Professional Documents

Culture Documents

Norm Cıvata inspection certificate

Uploaded by

ömer cılızOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Norm Cıvata inspection certificate

Uploaded by

ömer cılızCopyright:

Available Formats

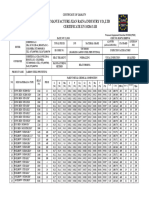

Norm Cıvata A.Ş. EN 10204 – 3.

1

15.12.2020

INSPECTION CERTIFICATE

DESCRIPTION M8x30 933-4017 8.8 C440 LOT NO B549A175 TEMPERATURE 22±3

PROPERTY CLASS 8.8 COATING ZN CR+3 MAVI BILL OF LADING NO 8000545474

NORM PART NO 920510000 CUSTOMER PART NO STOK BILL OF LADING QTY. 300

TOP COATING USTLAK YOK ORDER NO

COMPOSITION (From Çekme Kesit Sulama

%Mn %C %P %S %Si %Cr %Ni %Mo %Cu %Al %Ti

Supplier) Dayanımı Daralması Sertliği

CHARGE NO 10039135 0,9900 0,2400 0,0060 0,0030 0,1000 0,2000 0,0400 0,0100 0,0800 577,0000 57,0000 0,0280 0,0360 43,0000

DIMENSIONS 26.11.2020

TOLERANCE

NO CRITERIA DESCRIPTION CONTROL DEVICE CONTROL RESULTS

INTERVAL

Min Max 1 2 3 4 5 QUANTITY RESULTS

20 Major diameter 7,76 7,97 Digital mikrometre 7,86 7,86 7,86 7,86 7,86 5 OK

30 Pitch diameter 7,04 7,16 Pitch micrometer 7,05 7,05 7,05 7,05 7,05 5 OK

40 Distance under head 1,25 3,75 Profile projection 2,30 2,30 2,30 2,30 2,30 5 OK

50 Go Gauge Contr. ISO 6g Thread Go/NoGo gauge (6 OK 5 OK

60 No-go Gauge Contr. ISO 6g Thread Go/NoGo gauge (6 OK 5 OK

120 Width across flats 12,73 13,00 Digital caliper 12,8 12,85 12,82 12,86 12,81 5 OK

130 Width across corners 14,38 999999,0 Digital caliper 14,48 14,45 14,47 14,49 14,47 5 OK

150 Length 29,58 30,42 Digital caliper 29,8 29,85 29,86 29,83 29,86 5 OK

190 Marking control Visual OK 5 OK

Tests are made according to ISO 898-1

We hereby certify that the parts have been manufactured according to requirements of the applicable standards and found in comformity with its standards.

This document was created via computer. It is valid without signature.

Form No:

Prepared By Approval By

Quality Assurance Responsible Quality Assurance Manager

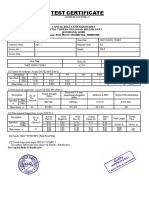

Norm Cıvata A.Ş. EN 10204 – 3.1

15.12.2020

INSPECTION CERTIFICATE

DESCRIPTION M8x30 933-4017 8.8 C440 LOT NO B549A175 TEMPERATURE 22±3

PROPERTY CLASS 8.8 COATING ZN CR+3 MAVI BILL OF LADING NO 8000545474

NORM PART NO 920510000 CUSTOMER PART NO STOK BILL OF LADING QTY. 300

TOP COATING USTLAK YOK ORDER NO

COMPOSITION (From Çekme Kesit Sulama

%Mn %C %P %S %Si %Cr %Ni %Mo %Cu %Al %Ti

Supplier) Dayanımı Daralması Sertliği

CHARGE NO 10039135 0,9900 0,2400 0,0060 0,0030 0,1000 0,2000 0,0400 0,0100 0,0800 577,0000 57,0000 0,0280 0,0360 43,0000

MECHANICAL 26.11.2020

TOLERANCE

NO CRITERIA DESCRIPTION CONTROL DEVICE CONTROL RESULTS

INTERVAL

Min Max 1 2 3 4 5 QUANTITY RESULTS

10 Wedge Loading Test Tensile testing machine OK 5 OK

20 Tensile strength (MPa) 800,00 1000,00 Tensile testing machine 930 935 936 933 935 5 OK

30 % Elongation 12,00 999999,0 Tensile testing machine 18 18 17 17 18 5 OK

40 Hardness (HRc) 22,00 32,00 Hardness (HRc) testing ma 28 29 29 28 29 5 OK

50 Surface Hardness (HV0.3) 250,00 320,00 Hardness (Hv) testing mach 300 302 306 303 301 5 OK

60 Decarburization (HV) 0,00 30,00 Hardness (Hv) testing mach 8 1 OK

80 Surface integrity Macroscope OK 5 OK

Tests are made according to ISO 898-1

We hereby certify that the parts have been manufactured according to requirements of the applicable standards and found in comformity with its standards.

This document was created via computer. It is valid without signature.

Form No:

Prepared By Approval By

Quality Assurance Responsible Quality Assurance Manager

Norm Cıvata A.Ş. EN 10204 – 3.1

15.12.2020

INSPECTION CERTIFICATE

DESCRIPTION M8x30 933-4017 8.8 C440 LOT NO B549A175 TEMPERATURE 22±3

PROPERTY CLASS 8.8 COATING ZN CR+3 MAVI BILL OF LADING NO 8000545474

NORM PART NO 920510000 CUSTOMER PART NO STOK BILL OF LADING QTY. 300

TOP COATING USTLAK YOK ORDER NO

COMPOSITION (From Çekme Kesit Sulama

%Mn %C %P %S %Si %Cr %Ni %Mo %Cu %Al %Ti

Supplier) Dayanımı Daralması Sertliği

CHARGE NO 10039135 0,9900 0,2400 0,0060 0,0030 0,1000 0,2000 0,0400 0,0100 0,0800 577,0000 57,0000 0,0280 0,0360 43,0000

PLATING 26.11.2020

TOLERANCE

NO CRITERIA DESCRIPTION CONTROL DEVICE CONTROL RESULTS

INTERVAL

Min Max 1 2 3 4 5 QUANTITY RESULTS

10 Color/Visual Cont. Visual OK OK OK OK OK 5 OK

20 Go gauge control-ISO 6h Thread Go/NoGo gauge (6 OK OK OK OK OK 5 OK

30 No-go Gauge Contr. ISO 6h Thread Go/NoGo gauge (6 OK OK OK OK OK 5 OK

40 Adhesion (Zinc) Visual inspection OK OK OK OK OK 5 OK

50 Corrosion resistance (White) 72 Salt spray test chamber OK OK OK OK OK 5 OK

60 Corrosion resistance (Red) 120 Salt spray test chamber OK OK OK OK OK 5 OK

70 Plating Thickness 7,00 999999,0 X-Ray coating thickness tes 10 10 10 10 10 5 OK

TM 210728 SRT

Tests are made according to ISO 898-1

We hereby certify that the parts have been manufactured according to requirements of the applicable standards and found in comformity with its standards.

This document was created via computer. It is valid without signature.

Form No:

Prepared By Approval By

Quality Assurance Responsible Quality Assurance Manager

You might also like

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- TM 215461 SRTDocument3 pagesTM 215461 SRTömer cılızNo ratings yet

- Certificats BackupDocument17 pagesCertificats BackupS. KaciouiNo ratings yet

- Calibrating Depth Gauge for Plastic Pipe ManufacturerDocument1 pageCalibrating Depth Gauge for Plastic Pipe Manufacturermba213No ratings yet

- GK 223370 SRTDocument1 pageGK 223370 SRTömer cılızNo ratings yet

- Analog Outside Micrometer - 130262486 - 25 MM YDocument15 pagesAnalog Outside Micrometer - 130262486 - 25 MM YishraqaliahsanNo ratings yet

- Certificado Calidad CodosDocument1 pageCertificado Calidad CodosAndresFelipeCorreaNo ratings yet

- AccreditationDocument40 pagesAccreditationWalid BdeirNo ratings yet

- Window MTCDocument4 pagesWindow MTCshamshadkadavath1998No ratings yet

- AMS CAL 0153 11 Dial Indicator (AutoRecovered)Document2 pagesAMS CAL 0153 11 Dial Indicator (AutoRecovered)Muhammad RahimNo ratings yet

- Final Inspection ReportDocument1 pageFinal Inspection ReportC. M. JebinNo ratings yet

- TSC - 22-23 - 5490-1 TachometerDocument2 pagesTSC - 22-23 - 5490-1 TachometerDebabrata MajhiNo ratings yet

- Adobe Scan 02-Jul-2022Document5 pagesAdobe Scan 02-Jul-2022Shamsher SinghNo ratings yet

- Ministry of Works and Transport-01220745 - 20220929051602Document1 pageMinistry of Works and Transport-01220745 - 20220929051602Okello StevenNo ratings yet

- Inspection Report: Khodiyar Spring IndustriesDocument1 pageInspection Report: Khodiyar Spring IndustriesVinay KumarNo ratings yet

- Godrej Calibration Certificate for Digital Weighing BalanceDocument16 pagesGodrej Calibration Certificate for Digital Weighing BalancemaniNo ratings yet

- CS PIPE MTC SampleDocument1 pageCS PIPE MTC SampleMark Joseph PagadorNo ratings yet

- 249-317 Tec Aero Tue-C-100-293Document1 page249-317 Tec Aero Tue-C-100-293KiranNo ratings yet

- LASER FERITI CERTIFICATE OF QUALITYDocument1 pageLASER FERITI CERTIFICATE OF QUALITYdario_791473996No ratings yet

- Certificado de TornilleríaDocument7 pagesCertificado de TornilleríaEdwin AlarcónNo ratings yet

- 43-Utm Load Cell Tensile Calibration CartificateDocument1 page43-Utm Load Cell Tensile Calibration CartificateCustomer SupportNo ratings yet

- Insitu California Bearing Ratio (CBR) Test With Dynamic Cone Penetrometer (DCP)Document1 pageInsitu California Bearing Ratio (CBR) Test With Dynamic Cone Penetrometer (DCP)salman al-fariziNo ratings yet

- Bill of Quantities: 22.0 Plumbing WorksDocument4 pagesBill of Quantities: 22.0 Plumbing WorksOne Oikos EngineeringNo ratings yet

- Liberty Galati S.A. - Romania: Inspection Certificate 20617901 ACCORDING TO: EN 10204/2004/3.1 DATE: 16.02.2020Document1 pageLiberty Galati S.A. - Romania: Inspection Certificate 20617901 ACCORDING TO: EN 10204/2004/3.1 DATE: 16.02.2020Felicia CioabaNo ratings yet

- INSPECTION CERTIFICATE FOR CARRIAGE BOLTSDocument1 pageINSPECTION CERTIFICATE FOR CARRIAGE BOLTSqualityNo ratings yet

- Elongation Index For Coarse Aggregate22mmDocument2 pagesElongation Index For Coarse Aggregate22mmMarwa AlasheebiNo ratings yet

- Certificado de Calibração - Validador 2023Document2 pagesCertificado de Calibração - Validador 2023Edson RamosNo ratings yet

- Certificado de Calibração - Validador (2022)Document2 pagesCertificado de Calibração - Validador (2022)Edson RamosNo ratings yet

- Oman Aviation Fuel Piping SpecificationDocument3 pagesOman Aviation Fuel Piping SpecificationaltipatlarNo ratings yet

- Jembatan Yetii Senggi MamberamoDocument55 pagesJembatan Yetii Senggi MamberamoKrisnataliaNo ratings yet

- Sertifikat Produksi Caa-2212-00097Document1 pageSertifikat Produksi Caa-2212-00097figo zaliNo ratings yet

- Laporan Kalibrasi Calliper LatihanDocument24 pagesLaporan Kalibrasi Calliper LatihanMuhammad BurhanuddinNo ratings yet

- 01.PG 10 BarDocument6 pages01.PG 10 BarSathish KarunNo ratings yet

- MILL TEST CERTIFICATE FOR 304 STAINLESS STEELDocument1 pageMILL TEST CERTIFICATE FOR 304 STAINLESS STEELMANIMARAN QC100% (1)

- MTC الاتفاق 18 ملىDocument1 pageMTC الاتفاق 18 ملىbwd51523No ratings yet

- Quality certificate analysisDocument6 pagesQuality certificate analysisClaudia TiradoNo ratings yet

- DC 958Document2 pagesDC 958mkarthiNo ratings yet

- Concrete Mix DesignDocument12 pagesConcrete Mix DesignAnand.5No ratings yet

- MTC Pipa Kotak 60x2, 50x2Document1 pageMTC Pipa Kotak 60x2, 50x2Pahala LumbantoruanNo ratings yet

- Test Certificate: CM/L-NO:5571169Document1 pageTest Certificate: CM/L-NO:5571169akashNo ratings yet

- RELIABLE TECHNICAL SERVICES CERTIFICATIONDocument2 pagesRELIABLE TECHNICAL SERVICES CERTIFICATIONMangesh Mohite0% (1)

- Mir 001Document2 pagesMir 001MCCIN L&WNo ratings yet

- AMS-CAL-0153-15 Dial IndicatorDocument2 pagesAMS-CAL-0153-15 Dial IndicatorMuhammad RahimNo ratings yet

- M25 Concrete Mix Design for Bottom PlugDocument10 pagesM25 Concrete Mix Design for Bottom PlugBscpl Repalle to EeppurpalemNo ratings yet

- ACC Concrete Modulus of Elasticity Test ReportDocument4 pagesACC Concrete Modulus of Elasticity Test ReportSabyasachi BangalNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- MOE Test Result of Acc ConcreteDocument4 pagesMOE Test Result of Acc ConcreteSabyasachi BangalNo ratings yet

- Test Certificate: (AS PER EN 10204 TYPE 3.1)Document2 pagesTest Certificate: (AS PER EN 10204 TYPE 3.1)qualityNo ratings yet

- Lionn Auto SoftwaresDocument2 pagesLionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- 300t Mexican Calibrations June 2023Document4 pages300t Mexican Calibrations June 2023marco chavezNo ratings yet

- AL-905-R-11202 Spec AG01 Rev. T02Document3 pagesAL-905-R-11202 Spec AG01 Rev. T02altipatlarNo ratings yet

- 7,-Qad-28sample Inspection Report Mach. 74-100Document1 page7,-Qad-28sample Inspection Report Mach. 74-100azadsingh1No ratings yet

- 10mm Gr60Document1 page10mm Gr60alshaya steelNo ratings yet

- CBH-22-169 Din 912 SHCS M10 X 30 Self 8.8Document1 pageCBH-22-169 Din 912 SHCS M10 X 30 Self 8.8qualityNo ratings yet

- APL-C2-22-372 Tire Pressure Gauge AIR TRAFFICDocument2 pagesAPL-C2-22-372 Tire Pressure Gauge AIR TRAFFICjoshuaNo ratings yet

- Ervin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyDocument2 pagesErvin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyreynaldoUHNo ratings yet

- Vernier CalliperDocument15 pagesVernier CalliperStudent ForeignNo ratings yet

- SD 221Document2 pagesSD 221peter njugunaNo ratings yet

- Quot. NDocument17 pagesQuot. NroxanaNo ratings yet

- Old Test SheetDocument13 pagesOld Test SheetImran SikandarNo ratings yet

- MarketsandMarkets - Foresighting Research & Advisory CapabilitiesDocument44 pagesMarketsandMarkets - Foresighting Research & Advisory CapabilitiesKaranvir singhNo ratings yet

- Concrete WorkDocument3 pagesConcrete WorkAbdul Ghaffar100% (1)

- Produk Fermentasi Tradisional Indonesia Berbahan Dasar Pangan Hewani (Daging Dan Ikan) : A ReviewDocument15 pagesProduk Fermentasi Tradisional Indonesia Berbahan Dasar Pangan Hewani (Daging Dan Ikan) : A Reviewfebriani masrilNo ratings yet

- Ba Etamatic Dlt2001 16 Aen 195Document156 pagesBa Etamatic Dlt2001 16 Aen 195Banu EdoNo ratings yet

- Marketing Management - Module 7Document18 pagesMarketing Management - Module 7SnehaNo ratings yet

- Clinical and Forensic Interviewing Sattler JeromeDocument9 pagesClinical and Forensic Interviewing Sattler Jeromeraphael840% (1)

- Publikasi Ketujuh TF-CCRDocument6 pagesPublikasi Ketujuh TF-CCRRiny AgustinNo ratings yet

- How To Prepare For The CFA Exam - QuoraDocument10 pagesHow To Prepare For The CFA Exam - QuoraaduragbeNo ratings yet

- NGS QC MetricsDocument7 pagesNGS QC MetricsAgustin BernacchiaNo ratings yet

- What Is A Gas CompressorDocument5 pagesWhat Is A Gas CompressorI AM NOT CHINESENo ratings yet

- BJT Mkwi4201 Bahasa InggrisDocument3 pagesBJT Mkwi4201 Bahasa Inggrisnatalia walunNo ratings yet

- INBO2020 Solutions 20200220Document11 pagesINBO2020 Solutions 20200220Abhik Kumar MajiNo ratings yet

- Quiz 2 MicroDocument14 pagesQuiz 2 MicroRoy CabarlesNo ratings yet

- DLL All Subjects 2 q4 w8 d2Document8 pagesDLL All Subjects 2 q4 w8 d2Kinder DarpingNo ratings yet

- Graduate School: Mariano Marcos State UniversityDocument2 pagesGraduate School: Mariano Marcos State UniversityLeslie Anne BiteNo ratings yet

- Special MantrasDocument5 pagesSpecial Mantrasvenkataramanneralla100% (2)

- International Case StudyDocument14 pagesInternational Case StudyPriyanka Khadka100% (1)

- 5th Weekly Exam - Plumbing ArithmeticDocument11 pages5th Weekly Exam - Plumbing ArithmeticArchie Gomocag0% (1)

- Pengaruh Promosi Kesehatan Metode Penyuluhan Tentang Hiv/Aids Terhadap Peningkatan Pengetahuan Remaja Di Sma N 5 Padang Sari Setiarini AbstrakDocument7 pagesPengaruh Promosi Kesehatan Metode Penyuluhan Tentang Hiv/Aids Terhadap Peningkatan Pengetahuan Remaja Di Sma N 5 Padang Sari Setiarini AbstrakRafi SalimNo ratings yet

- Joints, Bones & Healthy SkeletonsDocument2 pagesJoints, Bones & Healthy Skeletonsسكمي نعمة الكرمهNo ratings yet

- Stormwater Survey Gauges Rizal Tech University DesignDocument1 pageStormwater Survey Gauges Rizal Tech University DesignAlejandroGonzagaNo ratings yet

- M5 - Freedom of The Human PersonDocument8 pagesM5 - Freedom of The Human PersonMarisol OtidaNo ratings yet

- Granulation Machines Used For Dry Granulation and Wet GranulationDocument18 pagesGranulation Machines Used For Dry Granulation and Wet GranulationShaban Danish100% (1)

- Grade 10 Biology Week 8 Lesson 2 Worksheet 1 and SolutionsDocument4 pagesGrade 10 Biology Week 8 Lesson 2 Worksheet 1 and SolutionsAva HoNo ratings yet

- Effect of Summer Green Gram (Vigna Radiata L.) Varieties, Sulphur Levels and Fertilizer Levels On Quality, Nutrient Content and Uptake Under South Gujarat ConditionDocument3 pagesEffect of Summer Green Gram (Vigna Radiata L.) Varieties, Sulphur Levels and Fertilizer Levels On Quality, Nutrient Content and Uptake Under South Gujarat ConditionThakor BharviNo ratings yet

- Full Scale Tests of Heat Strengthened Glass With Ceramic FritDocument17 pagesFull Scale Tests of Heat Strengthened Glass With Ceramic FritKároly FurusNo ratings yet

- Kami Export - Exam Booster FCE Speaking Part 3 and 4Document2 pagesKami Export - Exam Booster FCE Speaking Part 3 and 4Valen JacobNo ratings yet

- Geology Lesson PlanDocument6 pagesGeology Lesson Planapi-501773574No ratings yet

- BTech - Chem Engg - Course StructureDocument6 pagesBTech - Chem Engg - Course Structureramesh dasariNo ratings yet

- Individual Assignment 2 - Article Review - Opm530Document2 pagesIndividual Assignment 2 - Article Review - Opm530Amir HafiyNo ratings yet