Professional Documents

Culture Documents

MPCPL BSR M10X1.5PX45 4140 B7 Blackodising M10-45-SB7

Uploaded by

Gaurav0 ratings0% found this document useful (0 votes)

19 views1 pageOriginal Title

MPCPL BSR M10X1.5PX45 4140 B7 BLACKODISING M10-45-SB7

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views1 pageMPCPL BSR M10X1.5PX45 4140 B7 Blackodising M10-45-SB7

Uploaded by

GauravCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

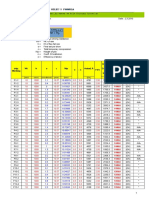

TURNING DIA.

MAJOR Ø 9.80 TO 9.95 9.00 TO 9.10

PITCH Ø 8.86 TO 8.99 Ø 10 BOTH SIDES

13±0.2 20±0.2 M10X1.5P

45±0.2

NOTE :

TOLERANCE FOR STUDS TO SUIT 6g RING

THREAD GAUGE.

REFERENCE STANDARD : ASME B 1.13M NOTE : GRINDING DIAMETER 8.92 TO 8.94

COATING : BLACKODISING

CRITICAL COMPONENT MACHINING DRAWING

DRAWN G. KELKAR THE DRAWING IS PROPRIETARY ARTICLE AND IS LOANED IN CONFIDENCE SUBJECT TO RETURN

UPON DEMAN. REPRODUCTION THEREOF OR MANUFACTURE OF PARTS THEREFROM IS NOT RAW MATERIAL 4140 Ø10

CHECKED B. SONAWANE PERMISSIBLE WITHOUT THE WRITTEN PERMISSION OF MASK FASTENERS PVT. LTD.

GENERAL MACHINING TOLERANCES for linear dimensions

APPROVED G. THORVE PRODUCT GRADE A193 B7

400 TO 1000 TO 2000 TO

0.5 UPTO 6 6 TO 30 30 TO 120 120 TO 400

NOTES : 1000 2000 4000

± 0.1 ± 0.2 ± 0.3 ± 0.5 ± 0.8 ± 1.2 ± 2.0

1) All dimensions are in mm. WEIGHT

2) Remove all sharp corners and edges by 0.5 radii / 0.5*45° GENERAL MACHINING TOLERANCES for angular dimensions

3) Critical dimension with its surface finish & GD&T marked LENGTH UPTO10 10 TO 50 50 TO 120 120 TO 400 400 TO 1000

as DRG. NO. MPCPL/M10-45-SB7

4) Dimensions showed in (_) only for reference. ANGLE ± 1° ± 0° 30' ± 0° 20' ±0° 10' ± 0 5'

5)For any clarification or suggestions please contact R&D. TITLE : STUD WITH BOTH SIDE RADIUS

SCALE : N.T.S

Machining from 6.3 um to 3.2 um M10 x 1.5P x 45L

Grinding from 0.8 um to 0.4 um

MASK FASTENERS PVT. LTD.

00 -- New Release 6) Refer table MFPL/MFG/TRSIZES FOR THREAD

DIMENSIONS.

REV. DCN. NO. BRIEF RECORD SIGN.

Reference Customer Drawing No.: PV15-258D11F

You might also like

- 3X45° Bar Stud Machining DrawingDocument1 page3X45° Bar Stud Machining DrawingGauravNo ratings yet

- Full 3-4 10unc 115 B7 BlackodisingDocument1 pageFull 3-4 10unc 115 B7 BlackodisingGauravNo ratings yet

- Full 3-4 10unc 130 B7 BlackodisingDocument1 pageFull 3-4 10unc 130 B7 BlackodisingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - RollingDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - RollingGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - GrindingDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - GrindingGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - RollingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - RollingGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - MarkingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - MarkingGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - MarkingDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - MarkingGauravNo ratings yet

- Gargi EnterprisesDocument10 pagesGargi EnterprisesGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - GrindingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - GrindingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - Blanking PDFDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - Blanking PDFGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - RollingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - RollingGauravNo ratings yet

- KGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingDocument1 pageKGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - BlankingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - BlankingGauravNo ratings yet

- Full M20X2.5PX210L A193 B8M CL-1Document1 pageFull M20X2.5PX210L A193 B8M CL-1GauravNo ratings yet

- M16X2PX52L 4140 B7 BlackodisingDocument1 pageM16X2PX52L 4140 B7 BlackodisingGauravNo ratings yet

- Eee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0Document1 pageEee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0GauravNo ratings yet

- Eee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0Document1 pageEee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0GauravNo ratings yet

- Full M12X1.75PX60 B7 ZN Al - BlankingDocument1 pageFull M12X1.75PX60 B7 ZN Al - BlankingGauravNo ratings yet

- M20X2.5PX60L 4140 B7 BlackodisingDocument1 pageM20X2.5PX60L 4140 B7 BlackodisingGauravNo ratings yet

- M16X2PX52L B8Document1 pageM16X2PX52L B8GauravNo ratings yet

- BEC 013 Automotie ElectronicsDocument70 pagesBEC 013 Automotie Electronicsjimshith jimmuNo ratings yet

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Document1 pageMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravNo ratings yet

- MPCPL BSR M10X1.5PX50 4140 B7 Blackodising M10-50-SB7 PDFDocument1 pageMPCPL BSR M10X1.5PX50 4140 B7 Blackodising M10-50-SB7 PDFGauravNo ratings yet

- MPCPL BSR M10X1.5PX45 4140 B7 Blackodising M10-45-SB7Document1 pageMPCPL BSR M10X1.5PX45 4140 B7 Blackodising M10-45-SB7GauravNo ratings yet

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Document1 pageMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravNo ratings yet

- MPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7Document1 pageMPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7GauravNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Full Semester Internship Roject Report: Piezo-Electric Hybrid Shock AbsorberDocument50 pagesFull Semester Internship Roject Report: Piezo-Electric Hybrid Shock AbsorberVarun GuptaNo ratings yet

- Fabric CoveringDocument32 pagesFabric CoveringQayyum KhairinNo ratings yet

- Diy Speaker ManualDocument27 pagesDiy Speaker ManualKent WaiNo ratings yet

- Faure Herman TLM MetersDocument2 pagesFaure Herman TLM MetersRadityaA.PerdanaNo ratings yet

- Comp Oil Filter Comparison With BaldwinDocument5 pagesComp Oil Filter Comparison With Baldwinanon_845964285No ratings yet

- Aisc-Mbma Steel Design Guide No 16Document14 pagesAisc-Mbma Steel Design Guide No 16sebastian9033No ratings yet

- KSB Movitec Type Series BookletDocument60 pagesKSB Movitec Type Series BookletRicardo BarrosNo ratings yet

- Report On Rock MechanicsDocument44 pagesReport On Rock MechanicsElyssa Michelle Caringas MicuaNo ratings yet

- Safe Operation and Use of Mobile Jaw CrushersDocument7 pagesSafe Operation and Use of Mobile Jaw Crushersテレブリコ ジェファーソンNo ratings yet

- Properties of WaterDocument23 pagesProperties of WaterJohnnardBelenNo ratings yet

- Ook Hiley's Formula - Back Calc For Driven PileDocument3 pagesOok Hiley's Formula - Back Calc For Driven PileHanafiahHamzahNo ratings yet

- Nitrogen DataDocument8 pagesNitrogen DatanitrovertNo ratings yet

- hlg01 WebDocument27 pageshlg01 WebBosko LacimicNo ratings yet

- Basewest: Model 601 Battery Pack Aircrew FlashlightDocument1 pageBasewest: Model 601 Battery Pack Aircrew FlashlightMilad YadollahiNo ratings yet

- Disinfect PipelinesDocument11 pagesDisinfect PipelinesgunsakNo ratings yet

- PDC Bits CourseDocument76 pagesPDC Bits CourseRobert Koch100% (1)

- 4f27e 2006 Workshop ManualDocument23 pages4f27e 2006 Workshop ManualTransmisiones Automáticas Chepe100% (5)

- Ed Ual Mini 202301Document51 pagesEd Ual Mini 202301DalaPaulaNo ratings yet

- Relay Relay: Solid State Relay Protection RelayDocument46 pagesRelay Relay: Solid State Relay Protection Relaymalikawais1No ratings yet

- Concrete Cylinder Testing Results TableDocument13 pagesConcrete Cylinder Testing Results TableAzim De LeonNo ratings yet

- CWTS Group 2Document4 pagesCWTS Group 2Justin Neo ParlanNo ratings yet

- Containers in Non Cellular ShipsDocument7 pagesContainers in Non Cellular Shipsjoeven64No ratings yet

- ts870 pm062r8Document54 pagests870 pm062r8acebouzouadNo ratings yet

- Astm C805 - 02 PDFDocument3 pagesAstm C805 - 02 PDFGilson ContattoNo ratings yet

- Dead Front Panels Backlit UserDocument2 pagesDead Front Panels Backlit UserBooknest CoNo ratings yet

- Fire Clay. Where To Collect Fireclay in Nature and How. Buying Fire ClayDocument7 pagesFire Clay. Where To Collect Fireclay in Nature and How. Buying Fire Clayvero66No ratings yet

- Formatwise ReportDocument9 pagesFormatwise ReportPooja BanNo ratings yet

- Velan Y-Pattern Globe CAT BG 04 10Document12 pagesVelan Y-Pattern Globe CAT BG 04 10mfcramer0% (1)

- Pi - Trahair - Inelastic Torsion of Steel I BeamsDocument12 pagesPi - Trahair - Inelastic Torsion of Steel I BeamspvecciNo ratings yet

- Magnetic Particle TestingDocument2 pagesMagnetic Particle TestingThanhdong DoNo ratings yet