ManualDocument23 pagesPilot 53in Sbach 342 ManualAlvaro ReyesNo ratings yet

- BHEL Feed BackDocument58 pagesBHEL Feed BackelrajilNo ratings yet

- Sidney Manufacturing: Side Wall Return Drag Conveyor Installation InstructionsDocument13 pagesSidney Manufacturing: Side Wall Return Drag Conveyor Installation InstructionsNuzuliana EnuzNo ratings yet

- Pages From NSH-SAOMPP-QCP-PI-021 Hydratight Procedure For Flange Hydraulic Torque TighteningDocument2 pagesPages From NSH-SAOMPP-QCP-PI-021 Hydratight Procedure For Flange Hydraulic Torque TighteningRajis Rahim100% (1)

- O&M FOR FLOATING AERATOR - NewDocument14 pagesO&M FOR FLOATING AERATOR - NewBaisel RahumanNo ratings yet

- Explain Briefly How Propeller Fit On PropellerDocument21 pagesExplain Briefly How Propeller Fit On PropellerEnzo Ruiz100% (1)

- Fis122 Cartridge Install PDFDocument4 pagesFis122 Cartridge Install PDFPdm BadakNo ratings yet

- Fis122 Cartridge InstallDocument4 pagesFis122 Cartridge InstalllubangjarumNo ratings yet

- Airmar Transducer InstallationDocument4 pagesAirmar Transducer InstallationmreltNo ratings yet

- 18 Can Size ChangeDocument9 pages18 Can Size Changedeleonarchie729No ratings yet

- Recommended Practice Wedge Lock Flush / Semi Flush ConnectionsDocument7 pagesRecommended Practice Wedge Lock Flush / Semi Flush Connectionszouke2002No ratings yet

- vx136qqdqdm2 SeriesDocument202 pagesvx136qqdqdm2 SeriesjosdiNo ratings yet

- Dfde EngineDocument22 pagesDfde EngineARGONAFTISNo ratings yet

- MEG GAP Analysis and Functional ReqmentDocument2 pagesMEG GAP Analysis and Functional ReqmentSachin Sikka50% (2)

- SB 388Document13 pagesSB 388oscarNo ratings yet

- Wood Prop Installation InstructionsDocument4 pagesWood Prop Installation InstructionsskytypeNo ratings yet

- W SER 0502 AD Manual Flange Torque TighteningDocument8 pagesW SER 0502 AD Manual Flange Torque TighteningAnonymous IJBjI0No ratings yet

- Helical and Spiral-Bevel Helical Gear Units: Installation Operation and Maintenance ManualDocument31 pagesHelical and Spiral-Bevel Helical Gear Units: Installation Operation and Maintenance ManualGanesh KumarNo ratings yet

- Morin ValveDocument6 pagesMorin ValveFélix VelascoNo ratings yet

- Chapter (4) Pump InstallationDocument21 pagesChapter (4) Pump Installationkarioke mohaNo ratings yet

- 05 1964 CH-Rear AxleDocument3 pages05 1964 CH-Rear AxleJose LaproviteraNo ratings yet

- Bha Handling (Driller) : 1) Elevators. 2) Slips. 3) Bowls. 4) Dog Collars (Safety Clamps) - 5) Drill Collars. 5) Subs. 6)Document17 pagesBha Handling (Driller) : 1) Elevators. 2) Slips. 3) Bowls. 4) Dog Collars (Safety Clamps) - 5) Drill Collars. 5) Subs. 6)aliNo ratings yet

- Led Display. Instruction Manual & Details: Pro-AnalyticalDocument12 pagesLed Display. Instruction Manual & Details: Pro-AnalyticalALFREDO LUIS ARROYO SANCHEZNo ratings yet

- Nipple Up-Down BopDocument6 pagesNipple Up-Down Bopsanjeet giri100% (2)

- Wi QPC 008 Alignment ProcedureDocument6 pagesWi QPC 008 Alignment ProcedureBudimanNo ratings yet

- 10 Von Klip Tip 10 Commandments of Prop CareDocument16 pages10 Von Klip Tip 10 Commandments of Prop CareNguyễn Đỗ Trọng BìnhNo ratings yet

- Seating The Propeller: Gland SealDocument7 pagesSeating The Propeller: Gland SealBhupender RamchandaniNo ratings yet

- Rigging LevellingDocument18 pagesRigging LevellingmentariiNo ratings yet

- Mba TornadoDocument17 pagesMba Tornadojemalves100% (1)

- Minda Corporation (Through Its Subsidiary) Announces A 50:50 Joint Venture With SBHAP, China (A BAIC Group Subsidiary) (Company Update)Document3 pagesMinda Corporation (Through Its Subsidiary) Announces A 50:50 Joint Venture With SBHAP, China (A BAIC Group Subsidiary) (Company Update)Shyam SunderNo ratings yet

- Agreement: E/ECE/324 E/ECE/TRANS/505 Rev.1/Add.25/Amend.5 6 August 2007Document2 pagesAgreement: E/ECE/324 E/ECE/TRANS/505 Rev.1/Add.25/Amend.5 6 August 2007tgvnayagamNo ratings yet

- Eddy-Current-Brakes Seminar Report PDFDocument21 pagesEddy-Current-Brakes Seminar Report PDFprashanta padhiary50% (4)

- SBL Company ProfileDocument11 pagesSBL Company ProfileadityaNo ratings yet

- Siddhachal Elite BrochureDocument27 pagesSiddhachal Elite BrochureLokesh BangaloreNo ratings yet

- Section 10 - Engine - Chapter 1Document24 pagesSection 10 - Engine - Chapter 1Cristian SterieNo ratings yet

- Senate Hearing, 112TH Congress - Taking Consumers For A Ride: Business Practices in The Household Goods Moving IndustryDocument116 pagesSenate Hearing, 112TH Congress - Taking Consumers For A Ride: Business Practices in The Household Goods Moving IndustryScribd Government DocsNo ratings yet

- 1944-1945 Royal Navy Ships Lost at SeaDocument23 pages1944-1945 Royal Navy Ships Lost at SeaNigel PostleNo ratings yet

- Case StudyDocument4 pagesCase StudyElisha K.No ratings yet

- Roberts Towing & Transport LLC Online PaymentDocument1 pageRoberts Towing & Transport LLC Online Paymentnkwfsyn7jvNo ratings yet

- Longstaffe GowanDocument10 pagesLongstaffe GowanclaudiaNo ratings yet

- Wiring Diagram For Brake Control (BS)Document7 pagesWiring Diagram For Brake Control (BS)Rendy MechanicNo ratings yet

- LaunchingDocument28 pagesLaunchingRolando ArciaNo ratings yet

- Projects 072019Document12 pagesProjects 072019Kanha GargNo ratings yet

- Copper Contract TurkeyDocument9 pagesCopper Contract TurkeyHasan Uyan67% (3)

- Automotive Interior Trim Bezel Mould DesignDocument17 pagesAutomotive Interior Trim Bezel Mould DesignagniflameNo ratings yet

- Seafares-Application Form PDFDocument3 pagesSeafares-Application Form PDFsergieNo ratings yet

- Check List - Air Compressor InspectionDocument1 pageCheck List - Air Compressor Inspectiondndudc100% (4)

- Business Proposal New VentureDocument18 pagesBusiness Proposal New VentureBramhananda ReddyNo ratings yet

- DI16Document2 pagesDI16Erln LimaNo ratings yet

- 5L40E PartsDocument49 pages5L40E PartsRaca ZivkovicNo ratings yet

- Tata Performance AppraisalDocument70 pagesTata Performance Appraisalbonat07100% (1)

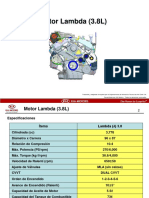

- 1.HM Lambda Engine CompletedDocument10 pages1.HM Lambda Engine CompletedAlex GarciaNo ratings yet

- Orifice Flange Union Assembly and Orifice Run Installation and Operation ManualDocument8 pagesOrifice Flange Union Assembly and Orifice Run Installation and Operation ManualNithin CpNo ratings yet

- Assignment 1 Modes of TransportDocument10 pagesAssignment 1 Modes of TransportWiwie Nur100% (1)

- ROYAL E-Booking - AzizDocument2 pagesROYAL E-Booking - AzizMaria SusanNo ratings yet

- GridView 202308221725i55Document18 pagesGridView 202308221725i55Arslan AyubNo ratings yet

- SSP 406 VW Adaptive Chassis Control DCCDocument32 pagesSSP 406 VW Adaptive Chassis Control DCCKevin HuangNo ratings yet

- Anti-Theft - Passive Anti-Theft Circuit (Antitheft and Alarm Systems) - ALLDATA RepairDocument1 pageAnti-Theft - Passive Anti-Theft Circuit (Antitheft and Alarm Systems) - ALLDATA RepairJesus SanchezNo ratings yet

- MOOE Case StudyDocument10 pagesMOOE Case Studyjayson te71% (7)