Professional Documents

Culture Documents

SAE J661 (FEB97) Brake Lining Quality Control Test Procedure

Uploaded by

octo widodoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAE J661 (FEB97) Brake Lining Quality Control Test Procedure

Uploaded by

octo widodoCopyright:

Available Formats

SAE J661 (FEB97)

Brake Lining Quality Control Test Procedure

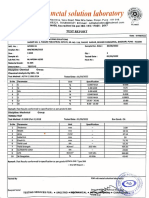

Client Stopco Friction Material, Inc. Work Order No. 062467

#15 1st Floor Cheng Men XI Test No. M22-169-13

Raod Foshan Guang Dong, 528000 Date 01 May 06

P.R. China Technician F. Thomas

Formulation AY1L Prepared By A. Vernatter

Sample A

Sample Mass Sample Thickness Indicator Sample Size

grams inches inches inches

Initial 3.4819 0.238 0.240 0.238 0.000 min max

Final 3.2176 0.207 0.208 0.212 -0.032 Length 0.989 0.990

Loss 0.2643 0.031 0.032 0.026 0.032 Width 0.970 0.988

Loss % 7.59% Average Thickness Loss 12.43%

SAE J866

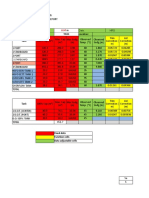

FIRST BASELINE FRICTION CLASSIFICATION SECOND FADE

Cycle Temp °F µ Sum Mean Class Minutes Temp °F µ

1 200 0.37 Normal 2.18 0.545 G 0.0 200 0.53 N

5 200 0.44 Hot 5.57 0.557 H 250 0.54 N

10 200 0.50 300 0.54 N

15 200 0.52 INDICATOR 350 0.56

20 200 0.53 -0.018 400 0.57 N

450 0.58 H

FIRST FADE WEAR TEST 500 0.57 H

Minutes Temp °F µ Cycle Temp °F µ 550 0.58 H

0.0 200 0.53 1 400 0.51 600 0.55 H

250 0.50 10 400 0.55 5.3 650 0.47 H

300 0.49 20 400 0.56

350 0.48 30 400 0.57 SECOND RECOVERY

400 0.47 40 400 0.56 Temp °F µ

450 0.46 50 400 0.57 600 0.59

500 0.45 60 400 0.57 500 0.60 H

4.6 550 0.43 70 400 0.58 400 0.58 H

80 400 0.58 300 0.56 H

FIRST RECOVERY 90 400 0.58 200 0.55

Temp °F µ 100 400 0.58

500 0.51 SECOND BASELINE

400 0.54 H INDICATOR Cycle Temp °F µ

300 0.54 H -0.027 1 200 0.53

200 0.58 5 200 0.54

WEAR TEST LOSS 10 200 0.54

Total Work = 6.83 MJ 0.009 15 200 0.55

Wear Rate = 0.039 g/MJ 20 200 0.55

Test Speed = 417 r/min

Test Load = 150 lbf Comments: No unusual noise or performance characteristics observed.

Cooler Pressure = 17.0 lb/in²

Heater Voltage = 87.0% FS

µ = Friction Coefficient

* = Temperature Not Achieved Signature

Ann Vernatter, Data Supervisor

for Greening Testing Laboratories, Inc.

19465 Mt. Elliott Avenue

Detroit, MI USA 48234-2786

+1 313 366 7160 • fax: +1 313 366 5415

info@greeninginc.com • www.greeninginc.com

The results depicted in this report are valid only for the samples submitted and may not reflect the performance of these materials in general.

The layout, composition and organization of this test report is a trademark of Greening Testing Laboratories, Inc. Copyright ©2005 Greening Testing Laboratories, Inc. All rights reserved.

Uncertainty data available upon request.

2014.XLS 03MR04 Page 1 of 2

SAE J661 (FEB97)

Brake Lining Quality Control Test Procedure

Client Stopco Friction Material, Inc. Work Order No. 062467

Formulation AY1L Test No. M22-169-13

FIRST BASELINE, FADE, RECOVERY

700 0.70

600 0.60

DRUM TEMPERATURE, °F

FRICTION COEFFICIENT, µ

500 0.50

400 0.40

300 0.30

200 0.20

100 0.10

0 0.00

FIRST BASELINE FIRST FADE FIRST RECOVERY

WEAR TEST

700 0.70

600 0.60

FRICTION COEFFICIENT, µ

DRUM TEMPERATURE, °F

500 0.50

400 0.40

300 0.30

200 0.20

100 0.10

0 0.00

0 10 20 30 40 50 60 70 80 90 100

CYCLE

SECOND BASELINE, FADE, RECOVERY

700 0.70

600 0.60 FRICTION COEFFICIENT, µ

DRUM TEMPERATURE, °F

500 0.50

400 0.40

300 0.30

200 0.20

100 0.10

0 0.00

SECOND FADE SECOND RECOVERY SECOND BASELINE

µ Drum Temperature

2014.XLS 03MR04 Page 2 of 2

You might also like

- SAE J661 (FEB97) : Brake Lining Quality Control Test ProcedureDocument2 pagesSAE J661 (FEB97) : Brake Lining Quality Control Test ProcedurePraveenkumar B 19PHD0419No ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- Storm Drainage - PVCDocument1 pageStorm Drainage - PVCMahmoud EldusokyNo ratings yet

- Orb ScanDocument2 pagesOrb ScanTech SHOWNo ratings yet

- Q1 Lot Number: 14997588: Certificate of ConformanceDocument3 pagesQ1 Lot Number: 14997588: Certificate of ConformanceOscar BasantesNo ratings yet

- Antoine Equation Curve FittingDocument2 pagesAntoine Equation Curve FittingJM Flores De SilvaNo ratings yet

- 103H6701 0140 SanyoDenkiDocument2 pages103H6701 0140 SanyoDenkiADRIANO SILVANo ratings yet

- Jyoti Steel Industries: Test Certificate As Per en 10204-3.1Document1 pageJyoti Steel Industries: Test Certificate As Per en 10204-3.1Gagat GongatNo ratings yet

- Ahu-P35-L05-33 CalDocument1 pageAhu-P35-L05-33 CalEddy NgNo ratings yet

- SITE TEST REPORT: Step & Touch Voltage Test: Contractor: SSEM Contract No:1453/00Document3 pagesSITE TEST REPORT: Step & Touch Voltage Test: Contractor: SSEM Contract No:1453/00Humayun AhsanNo ratings yet

- Datasheet de Un CapacitorDocument1 pageDatasheet de Un CapacitorSantiago Guerrero MartinezNo ratings yet

- Jindal Steel & Power LTD: Test CertificateDocument2 pagesJindal Steel & Power LTD: Test CertificateAmandeep Singh50% (2)

- Inspection Certificate: Remark Heat NO C Si MN P S CR Ni Mo V Cu C.E. ACC ACC ACC ACCDocument1 pageInspection Certificate: Remark Heat NO C Si MN P S CR Ni Mo V Cu C.E. ACC ACC ACC ACCYudha AlpiniusNo ratings yet

- Item #18 - 8 in Gate Valve 150# A216 - ID - 1000051424 & 10000514240 - Page - 4Document1 pageItem #18 - 8 in Gate Valve 150# A216 - ID - 1000051424 & 10000514240 - Page - 4Mostafa FadhelNo ratings yet

- Dorman HandbookDocument4 pagesDorman HandbooksharathkammarNo ratings yet

- CAT Category (D Default, S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesCAT Category (D Default, S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- Final CalculatorDocument125 pagesFinal CalculatorNang D. VuNo ratings yet

- Insulating Firebrick Data SheetDocument1 pageInsulating Firebrick Data SheetJackNo ratings yet

- CT 3622101003Document1 pageCT 3622101003imranNo ratings yet

- Esp Calculation StudioDocument7 pagesEsp Calculation StudioMohsin ShaikhNo ratings yet

- Units Normal Design Parameter Data CalculationDocument2 pagesUnits Normal Design Parameter Data CalculationMohammad BadakhshanNo ratings yet

- Shop Trial ME - 0001Document2 pagesShop Trial ME - 0001dsssaszNo ratings yet

- HW5 SolnsDocument11 pagesHW5 SolnsNaw AzNo ratings yet

- Ava7 50Document3 pagesAva7 50Socrates LaskaridisNo ratings yet

- Data Sheets ImportantesDocument4 pagesData Sheets ImportantesFabiano Ferreira SaldanhaNo ratings yet

- Surface Mount Silicon Zener Diode: SOD-323 Plastic PackageDocument4 pagesSurface Mount Silicon Zener Diode: SOD-323 Plastic Packagejose4445No ratings yet

- Certificates-50l O2 CylinderDocument6 pagesCertificates-50l O2 CylinderClaudia TiradoNo ratings yet

- Project Job Number EngineerDocument1 pageProject Job Number EngineerjenniferNo ratings yet

- Blind Flange TCDocument1 pageBlind Flange TCDEEPAKNo ratings yet

- Perbandingan Kekerasan Dan Tensile StrengthDocument9 pagesPerbandingan Kekerasan Dan Tensile StrengthMAx IMp BayuNo ratings yet

- List of Assemblies For Site: Wemyss, ON Job #: 0285065 Customer: RogersDocument1 pageList of Assemblies For Site: Wemyss, ON Job #: 0285065 Customer: RogersOdspiNo ratings yet

- Esp Calculation StudioDocument8 pagesEsp Calculation StudioMohsin ShaikhNo ratings yet

- AssignmentDocument6 pagesAssignmentSwathi SriNo ratings yet

- G WC F'C FR E N Hormigón 23.536 2.887 23168.343 8.632 Fy E AceroDocument3 pagesG WC F'C FR E N Hormigón 23.536 2.887 23168.343 8.632 Fy E Acerokebler kevNo ratings yet

- Prestressed Precast1Document5 pagesPrestressed Precast1mahmoud IbrahemNo ratings yet

- Query Print11Document1 pageQuery Print11Julio Cesar Santos de JesusNo ratings yet

- DVX-MTP-LA-QC-MAR-CW-003-Steel Asia RSBDocument13 pagesDVX-MTP-LA-QC-MAR-CW-003-Steel Asia RSBBert NiebresNo ratings yet

- 362Document2 pages362Ajay AsodariyaNo ratings yet

- 3 MM ss304Document1 page3 MM ss304Balaji DefenceNo ratings yet

- 6.2. Type Test Sheet 61195708-00Document1 page6.2. Type Test Sheet 61195708-00Martin FoxxxNo ratings yet

- Tes GrafikDocument6 pagesTes GrafikFadly SaputraNo ratings yet

- Schedule 80 PVC Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 80 PVC Pipe Dimensions & Pressure RatingsprathapNo ratings yet

- Acceptance Test Certificate (As Per IS: 7098-II-2011 & Approved GTP)Document1 pageAcceptance Test Certificate (As Per IS: 7098-II-2011 & Approved GTP)ANKITNo ratings yet

- MTR 18449 P1Document1 pageMTR 18449 P1Francisco Javier AyalaNo ratings yet

- HEA200 COLUMN - ٠٦٠٨٠٧Document1 pageHEA200 COLUMN - ٠٦٠٨٠٧Mahmoud MatarNo ratings yet

- BZT52C7V5S BZT52C10S. BZT52C3V9S. BZT52C24S. BZT52C12S. BZT52C5V1S BZT52C4V3S BZT52C13S BZT52C18S BZT52C20SDocument7 pagesBZT52C7V5S BZT52C10S. BZT52C3V9S. BZT52C24S. BZT52C12S. BZT52C5V1S BZT52C4V3S BZT52C13S BZT52C18S BZT52C20Smarthinus yesyurunNo ratings yet

- Dimension Bis Che & MecDocument3 pagesDimension Bis Che & MecPinku MaitiNo ratings yet

- Ked - Esp CalculationDocument1 pageKed - Esp Calculationabdul kalamNo ratings yet

- New Product: G5SBA20 and G5SBA60Document2 pagesNew Product: G5SBA20 and G5SBA60CarlosNo ratings yet

- Annex A: (Normative)Document6 pagesAnnex A: (Normative)calvente27No ratings yet

- Espectros de Diseño - AisladoresDocument8 pagesEspectros de Diseño - Aisladoresarturosg209No ratings yet

- 41Cr4 Chemical PDFDocument2 pages41Cr4 Chemical PDFGayathriRajasekaranNo ratings yet

- MBR 20200Document1 pageMBR 20200florin_af72222No ratings yet

- 1 8550-34CrAlNi710Document2 pages1 8550-34CrAlNi710Michel PortalNo ratings yet

- Jyoti Steel Industries: Test Certificate As Per en 10204-3.1Document1 pageJyoti Steel Industries: Test Certificate As Per en 10204-3.1Gagat GongatNo ratings yet

- CNP PDFDocument1 pageCNP PDFNguyen Duc CuongNo ratings yet

- Ullage Report-PARAXYLENEDocument1 pageUllage Report-PARAXYLENEbhavana kholaNo ratings yet

- Bahan Tabel Bab 4 5 170917Document5 pagesBahan Tabel Bab 4 5 170917erlangga suryarahmanNo ratings yet

- Competing On Value - : What's Your Competitive Edge?Document3 pagesCompeting On Value - : What's Your Competitive Edge?octo widodoNo ratings yet

- Mercon V SpecificationDocument22 pagesMercon V Specificationocto widodoNo ratings yet

- Commodity Vendor or Value Added Partner?Document4 pagesCommodity Vendor or Value Added Partner?octo widodoNo ratings yet

- Section 1: Products by ApplicationDocument7 pagesSection 1: Products by Applicationocto widodoNo ratings yet

- Patent Komposisi VIDocument17 pagesPatent Komposisi VIocto widodoNo ratings yet

- Proactive Maintenance at WeyerhaeuserDocument5 pagesProactive Maintenance at Weyerhaeuserocto widodoNo ratings yet

- What Do You Do With A High Particle CountDocument2 pagesWhat Do You Do With A High Particle Countocto widodoNo ratings yet

- Australian Standard: Engine Coolants Type A and Type B For Engine Cooling SystemsDocument7 pagesAustralian Standard: Engine Coolants Type A and Type B For Engine Cooling Systemsocto widodoNo ratings yet

- Understanding Foaming: Ashley Mayer, Noria CorporationDocument2 pagesUnderstanding Foaming: Ashley Mayer, Noria Corporationocto widodoNo ratings yet

- Creating An Effective Plant Lubrication ProgramDocument6 pagesCreating An Effective Plant Lubrication Programocto widodo100% (1)

- 8403 PDF CH04Document41 pages8403 PDF CH04octo widodoNo ratings yet

- Friction: Kenneth C LudemaDocument29 pagesFriction: Kenneth C Ludemaocto widodoNo ratings yet

- Super Sealer PI Sheet 07.02.12Document2 pagesSuper Sealer PI Sheet 07.02.12octo widodoNo ratings yet

- BIodiesel Kemenperin - PetrolabDocument12 pagesBIodiesel Kemenperin - Petrolabocto widodoNo ratings yet

- Specifications According To JIS-K-2234-1994Document1 pageSpecifications According To JIS-K-2234-1994octo widodoNo ratings yet

- Key Note Speech Dirjen ILMATE - MASPIDocument20 pagesKey Note Speech Dirjen ILMATE - MASPIocto widodoNo ratings yet

- Premium Protection 15W-40Document1 pagePremium Protection 15W-40octo widodoNo ratings yet

- Bobcat 260 EnglishDocument8 pagesBobcat 260 EnglishSeida Rojas CabelloNo ratings yet

- 2652 Duplex Piston Pump Mud PumpDocument2 pages2652 Duplex Piston Pump Mud Pumpalfonsoar447370100% (1)

- Edoc - Pub - Canrig Top Drive Model 1275 Ac PDFDocument4 pagesEdoc - Pub - Canrig Top Drive Model 1275 Ac PDFlilianaNo ratings yet

- B PowerstreamDocument12 pagesB PowerstreamKaler Soto PeraltaNo ratings yet

- Generator and Engine Generador y Motor Gerador e Motor: PCI2200 PCI2800 PCI5000Document92 pagesGenerator and Engine Generador y Motor Gerador e Motor: PCI2200 PCI2800 PCI5000CIVO CivoNo ratings yet

- Tabla de ConversionDocument30 pagesTabla de ConversionJesus Maria LizarzabalNo ratings yet

- Mitsubishi Marine Product Guide 2015 PDFDocument108 pagesMitsubishi Marine Product Guide 2015 PDFJORGE MONTESNo ratings yet

- GE 250 Engines CatalogueDocument2 pagesGE 250 Engines Cataloguesarvin silvarajo100% (1)

- Soal UAS Engine Piston 2020 UtamaDocument5 pagesSoal UAS Engine Piston 2020 UtamaKrasakKrusuk Si MaulNo ratings yet

- 789D Large Mining Truck BrochureDocument28 pages789D Large Mining Truck BrochureDiego CruzNo ratings yet

- Ipp Problems and QuestionsDocument16 pagesIpp Problems and QuestionsSecret DuhhhNo ratings yet

- Cummis Marino Datos TecnDocument2 pagesCummis Marino Datos TecnRamón ManglesNo ratings yet

- Equipment Chapter FourDocument13 pagesEquipment Chapter FourAshu TasfuNo ratings yet

- Me 323 (P3)Document3 pagesMe 323 (P3)MelindaNo ratings yet

- Minfc1664 Astm A519 Grade 1010Document4 pagesMinfc1664 Astm A519 Grade 1010ALEX MURPHYNo ratings yet

- Inplant Training Presentation Aniket Shinde 151Document17 pagesInplant Training Presentation Aniket Shinde 151ajayNo ratings yet

- Thermodynamics-Ii Lab: Submitted ToDocument61 pagesThermodynamics-Ii Lab: Submitted Toharis khalilNo ratings yet

- Tmi 24Document6 pagesTmi 24Anthony graciano leyvaNo ratings yet

- HsDocument49 pagesHsWilliam Dave DomasinNo ratings yet

- 45-53.8 11063344 PDFDocument40 pages45-53.8 11063344 PDFeng13No ratings yet

- KPM - k3vl - B - Series - DatasheetDocument55 pagesKPM - k3vl - B - Series - DatasheettitanwlxNo ratings yet

- Dynamic Braking Resistor CalculationDocument10 pagesDynamic Braking Resistor CalculationMuugii AmgaaNo ratings yet

- Air Volume and Pressure Guidelines For VHP GL Engines With TDI Air StartersDocument2 pagesAir Volume and Pressure Guidelines For VHP GL Engines With TDI Air StartersMuhammad AsadNo ratings yet

- Gear RatioDocument10 pagesGear RatioRachel Erica Guillero BuesingNo ratings yet

- Energy Industry Conversions LRGDocument2 pagesEnergy Industry Conversions LRGmaxrobnsonNo ratings yet

- Test 896: Massey-Ferguson MF 165 (Diesel) (Also MF 165 8-Speed Diesel)Document2 pagesTest 896: Massey-Ferguson MF 165 (Diesel) (Also MF 165 8-Speed Diesel)Nour SkyperNo ratings yet

- Vip 04 PipeDocument82 pagesVip 04 PipeDELFIN BRUTAS100% (2)

- Booklet Powertrain YMZ 2017Document13 pagesBooklet Powertrain YMZ 2017Michele GuerriniNo ratings yet

- Specifications: Ackhoe OaderDocument4 pagesSpecifications: Ackhoe OaderJUNIOR OLIVO0% (1)

- Air Dried Tissue Machine Drive System EnglishDocument11 pagesAir Dried Tissue Machine Drive System EnglishWilson FigueiraNo ratings yet