Professional Documents

Culture Documents

Mercon LV Specification (IHS 11 Jun 2012)

Uploaded by

octo widodoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mercon LV Specification (IHS 11 Jun 2012)

Uploaded by

octo widodoCopyright:

Available Formats

ENGINEERING MATERIAL SPECIFICATION

FLUID, AUTOMATIC TRANSMISSION WSS-M2C938-A

1. SCOPE

The material defined by this specification is for factory fill automatic transmission fluid (ATF) composed of

base oil and additives.

2. APPLICATION

This specification is released for factory fill application (including top offs) of various automatic

transmissions.

3. REQUIREMENTS

Material specification requirements are to be used for initial qualification of materials.

3.1 STANDARD REQUIREMENTS FOR PRODUCTION MATERIALS

Material suppliers and part producers must conform to the Company's Standard Requirements for

Production Materials (WSS-M99P1111-A).

3.2 COLOR Red

(ISO 2092)

3.3 VISCOSITY

New/Fresh fluid

At 100 °C (ASTM D 445) 6.2 mm2/sec (max.)

At -40 °C (ASTM D 2983) 12000 mPas (max.)

Shear Stability (CEC L-45-T93)

After 20 hrs KRL, KV at 100 °C 5.5 mm2/s, min

After 40 hrs KRL, KV at 100 °C 5.0 mm2/s, min

Evaporation loss, 150 °C, 2 hr, max. 10%

(Modified NOACK Test)

After NOACK Test, Viscosity at -40 °C 2000 mPa.s max change

3.4 FLASH POINT

(ASTM D 92) 180 °C (min)

3.5 DENSITY (at 15 °C) 0.841 gm/cc +/- 0.005

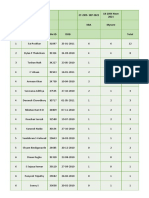

Date Action Revisions

2007 12 18 Revised Revised 3.16 C. Ved

2007 04 19 Revised Revised 3.3, 3.5, 3.6, 3.9.1, 3.9.2, 3.9.3, 3.9.4, 3.9.5, 3.9.6, 3.9.7, 3.10,

3.12.1, 3.12.3, 3.12.4, 3.15.1 table, 3.15.2, 3.15.4 & 3.15.5 C. Ved

--``,,,,,,,``,```,,,`,,,`,`````-`

2005 12 02 Activated C. Ved

Copyright Ford Motor Company Printed copies are uncontrolled

Provided by IHS under license with FORD

Copyright © 2007 Ford Global Technologies, LLC

Sold to:IHS Standards Store Purchase, 762592

Page 1 of 7

No reproduction or networking permitted without license from IHS Not for Resale,06/11/2012 02:18:52 MDT

ENGINEERING MATERIAL SPECIFICATION

WSS-M2C938-A

3.6 ANTI FOAMING PROPERTIES

(ASTM D 892)

Sequence I 50/0 ml (max)

Sequence II 50/0 ml (max)

Sequence III 50/0 ml (max)

--``,,,,,,,``,```,,,`,,,`,`````-`-`,,`,,`,`,,`---

Sequence IV (ASTM D 6082-01) 100/0 ml (max)

3.7 COPPER STRIP, max 1b

(ISO 2160/ASTM D 130, 3 h at 150 °C, no water added)

3.8 NONCORROSION AND NONRUSTING PROPERTIES No visible rust

(ASTM D 665, Procedure A, 24 h)

3.9 ELASTOMER COMPATIBILITY

3.9.1 ATRR-101 Nitrile after aging 168 h at 150 +/- 3 °C per ASTM D 471, para 6.1, with

aluminum block, must be within the limits below:

. Volume Change from original -3 to 4%

. Hardness, Durometer A 0 to 10

Change from original

3.9.2 ATRR-201 Polyacrylic, after aging 70 h at 163 +/- 3 °C in per ASTM D 471, para 6.1,

with aluminum block, must be within the limits below:

. Volume Change from original 0 to 6%

. Hardness, Durometer A +/- 5

Change from original

3.9.3 ATRR-300 Silicone after aging 240 h at 163 +/- 3 °C per ASTM D 471, para 6.1, with

aluminum block must be within the limits below:

. Volume Change from original 20 to 48%

. Hardness, Durometer A -40 to -15

Change from original

3.9.4 ATRR-400 Fluoroelastomer after aging 240 h at 163 +/- 3 °C per ASTM D 471,

para 6.1, with aluminum block, must be within the limits below:

. Volume Change from original 0 to 4%

. Hardness, Durometer A +/- 8

Change from original

Printed copies are uncontrolled

Copyright Ford Motor Company

Provided by IHS under license with FORD

Copyright © 2007, Ford Global Technologies, LLC

Sold to:IHS Standards Store Purchase, 762592

Page 2 of 7

No reproduction or networking permitted without license from IHS Not for Resale,06/11/2012 02:18:52 MDT

ENGINEERING MATERIAL SPECIFICATION

WSS-M2C938-A

3.9.5 ATRR-500 Ethylene-Acrylic after aging 240 h at 163 +/- 3 °C per ASTM D 471,

para 6.1, with aluminum block, must be within the limits below:

. Volume Change from original 5 to 15%

. Hardness, Durometer A +/- 5

Change from original

3.9.6 ATRR-600 Hypalon after aging 240 hrs. in candidate fluid at 163 +/-1 °C per ASTM

D 471, para 6.1, with aluminum block or fluid bath, must be within the limits below:

. Volume Change from original 5 to 35%

. Hardness, Durometer A -30 to 0

Change from original

3.9.7 ATRR-700 Hydrogenated Nitrile after aging 240 hrs. in candidate fluid at 163 +/-1 °C

per ASTM D 471, para 6.1, with aluminum block, must be within the limits below:

. Volume Change from original -2 to 4%

. Hardness, Durometer A 0 to 5

Change from original

3.10 ODOR

The fluid manufactured to this specification shall meet the Automatic Transmission Operations

Odor Test procedure. The fluids shall be found to be acceptable when it receives an

acceptability rating of 2 or less. The Automatic Transmission Engineering Operations odor test

procedure can be obtained by written request to:

Ford O H & S Department

Occupational and Environmental Health Sciences

20901 Oakwood Blvd

Dearborn, MI 48124

Tel: (313) 845-4588

3.11 TOXICITY

The fluid manufactured and formulated to this specification must not contain skin sensitization

components. The entire formulation must be validated by testing, the following specific rigorous

protocol. MSDS must accompany all containers other than tank cars quantities and Ford

Toxicology Identification Number must be prominently displayed.

The protocol details can be obtained by written communication to:

Occupational and Environmental Health Sciences

Central Laboratory Building CPN

15000 Century Drive, Room S-120

Dearborn, MI 48120

Tel: (313) 322-4113

Fax: (313) 845-5578

--``,,,,,,,``,```,,,`,,,`,`````-`-`,,`,,`,`,,`---

And requesting the following procedure: "Decision Tree: Dermatotoxicology Assessment of

High Production Volume Vehicle Fluids such as Transmission Fluids"

Printed copies are uncontrolled

Copyright Ford Motor Company

Provided by IHS under license with FORD

Copyright © 2007, Ford Global Technologies, LLC

Sold to:IHS Standards Store Purchase, 762592

Page 3 of 7

No reproduction or networking permitted without license from IHS Not for Resale,06/11/2012 02:18:52 MDT

ENGINEERING MATERIAL SPECIFICATION

WSS-M2C938-A

3.12 WEAR

3.12.1 VANE PUMP WEAR TEST, wt. loss, max

(ASTM D 6973 at 80 +/- 3 °C, 6.9 mPa) 10 mg

3.12.2 Four-Ball Wear Test, 40 Kg load, 2 hrs

(ASTM D 4172)

Average Wear Scar Diameter, mm max.

600 RPM, 100 °C (Average of 2 tests) 0.6

600 RPM, 150 C (Average of 2 tests) 0.6

3.12.3 Falex EP test

(ASTM D 3233)

--``,,,,,,,``,```,,,`,,,`,`````-`-`,,`,,`,`,,`---

No seizure load at 100 °C, 1 minute 500 lbs, min.

No seizure load at 150 °C, 1 minute 500 lbs, min.

3.12.4 Timken Wear Test, burnish width, mm

(ASTM D 2782)

4.08 kg load, 100 °C, 10 minutes 0.8 max.

(Average of 2 tests) No Scoring

4.08 kg load. 150 °C, 10 minutes 0.8 max.

(Average of 2 tests) No Scoring

3.12.5 FZG Gear wear test, Load Stage Pass

(ASTM D 5182)

1450 RPM, 15 min at 100 °C start temperature 11

1450 RPM, 15 min at 150 °C start temperature 11

3.12.6 Automatic Transmission Planetary Gear Fatigue Test

This dynamometer test procedure shows the fatigue life characteristics of an

automatic transmission gear train and its components. It is recommended for (but not

exclusive to) 1st, 2nd, Rev, and Final Drive gear sets. (Reference CETP: 07.01-L-

311)

3.12.7 Accelerated Overrunning One Way Clutch Test No Trenching

Overrun test using clutches (AX4N Low-Intermediate OWC) built with

11 double springs and 3 triple springs.

The inner race rotation is 4500 RPM's and the outer cam is stationary.

Automatic Transmission Fluid is heated to 230 °F at 6.5 ml/sec flow rate.

Duration of the test is 10 hours.

Contact: Delphi

Attn: David. Fox (419) 627-7055

3.13 MOISTURE, max 0.05%

(ISO 3733/ASTM D 95)

Copyright Ford Motor Company

Provided by IHS under license with FORD

Printed copies are uncontrolled Copyright © 2007, Ford Global Technologies, LLC

Sold to:IHS Standards Store Purchase, 762592

Page 4 of 7

No reproduction or networking permitted without license from IHS Not for Resale,06/11/2012 02:18:52 MDT

ENGINEERING MATERIAL SPECIFICATION

WSS-M2C938-A

3.14 OXIDATION TESTS

(FLTM BJ 110-04, 155 °C +/- 1)

Lead Coupon Weight Loss, 100 hrs, max 0.5%

Pentane Insolubles, 300 hrs, max 0.35%

Differential Infrared Carbonyl Absorbance

300 hrs, max 15/cm

Total Acid Number Change, 300 hrs, max 1.5

% Viscosity Change at 40 °C, 300 hrs, max 10%

Copper Strip Rating, 300 hrs, max 3B

Aluminum Strip Rating, 300 hrs, max. No Varnish

Sludge, 300 hrs, max. No Sludge

3.15 FRICTIONAL PERFORMANCE TESTS

3.15.1 Clutch Friction Durability Attachment I

(SAE # 2 machine, 30000 cycles, 135 °C with SD1777 & D 530-31 friction material)

Test Criteria SD-1777 material D 530-31 material

Midpoint Dynamic Coefficients (M) 0.140 – 0.165 0.14- 0.16

Low Speed Dynamic Coefficients (E) 0.135 – 0.160 0.14 – 0.18

Static Breakaway Coefficients 0.110 – 0.140 0.10 – 0.15

S/D (E/M) 0.950 – 1.100 0.95 – 1.15

3.15.2 Squawk Performance Test Attachment II

(GK test rig, BW 6510 friction material)

Fresh ATF 0.6 N/mm2, min pressure

Used/Aged ATF (300 hrs at 150 °C or 100 hrs at 170°C) 0.5 N/mm2, min pressure

3.15.3 Continuous Slip Evaluation (μ-V Characterization) Attachment III

(SAE # 2 machine, SD 1777C friction material)

115 hrs Pass

3.15.4 Low Speed Friction Evaluation

(LVFA, 0-300 rpm, 120 °C, SD-1777, D 530-31 & MS 022 friction materials)

--``,,,,,,,``,```,,,`,,,`,`````-`-`,,`,,`,`,,`---

ATF used – Fresh & Aged (300 hrs at 150 °C or 100 hrs at 170°C)

Friction Materials Coefficient of Friction

SD 1777 0.11 – 0.14

D 530-31 0.13 – 0.16

MS 022 0.10 – 0.13

Printed copies are uncontrolled

Copyright Ford Motor Company

Provided by IHS under license with FORD

Copyright © 2007, Ford Global Technologies, LLC

Sold to:IHS Standards Store Purchase, 762592

Page 5 of 7

No reproduction or networking permitted without license from IHS Not for Resale,06/11/2012 02:18:52 MDT

ENGINEERING MATERIAL SPECIFICATION

WSS-M2C938-A

3.15.5 Anti Shudder Durability Test

(SAE # 2 machine with ATF ageing apparatus, SD-1777 & D 531-70H friction

materials)

Test Hrs: 100 hrs dMu/dV > -10 max.

3.16 CLEANLINESS LEVEL - /18/15

(ISO 4406. At supplier manufacturing site prior to unloading into shipping containers)

3.17 QUALITY CONTROL/SUPPLIER TESTING

Annual validation required on production sample. Validation is to be completed by the first

week of the fifth month prior to a typical Job 1 date (Approximately 2 months prior to Job 1).

Test required for annual validation are 3.2, 3.3, 3.4, 3.5, 3.6, 3.9, 3.12, 3.14, 3.15.4.

Supplier in-house friction test results are acceptable after concurrence with the Product

engineering design & release / materials section.

Attachment I

Clutch Friction Durability

SAE NO. 2 MACHINE SET-UP PARAMETERS

Temperature: 135 +/- 3 °C

Pressure: 275 +/- 5 kPa

--``,,,,,,,``,```,,,`,,,`,`````-`-`,,`,,`,`,,`---

Velocity: 3600 rpm

Energy: 20740 +/- 100 J

Fill Volume: 305 mL +/- 5 mL

Total Cycles: 400 for each evaluation pack & 30000 for each durability pack

TEST SEQUENCE

Event Duration Cumulative Time, s Operation

1 10.0 (T1)* 0 to 10.0 High speed (HS) motor on (force released)

2 5.0 (T1 + T2)* 10.0 to 15.0 Motor off, force applied

3 5.0 (T4)* 15.0 to 20.0 Motor off, force released

4 0.5 20.0 to 20.5 Static Drive (SD) motor on to engage static drive

5 5.0 20.5 to 25.5 SD motor off, force released

6 0.5 25.5 to 26.0 SD motor off, force applied

7 5.0 26.0 to 31.0 SD motor on, force applied

8 5.0 31.0 to 36.0 SD motor off, force released

* = Reference SAE Friction Nomenclature Specification (SAE J1646)

Printed copies are uncontrolled

Copyright Ford Motor Company

Provided by IHS under license with FORD

Copyright © 2007, Ford Global Technologies, LLC

Sold to:IHS Standards Store Purchase, 762592

Page 6 of 7

No reproduction or networking permitted without license from IHS Not for Resale,06/11/2012 02:18:52 MDT

ENGINEERING MATERIAL SPECIFICATION

WSS-M2C938-A

Attachment II

Squawk Performance

GK Rig Machine Setup Parameters

Apply Pressure: 4200 kPa/sec.

Sampling Frequency: 500 Hz (1000 Hz with 500 Hz filter)

Fill Volume: 700 mL +/- 5 mL

TEST DESCRIPTION

Test Conditions - Discrete Data Points

Sliding Speed (m/s) Speed (rpm) Pressures (kPa) Temp °F

0.005 1

0.011 2

0.027 5 97 40

0.055 10

0.110 20

0.165 30

0.220 40

0.275 50 241 90

0.412 75

0.549 100

0.824 150

1.098 200

369 120

1.373 250

1.647 300

Attachment III

Continuous Slip Evaluation (μ-V Characterization)

--``,,,,,,,``,```,,,`,,,`,`````-`-`,,`,,`,`,,`---

Test Setup

TEMPERATURE, BATH 120 °C

APPLY PRESSURE 10 Kg/cm2

SLIDING SPEED 0 - 220

INTERVAL - HRS. 4 hrs

DATA ACQUISITION 1.90 SEC WITHIN 2.0 SEC. WINDOW

TEMPERATURE, TEST HEAD 120 °C

Test Description

• Break-in for 20 mins.

• Slipping mode for 50 mins.

• 20 dynamic engagements.

• Slipping mode for 50 mins.

• 20 Dynamic engagements.

• Slipping mode for 50 mins.

• 20 Dynamic engagements.

• μ vs. V data collection.

• 6 Dynamic engagements.

• Repeat sequence.

Printed copies are uncontrolled

Copyright Ford Motor Company

Provided by IHS under license with FORD

Copyright © 2007, Ford Global Technologies, LLC

Sold to:IHS Standards Store Purchase, 762592

Page 7 of 7

No reproduction or networking permitted without license from IHS Not for Resale,06/11/2012 02:18:52 MDT

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Competing On Value - : What's Your Competitive Edge?Document3 pagesCompeting On Value - : What's Your Competitive Edge?octo widodoNo ratings yet

- Commodity Vendor or Value Added Partner?Document4 pagesCommodity Vendor or Value Added Partner?octo widodoNo ratings yet

- Mercon V SpecificationDocument22 pagesMercon V Specificationocto widodoNo ratings yet

- Section 1: Products by ApplicationDocument7 pagesSection 1: Products by Applicationocto widodoNo ratings yet

- Patent Komposisi VIDocument17 pagesPatent Komposisi VIocto widodoNo ratings yet

- Proactive Maintenance at WeyerhaeuserDocument5 pagesProactive Maintenance at Weyerhaeuserocto widodoNo ratings yet

- What Do You Do With A High Particle CountDocument2 pagesWhat Do You Do With A High Particle Countocto widodoNo ratings yet

- SAE J661 (FEB97) Brake Lining Quality Control Test ProcedureDocument2 pagesSAE J661 (FEB97) Brake Lining Quality Control Test Procedureocto widodoNo ratings yet

- Understanding Foaming: Ashley Mayer, Noria CorporationDocument2 pagesUnderstanding Foaming: Ashley Mayer, Noria Corporationocto widodoNo ratings yet

- Creating An Effective Plant Lubrication ProgramDocument6 pagesCreating An Effective Plant Lubrication Programocto widodo100% (1)

- Friction: Kenneth C LudemaDocument29 pagesFriction: Kenneth C Ludemaocto widodoNo ratings yet

- Australian Standard: Engine Coolants Type A and Type B For Engine Cooling SystemsDocument7 pagesAustralian Standard: Engine Coolants Type A and Type B For Engine Cooling Systemsocto widodoNo ratings yet

- Super Sealer PI Sheet 07.02.12Document2 pagesSuper Sealer PI Sheet 07.02.12octo widodoNo ratings yet

- BIodiesel Kemenperin - PetrolabDocument12 pagesBIodiesel Kemenperin - Petrolabocto widodoNo ratings yet

- 8403 PDF CH04Document41 pages8403 PDF CH04octo widodoNo ratings yet

- Specifications According To JIS-K-2234-1994Document1 pageSpecifications According To JIS-K-2234-1994octo widodoNo ratings yet

- Key Note Speech Dirjen ILMATE - MASPIDocument20 pagesKey Note Speech Dirjen ILMATE - MASPIocto widodoNo ratings yet

- Premium Protection 15W-40Document1 pagePremium Protection 15W-40octo widodoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Link Belt ATC3130sDocument8 pagesLink Belt ATC3130sOscar CampoNo ratings yet

- Badminton Karnataka RankingDocument26 pagesBadminton Karnataka RankingManmeeth NNo ratings yet

- A Micro Project Report On Synchronous Motor: Matoshri Aasarabai Polytechnic, Eklahare, NashikDocument18 pagesA Micro Project Report On Synchronous Motor: Matoshri Aasarabai Polytechnic, Eklahare, NashikSudrshan B Barve100% (1)

- Miniature Model of Autonomous Vehicle Using Arduino UNO and Open CVDocument14 pagesMiniature Model of Autonomous Vehicle Using Arduino UNO and Open CVIJRASETPublicationsNo ratings yet

- U321a - Case - TransmissionDocument6 pagesU321a - Case - TransmissionbennieNo ratings yet

- IITD-Courses-of-Study MEMDocument1 pageIITD-Courses-of-Study MEMMohit KumarNo ratings yet

- D1105 E3bDocument2 pagesD1105 E3bVol VasylkevychNo ratings yet

- On-Car Analysis List From July 24th, 2018 Please Contact VW Helpline Before Attempting RepairDocument1 pageOn-Car Analysis List From July 24th, 2018 Please Contact VW Helpline Before Attempting RepairOleksiy OsiychukNo ratings yet

- Hyt - Ypl-02Document8 pagesHyt - Ypl-02guna rx100No ratings yet

- 2018 2019 - Seafirst CatalogDocument40 pages2018 2019 - Seafirst CatalogЯрослав БогдановNo ratings yet

- Foxboro StrasDocument28 pagesFoxboro StrasEmiro Revilla CatariNo ratings yet

- Allison 5000/6000 Series Off-Highway Transmissions Parts CatalogDocument3 pagesAllison 5000/6000 Series Off-Highway Transmissions Parts CatalogFilipposNo ratings yet

- Racine and Radial Vane PumpsDocument6 pagesRacine and Radial Vane PumpsVentas Control HidráulicoNo ratings yet

- Nonreturn ValveDocument3 pagesNonreturn Valveibrahim salemNo ratings yet

- Rlo Product Catalog 2019Document21 pagesRlo Product Catalog 2019Mohammed BabatinNo ratings yet

- LEXREF03Document8 pagesLEXREF03Alfredo GutierrezNo ratings yet

- 奔驰新E级W211维修手册 (英文版)Document189 pages奔驰新E级W211维修手册 (英文版)MarcosNo ratings yet

- Institutional Assessment Tools Driving NC IIDocument13 pagesInstitutional Assessment Tools Driving NC IIDeovir TesdaNo ratings yet

- Manifold Pressure Fuel Limiter For UG-8L Governors: Product Manual 03507 (Revision NEW)Document12 pagesManifold Pressure Fuel Limiter For UG-8L Governors: Product Manual 03507 (Revision NEW)wjzljNo ratings yet

- 20t Franna ManualDocument28 pages20t Franna Manualmilo_122_100% (1)

- Venue BrochureDocument10 pagesVenue BrochureTHARUN SNo ratings yet

- NP EX 4 CertusDocument6 pagesNP EX 4 CertusTTV TimeKpRNo ratings yet

- Depl. ING KIT410 MP Kit Levigatura Portatile X 60 100 125 + Ricambi 3.0 20111Document2 pagesDepl. ING KIT410 MP Kit Levigatura Portatile X 60 100 125 + Ricambi 3.0 20111azer tyNo ratings yet

- Auto Secure Private Car Package PolicyDocument6 pagesAuto Secure Private Car Package PolicyMalwaHonda GMNo ratings yet

- Ruthless Lover - AK RoseDocument352 pagesRuthless Lover - AK RosekhushiNo ratings yet

- 803M 853M 859M S N F293917 409162 L343918 409162 and 803MH 853MH 859MH S N F293764 409162 L343918 409162 Uptime Maintenance PlannerDocument4 pages803M 853M 859M S N F293917 409162 L343918 409162 and 803MH 853MH 859MH S N F293764 409162 L343918 409162 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- Graduation Thesis: Nanjing University of Aeronautics and AstronauticsDocument31 pagesGraduation Thesis: Nanjing University of Aeronautics and AstronauticsMohamed Omar IbrahimNo ratings yet

- Engine Life Cycles: When To Repair, When To ReplaceDocument23 pagesEngine Life Cycles: When To Repair, When To ReplacenrNo ratings yet

- Eicher Motors LimitedDocument24 pagesEicher Motors LimitedAadish JainNo ratings yet

- Acceptable Means Compliance Guidance Material Part 147 Module 12 Helicopter Aerodynamics Structures SystemsDocument4 pagesAcceptable Means Compliance Guidance Material Part 147 Module 12 Helicopter Aerodynamics Structures SystemsNarayanan PrajobNo ratings yet