Professional Documents

Culture Documents

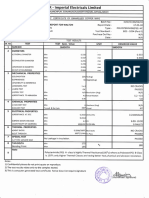

Acceptance Test Certificate (As Per IS: 7098-II-2011 & Approved GTP)

Uploaded by

ANKITOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acceptance Test Certificate (As Per IS: 7098-II-2011 & Approved GTP)

Uploaded by

ANKITCopyright:

Available Formats

Page 1 of 1

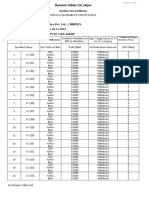

Dynamic Cables Ltd., Jaipur

ACCEPTANCE TEST CERTIFICATE

(as per IS: 7098-II-2011 & Approved GTP)

Customer :-NCPL/ MSEDCL/PCMC

W.O No - Civil/T/E/HO/76/2018 Dtd.07.02.2018

P. O. No. : 71/NCPL/EM/18-19 Date 23.10.2018

Name of the Work : Construction of Road in Area ward No - 7, charoli main Road to Burdevasti S.No 87,18 mtr DP Road in PCMC Area.

Tender No : 52/3 - 17/18

Cable Size :- 3CX300 Sqmm, 22KV HT Cable A2XWY Date of Inspection - 01.02.2019

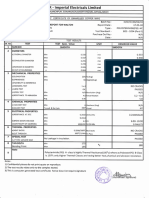

OBSERVED VALUES

DESCRIPTION OF TESTS SPECIFIED VALUES

Dr.No . A-1402 Dr.No . A-1403

A) DIAMETERS (mm)

Over All Diameter 94.19 94.28 App. 94±3

B) THICKNESS(mm) Avg Min Avg Min Avg Min

Insulation R 6.08 5.96 6.10 5.94 6.00 5.30

Y 6.06 5.91 6.07 5.91 6.00 5.30

B 6.05 5.93 6.08 5.91 6.00 5.30

Inner Sheath --- 0.82 --- 0.81 ----- 0.70

Outer Sheath --- 3.21 --- 3.29 ---- 3.00

Conductor Screening(mm) R 0.43 0.42 0.30 (App.)

Y 0.42 0.44 0.30 (App.)

B 0.42 0.43 0.30 (App.)

Insulation Screening (mm) R 0.42 0.43 0.30 (App.)

Y 0.42 0.42 0.30 (App.)

B 0.41 0.43 0.30 (App.)

Copper Tape (mm ) R 0.048 0.048 0.045 (App.)

Y 0.047 0.047 0.045 (App.)

B 0.048 0.047 0.045 (App.)

Eccentricity of Insulation 4.67 to 7.23 5.10 to 6.85 Max. 15%

C) TEST ON CONDUCTOR

No. of Strands 37 37 36

Tensile Strength N/mm2 NA NA

NA as per IS 8130-2013 Cl.7.2.1 & 7.2.2 note

Wrapping Test NA NA

D) ELECTRICAL TESTS

i) H.V.Test at 42 KV for To Withstand To Withstand To Withstand

5 minutes each connection

ii) HV Test 4Uo for 4 hrs. To Withstand To Withstand To Withstand

(iii) Conductor Resistance

Ohms/Km at 200C R 0.0958 0.0960 0.100 (Max.)

Y 0.0965 0.0960 0.100 (Max.)

B 0.0968 0.0963 0.100 (Max.)

iv) Partial Discharge at 1.73 Uo R 2 2 10 PC (Max.)

Y 2 3 10 PC (Max.)

B 2 2 10 PC (Max.)

v) Volume Resistivity (ohm-cm) R Y B R Y B

at 270C 3.0X1015 2.1X1015 4.3X1015 3.7X1015 2.5X1015 3.1X1015 1 x 1014 (min.)

at 900C 2.6X1014 3.5X1014 1.8X1014 2.1X1014 1.5X1014 2.4X1014 1 x 1012 (min.)

E) PHYSICAL TEST R Y B R Y B

Hot Set Test at 200 o C

a) Elongation under load 62 79 73 74 64 80 175 % (max.)

b) Permanent Elongation After 2.3 3.6 1.7 3.4 2.9 4.0 15 % (max.)

cooling

F) MECHANICAL TEST

a) Tensile Strength (N/mm2)

Insulation R 16.24 16.87 12 .5 (min.)

Y 16.23 16.65 12 .5 (min.)

B 16.86 16.75 12 .5 (min.)

Outer Sheath 13.75 13.76 12 .5 (min.)

b) Elongation %

Insulation R 515 598 200 (min.)

Y 590 621 200 (min.)

B 608 600 200 (min.)

Outer Sheath 221 182 150 (min.)

G) Armour Diameter (mm) 3.98 to 4.03 3.97 to 4.04 4.00±0.10

Embossing on cable:- dc 12.7/22KV Electric 3CX300 Sqmm A2XWY MSEDCL PCMC 2018 ISI CM/L-3118947

For Dynamic Cables Ltd. Witnessed by

Milind Inamdar, C/o -Krishnae Infrastructure Pvt

Lande B.P, Dy.E, E-Zone (Elect), PCMC, Pune 18

Ltd., Pune

Auth. Sign

P R KHADKE, Executive Engineer, GKUC

Iliyas Syed, Pave Tech Consultants, Pune

Testing Division, M.S.E.D.C.L , Pune

You might also like

- PRNT 84127Document1 pagePRNT 84127harelNo ratings yet

- Beam Design Calculation Sheet: Project Prepare Item Check Code Date (N/MM) (N/MM) (N/MM) (N/MM) (N/MM)Document4 pagesBeam Design Calculation Sheet: Project Prepare Item Check Code Date (N/MM) (N/MM) (N/MM) (N/MM) (N/MM)Dũng QuangNo ratings yet

- FM Full M10X1.5PX40 A193 B8 CL-2 ZN 30-003-1281680Document1 pageFM Full M10X1.5PX40 A193 B8 CL-2 ZN 30-003-1281680GauravNo ratings yet

- SWG 31 WDocument1 pageSWG 31 WRajesh RoyNo ratings yet

- SWG 31 WDocument1 pageSWG 31 WRajesh RoyNo ratings yet

- PRNT 84128Document1 pagePRNT 84128harelNo ratings yet

- SWG 30 WDocument1 pageSWG 30 WRajesh RoyNo ratings yet

- Damage assessment report for hydraulic cylinder rodDocument2 pagesDamage assessment report for hydraulic cylinder rodstkmNo ratings yet

- Dar 1120 001Document2 pagesDar 1120 001stkmNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- Part Number 22317EJW33, Spherical Roller Bearings - Steel CageDocument4 pagesPart Number 22317EJW33, Spherical Roller Bearings - Steel CageXiaoYaiZiZaiNo ratings yet

- 6055 DB 1402Document4 pages6055 DB 1402edgardNo ratings yet

- Type VR Medium Voltage Vacuum Circuit BreakerDocument6 pagesType VR Medium Voltage Vacuum Circuit BreakerpepeNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- Conso UD1t50Document5 pagesConso UD1t50Korng VuthaNo ratings yet

- Beam Design ReportDocument26 pagesBeam Design ReportOkechukwu NwaewoNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingGauravNo ratings yet

- Project:-Ato Eyasu Merachew G+2 Residential Date: - 25/12/2007 E.C Description: - Analysis and Design of Solid Slab By: - Abdela MohammedDocument7 pagesProject:-Ato Eyasu Merachew G+2 Residential Date: - 25/12/2007 E.C Description: - Analysis and Design of Solid Slab By: - Abdela MohammedGemechuNo ratings yet

- OTDR Report: Job InfoDocument2 pagesOTDR Report: Job InfoLanre OjelabiNo ratings yet

- OTDR Fiber39 Fail ReportDocument2 pagesOTDR Fiber39 Fail ReportLuPaNo ratings yet

- WS22211 E1 XL 2RSRDocument2 pagesWS22211 E1 XL 2RSRŽan KržanNo ratings yet

- C 2000Document1 pageC 2000Anonymous lv8SNRyNo ratings yet

- T 60 DiffsimulatorDocument3 pagesT 60 DiffsimulatorRandom NerdNo ratings yet

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Document1 pageMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravNo ratings yet

- PTR90 777814Document5 pagesPTR90 777814Sgly ZemogNo ratings yet

- Wi 0055DDocument110 pagesWi 0055DAndre Brama AlvariNo ratings yet

- F:/anni/contoh Htri/latihan 1.htriDocument1 pageF:/anni/contoh Htri/latihan 1.htriAnni RahmatNo ratings yet

- BQ 01/02/07/06/05/04: Lead Free: BF 01/02/07/06/05/04: Radial LeadsDocument4 pagesBQ 01/02/07/06/05/04: Lead Free: BF 01/02/07/06/05/04: Radial LeadsElectronicos CaldasNo ratings yet

- 3 MM ss304Document1 page3 MM ss304Balaji DefenceNo ratings yet

- Cyclone Wire Fence DUPADocument2 pagesCyclone Wire Fence DUPAxipotNo ratings yet

- TDC Certificate PDFDocument2 pagesTDC Certificate PDFAlaxmi NarayanNo ratings yet

- Norm Cıvata inspection certificateDocument3 pagesNorm Cıvata inspection certificateömer cılızNo ratings yet

- OTDR Report: General InformationDocument1 pageOTDR Report: General InformationAmaury OchoaNo ratings yet

- 3030 - S36W SMD LED DatasheetDocument22 pages3030 - S36W SMD LED DatasheetArturo mendozaNo ratings yet

- Cost BreakupDocument6 pagesCost Breakuppiyush sharma100% (1)

- 9mm multi-ganged potentiometer with rotary switch featuresDocument3 pages9mm multi-ganged potentiometer with rotary switch featuresIvan J RojasNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- Test Report Date ULR:-TC677119000007759P Name of Customer & Add. M/s Real Forge & FittingDocument14 pagesTest Report Date ULR:-TC677119000007759P Name of Customer & Add. M/s Real Forge & FittingAnurag YadavNo ratings yet

- Drum SpecsDocument2 pagesDrum SpecsThirusuganNo ratings yet

- Estimation ReportDocument3 pagesEstimation ReportAE MDHalliNo ratings yet

- Shear Test FormatsDocument2 pagesShear Test FormatspiteshNo ratings yet

- General Information: Location A Location BDocument3 pagesGeneral Information: Location A Location BZayed SyedNo ratings yet

- DCD0324 016Document3 pagesDCD0324 016Kevin RacelisNo ratings yet

- Sole Plate-628 R.STDDocument18 pagesSole Plate-628 R.STDVenkatakumarreddy kudumalaNo ratings yet

- BEAM DESIGN RESULTSDocument34 pagesBEAM DESIGN RESULTSOkechukwu NwaewoNo ratings yet

- DCD0656 Orangebuffer f16Document3 pagesDCD0656 Orangebuffer f16Kevin RacelisNo ratings yet

- PTD90 Series - 9 MM Multi-Ganged Potentiometer: FeaturesDocument3 pagesPTD90 Series - 9 MM Multi-Ganged Potentiometer: FeaturesДмитрийNo ratings yet

- MT 14 465 T1 Report Supplier 1 48.3mm TubeDocument1 pageMT 14 465 T1 Report Supplier 1 48.3mm TubeHaseeb KhanNo ratings yet

- Design of R.C.C Column Footing: Input DetailsDocument15 pagesDesign of R.C.C Column Footing: Input DetailsAbilaash VelumaniNo ratings yet

- DESIGN CODE IS:800-2007 SPLICE PLATEDocument2 pagesDESIGN CODE IS:800-2007 SPLICE PLATEmaheshbandhamNo ratings yet

- TacnaDocument20 pagesTacnaSnaider Mendoza VillegasNo ratings yet

- T 60 Diff SimulatorDocument4 pagesT 60 Diff SimulatorNeelakandan MasilamaniNo ratings yet

- Woven FabricDocument1 pageWoven FabricSohel NomanNo ratings yet

- Timken 22219EJW33-SphericalRollerBearings-SteelCageDocument4 pagesTimken 22219EJW33-SphericalRollerBearings-SteelCageArief sitompulNo ratings yet

- Datasheet Nema23Document1 pageDatasheet Nema23Juan De La TorreNo ratings yet

- Part Number 22320EMW33W800C4, Spherical Roller Bearings - Brass CageDocument4 pagesPart Number 22320EMW33W800C4, Spherical Roller Bearings - Brass CageMiguel Angel TandaypanNo ratings yet

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsFrom EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- Customer:-M/s Navinbhai Cables Pvt. Ltd. / MSEDCL: Routine Test CertificateDocument3 pagesCustomer:-M/s Navinbhai Cables Pvt. Ltd. / MSEDCL: Routine Test CertificateANKITNo ratings yet

- Routine Test Certificate for 3CX300 Sqmm, 22KV HT CableDocument1 pageRoutine Test Certificate for 3CX300 Sqmm, 22KV HT CableANKITNo ratings yet

- Cyprus Tender RM HT Cable AttachmentDocument1 pageCyprus Tender RM HT Cable AttachmentANKITNo ratings yet

- M/S Dynamic Cables Limited: F-260, ROAD NO. 13, V.K.I. AREA, JAIPUR Acceptance Test ReportDocument3 pagesM/S Dynamic Cables Limited: F-260, ROAD NO. 13, V.K.I. AREA, JAIPUR Acceptance Test ReportANKITNo ratings yet

- At BisonDocument1 pageAt BisonANKITNo ratings yet

- Shipping Mark 4CX 95 SQMM PDFDocument1 pageShipping Mark 4CX 95 SQMM PDFANKITNo ratings yet

- Captiva 2013 Systema Electric 3.0Document13 pagesCaptiva 2013 Systema Electric 3.0carlos martinez50% (2)

- Jenny Randles - Mind Monsters - Invaders From Inner Space (1990)Document219 pagesJenny Randles - Mind Monsters - Invaders From Inner Space (1990)DirkTheDaring11100% (15)

- Cycle1 Parta GettingtoknowyourstudentsDocument7 pagesCycle1 Parta Gettingtoknowyourstudentsapi-295073409No ratings yet

- Economics Not An Evolutionary ScienceDocument17 pagesEconomics Not An Evolutionary SciencemariorossiNo ratings yet

- Reliability Centered Maintenance (RCM)Document6 pagesReliability Centered Maintenance (RCM)Hoang Thanh VanNo ratings yet

- How to Critique a Work in 40 StepsDocument16 pagesHow to Critique a Work in 40 StepsGavrie TalabocNo ratings yet

- BudgetingForecastingCoursePresentation 1547839506611Document91 pagesBudgetingForecastingCoursePresentation 1547839506611ikakkos100% (2)

- CPC-COM-SU-4743-G External CoatingsDocument24 pagesCPC-COM-SU-4743-G External Coatingsaslam.amb100% (1)

- Travel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteDocument1 pageTravel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteMark Levin Munar100% (1)

- 9607 Syllabus Media StudiesDocument28 pages9607 Syllabus Media StudiesmisterNo ratings yet

- IPPD Presentation Roll OutDocument34 pagesIPPD Presentation Roll OutGracel Alingod Galay100% (1)

- MCC-2 (Intermediate & Finishing Mill)Document17 pagesMCC-2 (Intermediate & Finishing Mill)Himanshu RaiNo ratings yet

- Huawei Technologies Network Router B681Document12 pagesHuawei Technologies Network Router B681Eduardo Vaz RibeiroNo ratings yet

- API Documentation Alpha VantageDocument55 pagesAPI Documentation Alpha VantageFun WorldNo ratings yet

- Spru I 11444Document24 pagesSpru I 11444aalvarcaNo ratings yet

- MA 7 TranscriptDocument82 pagesMA 7 TranscriptBob AndrepontNo ratings yet

- ks20201 Sample Questions Psycholinguistics Module3Document6 pagesks20201 Sample Questions Psycholinguistics Module3Anurag TiwariNo ratings yet

- The World in Which We Believe in Is The Only World We Live inDocument26 pagesThe World in Which We Believe in Is The Only World We Live inYusufMiddeyNo ratings yet

- Professional Industrial Engineering Program: Technical EnglishDocument15 pagesProfessional Industrial Engineering Program: Technical EnglishFabio fernandezNo ratings yet

- Experiences in The OperationDocument7 pagesExperiences in The OperationUsama Bin SabirNo ratings yet

- Word ShortcutsDocument3 pagesWord ShortcutsRaju BNo ratings yet

- D Series: Instruction ManualDocument2 pagesD Series: Instruction ManualMartin del ValleNo ratings yet

- LPDocument5 pagesLPHeizyl ann VelascoNo ratings yet

- G8 - Light& Heat and TemperatureDocument49 pagesG8 - Light& Heat and TemperatureJhen BonNo ratings yet

- Herbarium Specimen Preparation and Preservation GuideDocument9 pagesHerbarium Specimen Preparation and Preservation GuideJa sala DasNo ratings yet

- 5 - Architect Fee AgreementDocument4 pages5 - Architect Fee AgreementJoevince Neil Gacus100% (2)

- Find Out Real Root of Equation 3x-Cosx-1 0 by Newton's Raphson Method. 2. Solve Upto Four Decimal Places by Newton Raphson. 3Document3 pagesFind Out Real Root of Equation 3x-Cosx-1 0 by Newton's Raphson Method. 2. Solve Upto Four Decimal Places by Newton Raphson. 3Gopal AggarwalNo ratings yet

- August Morning WorkDocument20 pagesAugust Morning Workapi-471325484No ratings yet

- Uop Teuop-Tech-And-More-Air-Separation-Adsorbents-Articlech and More Air Separation Adsorbents ArticleDocument8 pagesUop Teuop-Tech-And-More-Air-Separation-Adsorbents-Articlech and More Air Separation Adsorbents ArticleRoo FaNo ratings yet

- Ac and DC MeasurementsDocument29 pagesAc and DC MeasurementsRudra ChauhanNo ratings yet