Professional Documents

Culture Documents

SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - Blanking

Uploaded by

Gaurav0 ratings0% found this document useful (0 votes)

18 views1 pageOriginal Title

SW FULL M16X2PX70 A193 B7 ZN AL SM0000000002 - BLANKING

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - Blanking

Uploaded by

GauravCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

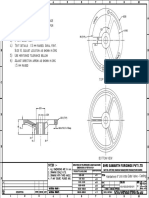

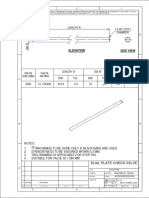

2X45°

BOTH SIDES Ø14.60

70±0.2 M16X2P

PROCESS BLANKING

DRAWN G. KELKAR THE DRAWING IS PROPRIETARY ARTICLE AND IS LOANED IN CONFIDENCE SUBJECT TO RETURN

UPON DEMAND. REPRODUCTION THEREOF OR MANUFACTURING OF PARTS THEREFROM IS NOT RAW MATERIAL 4140 Ø14.60

CHECKED B. SONAWANE PERMISSIBLE WITHOUT THE WRITTEN PERMISSION OF MASK FASTENERS PVT. LTD.

GENERAL MACHINING TOLERANCES for linear dimensions

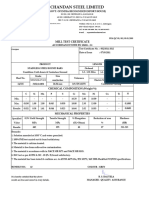

APPROVED G. THORVE PRODUCT GRADE A193 B7

400 TO 1000 TO 2000 TO

0.5 UPTO 6 6 TO 30 30 TO 120 120 TO 400

NOTES : 1000 2000 4000

± 0.1 ± 0.2 ± 0.3 ± 0.5 ± 0.8 ± 1.2 ± 2.0

1) All dimensions are in mm. WEIGHT 0.091 Kg

2) Remove all sharp corners and edges by 0.5 radii / 0.5*45° GENERAL MACHINING TOLERANCES for angular dimensions

3) Critical dimension with its surface finish & GD&T marked LENGTH UPTO10 10 TO 50 50 TO 120 120 TO 400 400 TO 1000

as DRG. NO. SW/SM0000000002

4) Dimensions showed in (_) only for reference. ANGLE ± 1° ± 0° 30' ± 0° 20' ±0° 10' ± 0 5'

5)For any clarification or suggestions please contact R&D. TITLE:

SCALE : N.T.S

Machining from 6.3 um to 3.2 um

FULL THREADED STUD M16X2PX70L

7/7/2020

-/- 00

-- New Release

MASK FASTENERS PVT. LTD.

6) Refer table MFPL/MFG/THRSIZES FOR THREAD

DATE / DIMENSIONS.

REV. No.

DCN. NO. BRIEF RECORD SIGN.

THIS DRAWING HAS BEEN CREATED ACCORDING TO ITEM DESCRIPTION IN PO; CUSTOMER HASN'T PROVIDED ANY PRODUCTION DRAWING.

You might also like

- IV Full m16 X 2px 85l 4140 b7 Blackodising h06100416s00015Document1 pageIV Full m16 X 2px 85l 4140 b7 Blackodising h06100416s00015GauravNo ratings yet

- Full M20X2.5PX210L A193 B8M CL-1Document1 pageFull M20X2.5PX210L A193 B8M CL-1GauravNo ratings yet

- KGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingDocument1 pageKGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingGauravNo ratings yet

- FM Full M10X1.5PX40 A193 B8 CL-2 ZN 30-003-1281680Document1 pageFM Full M10X1.5PX40 A193 B8 CL-2 ZN 30-003-1281680GauravNo ratings yet

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Document1 pageMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravNo ratings yet

- MACHINING DRAWINGDocument1 pageMACHINING DRAWINGGauravNo ratings yet

- 3X45° Bar Stud Machining DrawingDocument1 page3X45° Bar Stud Machining DrawingGauravNo ratings yet

- MPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7Document1 pageMPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7GauravNo ratings yet

- Full 3-4 10unc 115 B7 BlackodisingDocument1 pageFull 3-4 10unc 115 B7 BlackodisingGauravNo ratings yet

- M16X2PX52L 4140 B7 BlackodisingDocument1 pageM16X2PX52L 4140 B7 BlackodisingGauravNo ratings yet

- Channel Bend Profile-ADocument1 pageChannel Bend Profile-AhangloqueNo ratings yet

- Customer Pt. Unilever Indon Esia Project Name Spiral Conveyor System Project Number C075. 00131 CommisionDocument14 pagesCustomer Pt. Unilever Indon Esia Project Name Spiral Conveyor System Project Number C075. 00131 CommisionParama Ahmad ParahitaNo ratings yet

- Threaded RodDocument1 pageThreaded RodDhanu goswamiNo ratings yet

- PRNT 84128Document1 pagePRNT 84128harelNo ratings yet

- PRNT 84127Document1 pagePRNT 84127harelNo ratings yet

- C075.00170 : MULIABOGA CONV INCLINE & OUTPUT MESIN SPECIFICATIONDocument13 pagesC075.00170 : MULIABOGA CONV INCLINE & OUTPUT MESIN SPECIFICATIONAbel xNo ratings yet

- KGV 4 Uch Gate FinishDocument1 pageKGV 4 Uch Gate FinishMahendra PatilNo ratings yet

- Acceptance Test Certificate (As Per IS: 7098-II-2011 & Approved GTP)Document1 pageAcceptance Test Certificate (As Per IS: 7098-II-2011 & Approved GTP)ANKITNo ratings yet

- Bend 1Document1 pageBend 1karpagavalli NNo ratings yet

- Beam Design Calculation Sheet: Project Prepare Item Check Code Date (N/MM) (N/MM) (N/MM) (N/MM) (N/MM)Document4 pagesBeam Design Calculation Sheet: Project Prepare Item Check Code Date (N/MM) (N/MM) (N/MM) (N/MM) (N/MM)Dũng QuangNo ratings yet

- Base Magnetica 6306-1020Document1 pageBase Magnetica 6306-1020Martin Andre AlburquequeNo ratings yet

- Casting technical drawing dimensions tolerancesDocument1 pageCasting technical drawing dimensions tolerancesMahendra PatilNo ratings yet

- Sole Plate-628 R.STDDocument18 pagesSole Plate-628 R.STDVenkatakumarreddy kudumalaNo ratings yet

- Wac - Test Certificate 7313Document1 pageWac - Test Certificate 7313dian priyantoNo ratings yet

- Channel With Side Base Bend Profile-ADocument1 pageChannel With Side Base Bend Profile-AhangloqueNo ratings yet

- 3321-60055 PDDDocument1 page3321-60055 PDDdaniel.rabahdunordNo ratings yet

- 3046 DatasheetDocument2 pages3046 DatasheetKavabaNo ratings yet

- Multi-axis CNC machining drawingDocument1 pageMulti-axis CNC machining drawingtênchỉđểgọiNo ratings yet

- Inlet air attenuator dimensionsDocument1 pageInlet air attenuator dimensionsRomulo GomesNo ratings yet

- RCC13 Punching ShearDocument10 pagesRCC13 Punching ShearMark Angelo FloresNo ratings yet

- Revisions to Coupling Cut SheetDocument1 pageRevisions to Coupling Cut SheetRavishankarNo ratings yet

- 90 DegDocument5 pages90 DegAndrew CrookNo ratings yet

- MTI-7037 (97.500 MM FF UC 1278 SLEEVE) MuestraDocument1 pageMTI-7037 (97.500 MM FF UC 1278 SLEEVE) MuestraGUSTAVO LEZANONo ratings yet

- Spreadsheets To BS 8110Document10 pagesSpreadsheets To BS 8110T Satheesh KumarNo ratings yet

- Do Not Scale: SR - No. Qty. 1 1 2 1 3 1 4 1Document1 pageDo Not Scale: SR - No. Qty. 1 1 2 1 3 1 4 1vinothNo ratings yet

- Zone 14a: Crone Partners Punching Shear For Column C1 BS 25-Dec-2017 1 - 3904 45 460 8 600 0 450 0 0 0Document10 pagesZone 14a: Crone Partners Punching Shear For Column C1 BS 25-Dec-2017 1 - 3904 45 460 8 600 0 450 0 0 0vaideehNo ratings yet

- RCC13 Punching ShearDocument10 pagesRCC13 Punching ShearT Satheesh KumarNo ratings yet

- PRNT 32533Document1 pagePRNT 32533Matthew Kevin Kumar CNo ratings yet

- C86200 Manganese BronzeDocument1 pageC86200 Manganese BronzeDeepak KumarNo ratings yet

- Tube Products of India gears up with growthDocument12 pagesTube Products of India gears up with growthMohamed HarisNo ratings yet

- RCC13 Punching ShearDocument10 pagesRCC13 Punching Shearmathewsujith31No ratings yet

- PTR90 777814Document5 pagesPTR90 777814Sgly ZemogNo ratings yet

- Slab Punching H11Document10 pagesSlab Punching H11T Satheesh KumarNo ratings yet

- DatasheetDocument1 pageDatasheetStuxnetNo ratings yet

- Sample Test Cert. 07.09.2011 - 02Document1 pageSample Test Cert. 07.09.2011 - 02Vipul PanchalNo ratings yet

- Norm Cıvata inspection certificateDocument3 pagesNorm Cıvata inspection certificateömer cılızNo ratings yet

- Exp.: Date: 2/7/2020: Calculation of Measurement of Uncertainty As Per NABL 141Document1 pageExp.: Date: 2/7/2020: Calculation of Measurement of Uncertainty As Per NABL 141Mechtek LabNo ratings yet

- Samples Spection Report Signify Fio Sólido Vermelho 0,50mm2 440610001241Document1 pageSamples Spection Report Signify Fio Sólido Vermelho 0,50mm2 440610001241Moises NogueiraNo ratings yet

- 27MGDocument4 pages27MGtian integraNo ratings yet

- DPCV - Stop Pin - 0600Document1 pageDPCV - Stop Pin - 0600munish kanwarNo ratings yet

- Tentative Cycle Time EstimationDocument1 pageTentative Cycle Time EstimationdhokalerajNo ratings yet

- Guemisa: A-MAC-B97Document1 pageGuemisa: A-MAC-B97Gustavo YbañezNo ratings yet

- 1by2 in Specimen MouldDocument1 page1by2 in Specimen MouldSaurabh Kumar VermaNo ratings yet

- Erp-Reinf Shearwall R1Document6 pagesErp-Reinf Shearwall R1Gunawan Prc2020No ratings yet

- Spreadsheets To BS 8110Document10 pagesSpreadsheets To BS 8110Alma M. LaraNo ratings yet

- CBR Test ReportDocument17 pagesCBR Test ReportMuhammad AwaisNo ratings yet

- TCC15 Resistance of Retaining Members XLDocument8 pagesTCC15 Resistance of Retaining Members XLalexanderNo ratings yet

- 3X45° Bar Stud Machining DrawingDocument1 page3X45° Bar Stud Machining DrawingGauravNo ratings yet

- Full 3-4 10unc 115 B7 BlackodisingDocument1 pageFull 3-4 10unc 115 B7 BlackodisingGauravNo ratings yet

- Full 3-4 10unc 130 B7 BlackodisingDocument1 pageFull 3-4 10unc 130 B7 BlackodisingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - GrindingDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - GrindingGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - MarkingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - MarkingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - Blanking PDFDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - Blanking PDFGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - RollingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - RollingGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - GrindingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - GrindingGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - BlankingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - BlankingGauravNo ratings yet

- BEC 013 Automotie ElectronicsDocument70 pagesBEC 013 Automotie Electronicsjimshith jimmuNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - RollingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - RollingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - RollingDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - RollingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - MarkingDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - MarkingGauravNo ratings yet

- M16X2PX52L B8Document1 pageM16X2PX52L B8GauravNo ratings yet

- Gargi EnterprisesDocument10 pagesGargi EnterprisesGauravNo ratings yet

- M20X2.5PX60L 4140 B7 BlackodisingDocument1 pageM20X2.5PX60L 4140 B7 BlackodisingGauravNo ratings yet

- M16X2PX52L 4140 B7 BlackodisingDocument1 pageM16X2PX52L 4140 B7 BlackodisingGauravNo ratings yet

- Eee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0Document1 pageEee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0GauravNo ratings yet

- Full M12X1.75PX60 B7 ZN Al - BlankingDocument1 pageFull M12X1.75PX60 B7 ZN Al - BlankingGauravNo ratings yet

- Eee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0Document1 pageEee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0GauravNo ratings yet

- MPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7Document1 pageMPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7GauravNo ratings yet

- MPCPL BSR M10X1.5PX50 4140 B7 Blackodising M10-50-SB7 PDFDocument1 pageMPCPL BSR M10X1.5PX50 4140 B7 Blackodising M10-50-SB7 PDFGauravNo ratings yet

- MPCPL BSR M10X1.5PX45 4140 B7 Blackodising M10-45-SB7Document1 pageMPCPL BSR M10X1.5PX45 4140 B7 Blackodising M10-45-SB7GauravNo ratings yet

- No-Pick-Up Time of Traffic Paint: Standard Test Method ForDocument2 pagesNo-Pick-Up Time of Traffic Paint: Standard Test Method ForSudharsanNo ratings yet

- 5 Nemo Dat Rule PDFDocument9 pages5 Nemo Dat Rule PDFrajragavanNo ratings yet

- Johnson Graham Images You Should Not Masturbate To 2011 Penguin Group US Libgen - LiDocument84 pagesJohnson Graham Images You Should Not Masturbate To 2011 Penguin Group US Libgen - LiDa Costa Productions100% (1)

- Mbaft - 6403: Global Business Enviornment: MBA (FT) - March/April 2022Document2 pagesMbaft - 6403: Global Business Enviornment: MBA (FT) - March/April 2022Abhi BNo ratings yet

- CSH11-BOW BUD Industries Inc Product DetailsDocument3 pagesCSH11-BOW BUD Industries Inc Product DetailsRaul Lopez Reina50% (2)

- Preparation of Company Accounts: Chapter-01Document18 pagesPreparation of Company Accounts: Chapter-01My ComputerNo ratings yet

- The 9 Step Letter of Credit ProcessDocument1 pageThe 9 Step Letter of Credit ProcessGirish RanganathanNo ratings yet

- Operations Management With Analytics Workbook v2023Document43 pagesOperations Management With Analytics Workbook v2023Kristina Cassandra SagradaNo ratings yet

- GGSRDocument84 pagesGGSRKay AbawagNo ratings yet

- Curriculum Development Evaluation With Emphasis of TM2Document21 pagesCurriculum Development Evaluation With Emphasis of TM2Kurt john Abalos0% (1)

- Chap1-3 Illustration ProblemsDocument8 pagesChap1-3 Illustration ProblemscykablyatNo ratings yet

- Habitat Technician Job AddDocument2 pagesHabitat Technician Job AddRahmathNo ratings yet

- Notes - Unit 3Document26 pagesNotes - Unit 3ishita sabooNo ratings yet

- 4 Nord-Schrott PDFDocument6 pages4 Nord-Schrott PDFYakup AVCINo ratings yet

- Services Marketing PDFDocument53 pagesServices Marketing PDFApurva SrivastavaNo ratings yet

- Tutorial 6 (Week 7) QUESTIONDocument7 pagesTutorial 6 (Week 7) QUESTIONJahmesNo ratings yet

- Bain Report 2021 Global Private Equity ReportDocument76 pagesBain Report 2021 Global Private Equity ReportSam MoseleyNo ratings yet

- Understanding Process CostingDocument30 pagesUnderstanding Process CostingJehan MahmudNo ratings yet

- Accounts Part-II 4 PDFDocument26 pagesAccounts Part-II 4 PDFjibin samuelNo ratings yet

- The Warehouse Group Limited Block Trade Agreement 2021Document22 pagesThe Warehouse Group Limited Block Trade Agreement 2021PNo ratings yet

- May 2011Document43 pagesMay 2011rgsr2008No ratings yet

- OFPS Entrepreneurship 3e: © Oxford Fajar Sdn. Bhd. (008974-T), 2013 1 - 1Document33 pagesOFPS Entrepreneurship 3e: © Oxford Fajar Sdn. Bhd. (008974-T), 2013 1 - 1MD HOSSAINNo ratings yet

- Direct Marketing and Personal Selling ToolsDocument41 pagesDirect Marketing and Personal Selling ToolsARPIT TIRKEYNo ratings yet

- Impact of Green Marketing On Customer Satisfaction An Empirical StudyDocument7 pagesImpact of Green Marketing On Customer Satisfaction An Empirical StudyarcherselevatorsNo ratings yet

- Assignment 2.1 AccountingDocument7 pagesAssignment 2.1 AccountingColine DueñasNo ratings yet

- Retail Management MCQ Questions and AnswersDocument43 pagesRetail Management MCQ Questions and Answersafsana khatunNo ratings yet

- CISA Guidance On Essential Critical Infrastructure WorkersDocument15 pagesCISA Guidance On Essential Critical Infrastructure WorkersDanny ChaitinNo ratings yet

- Working Capital DaburDocument86 pagesWorking Capital DaburprateekNo ratings yet

- Tourism Impact AssessmentDocument9 pagesTourism Impact AssessmentNicole SarmientoNo ratings yet

- S Alyssa 2021Document6 pagesS Alyssa 2021aamir hayatNo ratings yet