Professional Documents

Culture Documents

PID Temperature Batch Counter Controller Operating Manual

Uploaded by

Balaso GaikwadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PID Temperature Batch Counter Controller Operating Manual

Uploaded by

Balaso GaikwadCopyright:

Available Formats

OPERATING MANUAL

OPERATING MANUAL

PID TEMPERATURE

BATCH COUNTER CONTROLLER

BC-1046D,2046,445

UTC-121P,221P & 421P

BC 1046D

BC 2046

BC 445

TOTAL TOTAL

R

BATCH COUNT R

BATCH CT

SET BATCH

RESET

ENT

SET

RESET

ENT

Technical Specification

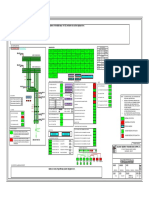

Model BC-1046D BC-2046 BC-445

UPPER:- 6 Digit 7 seg 0.56”, UPPER:- 6 Digit 7 seg 0.4”, UPPER:- 5 Digit 7 seg 0.3”,

Display red LED Display red LED Display red LED Display

LOWER:- 4 Digit 7 seg 0.4”, LOWER:- 4 Digit 7 seg 0.4”, LOWER:- 4 Digit 7 seg 0.3”,

green LED Display green LED Display green LED Display

Size(HXWXD) 96 X 96 X 45 mm 72 X 72 X 60 mm 48 X 48 X 95 mm

Panel Cutout 92 X 92 mm 68 X 68 mm 44 X 44 mm

Output 1 Relay, 1C/O,230V AC,5A & Buzzer 1 Relay, 2C/O,230V AC,5A & Buzzer

Power Supply 230V AC, 50 Hz, Approx 4VA 100 To 250V AC, 50/60 Hz, Approx 4VA

Sensor Proximity PNP/NPN (Selectable) & Micro Switch

Memory Nonvolatile

Protection Level IP-65(Front side) AS per IS/IEC 60529:2001

(As per request)

Operating

Temperature 0°C To 55°C

Relative

Humidity Up to 95% RH Non Condensing

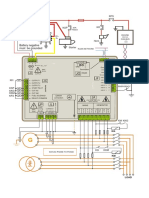

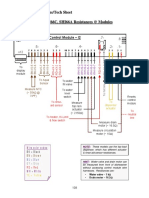

Connection Diagram 15 16 17

1 L +12V 8 Note:

230V AC 1. For NPN Proxi Short pin 3 & 4

50Hz,4VA I/P Proxi Connction to 4,6,5

2 N 9

NPN 2. For PNP Proxi Short pin 6 & 5

! Proxi Connction to 3,4,5

3 I/P 10

12 11 PNP 3. For Microswitch Short pin 6 & 5

+

BUZZER

- 4 GND 11

Micro switch Connection to 3 & 4

MICRO SWITCH:- M/S Connection 7 & 9 MICRO SWITCH:- 100 ~

M/S Connection 9 & 11

1 L 250V AC +8

50/60 HZ

4VA

7 BUZZER

5 NC 12 2 N

!

- 9

230V AC ! +12V

50Hz, 4VA 6 RESET

C 13 3 C 10

RELAY M/S RELAY

NO C NC +12V NPN PNP GND BUZZER I/P2 NO 11

L N 7 - NO 14 4

+

I/P I/P RST I/P1

6

1 2 3 4 5 6 7 8 9 10 18 19 20 5 GND NC 12

BC-1046D,2046,445 Page - 1 www.multispanindia.com

Key Operation

1) Press Key to go next

parameter.

2) Release the Key, to save

the set point.

3) Press Key for manual reset

For Program : of total count

Total Batch Count

Batch Count

Press Key

Press Key

.

Press Key To save & exit

For Program :

Total Batch Count

Batch Count

Press Key

Press Key

Press Key To save & exit

BC-1046D,2046,445 Page - 2 www.multispanindia.com

Working

* When set Count reaches at set value ,Relay and Buzzer will be ON.

* Relay will stay on up to the set Time.

* After completion of the set Time - both ,Relay and Buzzer will be OFF.

* If the set time is . then Instrument will work in manual mode and

user need to press Reset key to turn OFF Relay & Buzzer.

Set Count - 1: Advance setting for batch Count.

Set Count - 2: Batch setting.

When it reaches to set count 1, Relay & Buzzer will be ON, & when it reaches

to set count 2, Relay Buzzer will be OFF & Batch Count will be zero.

Always set the value of set 1 less then set 2.

Note:

Press key and power on the instrument Display will show parameters

‘SLOW’.”MEDIUM” & “FAST”

Set Speed Selection by Pressing key

SLOW : MAX RPM 500

MEDIUM : MAX RPM 5000

FAST: MAX RPM 15000

Press key to save the parameters

Procedure to set channel of program

Press Key

for 15 sec.

Change

Channel

by Pressing

Key

Press Key To save & exit

BC-1046D,2046,445 Page - 3 www.multispanindia.com

Safety Precautions

All safety related codifications, symbols and instructions that appear in this operating manual

or on the equipment must be strictly followed to ensure the safety of the operating personnel as

well as the instrument.

If all the equipment is not handled in a manner specified by the manufacturer, it might impair the

protection provided by the equipment .

=> Read complete instructions prior to installation and operation of the unit.

WARNING : Risk of electric shock.

Warning Guidelines

1) To prevent the risk of electric shock power supply to the equipment must be kept OFF while doing the wiring

arrangement. Do not touch the terminals while power is being supplied.

2) To reduce electro magnetic interference, use wire with adequate rating and twists of the same of equal size shall

be made with shortest connection.

2

3) Cable used for connection to power source, must have a cross section of 1mm or greater. These wires

should have insulations capacity made of at least 1.5kV.

4) A better anti-noise effect can be expected by using standard power supply cable for the instrument.

Installation Guidelines

1) This equipment, being built-in-type, normally becomes a part of main control panel and such in case the

terminals do not remain accessible to the end user after installation and internal wiring.

2) Do not allow pieces of metal, wire clippings, or fine metallic fillings from installation to enter the product

or else it may lead to a safety hazard that may in turn endanger life or cause electrical shock to the operator.

3) Circuit breaker or mains switch must be installed between power source and supply terminal to

facilitate power ‘ON’ or ‘OFF’ function. However this mains switch or circuit breaker must be

installed at convenient place normally accessible to the operator.

4) Use and store the instrument within the specified ambient temperature and humidity ranges as

mentioned in this manual.

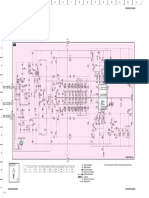

Mechanical Installation

B D E F 136mm - 5.35 inches

BC 1046D

120mm - 4.72 inches

MODEL A B

C D E F

A C

R

DIMENSIONS 96mm 96mm 92mm 92mm 3mm 45mm

B D E F 95mm - 3.75 inches

BC 2046

85mm - 3.34 inches

TOTAL

MODEL A B C D E F

A C

BATCH COUNT R

DIMENSIONS 72mm 72mm 68mm 68mm 3mm 60mm

SET RESET

ENT

68mm - 2.68 inches

B D E F

BC 445

TOTAL

60mm - 2.36 inches

MODEL A B C D E F

A C

BATCH CT

SET

ENT

BATCH

RESET

DIMENSIONS 48mm 48mm 44mm 44mm 3mm 95mm

1) Prepare the panel cutout with proper dimensions as show above.

2) Fit the unit into the panel with the help of clamp given.

3) The equipment in its installed state must not come in close proximity to any heating source,

caustic vapors, oils steam, or other unwanted process by products.

4) Use the specified size of crimp terminal (M3.5 screws) to wire the terminal block. Tightening the

screws on the terminal block using the tightening torque of the range of 1.2 N.m.

5) Do not connect anything to unused terminals.

Maintenance

1) The equipment should be cleaned regularly to avoid blockage of ventilating parts.

2) Clean the equipment with a clean soft cloth. Do not use isopropyl alcohol or any other cleaning agent.

3) Fusible resistor must not be replaced by operator.

Product improvement and upgrade is a constant procedure. So for more updated operating information and support,

Please contact our helpline : +91-9978991474/76/82 or Email at service@multispanindia.com Ver: 04-2018

BC-1046D,2046,445 Page - 4 www.multispanindia.com

You might also like

- Datasheet - PDF Ca723Document9 pagesDatasheet - PDF Ca723Jaime Sisalima PincayNo ratings yet

- Precision Waveform Generator/Voltage Controlled Oscillator FeaturesDocument10 pagesPrecision Waveform Generator/Voltage Controlled Oscillator FeaturesqwertyuiNo ratings yet

- Icl8038 PDFDocument12 pagesIcl8038 PDFmarcosNo ratings yet

- ICL8038Document14 pagesICL8038RAYLINo ratings yet

- Universal Digital Timer Utr 444 PDFDocument4 pagesUniversal Digital Timer Utr 444 PDFlabbasatyamNo ratings yet

- FAN7380 Half-Bridge Gate Driver: Features DescriptionDocument12 pagesFAN7380 Half-Bridge Gate Driver: Features Descriptionflo72afNo ratings yet

- TC7662A Charge Pump Dc-To-Dc Converter: General Description FeaturesDocument5 pagesTC7662A Charge Pump Dc-To-Dc Converter: General Description FeaturesHAITHAMNo ratings yet

- Powerite B7PT 7 Day Timer User GuideDocument2 pagesPowerite B7PT 7 Day Timer User GuideBill Halsted100% (1)

- Mine-Cap Family DatasheetDocument14 pagesMine-Cap Family DatasheetValentinIonescuNo ratings yet

- Overall alarms and bay configurationDocument1 pageOverall alarms and bay configurationAmarjit KulkarniNo ratings yet

- DRG Index and PDF All Drgs (Bd#28-42) (Rev-1) - 11kv NiedDocument76 pagesDRG Index and PDF All Drgs (Bd#28-42) (Rev-1) - 11kv Niedprobal nandyNo ratings yet

- Non-Invasive Blood Pressure Sensor Specification SheetDocument21 pagesNon-Invasive Blood Pressure Sensor Specification SheetJoseNo ratings yet

- 8A2512 PericomDocument4 pages8A2512 PericomandrasorNo ratings yet

- Schematic Drawings 173957 PDFDocument15 pagesSchematic Drawings 173957 PDFDutsan Rojas100% (1)

- KFS fuel solenoid control module documentationDocument1 pageKFS fuel solenoid control module documentationNabilBouabana100% (3)

- Pc9500N/Pc4800N Overall Circuit Diagram 6/8 (Pa) : Temperature SensorDocument1 pagePc9500N/Pc4800N Overall Circuit Diagram 6/8 (Pa) : Temperature SensorBoune WakandaNo ratings yet

- 28V-Input-Voltage Single-Cell Li-Ion Battery Charger With 10ma RegulatorDocument24 pages28V-Input-Voltage Single-Cell Li-Ion Battery Charger With 10ma RegulatorAlejandro DemitiNo ratings yet

- IX. Wiring Diagrams/Tech Sheet Measuring SHU66C, SHI66A Resistances at ModulesDocument4 pagesIX. Wiring Diagrams/Tech Sheet Measuring SHU66C, SHI66A Resistances at ModulesnilsNo ratings yet

- D D D D D D D D D D D: Description/ordering InformationDocument16 pagesD D D D D D D D D D D: Description/ordering InformationJay rayNo ratings yet

- Charge Pump Dc-To-Dc Voltage ConverterDocument11 pagesCharge Pump Dc-To-Dc Voltage ConverterRicardo KraftmanNo ratings yet

- 29.outline 415V Edg DB A&bDocument2 pages29.outline 415V Edg DB A&bOblivious Amr Din InsanityNo ratings yet

- LTstestsetsg 098Document1 pageLTstestsetsg 098Mohammad-Mahdi TaghipourNo ratings yet

- 20 MHZLSRDocument1 page20 MHZLSRMEGA_ONENo ratings yet

- JhreeDocument16 pagesJhreegoogle manNo ratings yet

- TC7662A Charge Pump Dc-To-Dc Converter: General Description FeaturesDocument8 pagesTC7662A Charge Pump Dc-To-Dc Converter: General Description FeaturesAlex KarimNo ratings yet

- HBB - Fuel Train - RA - Prebuild Option 3Document4 pagesHBB - Fuel Train - RA - Prebuild Option 3AlvaroJavierReyesNo ratings yet

- Max675 PDFDocument5 pagesMax675 PDFAndré SousaNo ratings yet

- Power Supply Schematic DiagramDocument2 pagesPower Supply Schematic DiagramFernando SotoNo ratings yet

- HP - HSTNS PL11 - PS 2122 1CDocument11 pagesHP - HSTNS PL11 - PS 2122 1CStephen SoosaiNo ratings yet

- Primary Up1: Pandemonium Power Supply Block Diagram REV.X3Document11 pagesPrimary Up1: Pandemonium Power Supply Block Diagram REV.X3Alex LuzNo ratings yet

- Interruptor de Presion KoboldDocument2 pagesInterruptor de Presion KoboldMagin Idelfonso TorreblancaNo ratings yet

- KA3842Document7 pagesKA3842QXNNo ratings yet

- EPF - SS MCC - IO - Allocation - Comm - Rev.4Document10 pagesEPF - SS MCC - IO - Allocation - Comm - Rev.4Ahmad RabieNo ratings yet

- Fairchild Power Switch (FPS) : Features DescriptionDocument12 pagesFairchild Power Switch (FPS) : Features DescriptioncomphomeNo ratings yet

- Ap 3843 CPDocument13 pagesAp 3843 CPJesus ChaileNo ratings yet

- Series R4V and R6V (Offboard Electronics) General Description Technical InformationDocument9 pagesSeries R4V and R6V (Offboard Electronics) General Description Technical InformationGustavo FreitasNo ratings yet

- 10W Amplifier With DC Volume Control: Multipower Bi50Ii TechnologyDocument13 pages10W Amplifier With DC Volume Control: Multipower Bi50Ii TechnologyfabioboogNo ratings yet

- Connettori XLRDocument1 pageConnettori XLRanon-330071No ratings yet

- PB1508GVDocument12 pagesPB1508GVNoelNo ratings yet

- LineDocument1 pageLineRohit SahNo ratings yet

- TC7136/TC7136A: Low Power 3-1/2 Digit Analog-to-Digital ConverterDocument22 pagesTC7136/TC7136A: Low Power 3-1/2 Digit Analog-to-Digital ConverterAngelo ZuñigaNo ratings yet

- Rev. Status: Customer Drawing ListDocument9 pagesRev. Status: Customer Drawing ListDebesh ChaudharyNo ratings yet

- Ir2166 (S) & (PBF) : PFC & Ballast Control IcDocument32 pagesIr2166 (S) & (PBF) : PFC & Ballast Control IcDelta PratamaNo ratings yet

- CC311 - Bom - Offer - Techsol - Onion - Washing - 2 - Line - Control - PanelDocument3 pagesCC311 - Bom - Offer - Techsol - Onion - Washing - 2 - Line - Control - PanelTECHXPERT SOLUTIONNo ratings yet

- TC1044S Charge Pump DC-TO-DC Voltage Converter: Features General DescriptionDocument11 pagesTC1044S Charge Pump DC-TO-DC Voltage Converter: Features General DescriptionAlex Lorz BalboaNo ratings yet

- uP6103 Synchronous Buck Controller Datasheet SummaryDocument15 pagesuP6103 Synchronous Buck Controller Datasheet SummarySelmar CavalcantiNo ratings yet

- Features DescriptionDocument23 pagesFeatures DescriptionQUANG MINH TRANNo ratings yet

- Sbas 022 DDocument27 pagesSbas 022 DWilson Yecit OrtizNo ratings yet

- Linkswitch-Xt Family DatasheetDocument18 pagesLinkswitch-Xt Family DatasheetAscenten TechnologiesNo ratings yet

- Lock Close Lock: Feeder Protection RelayDocument1 pageLock Close Lock: Feeder Protection RelayJulianNo ratings yet

- 9 - BLOK G7 - ElDocument2 pages9 - BLOK G7 - ElchepimancaNo ratings yet

- Vol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Document78 pagesVol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Akhosh KrishnaNo ratings yet

- KSG 1.5K SMDocument2 pagesKSG 1.5K SMGirasolar solarNo ratings yet

- AP8836 AC-DC PWM Controller <40Document15 pagesAP8836 AC-DC PWM Controller <40SamerNo ratings yet

- Typical 66,11kV Station TRF Bay View (GIS MODULE)Document1 pageTypical 66,11kV Station TRF Bay View (GIS MODULE)Amarjit KulkarniNo ratings yet

- KHP ManualDocument13 pagesKHP Manualthreephase electricNo ratings yet

- PWA FP381 schematic overviewDocument57 pagesPWA FP381 schematic overviewMichael Davenport0% (1)

- Dell Studio 1557 1558 Quanta FM9B UMA Rev 3A SchematicsDocument60 pagesDell Studio 1557 1558 Quanta FM9B UMA Rev 3A SchematicsNorma AngelicaNo ratings yet

- All DRG, Bom & Qap.-SalonDocument21 pagesAll DRG, Bom & Qap.-SalonKvenkataswamy Goud12No ratings yet

- DCU Heater Mod.Document36 pagesDCU Heater Mod.Varun Gupta100% (1)

- NASA Space Shuttle STS-41G Press KitDocument29 pagesNASA Space Shuttle STS-41G Press KitOrion2015No ratings yet

- Eaton Xenergy Light Add On Distribution Board Product Catalog 2017 en UsDocument140 pagesEaton Xenergy Light Add On Distribution Board Product Catalog 2017 en UsOmar Yasser HarbNo ratings yet

- Chemical KineticsDocument45 pagesChemical KineticsNatish JaglanNo ratings yet

- RMC Technical Material Specification SummaryDocument27 pagesRMC Technical Material Specification Summarysat palNo ratings yet

- 4.0 Xterra 2006Document48 pages4.0 Xterra 2006AUTOMOTRIZ TIPO SPCANo ratings yet

- Ge Generator Short Circuit CharachteristicsDocument120 pagesGe Generator Short Circuit CharachteristicsEoin O'MahoneyNo ratings yet

- Static TransferDocument13 pagesStatic TransferCristian BandilaNo ratings yet

- Topnews Brainbee q1 enDocument21 pagesTopnews Brainbee q1 enAdasson BravoNo ratings yet

- IC Learning Series 2013 - Sheet Metal FabricationDocument19 pagesIC Learning Series 2013 - Sheet Metal FabricationnskumarmNo ratings yet

- M.SC Mathematics Semester I.Document13 pagesM.SC Mathematics Semester I.Madhav patilNo ratings yet

- Transformer DifferentialDocument40 pagesTransformer Differentialshahrizal7100% (1)

- 2240 162 Pve U 004 SHT 3 3 01Document13 pages2240 162 Pve U 004 SHT 3 3 01Anagha DebNo ratings yet

- UNIT 5 - Special MachinesDocument33 pagesUNIT 5 - Special MachinesKapilachander ThangavelNo ratings yet

- Qw-484 Welder Performance Qualification (WPQ) : SEE QW-301 Section Ix, Asme Boiler & Pressure Vessel CodeDocument8 pagesQw-484 Welder Performance Qualification (WPQ) : SEE QW-301 Section Ix, Asme Boiler & Pressure Vessel CodeGobinderSinghSidhuNo ratings yet

- TransformersDocument5 pagesTransformersVishakhNo ratings yet

- Green FrameworkDocument22 pagesGreen Frameworkjalees23No ratings yet

- 8 INHE SD NF2 OM MTR002 A Three Phase Smart Meter Operation Manual FRDocument154 pages8 INHE SD NF2 OM MTR002 A Three Phase Smart Meter Operation Manual FRHous Sam100% (2)

- SOMDocument431 pagesSOMPradeepvenugopalNo ratings yet

- Brazil & China: Industrial InnovationDocument1 pageBrazil & China: Industrial InnovationPlinio JuniorNo ratings yet

- HVAC Brochure Rev No 12Document66 pagesHVAC Brochure Rev No 12steve@air-innovations.co.zaNo ratings yet

- Thermador Kitchen Design Guide 2012Document312 pagesThermador Kitchen Design Guide 2012PurcellMurray100% (3)

- Ata CodesDocument10 pagesAta CodesIvo SilvaNo ratings yet

- Boiler and Its TypesDocument11 pagesBoiler and Its TypesParas RaoNo ratings yet

- Ball Mill Operating Manual 266795 Manual InstrDocument48 pagesBall Mill Operating Manual 266795 Manual InstrHarish Chandra SinghNo ratings yet

- Maintenance ScheduleDocument22 pagesMaintenance Scheduleghanbari.s60No ratings yet

- 3 People and Planet Extra Practice: 3.1 VocabularyDocument4 pages3 People and Planet Extra Practice: 3.1 VocabularyBerta LlopisNo ratings yet

- The Indian Coffee House at ThiruvanathapuramDocument13 pagesThe Indian Coffee House at ThiruvanathapuramAdil BackerNo ratings yet

- Unit III Resonance and Coupled CircuitsDocument28 pagesUnit III Resonance and Coupled CircuitsSaravana SelvanNo ratings yet