Professional Documents

Culture Documents

Electrical M03 Connectors EN TXT

Uploaded by

Aimet TraslaviñaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical M03 Connectors EN TXT

Uploaded by

Aimet TraslaviñaCopyright:

Available Formats

Global Manpower Development

Electronics Troubleshooting ILT

Connectors

Module 3 - TEXT REFERENCE

SERV1877

Electronics Troubleshooting ILT

Module 3 - Connectors

Text Reference

Print Instructor Pages Print Participant Pages

© 2010 Caterpillar Inc.

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -2- Module 3 - Connectors

2_1

The purpose of a connector is to pass current from one wire to another. In order to

accomplish this, the connector must have two mating halves (plug or receptacle).

One half houses a pin and the other half houses a socket. When the two halves are

joined, current is allowed to pass.

With the increased use of electronic systems on Cat machines, servicing connectors

has become a critical task. With increased usage comes an increase in maintenance

on the wiring, connectors, pins, and sockets. Another important factor contributing

to increased repair is the harsh environment in which the connectors operate.

Connectors must operate in extremes of heat, cold, dirt, dust, moisture, chemicals,

etc.

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -3- Module 3 - Connectors

CONNECTORS

No Asperity Asperity

Pin Contacts Socket Contact No Contact

Condition of Asperity

Contact No Contact

Electrons

Converging

3_1

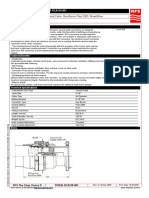

Pins and sockets have resistance and offer some opposition to current flow. Since

the surface of the pins and sockets are not smooth (contain peaks and valleys), a

condition known as asperity (roughness of surface) exists. When the mating halves

are connected, approximately one percent of the surfaces actually contact each

other.

The electrons are forced to converge at the peaks, thereby creating a resistance

between the contact halves. Although this process seems rather insignificant to the

operation of an electronic control, a resistance across the connector could create a

malfunction in electronic controls.

In order to achieve a minimum resistance in the pins and contacts, we need to be

concerned with the finish, pressure, and metal used in the construction of the pins

and contacts. Tin is soft enough to allow for “film wiping”, but it has high resistivity.

Copper has low resistivity, but it is hard. So in striving for minimum resistance and

the reduction of asperity, low resistance copper contacts are often plated with tin.

Film wiping occurs when pins and contacts are plated with tin, and when they are

mated together, they have a tendency to “wipe” together and actually smooth out

some of the peaks and valleys created by the asperity condition. Other metals, such

as gold and silver, are excellent plating materials, but are too costly to use.

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -4- Module 3 - Connectors

Contaminants

Contaminants are another factor that contribute to resistance in connectors. Some

harsh conditions that employ chemicals, etc. can cause malfunctions due to increased

resistance.

NOTE: Connectors can and do cause many diagnostic problems. It may

be necessary to measure the resistance between connector halves when

diagnosing electronic control malfunctions. Also, disconnecting and reconnecting

connectors during the troubleshooting process can give misleading diagnostic

information. Additionally, use breakout cables sparingly when troubleshooting

intermittent electrical problems.

Types of Connectors

Inform the participants that Several types of connectors are used throughout the electrical and electronic systems

connector service procedures can on Cat machines. Each type differs in the manner in which they are serviced or

be found in the appropriate Special repaired.

Instruction.

The following types of connectors will be discussed in detail:

Show Video SEVN3197 (Basic Wire

Maintenance) if time allows. • Vehicular Environmental (VE) Connectors

• Sure Seal Connectors

• Deutsch Connectors (HD10, DT, CE, and DRC Series)

• Ampseal Connectors

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -5- Module 3 - Connectors

5_1

VE Connectors

• VE stands for Vehicular The VE connector was used primarily on earlier Cat machine electrical harnesses

Enviornments where high temperatures, larger number of contacts, or higher current carrying

capacities were needed.

The connector required a special metal release tool for removing the contacts that

could damage the connector lock mechanism if the tool was turned during release

of the retaining clip.

NOTE: The metal release tools for this connector are no longer available as

they have been replaced with plastic release tools. Metal release tools (listed

in SEHS8038) may still be used if you have them, but may not be used for any

other type of electrical connector.

Specific information relating to the process required for installing VE connector

contacts (pins and sockets) is contained in Special Instruction--Use of VE Connector

Tool Group (Form SEHS8038).

This type of connector is no longer used on current product, but may still require

servicing by a field/shop technician.

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -6- Module 3 - Connectors

6_1

Sure Seal Connectors

• Typically found on Machines Sure Seal connectors used to be used extensively on Cat machines. These connector

housings have provisions for accurately mating between the two halves, but instead

• Up to 10 contacts (wires) of using guide keys or keyways, the connector bodies are molded such that they will

not mate incorrectly.

• Require the use of a special tool

6V3008 for installing contacts Sure Seal Connectors are limited to a capacity of 10 contacts (pins and sockets).

• Each end includes BOTH pins NOTE: Part numbers for spare plug and receptacle housings and contacts are

and sockets contained in Special Instruction–Use of 6V3000 Sure Seal Repair Kit (Form

SMHS7531).

• Different style pins and sockets

(open barrel type) Use special tool (6V3001) for crimping contacts and stripping wires.

• Part numbers contained in Sure Seal Connectors require the use of a special tool 6V3008 for installing contacts.

Special Instruction--Use of Use denatured alcohol as a lubricant when installing contacts. Special tooling is not

6V3000 Sure Seal Repair Kit required for removing pin contacts.

(Form SMHS7531)

Any holes in the housings not used for contact assemblies should be filled with a

9G3695 Sealing Plug. The sealing plug will help prevent moisture from entering the

housings.

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -7- Module 3 - Connectors

7_1

Deutsch Heavy Duty (HD10) Series Connectors

• Cylindrical connector The HD10 connector is a thermoplastic cylindrical connector utilizing crimp-type

contacts that are quickly and easily removed. The thermoplastic shells are available

• 3-, 5-, 6-, 9-pin models available in non-threaded and threaded configurations using insert arrangements of 3, 5, 6,

and 9 contacts. The contact size is #16 and accepts #14, #16, and #18 AWG wire.

• Typically used for datalink wires

(9 pin) The HD10 uses crimp-type, solid copper alloy contacts (size #16) that feature an ability

to carry continuous high operating current loads without overheating. The contacts

• Plug has sockets, Receptacle are crimp terminated using a Deutsch Crimp Tool, Cat part number 1U5805.

has pins

Deutsch termination procedures recommend NO SOLDERING after properly crimped

• Disassemble with Wire Removal contacts are completed.

Tool

The procedure for preparing a wire and crimping a contact is the same for all

• Repair kit: 190-8900 Deutsch connectors and is explained in Special Instruction–Servicing DT Connectors

(SEHS9615). The removal procedure differs from connector to connector and will be

explained in each section.

• Deutsch Crimp Tool, P/N 1U5805

• No soldering

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -8- Module 3 - Connectors

8_1

Deutsch Transportation (DT) Series Connectors

• 2-, 3-, 4-, 6-, 8-, 12-pin The DT connector is a thermoplastic connector utilizing crimp-type contacts that are

configuration quickly and easily removed and require no special tooling. The thermoplastic

housings are available in configurations using insert arrangements of 2, 3, 4, 6, 8,

• Typically used on engine and and 12 contacts. The contact size is #16 and accepts #14, #16, and #18 AWG

machine harnesses/sensors wire.

• Receptacles have pins, Plugs The DT uses crimp-type, solid copper alloy contacts (size #16) that feature an ability

have sockets to carry continuous high operating current loads without overheating. Stamped

and formed contacts are usually used during manufacturing and initial assembly

• Each end has wedges that must of harnesses using DT connectors. The crimp-type contacts are crimped using a

be in place Deutsch Crimp Tool, Cat part number 1U5804.

• Repair kit: 175-3700 The DT connector differs from other Deutsch connectors in both appearance

and construction. The DT is either rectangular or triangular shaped and contains

serviceable plug wedges, receptacle wedges, and silicone seals.

• Deutsch Crimp Tool, P/N 1U5805

The recommended cleaning solvent for all Deutsch contacts is denatured alcohol.

• No soldering

NOTE: For a more detailed explanation on servicing the DT connector, consult

Special Instruction–Servicing DT Connectors (SEHS9615).

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -9- Module 3 - Connectors

9_1

Cat Environmental Connectors (CE)

The CE connector is a special application connector. The CE Series connector can

accommodate between 7 and 37 contacts, with the 37 contact connector being used

on various electronic control modules.

The CE connector uses two different crimping tools. The crimping tool for #4 - #10

size contacts is a 4C4075 Hand Crimp Tool Assembly. The tool for #12 - #18 contacts

is the same tool as used on the HD and DT Series connectors (1U5804).

NOTE: For a more detailed explanation on servicing the CE connectors, refer to

Special Instruction–Use of CE/VE Connector Tools (SEHS9065).

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -10- Module 3 - Connectors

10_1

Deutsch Rectangular Connector (DRC)

• Rectangular thermoplastic The DRC connector features a rectangular thermoplastic housing and is completely

housing environmentally sealed. The DRC is best suited for use with external and internal

electronic control modules.

• 24-, 40-, 70-pin models available

The connector is designed with a higher number of terminals. The insert arrangements

• Typically used on ADEM 2 ECMs available are 24, 40, and 70 contact terminations. The contact size is #16 and

accepts #16 and #18 AWG wire.

• Keyed for proper orientation

The connector uses crimp-type, copper alloy contacts (size #16) that feature an

ability to carry continuous high operating current loads without overheating. Stamped

• Plug has sockets, Receptacle

and formed contacts are usually used during manufacturing and initial assembly of

has pins

harnesses using DRC connectors. The crimp-type contacts are crimped using a

Deutsch Crimp Tool, Cat part number 1U5804.

• No soldering

The connector contains a “clocking” key for correct orientation and is properly

• Disassemble with Wire Removal secured by a stainless steel jackscrew. A 4 mm (5/32 in.) HEX key is required to

Tool mate the connector halves. The recommended torque for tightening the jackscrew

is 25 inch pounds.

• Deutsch Crimp Tool, P/N 1U5805

NOTE: The DRC uses the same installation and removal procedures as the

HD10 series.

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -11- Module 3 - Connectors

11_1

Ampseal 16 Connector

• Newer style. Highway Truck The Ampseal connector features a thermoplastic housing with silicone rubber seals,

started using in 2006 ensuring an environmentally sealed connection that is able to withstand harsh, wet

conditions. Three color coded styles, each with a unique key pattern, ensure

• Used same pin/sockets as successful mating of the connectors.

Deutsch

Plug and receptacle assemblies feature a color coded terminal position assurance

• 2-, 3-, 4-, 6-, 8-, 12-pin models (TPA) cover that locks the pins or sockets in place. The TPAs are keyed according

available to their respective color code:

• Connector Position Assurance • Red: Key 1

(CPA) and Terminal Position • Gray: Key 2

Assurance (TPA) • Yellow: Key 3

• Green: Key 4

• Plug has sockets, Receptacle

has pins

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -12- Module 3 - Connectors

• Repair kit: 270-5051 Plug assemblies also feature a connector position assurance (CPA) lock that prevents

the unintended separation of plug and receptacle connections.

• Deutsch Crimp Tool, P/N 1U5805

The connector is designed for a maximum of 12 pins. Connector arrangements are

• No soldering available in 2-, 3-, 4-, 6-, 8-, and 12-pin versions. Connectors accept #14, #16, and

#18 AWG wire. The contacts are crimp terminated using a Deutsch Crimp Tool, Cat

part number 1U5804.

NOTE: Plug and receptacles will only accept wires with a specific range of

insulation diameters. Although contacts will accept other gauge wires with a

wider range of insulation diameters, only #14, #16, and #18 AWG wires with

recommended insulation diameters should be used. See REHS2556 for more

information regarding recommended insulation diameters, as well as a more

detailed explanation of servicing Ampseal connectors.

Caterpillar: Confidential Yellow

SERV1877 - 03/10 -13- Module 3 - Connectors

1 2

3 4

13_1

Connector Schematic Symbol

• Stress that in Deutsch The illustration above shows a typical schematic symbol of a connector. It is important

connectors, the plugs get to understand what each part of this symbol represents in order to properly identify

sockets only and the receptacles connectors and related components.

get pins only.

• 1- Receptacle

• In Sure Seal connectors, plugs • 2- Plug

and receptacles each have both

pins and sockets. • 3 - Pin

• 4- Socket

Caterpillar: Confidential Yellow

You might also like

- Off Grid Solar Hybrid Inverter Operate Without Battery: HY VMII SeriesDocument1 pageOff Grid Solar Hybrid Inverter Operate Without Battery: HY VMII SeriesFadi Ramadan100% (1)

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Gracella Irwana - G - Pert 04 - Sia - 1Document35 pagesGracella Irwana - G - Pert 04 - Sia - 1Gracella IrwanaNo ratings yet

- Condition Monitoring Program of HV Cable SystemsDocument5 pagesCondition Monitoring Program of HV Cable SystemsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 793D Off-Highway Truck FDB00001-UP (MACHINE) POWERED BY 3516B Engine (SEBP3976 - 170) - Documentation 2Document5 pages793D Off-Highway Truck FDB00001-UP (MACHINE) POWERED BY 3516B Engine (SEBP3976 - 170) - Documentation 2Duber Garcia pedrozaNo ratings yet

- Installation, Operation and Maintenance Instructions: Metalarm Series 6301 Ce Metal Detector SystemDocument12 pagesInstallation, Operation and Maintenance Instructions: Metalarm Series 6301 Ce Metal Detector SystemKarin AndersonNo ratings yet

- Analysis of The Electric Field Distribution Within MV Cable Joint in The Presence of Defects in Cable InsulationDocument11 pagesAnalysis of The Electric Field Distribution Within MV Cable Joint in The Presence of Defects in Cable InsulationEdgardo Ariel RodriguezNo ratings yet

- Mill-Max Ebook 05-19 V6Document15 pagesMill-Max Ebook 05-19 V6Karim MelNo ratings yet

- Operational Considerations For Underwater-Mateable ConnectorsDocument6 pagesOperational Considerations For Underwater-Mateable Connectorssm_carvalhoNo ratings yet

- Weidmuller Ferrules White PaperDocument6 pagesWeidmuller Ferrules White PapertotovasiNo ratings yet

- Wiring Tips For Connections and Routing Inside Industrial Control PanelDocument12 pagesWiring Tips For Connections and Routing Inside Industrial Control Panelwalter puma floresNo ratings yet

- WWWWQQQQQQQQQQQQQQDocument33 pagesWWWWQQQQQQQQQQQQQQrigoberto otinianoNo ratings yet

- Basic Concepts Electrical CircuitsDocument38 pagesBasic Concepts Electrical CircuitslakshmiraniNo ratings yet

- SBV07N03 061307Document8 pagesSBV07N03 061307Jaime MurilloNo ratings yet

- List of Experiments: Ge8261-Engineering Practices Laboratory - Group BDocument57 pagesList of Experiments: Ge8261-Engineering Practices Laboratory - Group BJeeva RathnamNo ratings yet

- Handbook On Plug in RelaysDocument45 pagesHandbook On Plug in RelaysSrinivas Enamandram100% (1)

- Fluke - How Cables and Connectors Impact Measurement UncertaintyDocument4 pagesFluke - How Cables and Connectors Impact Measurement UncertaintyMatias RamosNo ratings yet

- Effect of Intermittent Fretting On Corrosion Behavior in Electrical ContactDocument8 pagesEffect of Intermittent Fretting On Corrosion Behavior in Electrical ContactJean AbelaNo ratings yet

- Electrical: Er Transit Service ManualDocument76 pagesElectrical: Er Transit Service ManualArmando HernandezNo ratings yet

- Cable Fault Location in Medium Voltage of Sonelgaz Underground Network Recherche de Défaut de Câblé Dans Le Réseau Souterrain de SonelgazDocument12 pagesCable Fault Location in Medium Voltage of Sonelgaz Underground Network Recherche de Défaut de Câblé Dans Le Réseau Souterrain de SonelgazKamel MoridNo ratings yet

- Labnote PL243 ElectronicsDocument83 pagesLabnote PL243 ElectronicsVolodya SmolyakNo ratings yet

- Meltric Brochure Switch Rated enDocument24 pagesMeltric Brochure Switch Rated enSreekanthNo ratings yet

- Electrical ComponentsDocument26 pagesElectrical ComponentsVictor LuqueNo ratings yet

- Crimping TestDocument6 pagesCrimping TestAmit VijayvargiyaNo ratings yet

- Relay TutorialDocument3 pagesRelay Tutorialant29539432No ratings yet

- Waukesha Gas Engines: WarningDocument3 pagesWaukesha Gas Engines: WarningdfmolinaNo ratings yet

- 318eia Hca318 001Document2 pages318eia Hca318 001Ari SaputraNo ratings yet

- Prelim Exam JOPIADocument4 pagesPrelim Exam JOPIAGABRIEL ABRAM JOPIANo ratings yet

- 11 Major Causes of Power System FailuresDocument11 pages11 Major Causes of Power System FailuresHiram FloresNo ratings yet

- Crimping Technology PreDocument31 pagesCrimping Technology PreAlehegn ZurbetNo ratings yet

- Introduction To Military Standard Cylindrical ConnectorsDocument7 pagesIntroduction To Military Standard Cylindrical ConnectorsZac BismonteNo ratings yet

- Analysis of The Electric Field Distribution Within MV Cable JointDocument10 pagesAnalysis of The Electric Field Distribution Within MV Cable Jointmbmaterial5390No ratings yet

- Electrical Safety: Information BulletinDocument8 pagesElectrical Safety: Information BulletinThinh TranNo ratings yet

- Common Wire Splices and Joints m3q1Document13 pagesCommon Wire Splices and Joints m3q1Jonah BolivarNo ratings yet

- MSFC STD 781 ADocument8 pagesMSFC STD 781 AĐặng Xuân SơnNo ratings yet

- Finals Module 1 2 Avt 4232Document54 pagesFinals Module 1 2 Avt 4232angeloNo ratings yet

- Experiment No. 04: Title Domestic Wiring For Extension Board and Inverter. AimDocument8 pagesExperiment No. 04: Title Domestic Wiring For Extension Board and Inverter. AimStar LordNo ratings yet

- 3RD GP (ACTIVITY #3) : Circuits: DirectionsDocument3 pages3RD GP (ACTIVITY #3) : Circuits: DirectionsBeefWith PorkNo ratings yet

- css10 Week 5Document8 pagescss10 Week 5lesterNo ratings yet

- Electric Handpieces: An Overview of Current Technology: Focus OnDocument3 pagesElectric Handpieces: An Overview of Current Technology: Focus OnPRDAkNo ratings yet

- High Voltage Large Current Terminals For Hybrid ElDocument6 pagesHigh Voltage Large Current Terminals For Hybrid ElVăn BảoNo ratings yet

- Data Bulletin Transformer Electrostatic Shields: Overview: Shields and GroundingDocument8 pagesData Bulletin Transformer Electrostatic Shields: Overview: Shields and GroundingPABLO MAURONo ratings yet

- Feeder PillarsDocument8 pagesFeeder PillarsARYA JENANo ratings yet

- Splicing - Joining Electrical ConductorDocument35 pagesSplicing - Joining Electrical ConductorMARY ANN NUCEJANo ratings yet

- Fault Location On Power Cables - en - 002Document7 pagesFault Location On Power Cables - en - 002Poya ShefayeNo ratings yet

- Activity 2.pmdDocument2 pagesActivity 2.pmdMy EMailNo ratings yet

- Activity Activity Activity Activity Activity: ActivitiesDocument2 pagesActivity Activity Activity Activity Activity: ActivitiesHarsh ShahNo ratings yet

- Earthing of MV and LV Distribution LinesDocument9 pagesEarthing of MV and LV Distribution LinesmentongNo ratings yet

- Written Assesment in Splicing - Joining Electrical ConductorDocument9 pagesWritten Assesment in Splicing - Joining Electrical ConductorMARY ANN NUCEJA100% (1)

- Basic Electrical EngineeringDocument48 pagesBasic Electrical Engineeringjai prakashNo ratings yet

- Maharashtra Institute of Technology, Aurangabad Laboratory ManualDocument14 pagesMaharashtra Institute of Technology, Aurangabad Laboratory ManualReddyvari VenugopalNo ratings yet

- KDE200 Series User Manual 20180412Document88 pagesKDE200 Series User Manual 20180412Thanh Tuyền TrươngNo ratings yet

- Avoiding Common Code Mistakes: John WilesDocument3 pagesAvoiding Common Code Mistakes: John WilesKaher AlyteemNo ratings yet

- Electronics Workshop Manual 2Document141 pagesElectronics Workshop Manual 2Manu Yadav100% (1)

- Shielding-10 PDFDocument6 pagesShielding-10 PDFevensteveNo ratings yet

- 4 Pole Circuit BreakerDocument2 pages4 Pole Circuit BreakerMin ZayarNo ratings yet

- What Is A Contactor - Types, Working and ApplicationsDocument12 pagesWhat Is A Contactor - Types, Working and ApplicationsMUHAMMAD AHMEDNo ratings yet

- Underground Cable Fault Detection Using ZigbeeDocument36 pagesUnderground Cable Fault Detection Using ZigbeeRana AbrarNo ratings yet

- The Best Electrical Controls Business On The Planet!: Page 1 of 8Document8 pagesThe Best Electrical Controls Business On The Planet!: Page 1 of 8nandiniNo ratings yet

- Installation Manual 3ats, 3adts, 3Nts, 3Ndts G-Design 1600-3200 A Transfer SwitchesDocument8 pagesInstallation Manual 3ats, 3adts, 3Nts, 3Ndts G-Design 1600-3200 A Transfer SwitchesMahmoud M.AbdelalimNo ratings yet

- Electrical M04 ECUs enDocument13 pagesElectrical M04 ECUs enAimet TraslaviñaNo ratings yet

- Electrical M05 CatET enDocument19 pagesElectrical M05 CatET enAimet TraslaviñaNo ratings yet

- Electrical M09 SensorDiag enDocument13 pagesElectrical M09 SensorDiag enAimet TraslaviñaNo ratings yet

- Electrical M06 ElectSchem EN TXTDocument20 pagesElectrical M06 ElectSchem EN TXTAimet TraslaviñaNo ratings yet

- Matutum View Academy: (The School of Faith)Document14 pagesMatutum View Academy: (The School of Faith)Neil Trezley Sunico BalajadiaNo ratings yet

- 1 AlarmvalveDocument9 pages1 AlarmvalveAnandNo ratings yet

- Science9 Q4 Week2Document16 pagesScience9 Q4 Week2Maria Josie Lopez TumlosNo ratings yet

- Action Plan in T.L.E Project Title Objectives Activities Person-In-Charge Time Frame Success IndicatorDocument1 pageAction Plan in T.L.E Project Title Objectives Activities Person-In-Charge Time Frame Success IndicatorEdelmar BenosaNo ratings yet

- AN44061A Panasonic Electronic Components Product DetailsDocument3 pagesAN44061A Panasonic Electronic Components Product DetailsAdam StariusNo ratings yet

- 8 Adam AmuraroDocument28 pages8 Adam Amurarokmeena73No ratings yet

- A Method For Prediction of Gas/Gas Ejector PerformanceDocument6 pagesA Method For Prediction of Gas/Gas Ejector PerformancedhavaleshNo ratings yet

- Aex-Kissan KeralaDocument25 pagesAex-Kissan Keralabsh08070No ratings yet

- Cornish BoilerDocument3 pagesCornish BoilerDeepak KV ReddyNo ratings yet

- Microsome S9 Prep ProtocolDocument22 pagesMicrosome S9 Prep ProtocolSAN912No ratings yet

- Chrysler CDS System - Bulletin2Document6 pagesChrysler CDS System - Bulletin2Martin Boiani100% (1)

- DOT RequirementsDocument372 pagesDOT RequirementsMuhammadShabbirNo ratings yet

- Kursus Jabatan Kejuruteraan Mekanikal Sesi Jun 2014Document12 pagesKursus Jabatan Kejuruteraan Mekanikal Sesi Jun 2014ihsanyusoffNo ratings yet

- Or HandoutDocument190 pagesOr Handoutyared haftu67% (6)

- World BankDocument28 pagesWorld BankFiora FarnazNo ratings yet

- Masking Conventional Metallic Cast Post For Enhancing EstheticsDocument5 pagesMasking Conventional Metallic Cast Post For Enhancing EstheticsleilyanisariNo ratings yet

- Royal British College Dancesport TeamDocument10 pagesRoyal British College Dancesport TeamAnna rose CabatinganNo ratings yet

- 1en 02 PDFDocument96 pages1en 02 PDFAndrey100% (2)

- 03 IGT-Influence of Codes Guidelines and Other Regulations On The Tunnel Design in AustriaDocument48 pages03 IGT-Influence of Codes Guidelines and Other Regulations On The Tunnel Design in AustriaSudarshan GadalkarNo ratings yet

- World of Self, Family and Friends UNIT 4 - Lunchtime Speaking 37 Wednesday Friendship LanguageDocument11 pagesWorld of Self, Family and Friends UNIT 4 - Lunchtime Speaking 37 Wednesday Friendship LanguageAin NawwarNo ratings yet

- Yu ZbornikDocument511 pagesYu ZbornikВладимирРакоњацNo ratings yet

- Linux and The Unix PhilosophyDocument182 pagesLinux and The Unix PhilosophyTran Nam100% (1)

- Defining The Standards For Medical Grade Honey PDFDocument12 pagesDefining The Standards For Medical Grade Honey PDFLuis Alberto GarcíaNo ratings yet

- MCC333E - Film Review - Myat Thu - 32813747Document8 pagesMCC333E - Film Review - Myat Thu - 32813747Myat ThuNo ratings yet

- GST RATE LIST - pdf-3Document6 pagesGST RATE LIST - pdf-3Niteesh KumarNo ratings yet

- Week 1 Familiarize The VmgoDocument10 pagesWeek 1 Familiarize The VmgoHizzel De CastroNo ratings yet

- (Polish Journal of Sport and Tourism) The Estimation of The RAST Test Usefulness in Monitoring The Anaerobic Capacity of Sprinters in AthleticsDocument5 pages(Polish Journal of Sport and Tourism) The Estimation of The RAST Test Usefulness in Monitoring The Anaerobic Capacity of Sprinters in AthleticsAfizieNo ratings yet

- CESCOM 10 - Aircraft Status Report: Maintenance InspectionsDocument78 pagesCESCOM 10 - Aircraft Status Report: Maintenance InspectionsAlejandro BarradasNo ratings yet