Professional Documents

Culture Documents

J Meenu Vikas

Uploaded by

GEOGIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

J Meenu Vikas

Uploaded by

GEOGICopyright:

Available Formats

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

CBM PRODUCTION, TROUBLESHOOTING,

TRANSPORTATION AND WATER MANAGEMENT

1

JEEDULA MEENU VIKAS, 2Mr.K.MANOJ, 3Mr. K.S. RAMBABU

1

M.Tech Student, 2,3Assistant Professor

Department of Mechanical Engineering

KAKINADA INSTITUTE OF TECHNOLOGICAL SCIENCES, Ramachandrapuram

ABSTRACT Natural cracks, sometimes known as

cleats, in coal. In coals, these

India, along with other nations, is fractures, known as face cleats and

frantically looking for alternative energy butt cleats, are common. Hydraulic

resources such as coal bed methane (CBM), fracturing, on the other hand, is

shale gas, and gas hydrate to satisfy the required to increase output in most

rapidly growing demand for energy and the coal reservoirs.

rapid depletion of traditional energy

The gas storage mechanism in coal.

supplies. CBM is thought to be the most

While gas is trapped in the pore

feasible of the three. The next sections

spaces of ordinary rocks, it is

address the potential of CBM as a clean

adsorbed or adhered to the interior

energy source, the challenges associated in

surfaces of coal.

CBM manufacturing, and improved recovery

The presence of significant amounts

methods.

of water in coal seams. To decrease

1. INTRODUCTION

reservoir pressure and liberate the

Coal bed methane is commercially gas, water must be constantly

generated in the United States, and it has pushed from coal seams.

sparked interest across the globe as a Coal reservoirs have a low pressure.

possible supply of low-cost natural gas. To optimise gas flow, backpressure

Operators have adapted and used petroleum at the wellhead must be maintained

industry technologies to enhance the low. In addition, every gas generated

performance of their fields since the coal bed must be compressed before being

methane business began in the mid-1970s. sent to a sales pipeline.

Conventional oil and gas technology, on the The low rates of gas flow from coal

other hand, does not necessarily work well reserves. To create a cost-effective

for generating coal bed methane. project, capital expenditures and

operational costs must be kept to a

Because coal geology differs so minimum.

much from that of conventional gas

deposits, you'll need to adopt a Because of the particular features of

distinct strategy that considers: coalbed reservoirs, inefficiency will be

The rock's chemical makeup. Coal is minimal. Successfully developing a coalbed

90% organic, while traditional gas methane field requires careful management

deposits are almost entirely of both the technical and financial elements

inorganic. of the project. The Rock Creek Methane

Coal has a variety of mechanical from Multiple Coal Seams Completion

characteristics. Coal is brittle and Project was developed by Gas Research

prone to collapsing in the wellbore Institute (GRI) and Taurus Exploration, Inc.

because it is brittle and weak. to explore methods for commercially

generating coalbed methane resources. This

Vol 12, Issue4, 2021 www.jrmat.com Page No:327

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

field study location is southwest of recommendations for developing coalbed

Birmingham, Alabama, in the Black Warrior methane resources have been developed as a

Basin. The main goal of this project, which result of the Rock Creek project and the

began in 1983, is to develop technologies for efforts of other operators in the Black

producing methane from shallow, thin Warrior Basin. In the Black Warrior Basin,

numerous coal seams utilising single vertical collaboration and open communication

wellbores at a lower cost. The goal of the Ile between operators and service firms were

project is to figure out the optimum mix of required to improve both fundamental

drilling, completing, stimulating, and knowledge and practical expertise in

operating methods for producing these wells generating methane from coal seams

cheaply. Many practical methods and

1.1 FORMATION OF COAL BED METHANE

1.2 formation of coal bed methane and generated water management are all

variables that affect production potential.

Because temperature rises beyond Natural fracture networks are the most

the most suitable range for bacteria, water is sought-after locations for CBM development

ejected, porosity diminishes, and biogenic in most countries. Natural fracturing occurs

methane production reduces as bituminous in areas where geological features and

types mature. Simultaneously, heat degrades localised faulting have developed, increasing

complex organic molecules, releasing the number of production paths inside the

methane and other heavier hydrocarbons coal seam. The cost of bringing producing

(ethane and higher). The thermal wells online is reduced because to natural

decomposition of coal may also produce fracturing.

inorganic gases.

Although most coals contain

1.2.1 CONTROLING FACTORS OF methane, it cannot be commercially

CBM generated without the presence of open

Fracture permeability, development, fractures that offer pathways for the

gas migration, coal migration, coal desorbed gas to move to the well. Methane

distribution, geologic structure, CBM stays trapped in the coal bed matrix as long

completion choices, hydrostatic pressure, as the pressure exerted by the water table is

Vol 12, Issue4, 2021 www.jrmat.com Page No:328

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

higher than that exerted by the coal. Because For household water heating, tiny steam coal

water is typically saturated in coal cleats and (dry small steam nuts or DSSN) was utilised.

cracks, the hydrostatic pressure in the coal

seam must be reduced before the gas may The hardest, glossiest black coal,

move. anthracite, is mainly utilised for home and

commercial space heating. It's further split

1.2.2 COAL QUALITY into metamorphically altered bituminous

coal and "petrifield oil," which comes from

Under appropriate circumstances, Pennsylvania's reserves.

geological processes exert pressure on dead

biotic material over time, causing it to Graphite, the highest rank, is

metamorphose into: difficult to ignite and is seldom used as a

fuel; it is mainly utilised in pencils and as a

Peat, which is a predecessor to coal, lubricant in powder form.

is used as a fuel in certain parts of the world,

including Ireland and Finland. Peat is a very 1.2.3 COAL MATURATION

efficient absorber for gasoline and oil spills

on land and water in its dehydrated form. It's Coal is a carbon-rich rock formed

also utilised as a soil conditioner to help it from plant debris (peat) that collected in

hold and release water more slowly. wetlands and was then buried by natural

processes. As the plant material is buried

Lignite, often known as brown coal, deeper, it starts to coalize, releasing volatile

is the lowest rank of coal and is almost materials (water, carbon dioxide, light

entirely utilised to generate electricity. Jet is hydrocarbons, including methane) as it

a polished form of lignite that has been used transforms into coal. As coalification

as a decorative stone since the Upper progresses, it becomes more carbon-rich and

Palaeolithic. continues to release volatile materials.

Methane and other hydrocarbons are

Subbituminous coal, whose produced in coals as a result of thermal

characteristics vary from lignite to maturation, which begins around the sub-

bituminous coal, is mainly utilised as a bituminous “A” to high volatile bituminous

source of light aromatic hydrocarbons for “C” rank stage (see coal rank classification

the chemical synthesis sector and is chart), with amounts of methane produced

predominantly used as a fuel for seam increasing significantly throughout the

electric power production. medium to low volatile bituminous coal

Bituminous coal is a thick ranks.

sedimentary rock that is typically black, but The plains' shallow coals (e.g.,

may sometimes be dark brown, and has Ardley, Horsehose Canyon) have a low rank

distinct bands of brilliant and dull stuff. It's and have not produced significant amounts

mainly utilised as a fuel for steam electric of methane. Deeper coals (such as

power production, but it's also used for heat Mannville) have undergone more

and power in industry and to produce coke coalification (high rank) and have generated

in large amounts. and kept more methane than shallower coals.

Steam coal is a mixture of Methanogenic bacterial activity may

bituminous and anthracite coal that was have generated some coal bed methane

formerly extensively utilised as a locomotive (CBM). If the circumstances are right,

fuel. In this particular use, it is sometimes

referred to as "sea coal" in the United States.

Vol 12, Issue4, 2021 www.jrmat.com Page No:329

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

biogenic gas may be generated at any point methane (CBM) deposit. Several important

throughout the coalification process. best practises were integrated into a process

to evaluate the CBM potential of a variety of

Gas is held in coal as an adsorbed possible locations on a regular basis. Based

component on or within the coal matrix, as on accessible structural data, 3D static

well as as a free gas in the micropore models were created for each region. Coal

structure or cleats of a coal bed. Because characteristics like density and ash content

reservoir pressure holds the gas in place, were geo-statistically supplied into the

lowering the reservoir pressure enables gas models. Other characteristics that have been

to escape from the coal. established include gas content,

permeability, and Longmuir volume. To

1.2.4 FIXED CARBON

characterise the uncertainty in each

The fixed carbon content of coal correlation, an analysis of residual

refers to the carbon that remains after distribution between each correlation and its

volatile elements have been removed. data was utilised. Several options for

Because some carbon is lost in hydrocarbons reducing this uncertainty were explored.

with the volatiles, this varies from the final These varied from discrete trends to geo-

carbon of coal. Fixed carbon is a measure of statistical; property population applications.

how much coke can be extracted from a The impact of each on the predicted EUR

given quantity of coal. The volatility test, as was looked at. Production prototype

mentioned above, determines fixed carbon reservoir simulation models were developed

from the initial mass of the coal sample. and history matched. Because of the

complexity of the coal reservoir and the non-

1.2.5 TEMPERATURE GRADIENT uniqueness of the history match, further

work was done to capture the remaining

When a temperature gradient is

uncertainty and evaluate its effect on model

generated along the slag's penetration

output.

direction, the infiltration properties of

industrial coal slag into alumina (Al2O3) 1.4 COAL CLEAT ORIENTATION

refractory material are compared to those

obtained under near-isothermal Porosity is present in coal, although

circumstances. Experiments were carried out matrix permeability is low. Coal seams must

at a hot face temperature of 1450oC with a have a system of secondary permeability,

CO/CO2 ratio of 1.8, corresponding to an such as fractures, in order for fluids to be

oxygen partial pressure of 10-8 atm. The generated from them into a well-bore. Water

refractory that was exposed to a near and natural gas may move from matrix

isothermal temperature profile with higher porosity to the producing well via fractures.

average temperatures had a larger Cleat is a word used to describe the network

penetration depth than its counterpart that of natural cracks that develop in coal seams

was exposed to a steeper temperature when the coal matures. Cleats are formed as

gradient, which pooled and solidified on the a consequence of coal dehydration, local and

sample's surface. regional tensions, and overburden unloading.

Cleats regulate the directional permeability

1.3 MODELING OF COAL BED of coals, making them crucial for CBM

METHANE research via well location and spacing.

A successful development strategy

requires determining the possible range

recoverable quantities for a coal bed

Vol 12, Issue4, 2021 www.jrmat.com Page No:330

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

1.5 METHANE GAS MIGRATION when hydrostatic pressure is reduced by

water production. Gas desorbed and moved

The majority of gas in coal seams is into the cleats system, where it began to flow

absorbed by tiny laminations and micro towards the producing well. Faults may last

holes in coal macerals. Natural gas may also for many miles and are linked to geologic

migrate via more broad distributed fracture movement and structure. They can also be

sets linked to faults and tectonic jointing beneficial.

1.2 Coal maturity

2. LITERATURE SURVEY methane, which also received a federal tax

2.1 ITRODUCTION credit.

The venting of methane from coal CBM was identified as a significant

seams gave rise to coal bed methane. mining danger in the nineteenth century

Boreholes were bored into the seams of because the pressure of gases in coal seams

certain coal beds because they were known produced structural stress on mine beds,

to be "gassy" for a long time. In the late resulting in explosions and outbursts. These

1970s, the US federal government gave coal gases must be vented or controlled in order

bed methane a big push as a natural gas to manage this. However, because the

resource. While the government intended to severity of global warming is 25 times that

promote greater gas production, federal price of carbon dioxide over a 100-year period,

restrictions discouraged natural gas drilling the release of these gases into the

by maintaining natural gas prices below atmosphere added to the greenhouse effect

market levels. Research into a variety of (IFP engineers report 2008). CBM started to

unconventional gas sources, including coal be generated for use as a fuel from

bed methane, was sponsored by the US conventionally drilled wells in the late

Department of Energy. Federal pricing twentieth century, and it quickly established

restrictions were waived for coal bed itself as a major unconventional supply of

natural gas (Flores 1998).

Vol 12, Issue4, 2021 www.jrmat.com Page No:331

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

CBM is mostly made up of methane The major factors that sustain

and is comparable to other natural gas interest in CBM are

sources. To make it acceptable for storage

and transportation, it must be compressed or 1. Increased safety and productivity in coal

liquefied. Natural gas is expected to overtake mining operations

coal as the biggest source of energy 2. Potential for greenhouse gas reduction.

production in the United States by 2035,

according to the US Energy Information 3. Capture and storage of greenhouse gases.

Administration.

Co2 sequestration is referred to as

Gas is generated from both greenhouse gas capture and storage. This

conventional and unconventional sources to method, which involves injecting Co2 into

satisfy this need. Conventional gas deep coal, seems to be doubly appealing

production takes place in geological since it addresses the emission of this major

formations that are moderately porous and anthropogenic greenhouse gas while also

permeable, such as stand stone and improving CBM recovery.

carbonates. It is difficult to produce from

non-conventional deposits (e.g. CBM, shale Overall, CBM is a major energy

gas, tight gas, and gas hydrates). As gas source that is quickly expanding. According

demand grew and conventional gas supplies to the International Energy Agency (IEA),

dwindled, these non-conventional resources CBM accounted for 10% of natural gas

were initially tapped in the United States in output in the United States in 2008, 4% in

the 1970s. Legislative measures, such as the Canada, and 8% in Australia, and there has

elimination of wellhead price limits and been interest in CBM production in other

limitations on the use of gas for power nations with significant coal deposits, such

production, aided this. Incentives for the as India, China, Russia, and Indonesia

development of additional natural gas (Stevens 2010). In its 11th five-year plan,

sources are also available. By the 1990s, a China has designated CBM as one of 16

significant number of CBM wells would priority projects. Figure 1 shows the

have been established. worldwide CBM market volume by

application.

Vol 12, Issue4, 2021 www.jrmat.com Page No:332

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

2.1 Coal bed methane utilization based on end- use application.

2.2 Coal bed methane occur in worldwide

2.2 Coal bed methane occur in worldwide

3 POTENTIAL COAL FIELD OF CBM ONGC early evaluation, are the most

promising coal resources in the Damodar

3.1 CBM potential in India valley. Most Indian coals are below the

248 billion tonnes of total coal resources threshold maturation level of 0.8 VRO,

making it unlikely that enough thermogenic

Nearly all of it comes from the Gondwana methane production would be present to

Basins. The coal deposits in the Damodar saturate the coal under reservoir conditions.

Valley account for half of this resource, Biogenic methane resource through active

making them a prime exploration target. 0.8 hydro-geological play, as shown in a few

to 1.5 TCM is the estimated CBM resource foreign basins with less than threshold

(different resources). Jharia, Bokaro, North maturity. If such conditions exist in any

Karanapur, and Raniganj, according to an Indian coal basin, they might prove promisin

COAL FIELDS OF INDIA AND THEIR CATEGORIZATION

Category I Gondwana coals ranking Jharia, Bokaro, Raniganj and

High volatile bituminous A North Karanapur coal fields.

and above

CategoryII Gondwana coals ranking South Karanapur, Raniganj,

High volatile bituminous A PenchKanhanandSohagpur coal

and below fields.

CategoryIII Low ranking Gondwana coals Talchir, Ib, Pranhita-Godavari

Valleylandwardha valley coal

field.

CategoryIV Tertiary coal/ Lignite Cambay, Biknaneer-Nagaaur,

Barmer, assam-Arakan,

Cauvery and Himalayan foot

Hills Basins.

Vol 12, Issue4, 2021 www.jrmat.com Page No:334

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

Table 3.1 Coal fields categorization in India

Methane from coal beds may be found nearly everywhere where there is coal. Although it

is seen as a hazardous nuisance in the mining business, it has the potential to serve as a plentiful

source of clean energy to assist replace other depleting hydrocarbon sources.

State Coal field Resources Proved reserves

Orissa Talcher 40869.47 12311.10

West Bengal Raniganj 25558.85 12877.90

Orissa Ib-rever 22364.11 5401.83

Jharkhand Jharia 19430.06 15077.57

Chattisgarh Mand-raigarh 19106.04 1953.88

Andhra Pradesh Godavari Valley 17714.46 8791.13

Jharkhand N. karanapur 15860.91 8077.77

Jharkhand Rajmahal 14275.91 2077.97

Madhya Pradesh Singrauil 13478.31 5002.52

Chattisgarh Korba 10115.21 4980.58

Jharkhand E.Bokaro 7067.47 4980.58

Jharkhand S.Karanapur 6036.79 2542.18

Maharashtra Wardha Valley 5669.63 2944.42

Jharkhand W.Bokaro 5004.99 3488.10

Chattisgarh Hasdo-arand 4972.96 1183.36

West Bengal Birbhum 4683.02 7985.40

Madhya Pradesh Sohagpur 4602.63 1688.54

Table 3.2mState wise coal field in India

4. OPERATING WELLS AND operational expertise in a specific coal bed

PRODUCTIONEQUIPMENT methane field. This chapter will guide you

ANDTRANSPORTATION through the process of creating successful

production strategies. It will guide you

4.1 INTRODUCTION through:

Some specific production methods are • Preparing Surface Facilities for Production

required while operating coal bed methane

wells and production equipment. These • Unloading the Well

methods were mainly acquired via trial and • Bringing the Well on Line

error as well as on-the-job observation. For

example, field experience at the project has • Troubleshooting Well and Equipment

shown that the way you return a well after Problems

stimulation may have a big impact on how

quickly it recovers. Similarly, the method 4.2 Preparing Surface Facilities for

you choose to pump a well down may have Production

an impact on its production. Learning to

After the well has been fractured and

identify and solve common production

flowed back, and the pumping unit has been

issues has also been proven to significantly

installed, ensure sure the surface facilities

decrease production downtime.

and collecting system are ready to accept the

You will definitely discover methods that well's output. Preventing hazardous

operate well in your region as you acquire operating conditions, environmental issues,

Vol 12, Issue4, 2021 www.jrmat.com Page No:335

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

and needless downtime to repair facility

problems may all be avoided by doing this

inspection before bringing the well online. All flow valves between the

wellhead and the separation

The different pieces of equipment equipment should be opened.

you'll need to inspect may differ Make that all gas metering

significantly from one field to the equipment is operational and ready

next. This pre-production inspection to measure gas flow. Despite the fact

should cover not just equipment at that gas flow will likely be minimal

the wellhead, but also all at first, you should pressure test the

downstream lines and facilities such metre run or metering assembly to

as separators, metre runs, collecting ensure that no connections are

lines, drips, water treatment leaking.

facilities, and compressors, Check orifice metres to ensure sure

regardless of the kind of equipment they have the right size orifice plate

utilised. Check the following criteria for the amount of gas being

before bringing wells online: measured.

Ensure that all relevant federal, Check to see whether chart recorders

state, and municipal safety and or turbine flow metres are correctly

environmental laws have been calibrated.

followed. You may also be needed Check the gas compressor before

to inform local regulatory authorities allowing substantial gas flow to

of your intention to start producing commence to verify that it has

from the field. adequate capacity for the gas.

Notify the gas buyer when you plan

to start delivering gas so they may Because of increased gas production from

make any required preparations or other wells or changes in suction and

changes. You should also double- discharge pressures, loading circumstances

check that the gas composition may have altered since the compressor was

meets the contract requirements with originally built.

the gas buyer.

4.3 Unloading the Well

Ensure that all flow lines and pipes

are complete and correctly After verifying that the surface facilities are

connected to the relevant equipment. prepared for production, you are ready to

If you're using separation vessels, unload the well fluid to a pit or holding tank

ensure sure the drain valve is shut and initiate gas production. Operators in

and the liquid dump valve is fitted generally use one of two methods to unload

and functioning correctly. coal bed methane wells:

Depending on where you're

working, the kind of gas venting • Injecting Compressed Air or Nitrogen

equipment you'll require may vary.

• Pumping the Well Down

You may be required to exhaust gas

via a flare stack by certain state oil Injecting Compressed Air or Nitrogen

and gas regulatory bodies. Find out

about equipment regulations such as To unload wells and place them on

height and minimum distance from production as quickly as possible after

the wellhead by contacting your flowing back the fracture treatment, some

local regulatory authorities. coalbed methane operators inject

Vol 12, Issue4, 2021 www.jrmat.com Page No:336

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

compressed air or nitrogen into the wellbore. 2. Open the valve on the dump line.

By injecting air or nitrogen for a day or

more, operators can lift all the water out of a 3. Flow the produced water and gas into the

well, clean out any solid debris, and initiate separator.

gas flow rapidly. 4. Monitor the liquid level in the separator to

Though this method is quicker than pumping ensure that the size of the dump valve is

a well down, it could possibly damage the sufficient to discharge flow at maximum

coal formation. To prevent damage, you expected water flow rate.

should unload the well slowly. Lifting the

5. Continue to monitor the separator and

fluids with air or nitrogen can subject the well frequently during the early production

formation to a large pressure drawdown. time.

This drawdown could cause migration of

coal fines into the created fractures and 4.5 Troubleshooting Well and Equipment

significantly reduce the permeability of the Problems

fractures.

Because of the tight economic

Pumping the Well Down constraints of coal bed methane production,

your ability to quickly diagnose and correct

After flowing the well back following a operational problems is essential to success.

fracture treatment and cleaning out the well Though some of the problems may

to bottom, you can install the production troubleshoot and Equipment Problems be

tubing and down hole pump and begin

unique to coal bed methane, others are

pumping the well down. As you pump water common to most oilfield operations.

out of the well, the reservoir pressure drops

and methane starts to desorb, or detach itself, 5. TREATING AND DISPOSING

from the surfaces of the coal and flow into PRODUCED WATER

the wellbore.

5.1 Introduction

Unlike most conventional gas wells, when

you shut in coal bed methane well, you may The effective development of a coal bed

lose significant gas producing potential. methane plant hinges on the management of

When the well is shut in, water could generated water. Some companies have

encroach into the reservoir and raise the started projects and spent a lot of time and

reservoir pressure. Before gas production money digging and finishing wells, but they

will resume, this pressure must be reduced haven't been able to sell any gas because of

by once again pumping the well down. issues with producing water disposal.

Because water treatment and disposal may

4.4 Bringing the Well On Line account for a significant part of daily

operating expenses, poor planning of this

After you begin pumping the well operation might result in unanticipated

and fluids reach the surface, you are ready to expenditures, reducing the profitability of a

flow the well into the production facilities. project that would otherwise be lucrative.

The procedures below will help bring the

well on line: The nature of the generated water, the

treatment and disposal choices available, the

1. Adjust the rod linkage between the price of the different options, and the

separator’s float arm and float valve to regulatory requirements that control those

ensure the outlet valve closes at the bottom options are all factors that contribute to

of float travel.

Vol 12, Issue4, 2021 www.jrmat.com Page No:337

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

water disposal issues. Many water-related spacing. Characteristics of Methane-

issues may be avoided by conducting a Produced Water from Coal Beds.

geological and engineering assessment at the

start of the project. This chapter gives you an The pace at which water is removed from a

overview of the key topics to think about coal bed methane well is generally

when creating a strategy to manage determined by geologic characteristics,

generated water. formation permeability, completion

techniques, and pump size. Water output

• Coal Bed Methane Produced Water from a typical degasification well is

Characteristics typically higher at first and progressively

declines as the seam is dewatered. This

• Water Disposal Regulations and situation seems to apply to wells that

Permitting produce both large and low quantities of

• Designing a Water Disposal System water at first.

• Methods for Treating and Disposing Water of various quality and amounts is

Produced Water generated in tandem with methane gas. The

kind and depth of coal seams, however, have

5.2 Characteristics of Coal bed Methane the largest effect on the quality of generated

Produced Water waters. Deeper coal-produced waters seem

to be more mineralized than shallow coal-

Dewatering a well typically takes 1- produced waters, which are more likely to

30 days before gas starts to flow. However, have hydraulic linkages.

some wells may need to be pumped for

many weeks or months before methane The water quality generated by coal bed

begins to flow. Within the first month of a reservoirs varies greatly from one area to the

well's existence, water output typically drops next. The quality of the generated water is

by 70% to 90% of its original rate before similar to that of drinking water in certain

settling to a steady fall. This decrease places. The quantity of total dissolved solids

usually hits a plateau at some time and stays (TDS), which includes the concentration of

there for the remainder of the well's life. The chlorides, is the most important factor

time it takes to achieve a constant water flow affecting the quality of coal bed methane

is determined by the reservoir's size and well fluids. In the waters produced at the project

spacing. The longer the dewatering time, the site, total dissolved solids concentrations

bigger the reservoir and the greater the well vary from 500 to 27,000 mg/l.

Discharge Limitations

Water Characteristics

Water Characteristics Daily minimum Daily maximum Monthly average

Flow N/A monitor N/A

PH 6.0 9.0 N/A

Iron N/A 6.0mg/l 3.0mg/l

Manganese N/A 4.0mg/l 2.0mg/l

Chlorides(effluent) N/A monitor monitor

Dissolved oxygen 5.0mg/l N/A N/A

Vol 12, Issue4, 2021 www.jrmat.com Page No:338

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

BOD-5 N/A 45mg/l 30mg/l

Effluent toxicity testing quarterly

Conductivity N/A Continuous Continuous

monitoring monitoring

Chlorides(in stream) N/A 230mg/l N/A

Table 5.1

5.4 Considerations for Designing a Water 6. CBM PRODUCTION IN INDIA AND

Disposal System CONSUMING PLANT

To design an effective and 6.1 Introduction

economical water disposal system, you first

must consider the environmental regulations Essar's Raniganj (East) Block in

and permitting requirements for water West Bengal has achieved the 1 million

disposal in your area. Once you understand standard cubic metres per day production

these restrictions, you can begin evaluating milestone, making it India's first coal bed

the field criteria that will influence your methane asset. On Tuesday, it made the

selection of a treatment and disposal system. announcement in a statement. Essar is now

To design the system, you will need to know the country's biggest unconventional gas

or estimate these five parameters: company.

• Production start-up schedule The block is expected to produce 3

million standard cubic metres per day. The

• Water flow rates from each well known, probable, and potential gross coal

bed methane reserves in the Raniganj (East)

• Variations in flow rates over the life of the

Block are estimated to be 1.09 trillion cubic

project

feet, according to a 2016 study by

• Water quality Netherland Sewell & Associates Inc. The

Block is estimated to contain 270 billion

• Assimilative capacity of the discharge cubic feet of additional resources in the

stream or river 'contingent' category. Manish Maheshwari,

Essar's CEO of exploration and production,

Production Start-Up Schedule

said: "To turn reserves into production, we

The first step in determining field combined expertise with technology. The

disposal requirements is to prepare a average well productivity has more than

schedule of estimated production start-up doubled in the past year, the gas break-out

dates for each of the planned wells. This time in new wells has been lowered to days

schedule, which is based on drilling and rather than months, and the work-over cycle

completion schedules, will help you in has been cut in half. Win-win solutions have

estimating the total water rate over the life of emerged from our working partnership with

the field. The timing of initial well foreign service suppliers."

production can significantly influence the

amount of water that must be treated and Essar began supplying Matix

disposed at any given time. Fertilisers with 150,000 standard cubic

metres per day for pre-commissioning

operations. In addition to Matix, coal bed

methane is delivered to industrial customers

Vol 12, Issue4, 2021 www.jrmat.com Page No:339

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

in Durgapur's catchment region. Gas prices

are set in accordance with a methodology

announced by the government in October

2014.

6.1 Raniganj CBM Field Development Project

6.2PROJECT DESCRIPTION compressor which shall be gas turbine

driven. The compressed CBM Gas shall then

Essar Oil Limited (EOL) is engaged be distributed to Matix Fertilizer plant /

in Coal bed Methane (CBM) exploration Kolkata – Haldiatrunkline.

work in Raniganj East CBM block awarded

under the first round of CBM policy in DESIGN DATA

Burdhwan District of West Bengal, covering

an area of about 500 Sq. km. The CBM gas data considered for this pipe

line project is furnished below:

EOL has carried out exploration

operations and CBM gas is currently being CBM Gas flow : 3 MMSCMD.

produced from the test wells drilled. Gas

CBM Gas Temperature (Compressor Outlet)

production from about 50 wells shall be : 60 Deg C

gathered at one Gas Gathering Station

(GGS) where the gas shall be metered and CBM Gas Max Operating Pressure

compressed for further transmission to (Compressor Outlet) : 60 bar g

desired destination. Exploration operations is

continuing and it is expected that several CBM Gas Design Pressure : 75 bar g

further wells will be added to the system in

Desired destination (Matix Fertilizer Plant)

fewyears.

pressure : 55 bar g

A 16” CBM trunkline laid from

Approximate pipe length between

GGS1 to Durgapur. From this line one tap-

off is taken for Central compressor station. Main Compression station to Matix

In Central compression station, the 3 Fertilizer Plant : 25 km (approx)

MMSCMD of CBM Gas is compressed from

10bar g to 60 bar g using a centrifugal CBM Gas Composition:

Vol 12, Issue4, 2021 www.jrmat.com Page No:340

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

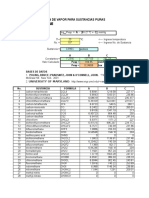

Comp Min Max Normal

Methane 85 98 94.5

Ethane 2 0 1

Propane 1 0 0.5

Butane 0 0 0

Nitrogen 7 0 2

CO2 5 2 2

Total 100 100 100

Molwt 18.84 16.6 17.12

Table 6.2

The following facilities shall be provided on existing PLC/DCS system for Matix

the pipe line network: Fertilizer Plant.

• The fire detection &fire fighting system of PIPE LINE SIZING

Central compressor station will be extended

to pig launching station. Pipeline sizing will be done

considering Central gas compressor station

• The fire detection &fire fighting system of discharge at 60 bar g pressure. The desired

Matix Fertilizer Plant will be extended to pig destination pressure in the battery limit of

receiving station. Matix fertilizer plant is 55 bar g.

• All instrument signals related to pig The line sizes have been selected

launcher shall connect to existing PLC/DCS such that the pressure in the battery limit of

system for central Matix fertilizer plant should not be below

desired pressure i.e. 55 bar g and the

Compressor station & instrument signals maximum velocity of gas in the pipeline

related to pig receiver shall connect to should be below 20 m/sec.

6.3 Gas liquid separation process in CBM field.

Vol 12, Issue4, 2021 www.jrmat.com Page No:1

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

6.4 Waste water treatment process in CBM field

6.5Gas Gathering Station in CBM field.

6.3 Matix Fertilizers and Chemicals Ltd. provides other pertinent details. The plant

will be able to achieve the design capacity in

6.3.1 Ammonia plant the whole range of CBM between the lean

This Process Description covers an and rich compositions.

ammonia plant being built for Matix In normal operation, 2,200 MTPD of

Fertilizers and Chemicals Ltd, West Bengal, warm ammonia and 2,870 MTPD of CO2

India. The feedstock is coal bed methane products are exported to the urea plant. In

(CBM). The plant is designed with a name case of urea plant stoppage, ammonia

plate capacity of 2,200 MTPD of warm product is exported as cold ammonia liquid

ammonia. The ammonia plant design and at -33°C to offsite storage at atmospheric

performance estimates are based on the pressure.

design Coal Bed Methane composition

shown in the Process Design Basis which

Vol 12, Issue4, 2021 www.jrmat.com Page No:342

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

7. CONCLUSION low gas content. As a result, it is currently

not being considered for CBM extraction.

India’s energy scenario This area, however, may be considered in

1. India's economy is one of the the future for methane extraction utilising

world's fastest expanding. sophisticated technology and in an

emergency situation.

2. GDP growth is now at over 8%

and is expected to reach over 10% in the CO2 sequestration aids in the

near future. prevention of global warming while also

assisting in the recovery of methane gas

3. In order to eliminate poverty and from coal beds that would otherwise be

achieve the country's human development uncovered. For efficient and cost-effective

objective, this GDP growth is needed. coal bed methane generation, however,

extensive and rigorous research are needed.

4. A 34-fold increase in primary India, which has 4.6 TCM of coal-bed

energy demand is expected to maintain such methane reserves, may increase its per

development. capita energy demand by successfully using

CBM.

5. According to the Integrated

Energy Policy Document, the country's REFERENCES

overall energy needs will rise from 500

MTOe to 2000 MTOe by 2031–32. Various of sources from internet viz.

Wikipedia and scholarly articles and

6. Efforts are being made to use all Google.

available energy resources—renewable, A journal of coal primer on the

non-renewable, coal-based extra, and so developments of CBM new source of

on—in order to satisfy this massive Tara's. natural gas environmental implications.

M/s Matix Fertilizers and Chemical A journal on the development of the

Limited is a successful complete CBM- Indian coal bed methane resources.

based urea factory in India. Essar oil limited exploration &

production division in Raniganj CBM

CBM technology is making Field Development Project.

excellent progress in proving itself as a Matix Fertilizers and Chemicals Ltd. In

greener energy security for India and the panagarh.

rest of the world. The production method

for methane from CBM, on the other hand, Coalbed Methane: Principles and

is significantly different from that of a Practices - Halliburton

typical gas reservoir. The research Brown, K.E., "The Technology of

discovered that coal type, rank, volatile Artificial Lift Methods, Volume 2a,”

matter, and fixed carbon all had a Pen well Publishing Company, Tulsa

significant impact on methane adsorption (1977).

capability in the coal bed. The maturity of American Petroleum Institute,

coal and the production of methane gas both “Recommended Practice for Care and

rise when the depth of the mine is increased. Use of Subsurface Pumps,” API RP

The Gondwana basin is now being 11AR, Third Edition, Washington, DC

developed as the most promising CBM (June 1989).

field. According to research, the Singareni American Petroleum Institute, “API

coal deposit in the Gandowana basin has a Specification for Subsurface Pumps and

Vol 12, Issue4, 2021 www.jrmat.com Page No:343

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

Fittings, ” API Spec 11AX, Seventh Drottar, K.R., D.R. Mount, and S.J.

Edition, Dallas (June 1979). Patti, 1989, “Biomonitoring of Coalbed

Klein, S.T., Robbins & Myers, Inc. “The Methane Produced Water from the

Progressing Cavity Pump in Coal bed Cedar Cove, Alabama Degasification

Methane Extraction,” SPE Paper 23454, Field,” Proceedings of the 1989

presented at the 1991 SPE Eastern Coalbed Methane Symposium, The

Regional Meeting, Lexington, Kentucky University of Alabama, Tuscaloosa,

(October 22-25). Alabama (April17-20).

Kuuskraa, V.A. and C.F. Brandenburg, Kuuskraa, V.A. and C.F. Brandenburg,

“Coal bed Methane Sparks a New “Coalbed Methane Sparks a New

Energy Industry,” Oil & Gas Journal, Energy Industry,” Oil& Gas Journal,

October 9, 1989. October 9, 1989.

Burkett, W.C., R. McDaniel, and W.L. Lee-Ryan, P.B., J.P. Fillo, J.T.Tallon,

Hall, “The Evaluation and and J.M. Evans, “Evaluation of

Implementation of a Comprehensive Management Options for Coalbed

Production Water Management Plan,” Methane Produced Water,” Proceedings

Proceedings of the 1991 Coalbed of the 1991 Coalbed Methane

Methane Symposium, Tuscaloosa,

Alabama (May 13-17).

Symposium, Tuscaloosa, Alabama (May 13-17).

Vol 12, Issue4, 2021 www.jrmat.com Page No:344

You might also like

- Visio-Refinery Block DiagramDocument1 pageVisio-Refinery Block Diagramankur2061100% (1)

- Map of Natural Gas Pipelines and Oil RefineriesDocument1 pageMap of Natural Gas Pipelines and Oil RefineriesSouthern California Public RadioNo ratings yet

- CBM Exploration TechniquesDocument1 pageCBM Exploration TechniquesAjay GurungNo ratings yet

- Completion Methods in Coal Seam Reservoirs: S.A. Holditch, SPE, SADocument7 pagesCompletion Methods in Coal Seam Reservoirs: S.A. Holditch, SPE, SAyosua putraNo ratings yet

- roadifer2003_what s really important to production and when _ cbm parametric studyDocument11 pagesroadifer2003_what s really important to production and when _ cbm parametric studymakhaNo ratings yet

- Report - CBMDocument57 pagesReport - CBMYash GurjarNo ratings yet

- Coal Bed MethaneDocument28 pagesCoal Bed MethaneMohammed Kabiruddin0% (1)

- Coal Based MethaneDocument6 pagesCoal Based MethaneNIlesh BhagatNo ratings yet

- Coal Bed MethaneDocument9 pagesCoal Bed Methanepartha das sharma100% (2)

- SPE 107714 Geosteering Horizontal Coalbed Methane Reservoirs: A Case StudyDocument7 pagesSPE 107714 Geosteering Horizontal Coalbed Methane Reservoirs: A Case StudyAll_n_CifuentesNo ratings yet

- Journal of Petroleum Science and Engineering: A. Agarwal, A. Mandal, B. Karmakar, K. OjhaDocument6 pagesJournal of Petroleum Science and Engineering: A. Agarwal, A. Mandal, B. Karmakar, K. OjhaAdyNo ratings yet

- The Pros and Cons of Reductive Matte Smelting For PGMsDocument4 pagesThe Pros and Cons of Reductive Matte Smelting For PGMsCristian Andres Florez VergaraNo ratings yet

- Key Advances in Coalbed Methane Technolo GYDocument33 pagesKey Advances in Coalbed Methane Technolo GYSri Varalakshmi MummidiNo ratings yet

- CBM MiningDocument14 pagesCBM MiningRaj SharmaNo ratings yet

- Notice of RetractionDocument6 pagesNotice of Retractionmyco samNo ratings yet

- SlagCarbonationReview AuthorreprintsDocument27 pagesSlagCarbonationReview AuthorreprintsK Suresh AkkihebbalNo ratings yet

- Bonding-Strengthening Technology in Coalbed CementDocument6 pagesBonding-Strengthening Technology in Coalbed CementCoolProphetNo ratings yet

- CBM Could Fulfill National Goals, Such As T He FollowingDocument28 pagesCBM Could Fulfill National Goals, Such As T He FollowingSri Varalakshmi MummidiNo ratings yet

- Ongc To Develop of Parbatpur Area in Jharia Coal Field in Jharkhand For Commercial Production of CBMDocument42 pagesOngc To Develop of Parbatpur Area in Jharia Coal Field in Jharkhand For Commercial Production of CBMSubhashree Mishra100% (3)

- IPA12 E 109 - Firstpage PDFDocument1 pageIPA12 E 109 - Firstpage PDFYayan MansoriNo ratings yet

- Dampak Lingkungan Dan Sosial Dari Pengembangan CBM Di IndonesiaDocument10 pagesDampak Lingkungan Dan Sosial Dari Pengembangan CBM Di IndonesiaMuhammad IkbalNo ratings yet

- B) - Coalbed GasDocument15 pagesB) - Coalbed GasSuci Amalia RendreanaNo ratings yet

- Coal-Bed MethaneDocument28 pagesCoal-Bed Methaneakgupta1946100% (2)

- Coal Bed MethaneDocument40 pagesCoal Bed Methanelaxman_mbmNo ratings yet

- H 2 Production Via Ammonia Decomposition Using Non-Noble Metal Catalysts: A Review Bell - Et - Al-2016-Topics - in - Catalysis-VoRDocument20 pagesH 2 Production Via Ammonia Decomposition Using Non-Noble Metal Catalysts: A Review Bell - Et - Al-2016-Topics - in - Catalysis-VoRAr DiNo ratings yet

- COAL101: Coal Begins Forming 360 Million To 290 Million Years AgoDocument2 pagesCOAL101: Coal Begins Forming 360 Million To 290 Million Years Agojavier lopezNo ratings yet

- Heliyon: A.A. Adeleke, J.K. Odusote, O.A. Lasode, P.P. Ikubanni, M. Malathi, D. PaswanDocument7 pagesHeliyon: A.A. Adeleke, J.K. Odusote, O.A. Lasode, P.P. Ikubanni, M. Malathi, D. PaswanChanaNo ratings yet

- Comparative study on sorption characteristics of coal seams from Barakar and Raniganj formations PTDocument38 pagesComparative study on sorption characteristics of coal seams from Barakar and Raniganj formations PTkanhaiya mishraNo ratings yet

- Low-cost aluminum MMC production via rapid mixing processDocument4 pagesLow-cost aluminum MMC production via rapid mixing processxharpreetxNo ratings yet

- International Journal of Mining Science and TechnologyDocument9 pagesInternational Journal of Mining Science and Technologyhasja palutaNo ratings yet

- Wu2020 Article DesignOfTheKeyBearingLayerAndSDocument15 pagesWu2020 Article DesignOfTheKeyBearingLayerAndSMonique ChiloaneNo ratings yet

- Essar's leadership in Indian CBM explorationDocument57 pagesEssar's leadership in Indian CBM explorationUtkNo ratings yet

- Journal of Natural Gas Science and EngineeringDocument7 pagesJournal of Natural Gas Science and Engineeringsameer bakshiNo ratings yet

- Medco CBM TrakindoDocument9 pagesMedco CBM Trakindopuput utomoNo ratings yet

- H03493 Advances CBMDocument16 pagesH03493 Advances CBMbagus918No ratings yet

- 280-1013-1-PBDocument16 pages280-1013-1-PBZahia ZinebNo ratings yet

- Advances in Alkali-Activation of Clay MineralsDocument28 pagesAdvances in Alkali-Activation of Clay Mineralsamira mansourkhodjaNo ratings yet

- bastian2005_assessment and development of the dry horseshoe canyon cbm play in canadaDocument13 pagesbastian2005_assessment and development of the dry horseshoe canyon cbm play in canadamakhaNo ratings yet

- Simulation Study CBM Case StudyDocument103 pagesSimulation Study CBM Case StudysriNo ratings yet

- Coalbed Methane Economic BoomDocument5 pagesCoalbed Methane Economic Boommeali513No ratings yet

- wei2007Document10 pageswei2007makhaNo ratings yet

- MicrowiveDocument10 pagesMicrowiveFarah TalibNo ratings yet

- CBM IndiaDocument5 pagesCBM IndiaAdmirerNo ratings yet

- Coal Bed Methane (CBM) Project ReportDocument20 pagesCoal Bed Methane (CBM) Project ReportVikram DasNo ratings yet

- Characteristics of Bauxite Residue-Limestone PelletsDocument18 pagesCharacteristics of Bauxite Residue-Limestone PelletsJavi Moros PortolésNo ratings yet

- Coal Bed Methane (CBM) : A Presentation ByDocument22 pagesCoal Bed Methane (CBM) : A Presentation ByNavarino LiveNo ratings yet

- Fukuoka Paper Saravanan 30-08-2015 4 Pages 1Document5 pagesFukuoka Paper Saravanan 30-08-2015 4 Pages 1sih190016No ratings yet

- Ccu Fact Sheet 2015Document4 pagesCcu Fact Sheet 20151412091090No ratings yet

- 016ironflotation Separationscandtech 2019Document15 pages016ironflotation Separationscandtech 2019AHMED ELMUBARAKNo ratings yet

- International Journal of Mining Science and Technology: Martin Brook, Bruce Hebblewhite, Rudrajit MitraDocument10 pagesInternational Journal of Mining Science and Technology: Martin Brook, Bruce Hebblewhite, Rudrajit MitraUdit kumarNo ratings yet

- COAL CHARACTERIZATION AND BLENDING PERSPECTIVEDocument15 pagesCOAL CHARACTERIZATION AND BLENDING PERSPECTIVEbhujakhia_748657110No ratings yet

- International Journal of Mining Science and TechnologyDocument9 pagesInternational Journal of Mining Science and TechnologySushanta Kumar BeheraNo ratings yet

- Its Not Only About Coal Mining Coal-Bed Methane (CBM) and Underground ...Document38 pagesIts Not Only About Coal Mining Coal-Bed Methane (CBM) and Underground ...puput utomoNo ratings yet

- SI Series Paper 04 Blast Furnace 2030 A Vision For Sustainable Iron ProductionDocument8 pagesSI Series Paper 04 Blast Furnace 2030 A Vision For Sustainable Iron ProductionHerlinaNo ratings yet

- An Investigation of The Factors Affecting The Recovery of Molybdenite in The Kennecott Utah Copper Bulk Flotation CircuitDocument9 pagesAn Investigation of The Factors Affecting The Recovery of Molybdenite in The Kennecott Utah Copper Bulk Flotation CircuitDaniel Ernesto Nauduan FloresNo ratings yet

- Application of Geophysical Well-Logs in Coal Bed MethaneDocument14 pagesApplication of Geophysical Well-Logs in Coal Bed MethaneKukuh Tri AtmantoNo ratings yet

- Abbas. 2010. Hydrogen Production by Methane PDFDocument31 pagesAbbas. 2010. Hydrogen Production by Methane PDFHafiz Rama Devara100% (1)

- 080 BergmanDocument10 pages080 BergmanYogesh LadNo ratings yet

- 2021-02 TSE - Concrete Embodied Carbon ArticleDocument2 pages2021-02 TSE - Concrete Embodied Carbon Articlef81lNo ratings yet

- Galetakis 3Document6 pagesGaletakis 3Ioannis KapageridisNo ratings yet

- Reclamation, Treatment and Utilization of Coal Mining WastesFrom EverandReclamation, Treatment and Utilization of Coal Mining WastesNo ratings yet

- Chemistry and Metallurgy: Second Revised and Enlarged EditionFrom EverandChemistry and Metallurgy: Second Revised and Enlarged EditionA. SherryNo ratings yet

- Well Logging Importance in Oil and Gas Exploration and ProductionDocument8 pagesWell Logging Importance in Oil and Gas Exploration and ProductionAnjan KumarNo ratings yet

- JETIR2003082Document6 pagesJETIR2003082GEOGINo ratings yet

- JETIR2003087Document7 pagesJETIR2003087GEOGINo ratings yet

- JETIR1908735Document9 pagesJETIR1908735GEOGINo ratings yet

- IJRAR19K7734Document9 pagesIJRAR19K7734GEOGINo ratings yet

- Fileserve Sir 4Document9 pagesFileserve Sir 4GEOGINo ratings yet

- Fileserve Sir 1Document5 pagesFileserve Sir 1GEOGINo ratings yet

- Fileserve Sir 3Document8 pagesFileserve Sir 3GEOGINo ratings yet

- JETIR1908730Document6 pagesJETIR1908730GEOGINo ratings yet

- Fileserve Sir 2Document8 pagesFileserve Sir 2GEOGINo ratings yet

- K GopinadthDocument10 pagesK GopinadthGEOGINo ratings yet

- IJRAR19K7733Document5 pagesIJRAR19K7733GEOGINo ratings yet

- NBA Criteria MatrixDocument59 pagesNBA Criteria MatrixGEOGINo ratings yet

- Acid TreatmentsDocument82 pagesAcid TreatmentsGEOGINo ratings yet

- Criteria 6Document10 pagesCriteria 6GEOGINo ratings yet

- Criteria 1Document2 pagesCriteria 1GEOGINo ratings yet

- Mines Act 1952 SummaryDocument33 pagesMines Act 1952 SummaryDhirendraRaviNo ratings yet

- Jetti GopiDocument21 pagesJetti GopiGEOGINo ratings yet

- Criteria 5 - Dr. N R N V Gowripathi RaoDocument32 pagesCriteria 5 - Dr. N R N V Gowripathi RaoGEOGINo ratings yet

- Criteria 2 & 6 - Files-GuidelinesDocument13 pagesCriteria 2 & 6 - Files-GuidelinesGEOGINo ratings yet

- Modified Criteria-1Document22 pagesModified Criteria-1GEOGI100% (1)

- Formal Letter Writing: Rama Krishna TangellaDocument18 pagesFormal Letter Writing: Rama Krishna TangellaGEOGINo ratings yet

- Criteria-7Document17 pagesCriteria-7GEOGINo ratings yet

- Lecture 01Document17 pagesLecture 01Devsoth NareshNo ratings yet

- Invistigation of Coal Mine FiresDocument58 pagesInvistigation of Coal Mine FiresGEOGINo ratings yet

- Common Errors: Neelima TeluguDocument25 pagesCommon Errors: Neelima TeluguGEOGINo ratings yet

- Criteria 2Document31 pagesCriteria 2GEOGINo ratings yet

- Often: J.Bala Raja Sekhar Asst Professor Aditya Engineering CollegeDocument23 pagesOften: J.Bala Raja Sekhar Asst Professor Aditya Engineering CollegeGEOGINo ratings yet

- CrackingDocument16 pagesCrackingGEOGINo ratings yet

- Difference Between Alkanes, Alkenes and Alkynes - Difference BetweenDocument7 pagesDifference Between Alkanes, Alkenes and Alkynes - Difference BetweenAjit KalelNo ratings yet

- Retarderi Kolicina UljaDocument12 pagesRetarderi Kolicina Uljaoprez oprezNo ratings yet

- Cy1104 - Engineering Chemistry Unit - 4 Fuels and Combustion Lecture PlanDocument22 pagesCy1104 - Engineering Chemistry Unit - 4 Fuels and Combustion Lecture PlanBeuna.No ratings yet

- Economides - Economics GTL Vs LNGDocument5 pagesEconomides - Economics GTL Vs LNGvsavvidouNo ratings yet

- Changes to excise duty rates on petroleum productsDocument4 pagesChanges to excise duty rates on petroleum productsvinodNo ratings yet

- Cyprus LNG Terminal EngDocument12 pagesCyprus LNG Terminal Engapi-252576407100% (1)

- PETRONASDocument29 pagesPETRONASAisyah RashidNo ratings yet

- Nutrition and Feeding BarcodesDocument12 pagesNutrition and Feeding BarcodesDione Ray TalipNo ratings yet

- (6648-0200-5-PS-MB-0001-F) Heat and Material Balance (200 Unit)Document34 pages(6648-0200-5-PS-MB-0001-F) Heat and Material Balance (200 Unit)Mohamed OuichaouiNo ratings yet

- SC TecDocument33 pagesSC TecChunyu LiNo ratings yet

- Petronet Corporate Presentation June 2011Document34 pagesPetronet Corporate Presentation June 2011veeruduNo ratings yet

- CALCULO DE LA PRESION DE VAPOR PARA SUSTANCIAS PURASDocument30 pagesCALCULO DE LA PRESION DE VAPOR PARA SUSTANCIAS PURASCarlos MartinezNo ratings yet

- Oil and Gas: Sector ProfileDocument21 pagesOil and Gas: Sector ProfileKalpitNo ratings yet

- Interthane 990 BM PrintDocument9 pagesInterthane 990 BM Printmiqa sunaloiusNo ratings yet

- Converter Transmissions For Off-Road Equipment (Off-Road Vehicles, Special Vehicles, Lift Truck) List of Lubricants TE-ML 03Document11 pagesConverter Transmissions For Off-Road Equipment (Off-Road Vehicles, Special Vehicles, Lift Truck) List of Lubricants TE-ML 03Edison GonsalvesNo ratings yet

- Class 10 Chapter 8 Part IIDocument33 pagesClass 10 Chapter 8 Part IIganeshNo ratings yet

- Cracking: Submitted By: Soma Khalid. Lulav Saeed. Media Hassan. Hallat Hamza. Submitted byDocument22 pagesCracking: Submitted By: Soma Khalid. Lulav Saeed. Media Hassan. Hallat Hamza. Submitted byLulav BarwaryNo ratings yet

- Indonesia Oil & Gas Report Q1 22 - FitchDocument111 pagesIndonesia Oil & Gas Report Q1 22 - FitchFTNo ratings yet

- Origin of PetroeumDocument75 pagesOrigin of PetroeumOliverQueenNo ratings yet

- Download more from www.TheDarshika.comDocument10 pagesDownload more from www.TheDarshika.comPreeti kumariNo ratings yet

- KATALOG - ORLEN - 2022 - PL - Lipiec 2022Document48 pagesKATALOG - ORLEN - 2022 - PL - Lipiec 2022mostafaNo ratings yet

- CHE F422 - Compre - PRT PDFDocument4 pagesCHE F422 - Compre - PRT PDFTarun MandalamNo ratings yet

- Oil and Gas IndustryDocument23 pagesOil and Gas IndustryJoshwin JacobNo ratings yet

- Reliance Petroleum LTDDocument65 pagesReliance Petroleum LTDnijjar_4_u9916No ratings yet

- AAPG Alexandria GTWDocument3 pagesAAPG Alexandria GTWmohame30dNo ratings yet

- Lecture 2 - S1 - 96 PDFDocument15 pagesLecture 2 - S1 - 96 PDFAnonymous dSQiRGNo ratings yet

- 00000330Document64 pages00000330Bahman MatouriNo ratings yet

- Gail Investor PresentationDocument31 pagesGail Investor Presentationsurya167No ratings yet