Professional Documents

Culture Documents

M043 Aux. Generator Engine - Service Manual

M043 Aux. Generator Engine - Service Manual

Uploaded by

Ashly Joseph0 ratings0% found this document useful (0 votes)

72 views276 pagesM043

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentM043

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

72 views276 pagesM043 Aux. Generator Engine - Service Manual

M043 Aux. Generator Engine - Service Manual

Uploaded by

Ashly JosephM043

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 276

SNO. 124

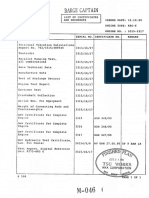

BERGE CAPTAIN

SERVICE MANUAL

ISHED >)

PON

ae WORKS

BERGEN

DIESEL

>

@_ULSTEIN

4

Bergen Diesel as

fs a M-043

SNO.124

BARGE CAPTAIN

SERVICE MANUAL

Engine type KRG

KRGB

BERGEN

x DIESEL ¢

SU Ww

NKK ORKs | ,

en CoRPoRaTion | J

Ss Prer, sap bl

tssued 1990

BERGEN INTRODUCTION

This Service Manual has been compiled to assist personnel responsible for the operation and

maintenance of Bergen Diesel engines, and should therefore always be available for the

technical staff.

Technical data and information in this Service Manual should be considered as confidential.

In this Service Manual, care has been taken to ensure that the engine is presented as

thoroughly as possible. Development and progress in design may, however, together with

‘special application, make alterations of detail necessary.

It should also be observed that, although this Manual describes a certain equipment, such

‘equipment is not necessarily delivered as standard.

While reserving the right to make any allerations in design which we considor advisable, such

an alteration can not-be regarded as retrospective. We also reserve the right to make

alterations in the Service Manual.

SvingJHULSENDE

FLYWHEEL END

Hinten

(Kupptunasse ite)

eh

Hes aa

Technical data

| | Testbed results

|| Main sections

SERVICE MANUAL FOR BERGEN DIESEL ENGINE

oe

oO

ec

|| Service

|| Spare parts

| | Operating instructions

| | Maintenance

| tose EEE Soe a =

Bed Frame

|| Cylinder Block

|| Cylinder Head

Gaps and Covers

Crankshatt

Piston and connecting rod

|| Camshatts

Operation of Inlet - and

Exhaust valves

|| Starting

|| Governing

Manoeuvring

Remote Control

Alarm Equipment

}| Automation

|| Charge air

ue! Oil

|| Exhaust 7

Pump Drive

|| Lubricating Oil

| Cooling Water 8

Mounting Instructions

‘Sundries

TABLE OF CONTENTS

Main technical data

Technical data

Manufacture data

Crankshaft deflection

Testbed results

Longitudinal section of engine

Gross section of engine

CHAPTER 0

0.1.01.-

0.1.02.-

0.1.03.

0.2.01

0.3.01.

Aug. -90

MAIN TECHNICAL DATA 0.1.01.1

BERGEN ‘Sept-90

ye ENGINE NO: 3315-17 K

a seen cee

1.__Engine data

gine type... -. +--+ eee eats cee. KRG

Bore ened 250 mm

Stroke |... eres 300 mm

‘Swept Volume pr. cylinder 14,7 dm3

Campression Ratio .... 12,5

Number of Cylinders

Pre-injection angle.

A-Dimension (Fuel Injection

Information on power output is related to external working conditions

(engine room temperature, baromelic pressure, sea_ walter

temperature etc. and will be ‘supplied in agreement between buyer

and Bergen Diesel A.S. (Otherwise, see the test-bed results.)

Maximum continuous power output and speed, based on the actual

running conditions, are printed together with engine no. on the name

plate, which is attached to the engine.

{Otherwise, see the test-bed results.)

rection of rotation and firing order

Clockwise rotation, - facing the engine flywheel end.

Anticlockwise rotation, -"facing the engine flywheel end.

ENGINE NO. 3315-17 FIRING ORDER: 1-5-3-6-2-4

The cylinders are numbered from the pump end towards the flywheel

end.

Cylinder head valves.

a. Safety valve, opening pressure... 2... se 2e eee eee oe 475. bar

injection valve, see fuel oil system in section 5.

b. __ Inlet- and exhaust valves

‘Check values for opening- and closing times of valves:

The check Is to be carried out with zero tappet clearance,

and the angles are read when the push rod has a lift of 1,8

mm. Note that tapped clearance Is adjusted to 0,3 mm after

the check is finished.

Check values :

Infet valve in opening phase 30° before T.

Inlet valve in closing phase B.D.

Exhaust valve in opening phase 35° before 8.0.

Exhaust valve in closing phase 25° after T.

Sete ue 280 bar

c. Injection valve, opening pressure

3.___Main Lube Oil System Data

Lube oil pump’s relief valve opens at...

Lube oil pressure, inlet engine at full speed

(oil pressure control valve’s opening pressure) ..-.---- secees | 4°5) bar

4,___Crankcase Safety Valve Data

Opening pressure

5. __ Flexible Engine Mounting. Buller clearance B (See inst. 2.1.02) - mm

*—TThe clearance is given when butters are arranged.)

eerie eeee sere eerie ett 0.1 bar

2312-13

TECHNICAL DATA

BERGEN DIESEL TYPE KR

GENERATOR ENGINES

LE 722/54

ENGINE DATA

‘TYPE OF ENGINE

NUMBER OF CYLINDERS

‘CYLINDER BORE

PISTON STROKE

MAX. CONT. RATING

MAX.CONT.RATING ALTERNATOR

GENERATOR EFFICIENCY

MAX.CONT.RATING ALTERNATOR

WITH COS(fij= 80

BMEP AT M.C.R.

ENGINE SPEED AT MAX. LOAD

MEAN PISTON SPEED

‘COMPRESSION RATIO

DISPLACEMENT

MAX. FIRING PRESSURE

MECHANICAL EFFICIENCY

BESSE2 ,aeags, ,

FUEL OIL DATA

SPECIFIC FUEL OIL CONSUMPTION G/KWHE 290.0

" . . G/HRH 140.0

FUEL OIL CONS. AT RATED OUTPUT —KG/Ht 194.0

7 « Lt 228.0

FUEL OIL FEED PUXP CAPACITY /H 525.0

RECOM. VOL. OF DAYTANK (E0,DNV) 3 5.0

AIR STARTING DATA

MAX. START AIR PRESSURE BAR 30.0

MIN. ” . BAR 15.0

NO. OF STARTS,250 L. RECEIVER - 27.0

. 225 Le . - 8.0

SERGEN

LOBRICATION DATA

LOBRICATING OIL : SAE-30

LOB. OIL PUMP CAPACITY

LWUB.OIL PRES. AFTER FILTER

7 ALARM SET POINT

= SHUTDOWN SET POINT

‘NORMAL TEMP. AT ENGINE INLET

MAX. TEMP. =

ALARM SET POINT

SPEC. LUB.OIL CONSUMPP. , APPROX.

LUB-OIL CONSUMPT. ,APPROX.

“IN CRANKCASE, MAX.

“ “ MIN.

HEAT DISSIPATION LUB.OIL COOLER

ROCKER ARM SYSTEM

WUB.OLL PUMP CAPACITY

WB. OIL PRESSURE

WB. OIL PRESSURE ALARM SET POINT

COOLING WATER DATA

LOW TEMP. F.W. SYSTEM :

MAX. TEMP. AT SYSTEM INLET

MAX.FLOW, 2-STAGE ‘CA-COOLERS

JACKET WATER SYSTEM :

FLOW RATE

PRESSURE RISE ,PUMP

"vy, ALARM SET POINT ABV.AMB.

NORMAL TEMP. AT OUTLET

ALARM TEMP. SET POINT

SHUT DOWN SET POINT

MAX. TEMP. RISE IN ENGINE

~ INCL. 2.STAGE cA-COOLER

EXP. TANK VOLUME, ONE ENGINE

“ COMMON

EXP. TANK HEIGHT OVER ENGINE

FRESH WATER QUANTITY IN ENGINE

JACKET WATER COOLER

HEAT DISSIPATION

"

HEAT DIS. INCL. 2.ST. CA-COOLER

ERG - 6

43/H 18.8

BAR 4.0-5.0

BAR 2.5

BAR 2.0

DEG.c 50-55

DEG.¢ 60

DEG.¢ 65

G/KWH 1.3

LIT/H 1.5

ur 750.0

LIr 520.0

MO/H 320.0

KCAL/H = 77000

LIT/H 260.0

BAR 0.2-0.3

1E722/54

2/3

kngew LE722/54

: 3/3

AIR DATA

KRG - 6

TURBOCHARGER ~ BBC,TYPE : - VIR-214

CHARGE AIR COOLER, 2-STAGE - VRF40

AIR CONSUMPTION, EXCL. VENT. ™3/H 7300.0

CHARGE AIR PRESSURE ABV. ANB. BAR .2.0-2.2

CHARGE AIR TEMP. NORMAL DEG.c 55-60

ALARM SET POINT DEG.C 65

CHARGE AIR COOLER, 2-STAGE

HEAT DISSIP. H.T. STAGE MO/H 725.0

: " KCAL/H 173000

- U.P. STAGE MI/H 425.0

KCAL/H 102000

EXHAUST DATA

EXHAUST GAS MASS FLOW KG/H 8300.0

La VOLUME FLOW M3/H_ —14500.0

TEMP. AFTER CYL. DEG.c 370.0

Fe « ‘TURB. DEG.c 340.0

MAX. PRES.DROP TURB.-ATM. MMWG 300.0

AVAILABLE EXH. GAS ENERGY :

200 % TOAD EXH.GAS MASS FLOW —-KG/HH_—s8300.0

TEMP DEG.C 340.0

60 & LOAD EXH.GAS MASS FLOW KG/H_: 6600.0

7 «TEMP DEG.C 320.0

50 & LOAD EXH.GAS MASS FLOW KG/H 4800.0

" «TEMP DEG.c 285.0

VENTILATION DATA

NEAT DISSIP. FROM ENG. BY VENT. MI/H 2180.0

. " KCAL/H 43000

“ ALT. M/H 185.0

KCAL/H 44000

Engine ratings are according to 1s0 3046/1, they

also meet conditions of max. 45 deg.c ambient ate

Semperature and max. 32 deg.c cooling water temp.

~ NOTE ~ Due to cont. development, some spec. may change.

890704 SHa

FABRIKASJONSDATA. 0.1.02.1

Motor nr. : 3315 Sept. -88

15 A. Innstilling av brenstoff- pumpene

Sylinder nr. (Rekkemotor eller V-motor)

Sylinderrekke A (V-motor)

a 7s |,6|7 3a | 9

preinjection angle |

(eeatbstore 0

Forinnspreytnings-

vinkel.

(Grader for T.D.C.)

A= Dim.

A-mal (mm)

15

13,50

3,35

3,30

3,50 13,90 |3,05

Ta

Mellomlegg

tykkelse (mm)

Teer

y!

Pakningtykkelse

sylinderblokk -

sylinderforing (mm)

12,50

2,90

2,70

3,40 /2,55 | 3,60

2,25

2,25

2,25

2.25 |2,25 |2,25

158. Innstilling av brenstoff-pumpene

sylinder nr.

Sylinderrekke B (V-motor)

4 5 6 7 8 9

vinkel:

(Grader for T.D.C.)

Cena

A-mal (mm)

Thickness

sylinderblokk ~

sylinderforing (mm)

FABRIKASJONSDATA 0.1.02.1

‘ ' Motor nr. : 3316

s Sept. -88

A mentof fuel ps 15 A. Innstilling av brenstoff-pumpene

= ee

: 0 sylinder nr. (Rekkemotor eller V-motor)

: -Engine Sylinderrekke A (V-motor)

1 Zee 4 5 6 |7 8 9

sinjecion

jeg: bere

Forinnsproytnings- ( |15 15/45 15115

vinkel.

(Grader for T.D.C.)

(mn :

43,25 3,43

A-mal (mm)

hickn t

Mellomlegg 13,40 3,30

tykkelse (mm)

2.50 |2,25 |2,50 (2,25 |2,25 |2,25

Pakningtykkelse

sylinderblokk -

sylinderforing (mm)

ij t 15 B. Innstilling av brenstoff-pumpene

5 Glinde Sylinder nr.

Sylinderrekke B (V-motor)

1 2 3 4 5 6 7 8 9

sea base Be

Forinnspraytnings-

vinkel

(Grader for T.D.C.)

A -mal (mm)

Thiekn f spa

Pakningtykkelse

isylinderblokk -

sylinderforing (mm)

pincktn A U FABRIKASJONSDATA 0.1.02.1

ana Motor nr. : 3317 Ser lige

ad tof fuel 15 A. Innstilling av brenstoff-pumpene

oe

finder No., Sylinder nr. (Rekkemotor eller V-motor)

Gs Sylinderrekke A (V-motor)

1 2 | 3 af[sfe6|?7 a | 9

aaa

[easbsion 86

Forinnsproytnings- |! [15 15/144) 15— 115

vinkel.

(Grader for T.D.C.)

= 3,32 (3,45 |3,56 |3,49 |3,52 |3,47

‘A- mal (mm) eee lee

iekness of spacer

Mellomlegg Bess l210 |2,70 |2,50 [2,30 |2,50 |2,10

tykkelse (mm) +

ckne askat

black = cy. line

Pakningtykkelse [225 2.25 |2.25 [2,25 |2,.25 |2,25

sylinderblokk -

sylinderforing (mm)

SBA jentof fuel oil 15 B. Innstilling av brenstoff-pumpene

No sylinder nr.

Sylinderrekke B (V-motor)

os ea a][s5s [6 |7 a | 9

Forinnspraytnings-

vinke

(Grader for T.0.C.)

1Dim. (nm)

A-mal (mm)

i ness Of spacer:

Mellomlegg

tykkelse (mm)

kness of gasket

lock = cyt liner

Pakningtykkelse

sylinderblokk -

sylinderforing (mm)

CRANKSHAFT DEFLECTION CONTROL 0.1.03.1

TNDIKERING AV VEIVAKSEL

BERGEN ENGINE NO./MOTOR NR.: 3315 KRG-4 y_) gg

ANTICLOCKHISE ROTATION ; CLOCKNISE ROTATION

VENSTREGAENOE HOTOR | HaYREGAENOE MOTOR

INDICATES DIRECTION OF ROTATION i

VISER MOTORENS OREIERETNING

SEEN FROM THE FLYWHEEL END

SETT FRA MOTORENS SVINGHJULSENOE

CONTROL MEASUREMENT TO BE MADE IN DIRECTION OF ROTATION

THOIKERING FORETAS | ORELERETNINGEN

JESSIE SSIES IEEE II IDES HOUSE II IISA SESSA

*CRANK * CRANK POSITION/VEIVSTILLING *

* NO. + panna n-------= ===. -*

avEIV * 1 * 2 * 3 * *

* NR. *BOTTOM / BUNN* * TOP / TOPP * *

fennla ee paw tan nnn na n= === t= === t=

* * COLD * WARM * COLD * WARM * COLD * WARM # COLD * WARM #

* * KALD * VARM * KALD * VARM * KALD * VARM * KALD * VARM #

tonne note

0.0* 0.0* 0.0 * 0.0 *

0.0 * 40.5 # 41.0 * +2.0 *

#30 * 0.0 * 0.0 * 41.5 * 0.0 * 42.0 * -3.0 * 41.5 * -3.0 *

ns

0.0 * +2.0 * +1.0 * +2,0 * -3.0 * 41.5 * -2.0 *

0.0 * 41.5 * 0.0 * +2.0 *# -2.5 * 41.0 * -2.0 *

* 6 * 0.0 * 0.0 * 41.5 * 0.0 * 42.5 * -1,0 * 41.5 4 0.0 *

JESS SIOIOI ISIDORE TIO TTT ASIA

REMARKS : MEASURED ON TEST-BED FLEXIBLE MOUNTED. -

~BEMERKNINGER: re

MEASUREMENT IN: 1/100 mm

MALT . 1/100, mm

(Engrne-7Motor type : - DATE/DATO~: SIGN.

aS] 260] 95 COLD/KALD: 11.07.90 AS

VARM/WARM: 16.07.90 AS

Hy

CRANKSHAFT DEFLECTION CONTROL 0.1-03.1

INDIKERING AV VEIYAKSEL

BERGEN ENGINE NO. /MOTOR WR.: 3316 KRG-

Nov .-85

Cl ANTICLOCKWISE ROTATION

* REMARKS: : MEASURED ON TEST-BED FLEXIBLE MOUNTED. -

CLOCKWISE ROTATION

H@YREGAENOE MOTOR

VENSTREGAENDE MOTOR

INDICATES DIRECTION OF ROTATION ij

VISER MOTORENS DREJERETNING

SEEN FROM THE FLYWHEEL ENO

SETT FRA MOTORENS SYINGHJULSENOE

CONTROL MEASUREMENT TO BE MADE IN DIRECTION OF ROTATION

INDIKERING FORETAS | ORELERETNINGEN

SRS SIDI ISIE DSI IIIS DIS IEEEDIIIS DIS IOI II SII IIE IR |

atone enn naan nn nnn nen

*CRANK * CRANK POSITION/VEIVSTILLING +|

* NO. #=— aan. ‘|

*vEIV * 1 * 2 * 3 * 4 *

* NR. ‘*BOTTOM / BUNN* * TOP / TOPP * *

tewen neo ann = tennant a *

* * COLD * WARM * COLD * WARM * COLD * WARM * COLD * WARM *

* * KALD * VARM * KALD * VARM + KALD * VARM * KALD * VARM +

* 1 * 0.0% 0.0% 0.0 *-0.5 * 0.0 *

* 5 * 0.0 * 0.0 * 40.5 # -1.5 * 40.5 * 3.0 # 41.0 * -2.0 *

fenennn eee

* 6 * 0.0 * 0.0 * 0.0 * =1.5 * -0.5 * -3.5 * 0.0 * -1.5 *

FEES EDIE E DODDS III III III III III III III TI I I I IITA

- BEMERKNINGER: :

PEASUREMENT IN: 1/100 am

HALT 1/100 mm

agine=/Wotor type

DATE/DATO “~SIGN.

COLD/KALD: 12.07.90 OM

VARM/WARM: 17.07.90 AS

L-K-8 : 7

CRANKSHAFT DEFLECTION CONTROL 0.1.03.1

INDIKERING AV VETVAKSEL

BEAGEN

ne ENGINE NO./MOTOR NR.: 3317 KRG-6| Nov.-85

ANTICLOCKWISE ROTATION “ CLOCKWISE ROTATION

Cy ana ie Cl] Sere

INDICATES OIRECTION OF ROTATION

VISER MOTORENS OREIERETNING

SEEN FROM THE FLYWHEEL END

SETT FRA MOTORENS SVINGHJULSENDE

CONTROL MEASUREMENT TO BE MADE IN OIRECTION OF ROTATION

INDIKERING FORETAS 1 OREIERETNINGEN

JES ISSO ODDS E BOBO SOE ISD III IDI IIIOIISNE II IIE

*CRANK * CRANK POSITION/VEIVSTILLING : *

* NO. te aannn -*

*vEIV * i * 2 * 3 * 4 *

* NR. *BOTTOM / BUNN* * * *

ene nn ata nee ==#---------. * * *

* * COLD * WARM * COLD * WARM * COLD * WARM + COLD * WARM #*

* * KALD * VARM * KALD * VARM * KALD * VARM + KALD * VARM *

a *

* 4 *

0.0 * *

ai---. *

0.0 * 40.5 * -0.5 * 41.5 * -2.5 * 41.0 * -2.0 *

* +1.0 * -2.0

0.0 *

* 0.0% -2.5 *

* 6 * 0.0 * 0.0 * 42.0 * -1.0 * 43,5 * -3.0 * 42.0 * -3.5 #

SBI SSD UIIE DIEU ODED EOE E EIS IDIDIO IDS IIE IIE

REMARKS + MEASURED ON TEST-BED FLEXIBLE MOUNTED. Hee

BEMERKNINGER: MEASUREMENT IN: 1/100 mm

MAL wed L100 mm

[Engine-/Motor typey & ] 5

RK = 7

TUTE DATE/DATO SIGN.

COLD/KALD: 19.07.90 OM

VARM/WARM: 23.07.90: OM

L-k-8

ENGINE TEST REPORT

JESSE SEES EIEIO IID III III IID IORI IAI III IOI IS SSI:

Engine no. : 3316 Engine type 2 KRG-6

Max. cont. rating (kW) : 1020 Engine speed (rpm) :

Gen. make : TATYO

Gen. no. 212197

Gen. spec.: kW ‘kVA Volt Amp. Hz cos fi

” : 930 1163 450 1492 60 0.8

owner + BERGESEN D.Y. A/S

Shipyard : NKK

Yard | nos: 124

Classification society : DNV EO

Tested date’

90.07.16

Fuel type (-) = MO Viscosity (cSt) : 3.0

Lower calorific value (MI/kg): 42.7 Density (g/cm3) : 0.84

Calibrated fuel quantity ‘(g): 5060

Mech. overspeed adjusted (rpm): 865

Test approved by: A 5

Bergen Diesel date: Mbt fe sign.: “O- few wer

Buyer date: sign.:

Owner date: ign.:

ate. sign d \ pe

Classification society date: 3(/%-9)) sign.: wn Bobs

date: sign.:

SEEDS ISIIOIS SISSIES SEIS EIIIS SUSI IUEISIDINIEDID SEES UIEIDODNEDO

TESTBED RESULTS ENGINE NO.: 3316.

Reading no.: 1 Date : 16. 7.90. Time : 11.52.56.

TEESE III OIE DIEU III IIE IIIA TIARA A

Nom. output (3) 100. Running hours (hy 2.0

Engine speed (rpm) 720. B.m.e.p. (bar) 18.2

Engine output (kil) 967. Fuel consump. time (sec) 95.1

Generator output (kif) 929. Spec. fuel consump. (g/kWh) 198.1

Barometric press. (mbar) 1013.0

Temp. engineroom (C) 24.0

Relative humidity (@) 60.0

LUBE-OIL : COOLING WATER =

Temp. engine inlet (C) 56.0 Temp. engine inlet (Cc) 80.0

Temp. engine outlet (C) 64.0 Temp. engine outlet (C) 84.0

Press. engine inlet (bar) 4.3 Press. engine inlet (bar) 2.2

Fuel oil press. (bar) 2.6 Rocker arm press. (bar) 8

Fuel oil temp. (C) 40.0 Nozzle oil press. (bar) 17

CYL. BANK (A for in-line engine)

Turbocharger speed (xpn) * 31700. *

Charge air press. (bar) * 1:80 +

Charge air temp. receiver (c) * 53.60 #

Cool.water temp. CA.cooler inlet (c) + 21.20 * 0.08 6

Fuel rack index - mean

Exhaust-gas temp. after cyl. 1 (cy) * 368. * o. *

. * aera ae 382. * o. *

* . "3 Cae 356. * oO. *

” . ont " * 362. * oO *

” ” "35 "8 361. * a. *

” ” PEHe) " * 352. * 0. *

fs . "mean" * 363. * 0. *

7 " turbin" * a. * o. *

Max. cylinder press. cyl. 1 (bar) * 228. * 0. *

" “2 oo # 127. * oO. *

” " 3 " * 327. * oO. *

. "4 "oe 127. * 0. *

” eee oo 128. * 0. *

. " 6 " & 127. * o. *

. mean" * 127. * o. *

JESSIE IEEE IIIS SISSIES DUI III II II IIR IID IIA II I

BERGEN

TESTBED RESULTS ENGINE NO.: 3316.

Reading no.: 2 Date : 16. 7.90. Time : 13.43.35.

SESE III ISO IDOI III III IES IIIS IIS II III III III III TI ITI

Nom. output (2) 100. Running hours a) 4.0

Engine speed (zpm) 720. B.m.e.p. (bar) 18.3

Engine output (kW) 969, Fuel consump. time (sec) 94.3

Generator output (KW) 931. Spec. fuel consump. (g/kWwh) 199.5

Barometric press. (mbar) 1010.0

Temp. engineroom (C) 24.0

Relative humidity (3) 58.0

LUBE-OIL =: COOLING WATER :

Temp. engine inlet (C) 55.0 Temp. engine inlet (C) 80.0

Temp. engine outlet (C) 64.0 Temp. engine outlet (C) 86.0

Press. engine inlet (bar) 4.3 Press. engine inlet (bar) 2.2

Fuel oil press. (bar) 2.6 Rocker arm press. (bar) +8

Fuel oil temp. (C) 40.0 Nozzle oil press. (bar) 17

¢YL. BANK (A for in-line engine) * A * B *

Turbocharger speed (rpm) * 31945. * 0. *

Charge air press. (bar) * 1.820 + 0.00 *

Charge air temp. receiver (c+ 55.5 * 0.0 +

Cool.water temp. CA.cooler inlet (c) * 24.40 * 0.00 *

Fuel rack index - mean (mm) * 29.5 * 0.0 *

Exhaust-gas temp. after cyl. 1 (c) * 372. * oO. *

. * mea oe 384, * oO. *

. " » 3 "8 358. * o. *

* * "4 "8 367. * o. *

7 7 ries "8 366. * o. *

” ” " 6 "ok 356. * oO. *

7 . "mean" #* 367. * 0. *

. . turbin" # 0. * oO. *

Max. cylinder press. cyl. 1 (bar) * 128. * 0. *

7 "2 “8 128. * 0. *

7 "3 “ # 127. * 0. *

i “4 “8 129. * 0. *

f mits "2 130. * 0. *

. act " 129. * oO. *

f mean 4" * 129. * oO. *

IEEE SESS ISIS IO IED IE ID DSSS DI DIED bp bbb nS biti

BERGEN

TESTBED RESULTS ENGINE NO.: 3316.

Reading no.: 3 Date : 16. 7.90. Time : 14.28.38.

ISSO OHSS SSSI IESE ESD IED IIE IIIS IESE ISIE IIS IID

Nom. output (4) 110. Running hours (h) 1.0

Engine speed (zpm) 720. B.m.e.p. (bar) 20.0

Engine output (ki) 1060. Fuel consump. time (sec) 0.0

Generator output (ki) 1019. Spec. fuel consump. (g/kWh) 0.0

Barometric press. (mbar) 1012.0

Temp. engineroom (Cc) 25.0

Relative humidity (@) 58.0

LUBE-OIL : COOLING WATER :

Temp. engine inlet (C) 54.0 Temp. engine inlet (Cc) 80.0

Temp. engine outlet (C) 64.0 Temp. engine outlet (C) 86.0

Press. engine inlet (bar) 4.3 Press. engine inlet (bar) 2.2

Fuel oil press. (bar) 2.5 Rocker arm press. (bar) “8

Fuel oil temp. (C) 40.0 Nozzle oil press. (bar) 1.7

cYL. BANK (A for in: * aA * B *

Turbocharger speed (rpm) * 33369. * oO. *

Charge air press. (bar) * 2.10 * 0.00 *

Charge air temp. receiver (c) * 56.6 0.0 *

Cool.water temp. CA.cooler inlet (c) * 25.4 * 0.00

Fuel rack index - mean (mm) * 32.00 * 0.0 #

Exhaust-gas temp. after cyl. 2 (Cc) * 383. * 0. *

. * aD "oe 393. * oO. *

” . "3 "8 369. * oO. *

" (essere janet] " # 376. * oO. *

. . " 5 o 8 377. * 0. *

f ” "6 "8 367. * 0. *

7 ” "mean" * 377. * 0. *

. a turbin" + 0. * 0. *

Max. cylinder press. cyl. 1 (bar) * 0. * 0. *

7 “2 eee 0. * o. *

* "3 * o. * oO. *

7 ea a 0. * oO. *

” os “2 0. * 0. *

. "6 " ® oO. * o. *

" mean" * 0. * oO. *

SEES IIE IE HIB E EEE EI IODIDE DIDI IIE III II III IDI III IEE

TESTBED RESULTS ENGINE NO: 3316.

Reading no.: 4 Date : 16. 7.90. Time : 14.57.38.

peers ter sr erer errr r i retire teeter eter iter trl itr itr rere terre tr Tatts Ty

Nom. output (8) 75. Running hours (a) 5

Engine speed (zpn) 720. B.m.e.p. (bar) 13.4

Engine output (kW) 720. Fuel consump. time (sec) 0.0

Generator output (ki) 681. Spec. fuel consump. (g/kWh) 0.0

Barometric press. (mbar) 1012.0

Temp. engineroom (C) 25.0

Relative humidity (3) 58.0

LUBE-OIL : COOLING WATER :

Temp. engine inlet (Cc) 54.0 Temp. engine inlet (Cc) 77.0

Temp. engine outlet (Cc) 64.0 Temp. engine outlet (Cc) 82.0

Press. engine inlet (bar) 4.3 Press. engine inlet (bar) 2.2

Fuel oil press. (bar) 2.6 Rocker arm press. (bar) 8

Fuel oil temp. (C) 41.0 Nozzle oil press. (bar) 17

CYL. BANK (A for in

-1ine engine)

Turbocharger speed (rpm)

Charge air press. (bar)

Charge air temp. receiver (c)

Cool.water temp. CA.cooler inlet (Cc) * 25.9 * 0.0 *

Fuel rack index - mean (mm) * 23.0 * 0.00 *

Exhaust-gas temp. after cyl. 1 (c) * 335. * 0. *

. ” "2 "oe 353. * 0. *

7 ” reg eres 329. * oO. *

* . "4 "8 341. * o. *

” " a 5 " 2@ 336. * o. *

. . aitilg: " # 333. * oO. *

. . “mean. * 338. * oO. *

7 ” turbin" * 0. * oO. *

Max. cylinder press. cyl. 1 (bar) * oO. * 0. *

* ro 2 7 o. * oO. *

7 “3 noe a * o. *

* peg oun o * ° *

* * 5 me a * o. *

“6 no o: * 0. *

ki mean = * oO. * oO. *

JESSE IIIT IDTE ED ISDE IOUS II II IIIA IIIa III III IIE

TESTBED

Reading no.: 5

Nom. output ()

Engine speed (pn)

Engine output (ke)

Generator output (xn)

Barometric press. (mbar)

Temp. engineroon (c)

Relative humidity (@)

LUBE-OIL :

Temp. engine inlet (Cc)

Temp. engine outlet (C)

Press. engine inlet (bar)

Fuel oil press.

Fuel oil temp.

(bar)

(c)

BANK

CYL.

Turbocharger speed

Charge air press.

(A for in-line

Charge air temp. receiver

BERGEN

RESULTS

ENGINE NO:

Date : 16. 7.90. Time :

50. Running hours ay

720. B.m.e.p. (bar)

473. Fuel consump. time (sec)

449. Spec. fuel consump. (g/kWh)

1012.0

25.0

58.0

COOLING WATER :

56.0 Temp. engine inlet (C)

64.0 Temp. engine outlet (C)

4.3 Press. engine inlet (bar)

2.6 Rocker arm press. (bar)

43.0 Nozzle oil press. (bar)

Cool.water temp. CA.cooler inlet

Fuel rack index - mean

Exhaust-gas temp. after cyl.

cyl.

engine) * a *

(rpm) * isi

(bar) * *

(c) * *

arte 7

(mm) * 17.000 *

1

2

3

4

5

6

mean

turbin

1

aAnaers

mean

(c)

Rae

(bar)

*

*

*

*

3316.

15.16.41.

YES OID IIIS IIE IIIS III TIA TIT III RIT III III IITA

8

0.

0.

oobu

SEES IUD IDI IIIB IEEE IEEE ESITIIEO II IIIS III III II III II II IE

TESTBED RESULTS ENGINE NO: 3316.

Reading no.: 6 Date : 16. 7.90. Time : 15.38.52.

TES SEDI IGO DIDO UE IIS ISDE ISDS IIIT III IAI IIE

Nom. output (4%) 25. Running hours (h) 5

Engine speed (rpm) 720. B.m.e.p. (bar) 4.9

Engine output (kW) 258. Fuel consump. time (sec) 0.0

Generator output (kW) 237. Spec. fuel consump. (g/kWh) 0.0

Barometric press. (mbar) 1012.0

Temp. engineroom (C) 25.0

Relative humidity (3) 58.0

LUBE-OIL : COOLING WATER

Temp. engine inlet (C) 57.0 Temp. engine inlet (¢) 77.0

Temp. engine outlet (C) 63.0 Temp. engine outlet (C) 79.0

Press. engine inlet (bar) ° 4.3 Press. engine inlet (bar) 2.2

Fuel oil press. (bar) 2.7 Rocker arm press. (bar) “8

Fuel oil temp. (C) 48.0 Nozzle oil press. (bar) 1.7

CYL. BANK (A for in-line engine) * aA * B *

Turbocharger speed (zpn) * 14795. * 0. *

Charge air press. (bar) * taz7* 0.00 *

Charge air temp. receiver (+ 35.5 # 0.0 *

Cool.water temp. CA.cooler inlet (¢c) * 26.6 * 0.0 0

Fuel rack index - mean (mm) * 11.00 * 0.0 0 *

Exhaust-gas temp. after cyl. 1 (Cc) *

: * wo "8

» . 3 "8

” . "4 »

” . 5 os

. ” " 6 " #*

” * " mean = *

f - turbin" *

Max. cylinder press. cyl. 1 (bar) * 72. * 0. *

* 7 2 os 72. * 0. *

” 3 " ® 72. * 0. *

” " 4 . # 72. * 0. *

” 5s “o# 7. * 0. *

” "6 “ * 72. * 0. *

. mean" # 72. * 0. *

JES OSES SEES GHEE IUD SOO ISI IEEE IIE SI III RII IIE

ENGINE NO.3316 Governor-test: 0 - 50 % load ON.

Speed incr.= .2% Speed decr.= -4.4 % Stab. time = 1.4 sec.

800. j i i

i 1

eS

Bro —s

2875. 4 1 +}

$3 y |

3

R650 4 +

e \ |

625. 7 T

E | \

Sg00. +t +t

°. 4 2. 3 4 5. 8 7. 10.

f : 8. 9

Time (sec) 16.07.80 tb.

rpm)

speed, (

sa

ine sf

@

B

&

ge

8

ENGINE NO.3346 Governor-test: 50 - 100 % load ON.

Speed incr.= 2% Speed decr.= -8.6 % Stab. time = 3.6 sec.

1 1

1 1

| 1

4 +

|

T

I

I | 1

i i l

I !

| i

7q t tT

L, { +

0. 4. 2. 3. 4. 5. 8. 8. 3. 40.

Time — (sec) 16.07.80 tb.

e spe

ngi

ENGINE NO.3346 Governor-test: 100 - 0 % load OFF.

Speed incr.= 8.2% Speed decr.= -.1 % Stab. time = 3.4 sec.

Fe

|

. det

vo, i. 2. 3. 4, 5. 8. 7 8. .

Time (sec) 16.07.90 tb.

3. 10.

BERGEN

ENGINE TEST REPORT

JESSIE ODED IDES O ODES IIE II IEEE III IIIS IIIA:

Engine no. : 3315 Engine type : KRG-6

Max. cont. rating (kW) : 1020 Engine speed (rpm) : 720

Gen. make : TAIYO

Gen. no.: 212196

Gen. spec.: kW kva volt Anp. Hz cos fi

" + 930 1163 450 1492 60 0.8

owner 3 BERGESEN D.¥. A/S

Shipyard : NKK, JAPAN

Yard no.: 124

Classification society : DNV ZO

Tested date 90.07.12

Fuel type (-) = MDO Viscosity (cSt)

Lower calorific value (MJ/kg): 42.7 Density (g/cm3)

Calibrated fuel quantity (g): 5060

°

&

=

Mech.overspeed adjusted (rpm): 865

Test approved by:

Bergen Diesel date: sign.: feo

Buyer date: sign.:

owner date: sign.:

ji ‘\

Classification society aate:3C/?-%) sign.: thay 1B. rok

date: sign. ~

GSES ISI III IIIS IIIS IODIDE ISIS ISI ORI IOTSPON DDE Ie

BERGEN

TESTBED RESULTS ENGINE NO.: 3315.

Reading no.

SOROS

1 Date : 13. 7.90. Time 8.50.15.

SEES EDIE DD SUISSE IIIS SII IIa IIIa

Nom. output (8) 100. Running hours (n) 2.0

Engine speed (xpm) 720. B.m.e.p. (bar) 18.2

Engine output (ki) 966. Fuel consump. time (sec) 94.5

Generator output (kW) 928. Spec. fuel consump. (g/kWh) 199.6

Barometric press. (mbar) 995.0

Temp. engineroon (C) 22.0

Relative humidity (3) 56.0

LUBE-OIL : COOLING WATER :

Temp. engine inlet (C) 55.0 Temp. engine inlet (C) 78.0

Temp. engine outlet (C) 64.0 Temp. engine outlet (C) 83.0

Press. engine inlet (bar) 4.5 Press. engine inlet (bar) 2.3

Fuel oil press. (bar) 2.3 ‘Rocker arm press. (bar) 8

Fuel oil temp. (C) 37.0 Nozzle oil press. (bar) 1.7

CYL. BANK (A for in-line engine)

Turbocharger speed (xpm)

Charge air press. (bar)

Charge air temp. receiver ()

Cool.water temp. CA.cooler inlet (c) * 17.60 #* 0.0 *

Fuel rack index - mean (amy * 30.0 * 0.0 6

Exhaust-gas temp. after cyl. 12 (Cc) * 342. * 0. *

“ . ste: “oe 368. * o. *

. . 3 rd 343. * oO. *

" . "4 "8 360. * 0. *

" . "5 os 366. * oO. *

* . " 6 oo8 363. * oO. *

. * “mean * * 357. * oO. *

: 7 turbin" * o. * o. *

Max. cylinder press. cyl. 1 (bar) * 131. * 0. *

. nD " # 731. * Oo. *

. "3 " # 731. * oO. *

7 "4 ue 131. * 0. *

” "5 "8 131. * 0. *

. "6 oo 130. * 0. *

a mean" 132. * o. *

JESSIE EDIE IDE IOS OE IONS I IUDIIHII IID IDE II IODIDE

Met ‘

TESTBED RESULTS ENGINE NO.: 3315.

Reading no.: 2 Date : 13. 7.90. Time : 10.37.31.

poveres le sre Serwertrsrrtrr eres rere terete rere rr rt tit tr errr errtt seer T sy

Nom. output (8) 100. Running hours (4) 4.0

Engine speed (rpm) 720. B.m.e.D. (bar) 18.2

Engine output (kW) 960. Fuel consump. time (sec) 94.7

Generator output (kW) 923. Spec. fuel consump. (g/kwh) 200.2

Barometric press. (mbar) 1005.0

Temp. engineroon (C) 22.0

Relative humidity (8) 59.0

LUBE-OIL : COOLING WATER :

Temp. engine inlet (Cc) 55.0 Temp. engine inlet (Cc) 80.0

Temp. engine outlet (Cc) 64.0 Temp. engine outlet (C) 84.0

Press. engine inlet (bar) 4.5 Press. engine inlet (bar) 2.3

Fuel oil press. (bar) 2.6 Rocker arm press. (bar) 7

Fuel oil temp. (C) 39.0 Nozzle oil press. (bar) 17

CYL. BANK (A for in-line engine) * aA * B *

Turbocharger speed (rpm) * 31914. * 0. *

Charge air press. (bar) * 1.95 * 0.00 *

Charge air temp. receiver c) * 52.20 * 00 080

Cool.water temp. CA.cooler inlet (Cc) * 18.20 * 0.0 88

Fuel rack index - mean (mm) * 30.0

Exhaust-gas temp. after cyl. 1 (c) * 349. * *

= f = 2 = #7 369. iad *

fs i if 3 = * 346. ia *

if = = 4 = * 361. * *

. ” 5 ” * 369. * *

= aa = 6 = = 364. = *

- isd "mean = inf 360. iad *

f a turbin " * 0. ia *

Max. cylinder press. cyl. 1 (bar) * 130. * oO. *

” fA 2 ” * 129. * Oo. *

ial # 3 = * 129. * oO. *

fe iad 4 ia: * (130. * oO. *

= ind 5 = = 130. * oO. *

i _ 6 = * 128. * oO. *

i! mean = * 129. * oO. *

JESSE OEE ISSO DII ESOS SII IIIS IIE OI ISIE II IIIS III IIIT

BERGEN

TESTBED RESULTS ENGINE NO.: 3315.

Reading no.: 3 Date : 13. 7.90. Time : 12.15. 4.

IEEE EEE SESS S EI IEEE IDE SIO IDI IOS III IIIS IIIT

Nom. output (8) 110. Running hours (a) 1.0

Engine speed (rpm) 720. B.m.e.p. (bar) 20.0

Engine output (kW) 1061. Fuel consump. time (sec) 0.0

Generator output (kW) 1020. Spec. fuel consump. (g/kWh) 0.0

Barometric press. (mbar) 1015.0

Temp. engineroom (C) 24.0

Relative humidity (8) 61.0

LUBE-OIL : COOLING WATER : :

Temp. engine inlet (C) 54.0 Temp. engine inlet (C) ~ 80.0

Temp. engine outlet (C) 65.0 Temp. engine outlet (C). 85.0

Press. engine inlet (bar) 4.5 Press. engine inlet (bar) 2.2

Fuel oil press. (bar)... 2.7 Rocker arm press. (bar) ce

Fuel oil temp. (C) 39.0 Nozzle oil “press. (bar) Le

CYL. BANK (A for in-line

Turbocharger speed (zpm) *

Charge air press. (bar) +

Charge air temp. receiver (c) *

Cool.water temp. CA.cooler inlet (Cc) *

Fuel rack index - mean (mm) * 32.0

Exhaust-gas temp. after cyl. 1 (Cc) * 363. *

. « meee " # 385. *

. * » 3 " * 357. *

” " » 4 "4 372: *

” ” os " * 380. *

« a mace o # 374. *

" " " mean =" # 372. *

. " turbin* #* o. *

Max. cylinder press. cyl. 1 (bar) * *

i nD «8 *

" 3 «8 *

° "4 oo * *

" " 5 "8 *

® » 6 " * *

" mean" # *

IEEE EOI DIESE II ISI IDS III IIIS SIIB III

BERGEN

TESTBED RESULTS ENGINE WO.: 3315.

Reading no.: 4 Date : 13. 7.90. Time : 10.56.42.

JESSE EGE EONISnISIHII SS ISIE IEE IRIE DDE ICSE ISHII IS IEEE ISIE

Nom. output (@) 75. Running hours (a) 5

Engine speed (rpm) 720. B-m.e.p- (bar) 13.6

Engine output (kv) 719. Fuel consump. time (sec) 0.0

Generator output (kW) 690. ‘Spec. fuel consump. (g/kWh) 0.0

Barometric press. (mbar) 1010.0

Temp. engineroom (C) 22.0

Relative humidity (8) 61.0

LUBE-OIL : COOLING WATER :

Temp. engine inlet (Cc) 55.0 Temp. engine inlet (C) 80.0

Temp. engine outlet (C) 64.0 Temp. engine outlet (C) 83.0

Press. engine inlet (bar) 4.5 Press. engine inlet (bar) 2.2

Fuel oil press. (bar) 2.9 Rocker arm press. (bar) +7

Fuel oil temp. (C) | 40.0 Nozzle oil press. (bar) 1.7

CYL. BANK (A for in-line engine)

Turbocharger speed (rpm) * 27469. * 0. *

Charge air press. (bar) * 1.30 * 0.00 *

Charge air temp. receiver (c) * 44.40% 0.00 *

Cool.water temp. CA.cooler inlet (Cc) * 18.4 * 0.0 *

Fuel rack index - mean (mm) * 23.5 * 0.00 *

Exhaust-gas temp. after cyl. 1 (c) * 319. * o. *

. * "2 “ 340. * oO. *

" . "3 oF * Oo. *

” . » 4 oe * O. *

" . 5 " * * 0. *

* ” ect gt " * * oO. *

" . * mean oo" # * oO. *

" . turbin" #* * *

Max. cylinder press. cyl. 1 (bar) * o. * oO. *

u wD ree oO. * oO. *

" "3 ue O. * oO. *

" "4 “8 oO. * o. *

« Paar " * o. * oO. *

" " 6 " * 0. * oO. *

” mean" * 0. * oO. *

SHEESH EES SHEE CEES HEE IEIIEUDEEDIEDDIUDOOUIED IIIS EEE OED

BERGEN

TESTBED RESULTS ENGINE NO: 3315.

Reading no.: 5 Date : 13. 7.90. Time : 11.45.45.

TIDES TESS IIIS ESS ISDS EES U TIES TAIE

Nom. output (4) 50. Running hours (a) 5

Engine speed (zpm) 720. B.m.e.p. (bar) 9.4

Engine output (kw) 496. Fuel consump. time (sec) 0.0

Generator output (kW) 471, Spec. fuel consump. (g/kWh) 0.0

Barometric press. (mbar) 1015.0

Temp. engineroon (C) 22.0

Relative humidity (@) 61.0

LUBE-OIL : COOLING WATER :

Temp. engine inlet (Cc) 56.0 Temp. engine inlet (C) 80.0

Temp. engine outlet (Cc) 63.0 Temp. engine outlet (C) 82.0

Press. engine inlet (bar) 4.5 Press. engine inlet (bar) 2.2

Fuel oil press. (bar) 2.9 Rocker arm press. (bar) 7

Fuel oil temp. (C) 41.0 Nozzle oil press. (bar) 1.7

CYL. BANK (A for in-line engine) * a *

Turbocharger speed (rpm) * 22288. *

Charge air press. (bar) * :7000*

Charge air temp. receiver ic) * 37.80 +

Cool.water temp. CA.cooler inlet (C) * 18.6 * 0.00

Fuel rack index - mean

Exhaust-gas temp. after cyl. 1

2

. ” "3

. . ” 4

. . 5

* * "6

. . "mean

" . turbin *

Max. cylinder press. cyl. 1 * *

* an) * * *

. "3 " # * *

. " 4 "4 * *

. "5 8 * *

. " 6 oe * *

” mean" * o. * 0. *

JESUS ISIE EOD ISDS EIS ERIE SIEE SII ISI TIS IIIA

BERGEN

TESTBED RESULTS ENGINE NO: 3315.

Reading no.: 6 Date : 13. 7.90. Time : 12. 1.36.

JUSSI ISDE ISS ISIISIII ISIS DSI DIDI IIIS OSI IIIS IAI DAI

Nom. output (4) 25. Running hours (h) 5

Engine speed (rpm) 720. B.m.e.p. (bar) 4.8

Engine output (ki) 255. Fuel consump. time (sec) 0.0

Generator output (kW) 234. Spec. fuel consump. (g/kWh) 0.0

Barometric press. (mbar) 1015.0

Temp. engineroom (C) 23.0

Relative humidity (4) 61.0

LUBE-OIL COOLING WATER :

Temp. engine inlet (Cc) 56.0 Temp. engine inlet (C) 80.0

Temp. engine outlet (C) 63.0 Temp. engine outlet (Cc) 81.0

Press. engine inlet (bar) 4.5 Press. engine inlet (bar) 2.2

Fuel oil press. (bar) 3.0 Rocker arm press. (bar) “7

Fuel oil temp. (C) 42.0 Nozzle oil press. (bar) 1.7

CYL. BANK (A for in-line engine) * A * B *

Turbocharger speed (zpm) * = 15067. * 0. *

Charge air press. (bar) * 1250 #* 0.000 *

Charge air temp. receiver (c) * 31.800 + 0.000 *

Cool.water temp. CA.cooler inlet (c) * 18.6 * 0.00 *

Fuel rack index - mean (nm)

Exhaust-gas' temp. after cyl. 1 (C)

” " 2 *

” ® latte gl "

" * “4 .

” . "os ”

” . " 6 .

. . ” mean *

” , turbin "

Max. cylinder press. cyl. 1 (bar) * 71. * 0. *

* a aos 73. * 0. *

” oot “ # 73. * 0. *

" "4 o * 72. * 0. *

“ "5 oe 72. * o. *

" lace gl oo ® 32. * oO. *

“ mean "+ 72. * 0. *

JESSE ISIE EDU EDIE I EEDDEID IS IEEEEEOUIIISEEEOD EDD I IEE

(rpm)

a

gq

a

d

8

8

gine Spee

=

Eng

oS

3

s

-ENGINE NO.3345 Governor-test: 0 - 50 load ON.

Speed incr.= .3% Speed decr.> -4.9 % Stab. time = 2.4 sec.

1

| |

!

1

T

|

1

4 i

|

1

i T

+ a | or mo

0. 1. 2. 3. 4 5. 6. te 8. 3. 40.

Time (sec)

13,07.90 tb

ENGINE NO.3315 Governor-test: 50 - 100 % load ON.

Speed incr. 4

Speed decr.= -5.2 %

T

Stab.

time = 3.0 sec.

tH] oe

LL

i

I

0

Time

1

(ec)

wot

t+

7.

8. 3. 10.

43.07.90 tb.

_ ENGINE NO.3315 Governor-test: 100 - 0 % load OFF.

0. Speed incr.= 9.5% Speed decr.= ~.2 % Stab. time = 3.9 sec.

ee

T

i

t

3875. L

3 3 !

B65 +

2 I

2

825. 4

Sg00. faa a

oO. 4. 2. a. 4. 5. 6. 7. 8. 9. 40.

Time (see) 13.07.90 tb.

ENGIWE

BERGEN

TEST

REPORT

IEEE SS Eni i Spinnin SSUES IIIS ISIE IIIS UTED III EEE SDE

Engine no. : 3317 Engine type : KRG-6

Max. cont. rating (kW) : 1020 Engine speed (rpm) : 720

Gen. make : TATYO FEWSOC

Gen. no.: 212198

Gen. spec.: kW kVA volt Amp. Hz cos fi

" 2 930 1163 3X450 1492 60 0.8

Owner : BERGESEN D.¥. A/S

Shipyard : NKK

Yard no.: 124

Classification society :

Tested date '

Fuel type

ee

Lower calorific value (MI/kg)

Calibrated fuel quantity

Mech. overspeed adjusted

Test approved by:

Bergen Diesel

Buyer

Owner

Classification society

Dnv + £0

23.07.90

: MDO

2 42.7

(g)? 5060

(xpm): 865

Viscosity

Density

date: £3-7-9o

date:

date:

aate:23/9-40

aate:2Y/y-Go

sign: Jalecn Belt hal

sign.:

sign.:

sign.:

sign

JESSE ESSE IS IOI DI IDS I IDE UII nO I binbinbbini ibn ibbi iii iit

TESTBED RESULTS ENGINE NO: 3317.

Reading no.: 1 Date : 23. 7.90. Time : 10. 2.42.

JOS BS SOD I SSIS Snir ISD IDS IDES AIO SIDED:

Nom. output (3) 100. Running hours (hy 2.0

Engine speed (xpm) 720. B.m.e.p. (bar) 18.4

Engine output (kf) 974. Fuel consump. time (sec) 94.2

Generator output (ki) 936. Spec. fuel consump. (g/kwh) 198.7

Barometric press. (mbar) 1018.0

Temp. engineroom (C) 25.0

Relative humidity (8) 58.0

LUBE-OIL : COOLING WATER :

Temp. engine inlet (C) 54.0 Temp. engine inlet (C) 78.0

Temp. engine outlet (C) 64.0 Temp. engine outlet (C) 82.0

Press. engine inlet (bar) | 4.5 Press. engine inlet (bar) 2.3

Fuel oil press. (bar) 3.0 Rocker arm press. (bar) 7

Fuel oil temp. (C) 38.0 Nozzle oil press. (bar) 1.7

CYL. BANK (A for in-line engine) * A * B *

Turbocharger speed (rpm) * 31513. * 0. *

Charge air press. (bar) * 1.90 * 0.00 +

Charge air temp. receiver (c) * 52.4 * 0.000 *

Cool.water temp. CA.cooler inlet (Cc) * 22.6 0.00

Fuel rack index - mean (mm) * 30.0 *

Exhaust-gas temp. after cyl. 1 (c) * 352. *

” " mired "8 369. *

" ” "3 «oe 357. 7

* " "4 noe 371. *

* ” "5 “8 378. 7

i “ " 6 "oe 360. *

“ . "mean" + 365. *

" " e °. *

130. * oO. *

231. * oO. *

129. * oO. *

130. * 0. *

130. * oO. *

131. * 0. *

130. * o. *

IRIE EDIE ITED ISIS IIIS EEE EERIE IEEE UUDD EEE IDE DE

TESTBED RESULTS ENGINE NO: 3317.

Reading no.: 2 Date : 23. 7.90. Time : 11.59.22.

TEES HO EEE SE URE OE SE TEETER IDE HETERO ISIDORE SOO ISIE

Nom. output (%) 100. Running hours (h) 4.0

Engine speed (xpm) 720. B.m.e.p. (bar) 18.4

Engine output (kw) 973. Fuel consump. time (sec) 94.2

Generator output (kN) 935. Spec. fuel consump. (g/kWh) 198.7

Barometric press: (mbar) 1018.0 :

Temp. engineroom (ce) 26.0

Relative humidity (8) 55.0

LUBE-OIL : COOLING WATER :

Temp. engine inlet (Cc) 54.0 Temp.. engine inlet (C) 79.0

Temp. engine outlet (Cc) 64.0 Temp. engine outlet (C) 83.0

Press. engine inlet (bar) 4.4 Press. engine inlet (bar) 23

Fuel oil press. (bar) 3.0 Rocker arm press. _— (bar) 8

Fuel oil temp. (Cc) 3810 Nozzle oil press. (bar) 2117

CYL. BANK (A for in-line engine) * Aye B *

Turbocharger speed (rpm) *

Charge air press. (bar) *

Charge air temp. receiver ic) *

Cool.water temp. CA.cooler inlet (Cc) *

Fuel rack index - mean (am) *

Exhaust-gas temp. after cyl. 1 (cy * 353. * o. *

« « “2 ieee 371. * 0. *

” . “3 nd 361. * 0. *

” . ” 4 oe 374. * 0 *

” ” "5 ” 380. * oO. *

" . " 6 " 363. * oO. *

” ” "mean" * 367. * 0. *

* * " * oO. * 0. *

Max. cylinder press. cyl. 1 (bar) * 130. * 0. *

. ected noe 130. * 0. *

. rang nd 129. * a. *

. " 4 cd 129. * o. *

® "5 ne 131. * 0. *

. " 6 "oe 331. * 0. *

” mean * * 130. * 0. *

JES ERIS SSIS ISI IES HIUDI EEE EEE IS IIIS IDIIDIIIE IEICE

TESTBED RESULTS ENGINE NO.: 3317.

Reading no.: 3 Date : 23. 7.90. Time : 12.52.49.

JADE ESIE I SISSIES inin aS IDO SESS SEIS EEA EDISTO AE

Nom. output (%) 110. Running hours (h) 1.0

Engine speed (xpn) 720. B.m.e.p. (bar) 19.9

Engine output (kW) 1054. Fuel consump. time (sec) 87.0

Generator output (kW) 1023. Spec. fuel consump. (g/kWh) 198.6

Barometric press. (mbar) 1018.0

Temp. engineroom (C) 25.0

Relative humidity (3) 53.0

LUBE-OIL COOLING WATER +

Temp. engine inlet (C) 54.0 Temp. engine inlet (C) 80.0

Temp. engine outlet (C) 64.0 Temp. engine outlet (Cc) 84.0

Press. engine inlet (bar) 4.4 Press. engine inlet (bar) 2.3

Fuel oil press. (bar) 3.1 Rocker arm press. (bar) +8

Fuel oil temp. (C) 37.0 Nozzle oil press. (bar) 1.7

CYL. BANK, (A for in-line engine)

Turbocharger speed (rpm)

Charge air press. (bar)

Charge air temp. receiver ()

Cool.water temp. CA.cooler inlet (Cc) * 22 ares, 0.0

Fuel rack index - mean

Exhaust-gas temp. after cyl. 1

” * nD

* . watts

* . mitea

. * aitite:

. . Guar

. . " mean

Max. cylinder press. cyl. 1 (bar) * * *

y aD en * *

. "3 o & * *

. "4 " o# * *

” "5 "8 * *

” " 6 oo * *

. mean“ # 137. * oO. *

SESE EEE EEE III EIDE DE IEEE EE OE III IIS IIT III III IIIT AAD

TESTBED RESULTS ENGINE NO.: 3317.

teading no.: 4 Date : 23. 7.90. Time : 14.41.17.

SOBRE SOS SDSS ISSO IEEE OD IES ISIS III IIS IIIT III

‘om. output (3) 75. Running hours (h) 5

ingine speed (zpm) 720. B.m.e.p. (bar) 13.8

ingine output (kW) 731. Fuel consump. time (sec) 123.7

ienerator output (kW) 701. Spec. fuel consump. (g/kWh) 201.5

larometric press. (mbar) 1017.0

‘emp. engineroom (C) 24.0

telative humidity () 59.0

WBE-OIL : COOLING WATER

‘emp. engine inlet (C) 57.0 Temp. engine inlet (C) 79.0

‘emp. engine outlet (C) 64.0 Temp. engine outlet (C) 82.0

‘ress. engine inlet (bar) 4.7 Press. engine inlet (bar) 2.3

‘uel oil press. (bar) 3.0 ‘Rocker arm press. (bar) 8

‘uel oil temp. (C) 40.0 Nozzle oil press. (bar) 1.7

WL. BANK (A for in-line engine)

turbocharger speed (rpm) * 27160. * o. *

tharge air press. (bar) * 1.220 * 0.00 *

tharge air temp. receiver (c) * 45.0 * 0.0

tool.water temp. CA.cooler inlet (¢) * 22.70 * 0.0 *

tuel rack index - mean (mm) * 24.0

t

t

‘

'

txhaust-gas temp. after cyl. 1 (c) * 325. *

" * «3 rary 342. *

" ” "3 noe 340. *

" . » 4 "8 34a. *

" ® 5 “ # 352. *

" " » 6 oo * 344. *

” ” "mean" * 342. *

” " turbin " # *

lax. cylinder press. cyl. 2 (bar) * 0. * 0. *

* nD ue o. * oO. *

” 3 “8 0. * 0. *

” "4 "8 oO. * o. *

” "5 "ok 0. * 0. *

" " 6 "oR o. * 0. *

‘ mean" # o. * oO *

HESIOD IE III IIE IIIS III II III IIIS IIIT IIA II III II

BERGEN

TESTBED RESULTS ENGINE NO.: 3317.

Reading no.: 5 Date : 23. 7.90. Time : 15. 2.56.

TEED ISB IOSD IDE IIIS IID II ISI IIIT a III IIS III I ITAA

Nom. output (2) 50. Running hours (h) 5

Engine speed (xpm) 720. B.m.e.p. (bar) 9.2

Engine output (kit) 486. Fuel consump. time (sec) 177.1

Generator output (kit) 462. Spec. fuel consump. (g/kWh) 211.6

Barometric press. (mbar) 1017.0

Temp. engineroon (C) 24.0

Relative humidity (3) 58.0

LUBE-OIL = COOLING WATER :

Temp. engine inlet (C) 56.0 Temp. engine inlet (C) 80.0

Temp. engine outlet (C) 64.0 Temp. engine outlet (Cc) 82.0

Press. engine inlet (bar) 4.7 Press. engine inlet (bar) 2.3

Fuel oil press. (bar) 3.0 Rocker arm press. (bar) +8

Fuel oil temp. (C) 40.0 Nozzle oil press. (bar) 17

CYL. BANK (A for in-line engine) * A *

Turbocharger speed (zpm) * 21604. *

Charge air press. (bar) * 1630 *

Charge air temp. receiver (cy) * 38.8 +

Cool.water temp. CA.cooler inlet (c) * 22.6 + 0.000 *

Fuel rack index - mean (mm) * 18.0 * 0.00 *

Exhaust-gas temp. after cyl. 1 (C) * 296. * 0. *

" 7 "2 ect 312. * 0. *

” . "3 "oe 316. * 0. *

” ” » 4 “8 323. * o. *

” . » 5 ” 325. * o *

” . “6 " 324. * oO. *

. " © man * # * *

” ” turbin" + * *

Max. cylinder press. cyl. 1 (bar) * 0. * 0. *

" "> oe o. * oO. *

” "3 "oe oO. * o. *

" "4 "ok o. * O. *

" "5 "8 O. * oO. *

" "6 ‘4 0. * o. *

” meen ee o. * oO. *

SESE IIIA III IIIS III III III III IIIS II ITA TI I A IIIT DA

TESTBED RESULTS ENGINE NO.: 3317.

Reading no.: 6 Date : 23. 7.90. Time : 15.25.27.

JE SSIES EIEIO IIIB II III III III IAAI III IAAI

Nom. output (#) 25. Running hours (hy “5

Engine speed (zpn) 720. B.m.e.p. (bar) +9

Engine output (kW) 261. Fuel consump. time (sec) 290.0

Generator output (kW) 240. Spec. fuel consump. (g/kWh) 240.4

Barometric press. (mbar) 1017.0

Temp. engineroom (C) 25.0

Relative humidity @) 58.0

LUBE-OIL COOLING WATER :

Temp. engine inlet (Cc) 57.0 Temp. engine inlet (¢) 78.0

Temp. engine outlet (C) 64.0 Temp. engine outlet (C) 81.0

Press. engine inlet (bar) 4.7 Press. engine inlet (bar) 2.3

Fuel oil press. (bar) 3.0 Rocker arm press. (bar) “8

Fuel oil temp. (C) 43.0 Nozzle oil press. (bar) 1.7

CYL. BANK (A for in-line engine) * A * B

Turbocharger speed (xpm) * 14959. * 0.

Charge air press. (bar) # 1220 «* 0.00

Charge air temp. receiver (cy) * 33.7 * 0.0

Cool.water temp. CA.cooler inlet (c) * ee eret am 0.00

Fuel rack index - mean

Exhaust-gas temp. after cyl. 1 (C) * 277. * 0. *

* * n 3 oe 261. * oO. *

* * *

* * *

* * *

* * *

* * *

* *

* *

* *

” * *

” * o. *

. * 0. *

" * oO. *

" * oO. *

IEEE III IIE DEESIDE DIEU IOI IODIDE IIASA IIIA IIIA IE

Enaige speed

7

3

ENGINE NO.3317 Governor-test: 0 - 50 % load ON.

Speed incr.= 3% Speed decr.= -6.2 % Stab. time = 3.0 sec.

eer

+

q

I

!

|

T

|

0, i

: Time {see}

23.07.80 tb.

_ENGINE NO.3347 Governor-test: 50 - 100 % load ON.

z goo, Speed iner.= _.0 x Speed decr.= -8.2 % Stab. time = 3.5 sec.

¢ |

r 780

<4

o

8

1

1

|

I

|

}

.

3

6

(rpm)

~

3

Pet

ore erator

8

‘a

B

3

Engine speed

8

|

|

7 4.

Time (sec)

23.07.80 tb.

{

BERGEN

800.

780.

y780.

‘e740.

a

ine speed

ng:

“1880.

2700.

680.

ENGINE NO.3317 Governor-test: 100 - 0 % load OFF.

Speed incr.= 9.4%

Speed decr.= -.2%

Stab. time = 3.8 sec.

T

\

| 1

4 —_|__|

eae ener Sere sr

nas Saul

Jem -

s

1

|

i

1

itt

oO. 1. Ce 3. 10.

Time (sec)

23.07.90 tb.

obeed

Set

JESSE SSS HSS IIIS ISIS ESE ISSIR II IDI EEIIIIIIIDII II IDI ISIE EOE

PARALLELLTEST ENGINE NO.1: 3315 and NO.2: 3316 DATE: 17.07.90

SERS GEE OTE EIS S EST IEIIETIEIIISII III IID III III III IIA II

LOADCONDITION (#) * o+ 25 * 78

* 100 * 110 *

Speed NO.2 (rpm) * 749.0 * 741. o* 735. 0 * 728.0 * 720.0% - *

Speed No.2" * * eo ee

Act.sign-NO.1 vde

Act.sign.NO.2 Vde

42.43 43.38 * 4.46 * 5.70% =

42.56 * 3.47 * 4,50 * 5.69% —

output vol (kW) * - * *

Output No.2 0" * 7 ot *

-=-=----- *

voltage (wac) * 450. * 450. * 450. * 450. * 450. * - *

current NO.1 (a) * - * - #583, * 867, * 1167.4 - *

GaereatiMOssugn Aint iciiuemieniisaieeciinumee sin 1203.4 - #*

*

*

* 11.0 * 17.0 * 23.0 *29.5* - *

* 11.5 * 17.0 * 23.0 *29.5% - *

Fuel rack NO.1

Fuel rack NO.2

Governor type : Woodward 2301 with act. 3199.

Droop~potmeter value NO.1. terminal 13-14 (kohm): 17.72

w yas 8 21S

No.2. terminal 13-14 (kohm): 17.82

w 14-15 wp 2.28

Test confirmation:

Bergen Diesel A.S :

omer / Buyer :

Class. society :

ISS EIS SERIES ESSE SUID EIDE ORES DIO I IITA

BERGEN

JESSIE SEDO IOC EUEHDU SDSS DED E EEE ESE IIIS EEE

PARALLELLTEST ENGINE NO.1: 3317 and NO.2: 3316 DATE: 23.07.90

SUB EIE EES ISDE SESS INDEED DDS IIS SEE TIAA A DAE

LOADCONDITION (%) *app.10* 25 * 50 * 75 #100 #110 *

Speed NO.1 (rpm) * 747.0 * 742.5 * 735.5 * 728.0 * 720.5% —

Speed No.2 | HR

Output NO.1 (kW) * 76. * 200. * 441. “* 699. * 927. * ~

Output NO.2 0" * 102, * 230. * 476. * 720. * 929. * -

Voltage (VAC) * 450. * 450. * 450. * 450. * 450. * -

current NO.1 (A) * 97. #256. * 565. * 901. * 1189.*

current NO.2. " * 131. * 295. * 610. * 928. ¥* 1191.*

Act.sign.NO.1 Vdc * 1.64 * 2.27 * 3.26 * 4,35 * 5.31 *

Act.sign.NO.2 Vdc * 1.68 * 2.33 * 3.40 * 4.55 * 5.56 *

Fuel rack NO.1 * 7.0 * 11.0 * 17.0 * 24.0 * 30.0% -

Fuel rack NO.2 * 7.0 * 10.5 * 17.0 * 24.0 * 30.0 * -

'

RRR ERE E ER REE

Governor type : Woodward 2301 with actuator 3199.

Droop-potmeter value NO.1. terminal 13-14 (kohm): 17.60

"44-15 wor 2.38

NO.2. terminal 13-14 (kohm): 17.86

v N45 "2.27

Test confirmation:

Bergen Diesel A.S

Owner / Buyer

Class. society

JESS EIEIO DODD DIDI II IEEE EIEIO

BERGEN

JES EHS IEEE EEE SHEE E DIDI SEIT II IIIT IIA IITA

PARALLELLTEST ENGINE NO.1: 3317 and NO.2: 3315 DATE: 24.07.90

THESES SETHE SEI IR SHES IDI SIDI ESE III III IAI IIIT IIIA

LOADCONDITION (%) *app.10 * 25 * 50 * 75 * 100 * 110 *

Speed NO.1 (rpm) * 746.0 * 742.0 * 734.5 * 727.0 * 720.04 - *

Speed Nol2 0 HR a

output No.1 (kW) * 94. * 209, * 454. *936.*% - *

output No.2 0" #125. # 243. * eect

eee oan *

Voltage (VAC) #450. * 450, * 450. *450.* - *

eee ae *

Current NO.1 (A) * 120. * 269. * 582. * 904. # 1201.4 - *

Current NO.2 9" * 161. * 312. #* 612. * 927. * 1186.* - *

Act.sign.NO.1 Vdc * 1.62 * 2.18 * 3.22 * 4.26 *5.22* - *

Act.sign.NO.2 Vdc * 1.87 * 2.52 * 3.67 * 4.80 * 5.84 * - *

Fuel rack NO.1 * 7.0 * 11.0 * 17.5 * 24.0 *30.0* - *

Fuel rack NO.2 + 7.5 * 11.5 * 17.5 * 24.0 - +

Governor type : Woodward 2301 with actuator 3199.

Droop-potmeter value NO.1. terminal 13-14 (kohm): 17.61

“ yanas 2.38

NO.2. terminal 13-14 (kohm): 17.71

w 44-15" 218

Test confirmation:

Tate, Betrbek

Bergen Diesel A.S 24.07.90

Owner / Buyer

Class, society

IRIE SESS IEEE DED IIS UIOUIOI DSSS EOEE IEEE bbb ini nin

LONGITUDINAL SECTION 0.2.01.1

BERGEN TURBOCHARGER AT ENGINE PUMP END Nov. -83

al DRAWING NO. 528/11 KRG

~~“ eee

Description Chapter

ft

Exhaust gas outlet

fa

2 | Charge air bend “Turbocharger and charge air

cooler” 7

3. Fuel oil injection pump “Fuel oil Injection pump" 7

4. Push rod. "Exhaust and inlet valve drive

mechanism” 4

5. _ Pipe, cooling water outlet “Cooling water system” ‘ 8

6. Camshaft “Camshaft” 4

7. Fuel oil injection valve “injection valve” 7

Cylinder head "Cylinder head” fae

Charge air receiver Charge air receiver and end 7

covers”

10. | Controt shaft Governing the fuel injection 5

pumps"

14. }instrument panel "Instrument pane!” 6

42. | Synchronizing motor: See. separate ‘instruction: manual =

13. | Governor ‘See separate instruction manual

14. Camshaft chain wheel "Gamshatt” 4

15. | Tachogenerator “Governor drive" 5

46. | Housing, governor drive "Governor drive” 5

17. Chain, camshaft drive "Camshatft drive, chain tensioner” 4

18. Flywheel bearing "Crankshaft main bearings” 2

19. Generator shaft et

20. Flywheel "Mounting of flywheel” 3

21. Cover, camshaft housing "Caps and covers” ie

22. | Crankcase door "Caps and covers” 2

0.2.01.2

LONGITUDINAL SECTION

Nov. -83 TURBOCHARGER AT ENGINE PUMP END

KRG DRAWING NO. 528/11

Description

23: | Cylinder liner "Cylinder finer”

24. — | Counterweight “Crankshaft”

25. | Suction pipe, lubr.oil sump “Cylinder block, engine foundation

and lubr. oil sump”

26. | Connecting rod “Piston and connect. rod assembly”

27. . | Main bearing... Crankshaft main bearings”...

28. | Strainer plate

29. |Crankshatt *Crankshatt”

30. | Engine foundation “Cylinder block, engine foundation

and lubr.oil sump”

31. | Valve gear lubr.oil tank "Valve gear lubr.oil system"

32. | Rotating mass "Grankshatt”

33. | Lubr.oil pump “Lubr.oil pump for main

tubr. oil system”

34, | Cooling water pump "Cooling water pump with drive”

35. _ {Idler gear “Idler gear, cooling water pump

drive”

36. | Charge air cooter “Turbocharger and charge air

cooler”

37. | Start air distributor "Start air distributor with drive”

38. | Fuel injection cam "Camshatt”

39. | Cylinder block Cylinder block, engine foundation

and tubr.oil sump"

40. | Turbocharger “Turbocharger and charge air

cooler”

41, {Gasket

42, | Gasket |

TYPE KR@IAY

4566731

Buy

CROSS SECTION 0.3.01.1

BERGEN Nov. -83

et DRAWING NO. L 566/31 KRG

Description Chapter

1 | Exhaust pipe "Exhaust manifold” 7

2. | Exhaust pipe covering

3. 1g water outlet "Cooling water system” 8

4. icator valve | afety- and indicator valve” 2

5. "Exhaust and inlet valve drive

mechanism” 4

6. | Charge air receiver "Charge air receiver and end

covers” 7

7. | Control shaft “Governing the fuel injection

pumps” 7

8. | Camshaft cover “Caps and covers” 2

9. |Camshatt “Camshaft” 4

10. _ |Chain wheel cover "Caps and covers” 2

11. [Connecting rod "Piston and connecting rod

assemby" 3

aban

12. | Cylinder block "Cylinder block, engine foundation

and lubr.oil sump” 2

13. | Main bearing cap *Crankshatt main bearings" 2

14. |Counterweight *Crankshatt” 3

15. | Suction pipe, lubr. 6il sump "Cylinder block, engine foundation

and lubr. oil sump" 2

16. | Engine foundation “Cylinder block, engine foundation

and lubr.oil sump” 2

17. | Crankshaft "Crankshaft" - 3

18. _ |Crankcase door “Caps and covers” 2

19. | Lubr. oil main distributor pipe _—_| "Main lubr.oil system” 8

0.3.01.2

CROSS SECTION

Nov, -83 BERGEN

KRG DRAWING NO. L 566/31 ee

Description Chapter

20. ‘Cylinder liner. "Cylinder liner” Es

21. | Cooling water distributor pipe _| "Cooling water system” 8

22. _ | Start air distributor pipe "Air starting system KR-6, -8 and -9" 5

23. Cylinder head "Cylinder head” 2

TABLE OF CONTENTS

Dec. - 83

CHAPTER 1

Service, guarantee, returning of parts ........ eons 1.1.01

Damage report sae eee

Ordering of spare parts : ee rarer ieee anna 02

Operating instructions 1.201

Break-downs, causes and remedies . . . : cee eeeeeees 1.3.01

Special tools bene See Feber i)

Standard tools 1.4.03

Routine maintenance in general. ean -. 1.5.01

Table of routine maintenance ee grea ener e502

Lubricant guide eerie eee 15.03

Clearances .......... pesomtins , 1.6.01

Tightening of bolts in general ..... Be eons cestanran nna dds701)

Table of tightening specifications ....... 6.6... sees eee pent 7.02

Tightening of screw fastenings in general .......... 1.7.03

‘SERVICE 1.1.01.1

BERGEN . GUARANTEE April -87

oe RETURNING OF PARTS: L-K-B

Fa 5, EEE

1,__ Service.

Our service department will provide any technical information required after delivery of the

engine,

This department will also later on be in contact with the customer to prevent or correct any

breakdowns which may occur.

The service department will also ensure that each engine is supplied with the proper spare

parts.

In order to improve our producis it is of great importance that our customers give us a feed-

back on all problems that may occur on the machinery. A special form “DAMAGE REPORT”,

has been made for this purpose.

Nis recommended only to use original spare parts from. our spare part stock.

2. Guarantee.

‘The guarantee conditions are made clear in the Purchase Contract.

All paris delivered by us and replaced during the guarantee period are our property.

All guarantee claims must be followed by "DAMAGE REPORT".

3.__ Returning of parts.

When returning parts in connection with guarantee claim, repair or delivery of wrong parts, the

following has to be stated: 7

Reason for returning of parts.

The name of the part and part no.

The name of the ship and order no.

Our order no.

The parts are to be forwarded with (reight paid for.

‘The parts are to be properly packed. Smooth surfaces are to be prevented against corrosion.

Packing note to be enclosed the shipment and copy to be forwarded to:

Bergen Diesel AS

Postboks 924

5002 Bergen

DAMAGE REPORT

Customer : Bergen Diesel

File: File:

Vessel Engine Engine

Installation: type: no:

Damage occured:

Place: e z Date:

Component/system damaged:

Location

Ref. Service Manual

Component Serial No

Total running hours

Hours since last overhaul

Lub.oil used

Lub.

I consumption kg/h

Il

Fuel oi! used

Description of damage

4 Observed condition prior to damage:

5 Assumed cause of damage:

6 Additional information:

7 Forinternal use Bergen Diesel A.S:

Filled in by

Title :

This report has to be sent to Bergen Diesel A.S, P.O.Box 924, 5002 Bergen, Norway,

when damage occurs on components included in Bergen Diesel delivery.

Damage report must follow all guarantee-claims.

DAMAGE REPORT

BERGEN

Customer Bergen Diesel

File File:

Vessel Engine Engine

Installation: type: no:

1 Damage occured:

Place: : Date:

Ss

2. -component/system damaged:

Location

Ref. Service Manual

Component Serial No

Total running hours

Hours since last overhaul

Lub.oil used

Lub.oil consumption kg/h

Fuel oil used

3 Description of damage

4 Observed condition prior to damage:

5 Assumed cause of damage:

6 Additional information:

7 Forinternal use Bergen Diesel A.S:

Filled in by

Title :

This report has to be sent to Bergen Diesel A.S, P.O.Box 924, 5002 Bergen, Norway,

when damage occurs on components included in Bergen Diesel delivery.

Damage report fust follow all guarantee-claims.

DAMAGE REPORT

Customer

File:

Bergen Dieset

File:

Vessel Engine

Installation: type:

Damage occured:

Place:

Componenvsystem damaged:

Location

Ref. Service Manual

Component Serial No

Total running hours

Hours since last overhaul

Lub.oil used

Lub.oil consumption kg/h

Fuel oil used

Description of damage

Engine

no:

4 — Observed condition prior to damage:

5 Assumed cause of damage:

6 Additional information:

7 ~~ Forinternal use Bergen Diesel A.S:

Filled in by

Title :

This report has to be sent to Bergen Diesel A.S, P.0.Box 924, 5002 Bergen, Norway,

when damage occurs on components included in Bergen Diesel delivery.

Damage report must follow all quarantee-claims.

fash 1.2.02.

Dec. -82

ORDERING OF SPARE PARTS

This Service Manual also serves as spare part catalogue.

When ordering a component, Took up the drawing and the corresponding instruc-

tion in which the component is discribed; and state the following:

1. Name of component according to service manual.

2. Item no. according to drawing.

3. Drawing no.

4. Engine no. according to name plate on the engine.

5. Component manufacturer and series no.

S a e

EXAMPLE:

For engine no. 2984 is to be \\\ Ny

ordered 1 gasket for safety- and \ f

indicator valve.

The gasket is shown as item

Wo. 4 in drawing No. L 566/13.

State in the order:

1 gasket,

item No. 4, drawing No. L 566/13.

Engine No. '2984.

IS !

Some components may have the manufacturers name and part number cast or stamped

on, If so, it is desireable to have this stated in the order.

THE SERIES NO. IS NOT IDENTICAL TO THE DRAWING NO. IN THE SERVICE MANUAL

By ordering spare parts according to this procedure, our service department

will ensure that your engine is supplied with the proper parts.

Parts that can not be identified according to the above, have to be described.

State name of the part and where on the engine it is located.

A clear description accompanied by a sketch or a photo will facilitate the work

of the service department, and misunderstanding will be avoided.

ALWAYS STATE THE ENGINE NO. WHEN ORDERING SPARE PARTS

BMV is interested to know how many hours the replaced part has been in opera-

tion, and if there is any spesific cause for replacement.

KL

te as

OPERATING INSTRUCTIONS )

In order to obtain maximum performance and safe operation of the engine under

all running conditions, proper care and maintenance is required. Should, how-

ever, faults occur during operation, it mst be corrected imediately, even

if the fault seens minor.

Below are given some instructions on maintenance of the engine before start

and during operation, which the engine crew should specially keep in mind,

1. PREPARATION FOR START AFTER INSTALLATION, AFTER A LONG PERIOD OF STAND-

STILL OR A LARGE OVERHAUL

1.1 | The crankcase should be thoroughly cleaned, and all internal parts should

be wiped off if necessary. All internal boits and nuts should be

tightened and secured.

Be aware that a loose pin, or an untightened bolt, screw, or nut, might

cause serious damage, especially if not accessible during operation.

START AIR SYSTEM

1.2 All pipes from the starting air vessels should be blown free of dirt,

contaminations and condensed water with compressed air.

1.3. Check the air pressure in the starting air bottles. See “Technical Data".

1.4 The roller bearing in the start afr distributor is lubricated with

grease. xx)

FOR KR-3_ AND KR-5 ONLY

1.5 The teeth of the flywheel ring gear is inserted slightly with Molycote

grease.

1.6 Loosen the start air supply pipe on the start motor and pour 0.1 litre

Jub.of1 into starter inlet.

1.7. Fill the start motor lub.oi7 tank to maximum level, and bleed the Tub.of1

supply pipe to the automatic lubricator.

LUB.OIL SYSTEM

1.8 Before filling up with lub.ot1, the lub.of1 sump should be carefully

inspected. Contaminations and corrosion (if any) are removed. Use rags,

not cotton waste, when wiping off. :

If the lub.of? applied is not approved by BMV, our warranty

responsibility will be excluded.

x When running on heavy of1: See also "Fuel oi] system, heavy fuel of]

general".

xx) Does not apply for KR-3 and KR-5.

K

1.2,01.2

Oct. -80

OPERATING INSTRUCTIONS *)

1.9 After a long period of standstill, the of] sump and lub.ofl tank mst

‘be drained for water and contaminations.

1.10 The engine is rotated slowly as lub.oi] is pumped through the system by

the lub.o11 priming punp. Assure that the lub.oi1 reaches all places to

be lubricated.

1.11 Inspect the lub.of] filters and clean them if necessary.

1.12 Before filling up the valve gear lub.of1 tank, drain it for water and

deposits.

1.13 If the valve gear lub.of1 is mixed with fuel of1, it ought to be renewed.

FUEL _OIL_SYSTEM

1.14 Before filling up with fuel ofl, tanks and pipes should be carefully

inspected.

Corrosion’ and deposits are renoved.

1,15 After a long period of standstill, the fuel of] tanks should be drained

for water and contaminations.

Check the oi] level.

1.16 Disconnect the fuel of] pipe at the fuel of] priming pump, and let the

of] flow until it is free of contaminations from the fuel of] tank and

pipes.

Check the fuel of filters and replace the inserts if necessary.

1,17 Expel all trapped air in the fuel of7 system by bleeding the filter

housing and the distributor pipe from the fuel injection pumps.

2. START OF ENGINE AFTER A LONG PERIOD OF STANDSTILL

‘See also “Air starting system

Instructions for start and stop of engine plants are gfven in chapter 5

and separate instruction book “Control System". The instructions given

below are therefore to be considered as a general description.

2.1 The tool for turning the engine must be removed from the engine.

2.2 The indicator valves are closed according to section 1.10

2.3 Open the fuel ofl, lub.oi1, starting air, -and cooling water valves.

2.4 The pneumatic control system is supplied with air and the alarm system is

put into function (Propulsion plant only).

x) When running on heavy of; See also “Fuel oi] system, residual fuels*. (

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PCC3200 Com CableDocument1 pagePCC3200 Com CableAshly JosephNo ratings yet

- SL-RE-2015-011 - Instruction 4102 & Gearwheel FactsheetDocument8 pagesSL-RE-2015-011 - Instruction 4102 & Gearwheel FactsheetAshly JosephNo ratings yet

- PCC 3200 Service ManualDocument44 pagesPCC 3200 Service ManualAshly JosephNo ratings yet

- PCC 1301-Data Link-Cable ConnectionsDocument1 pagePCC 1301-Data Link-Cable ConnectionsAshly JosephNo ratings yet

- 580 Manual MMC-153 RV5-9-98Document40 pages580 Manual MMC-153 RV5-9-98Ashly JosephNo ratings yet

- P13 0058 Pabx DMD 001Document7 pagesP13 0058 Pabx DMD 001Ashly JosephNo ratings yet

- Mini-RadaScan Installers SheetDocument1 pageMini-RadaScan Installers SheetAshly JosephNo ratings yet

- EMRI SF7 V2.0 Rev 1Document2 pagesEMRI SF7 V2.0 Rev 1Ashly JosephNo ratings yet

- M044 Aux. Generator Engine - Torsional Vibration Calculations (Applying The Test Data of SNo. 123)Document24 pagesM044 Aux. Generator Engine - Torsional Vibration Calculations (Applying The Test Data of SNo. 123)Ashly JosephNo ratings yet

- DCU 305 R2 and R3 TroubleshootingDocument6 pagesDCU 305 R2 and R3 TroubleshootingAshly JosephNo ratings yet

- M046 Aux. Generator Engine - List of Certificates and DocumentDocument107 pagesM046 Aux. Generator Engine - List of Certificates and DocumentAshly JosephNo ratings yet

- M042 Aux. Generator Engine - Sundry InstructionDocument226 pagesM042 Aux. Generator Engine - Sundry InstructionAshly JosephNo ratings yet

- 2301A Speed Control: ApplicationsDocument4 pages2301A Speed Control: ApplicationsAshly JosephNo ratings yet

- s71500 Compare Table enDocument118 pagess71500 Compare Table enAshly JosephNo ratings yet

- ID-DCU Marine 2.2.2 New FeaturesDocument6 pagesID-DCU Marine 2.2.2 New FeaturesAshly JosephNo ratings yet

- ComAp IGS-NT Marine Application Notes - 2014 - 5Document8 pagesComAp IGS-NT Marine Application Notes - 2014 - 5Ashly JosephNo ratings yet

- IOM 200 Application Notes, Analogue Interface For AGC 200, 4189340614 UK - 2014.10.24Document14 pagesIOM 200 Application Notes, Analogue Interface For AGC 200, 4189340614 UK - 2014.10.24Ashly JosephNo ratings yet

- PVRE SpecDocument1 pagePVRE SpecAshly JosephNo ratings yet

- AGC 200 Data Sheet 4921240362 UK - 2013.05.28Document32 pagesAGC 200 Data Sheet 4921240362 UK - 2013.05.28Ashly JosephNo ratings yet