Professional Documents

Culture Documents

Cement Stabilized Moorum - 210429 - 030018

Uploaded by

Sudip MukhopadhyayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Stabilized Moorum - 210429 - 030018

Uploaded by

Sudip MukhopadhyayCopyright:

Available Formats

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 13, Issue 6 Ver. V (Nov. - Dec. 2016), PP 44-48

www.iosrjournals.org

Potential of Cement Stabilized Moorum as Construction Material

Jyothi Swarup Deevi 1, Manikanta K V 2

1

(Assistant Professor, Department of Civil Engg, St.Ann’s College of Engineering & Technology, chirala, India)

2

(Assistant professor, Department of Civil Engg, Visvodaya Engineering College, Kavali, India)

Abstract: Soil stabilization is being done to improve the properties of locally available soils to make them

suitable for required construction activity. Cement stabilization is one of the oldest methods of stabilization of

soils to improve strength and reduce permeability. Most of the research on cement stabilization of soils is done

with regards to volume stability, strength improvement interms of Unconfined Compressive Strength, bearing

capacity and permeability. In the present work, the mechanism of cement stabilization of soils, factors affecting

cement stabilization, previous works related to cement stabilization have been reviewed. Present study, is

intended to assess the suitability of locally available moorum soil stabilized by cement for use as alternate to

low grade conventional concretes. Cube compressive strengths of cement stabilized moorum has been

determined by testing cubes of size 15cm×15cm×15cm after curing periods of 7,14 and 28 days. The percentage

cement used for stabilization is varied from 0 to12 in increments of 3 percent. 53 grade OPC cement is used to

stabilize the moorum soil. The chemical properties of moorum have been also determined to assess the

suitability for use with cement. The cement stabilized moorum with 7 percent and 9 percent stabilizer yielded

compressive strengths equivalent to M7.5 and M10 grade concretes. The strengths of cement stabilized moorum

has been also assessed in terms of C.B.R. Addition of 3 percent cement by weight to moorum has resulted in

C.B.R more than 30 percent and hence indicated its suitability as sub base material for pavement construction.

Keywords: Cement stabilization, Mooram, CBR, OMC , MDD.

I. Introduction

Soil stabilization is referred to as a procedure in which a special soil is proportioned or adding or

removed, or a cementing material, or other chemical material is added to a natural soil material to improve one

or more of its properties. One of the most common methods of stabilization includes the mixing of natural

coarse-grained soil and fine-grained soil to obtain a mixture that develops adequate internal friction and

cohesion and there by provides a material that is workable during placement but will remain stable further. All

the soils available at the site may not be readily available for required purpose so for improving the engineering

properties of available soil, stabilization is required.

Soil stabilization is the process of improving the engineering properties of the soil and thus making

more stable. It is required when the soil available for construction is not suitable for the intended purpose .In its

broadest senses, stabilization includes compaction, pre consolidation, drainage and many other such process.

However, the term stabilization is generally restricted to the processes which alter the soil material itself for

improvement of its properties. A cementing material or a chemical is added to a natural soil for the purpose of

stabilization. Soil stabilization is used to reduce the permeability and compressibility of the soil mass in earth

structures and to increase its shear strength. Soil stabilization is required to increase the bearing capacity of

foundation soils. However, the main use of stabilization is to improve the natural soils for the construction of

highways and airfields. The principles of soil stabilization are used for controlling the grading of soils and

aggregates in the construction of bases and sub bases of the highways and airfields. Soil stabilization is also

used to make an area trafficable within a short period of time for military and other emergency purposes.

Sometimes, soil stabilization is used for city and suburban streets to make them more noise-absorbing.

II. Aim and objectives of study

The present work is aimed at stabilizing locally available Moorum with cement for assessing its

potential as construction material. To achieve the aim, work has been planned with the following objectives.

Objectives:

1. To determine Engineering properties of locally available Moorum

2. To evaluate chemical properties of Moorum to assess its suitability for stabilization with cement.

3. To study the effect of addition of cement on engineering properties of Moorum soil.

4. To assess compressive strength of cement stabilized Moorum by testing cubes cured for 7, 14 and 28 days.

5. To study the improvement in C.B.R of Moorum soil with cement stabilization

DOI: 10.9790/1684-1306054448 www.iosrjournals.org 44 | Page

Potential of Cement Stabilized Moorum as Construction Material

III. Material properties

i) Properties of Mooram

Table 1 : Engineering properties of Mooram

S.No Engineering Properties Values

1 Specific Gravity 2.67

2 Liquid Limit (%) 25

3 Plastic Limit (%) NP

4 Grain Size Analysis

(a) Gravel (%) 36.3

(b) Sand (%) 54.7

(c) Fines (%) 9.0

(d) Coefficient of Uniformity 45.45

(e) Coefficient Curvature 1.1

5 IS Classification SW-SM

6 Compaction Characteristics

(a) Maximum Dry Density (g/cc) 2.03

(b) Optimum Moisture Content (%)

6.5

7 CBR value (%) 18.9

Table 2 : Chemical Properties of Moorum

S.No Chemical Properties Value

1 PH of soil(1:5)(W/V) 7.69

2 Water Soluble Chlorides (%) 0.008

3 Water Soluble Sulphates (%) 0.002

ii) Properties of Cement

Table 3 : Cement Properties

S.No Property Value

1 Specific Gravity 3.1

2 Fineness (%) 96

3 Consistency

(a) Normal Consistency (%). 33

(b) Initial Setting Time. 1hr 13 minutes

(c) Final Setting Time. 8hr 10minutes

4 Compressive Strength (Mpa)

at 3 days 28.2

at 7 days 34.1

IV. Stabilization of Mooram with Cement

i) Effect of cement addition on compaction characteristics

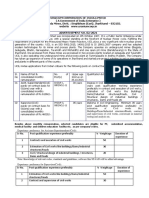

Table 4: Compaction Characteristics of Cement Stabilized Moorum

S.No Cement Content (%) Optimum Moisture Maximum Dry

Content (%) Density(g/cc)

1 3 6.5 2.16

2 6 8.6 2.19

3 9 9.2 2.26

4 12 10.3 2.31

12

Optimum Moisture

10

8

Content (%)

6

4

2

0

0 5 10 15

% Cement Added

Fig.1 : Variation of O.M.C with Percentage Cement Added

DOI: 10.9790/1684-1306054448 www.iosrjournals.org 45 | Page

Potential of Cement Stabilized Moorum as Construction Material

Fig. 2: Variation of M.D.D with Percentage Cement Added

ii) Effect of cement addition on compaction characteristics

Table 5 : Plasticity Characteristics of Moorum Stabilized by Cement

S.No (% ) Cement content added Plasticity Characteristics

LL (%) PL (%) PI

1 3 23 NP NP

2 6 21 NP NP

3 9 20 NP NP

4 12 18 NP NP

iii) Effect of Cement addition on strength characteristics

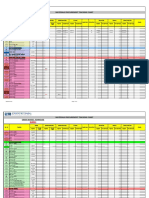

Table 6: Effect of Cement addition on strength characteristics

Compressive Strength of Cubes (N/mm2)

S.No Cement Content (%)

7 days 14days 28 days

1 3 0.6 1.11 2.07

2 6 3.92 5.03 6.96

3 9 7.77 9.185 12.59

4 12 10.8 12.74 16.29

18

Compressive Strength (N/mm2)

16

14

12

10

7 days

8

14 days

6

28 days

4

0

0 5 10 15

% Cement Added

DOI: 10.9790/1684-1306054448 www.iosrjournals.org 46 | Page

Potential of Cement Stabilized Moorum as Construction Material

Table 7 : California Bearing Ratio Values of Cement Stabilized Moorum

S.No Cement content (%) Optimum Moisture Days CBR value (%)

Content (%)

1 0 6.3 7 18.9

2 3 6.5 7 34.79

3 6 8.6 7 93.43

V. Summary

i) Pproperties of mooram soil

Engineering properties of Moorum soil presented in Table indicate that the soil sample is coarse

grained with predominant percentage of sand. Based on the gradation and plasticity characteristics it classified

as well graded silty sand (SW – SM) as per ISSCS (Indian Standard Soil Classification System). From plasticity

characteristics, it can be noted that soil is Non plastic (NP). The Moorum has C.B.R value of 18.9% and hence it

cannot be used in sub base courses of flexible pavements. The sub base layers demand use of Moorum soil with

soaked C.B.R 20% and 30% for normal and heavy trafficked roads respectively. Chemical properties of

Moorum presented in Table 3.2, reveal that durability of cement is not effected by its environment (P H = 7.19,

Chlorides = 0.08%, sulphates = 0.02%).

ii) Properties of cement

The properties of cement presented in Table confirm the grade of cement (53grade) and its quality.

iii) Stabilization of mooram with cement

a) Compaction Characteristics

Compaction characteristics of cement stabilized Moorum presented in Table indicate that O.M.C

values increased with increase in percentage cement added to Moorum. The increase in O.M.C values can be

attributed to increased specific surface of mix, with increased percentage of cement (cement being fine grained).

It can be further seen from Table that the M.D.D values also increased with increase in percentage of cement

addition to Moorum. The increased M.D.D values are due to introduction of cement in to the voids of soil.

b) Plasticity characteristics

From Table, it can be observed that liquid limit of Moorum stabilization with cement decreases with

increased percentage of cement added. The reduction in values of liquid limit is due to cation exchange

processes involved in cement stabilization of soil. As the Moorum is non plastic, it remained non plastic at all

percentages of cement addition.

c) Strength Characteristics

Above Fig. reveals that compressive strength of cement stabilized cubes increased linearly with

increase in percentage of cement added. The compressive strength of cubes increased with increase in curing

period. It can be noticed from Fig. that cement stabilized Moorum cubes yielded compressive strength

equivalent to M7.5 and M10 grade concrete. Hence, cement stabilized Moorum may be used as alternative to

conventional concrete in mass cement concrete applications such as construction of gravity retaining walls,

forming sub base for cement concrete roads etc.

From Table, it can be seen that addition of 3% of cement to Moorum has yielded C.B.R value above 30%, hence

cement stabilized Moorum can be used in sub base of pavements.

VI. Conclusions

Based on experimental study carried out on cement stabilized locally available Moorum following conclusions

have been made.

The locally available Moorum selected for the study is a well graded coarse grained soil with little amount

of non plastic fines. As the Moorum does not contain excess percentage of sulphates and chlorides, it may

be considered for stabilization with cement.

The compressibility of Moorum decreases with increase in percentage of cement addition.

The compaction characteristics both O.M.C and M.D.D increase with increase in percentage of cement

added to the Moorum.

The compressive strength of cement stabilized Moorum increases linearly with increase in percentage of

cement used for stabilization.

The strength of cement stabilized Moorum increases with curing period.

The compressive strength of cement stabilized Moorum cubes with 7% and 9% cement have strengths

equals to strengths of M7.5 and M10 grade concrete cubes.

The C.B.R values of Moorum treated with cement increase significantly.

The amount of cement required for modifying the Moorum as sub base material is only 3%.

DOI: 10.9790/1684-1306054448 www.iosrjournals.org 47 | Page

Potential of Cement Stabilized Moorum as Construction Material

Hence locally available Moorum under study can be effectively stabilized by cement and can be used

as replacement for M7.5 and M10 grades of concrete in mass concrete applications, bed concreting and also in

sub base layers of pavements.

Limitations

The results are applicable for Moorum under study with 53grade OPC as stabilizer.

The results may vary if PPC is used as stabilizer and with grade of cement.

The study did not cover durability accepts of cement stabilized Moorum.

Scope of further study

Similar studies may be carried out on gravelly soils.

The effect of grade of concrete on strength of stabilized soil may also be studied.

The split tensile strength and flexural strength of cement stabilized Moorum may also be studied for

extended scope of application.

References

[1]. Ali, G A Youssef, A-FA(1983),” Stabilization of Silt: A Case Study For Low-Volume Roads in Saudi Arabia”, pagination (283-

290).

[2]. Arora, K.R (2000), “Soil Mechanics & Foundation Engineering”, Standard Publishers, Delhi.

[3]. Antonio Viana da Fonseca, Rodrigo Caberlon Cruz and Nilo Cesar Consoli (2009), “ Strength Properties of Sandy Soil- Cement

Admixtures ”, Geotech Geol Eng Vol.27,pp 681-686.

[4]. B.V. Venkatarama Reddy and A. Gupta(2004), “ Characteristics of Soil-Cement Blocks Using Highly Sandy Soils ”, Materials and

Structures, Vol.38, pp 651-658.

[5]. Consoli NC, Lopes LS Jr, Heineck KS(2009), “Key Parameters for the Strength Control Of Lime Stabilized Soils”, J mater Civ Eng

21(5), pp 210-216.

[6]. Dupas JM, Pecker A (1979), “Static and Dynamic Properties of Sand- Cement”, J Geotech Eng Div, Vol 105(3),pp 419-436.

[7]. E.A. Basha, R. Hashim, H.B. Mahmud, A.S. Muntohar (2004),”Stabilization of Residual Soil with Rice Husk Ash and Cement”,

vol (19) pp 448-453.

[8]. Eze-Uzomaka, Osondu Johnson, Agbo, Daniel (2010), “Suitability of Quarry Dust as Improvement to Cement Stabilized-Lateritefor

Road Bases”, vol 15, Bund (K).

[9]. Goecker, WL, MOH Z C, Davidson, and DT.Chu,TY(2004), “Stabilization of Fine and Coarse Grained Soils with Lime and Fly

ash Admixtures”.

[10]. Ingles OG, Metcalf JB(1972), “Soil Stabilization- Principles and Practice”, Butterworths Pty. Limited, Australia, pp 366.

[11]. Kobayashi Haruo, Nakano Hiroyuki, Fukushima Shinji and Kitajima Akira (2000), “Soil Stabilization to Prevent Slaking of Mud-

Stone Gravely Soil in Terre-Armee Embankment”, Vol 645 pp (291-306).

[12]. M.L.Jackson(1967), “Soil Chemical Analysis”, Prentice- Hall of India Private Limited, New Delhi

[13]. Mitchell,J.K(1975), “Fundamentals of Soil Behaviour”, Johan Wiley & Sons,Inc; Newyork.

[14]. Porbaha A, Tanaka H, Kobyashi M(1998), “State of Art in Deep Mixing Technology”, Part-III-Geomaterial Characterization,

Ground Improvement, J ISSMGE Vol.4 (3), Pp 91- 110.

[15]. Thome A, Donato M, Consoli NC, Graham J(2005), “Circular Footings on A Cemented Layer above weak Foundation Soil”,

Canadian Geotech J 42, pp 1569-1584.

[16]. All Relevant IS Codes of Practice.

DOI: 10.9790/1684-1306054448 www.iosrjournals.org 48 | Page

You might also like

- Study of Strength Characteristics of Cement Stabilized Gravelly SoilDocument6 pagesStudy of Strength Characteristics of Cement Stabilized Gravelly SoilAnonymous CUPykm6DZNo ratings yet

- Soil StabilisationDocument5 pagesSoil StabilisationGaurav DhimanNo ratings yet

- Experimental Investigation of Soil Stabilization by Using Alum SludgeDocument7 pagesExperimental Investigation of Soil Stabilization by Using Alum SludgeIJRASETPublicationsNo ratings yet

- Civil Engineering JournalDocument15 pagesCivil Engineering JournalHhowtobe YounesNo ratings yet

- Investigation On Effect of Coir Fiber in Clayey Soil: Himanshu Bhatt, Harshit VarshneyDocument7 pagesInvestigation On Effect of Coir Fiber in Clayey Soil: Himanshu Bhatt, Harshit VarshneyharshitNo ratings yet

- Stabilization of Black Cotton Soil Using Rice Husk Ash For Flexible Pavement ConstructionDocument7 pagesStabilization of Black Cotton Soil Using Rice Husk Ash For Flexible Pavement ConstructionIJRASETPublicationsNo ratings yet

- Stabilization of Soil by Using Fly AshDocument4 pagesStabilization of Soil by Using Fly AshAmrit AcharyaNo ratings yet

- Chapter 3Document24 pagesChapter 3Md Ashiqur RahmanNo ratings yet

- Comparison of Geotechnical Engineering Properties of Black Cotton Soil by Adding Lime and Sugarcane Straw AshDocument3 pagesComparison of Geotechnical Engineering Properties of Black Cotton Soil by Adding Lime and Sugarcane Straw AshIJIRSTNo ratings yet

- Applied Sciences: Dimensional Stability of SBR-Modified Cementitious Mixtures For Use in 3D Additive ConstructionDocument13 pagesApplied Sciences: Dimensional Stability of SBR-Modified Cementitious Mixtures For Use in 3D Additive Constructionmalaya tripathyNo ratings yet

- SNF Based ConcreteDocument7 pagesSNF Based ConcreteJairamMiryalaNo ratings yet

- Effect of Water Cement Ratio On The Work PDFDocument8 pagesEffect of Water Cement Ratio On The Work PDFMohamed HamdyNo ratings yet

- PREDICTION OF COMPRESSIVE STRENGTH OF CONCRETE WITH AGRICULTURAL WASTE AND NATURAL FIBRE 2024Document5 pagesPREDICTION OF COMPRESSIVE STRENGTH OF CONCRETE WITH AGRICULTURAL WASTE AND NATURAL FIBRE 2024Nagaraja M LNo ratings yet

- 1218 2818 1 PBDocument8 pages1218 2818 1 PBmahparaNo ratings yet

- 49 Dubey JainDocument6 pages49 Dubey JainDAVID CCALANo ratings yet

- Experimental Investigation of RCC Beam For Analyzing Crack Variation by DIC MethodDocument9 pagesExperimental Investigation of RCC Beam For Analyzing Crack Variation by DIC MethodJaydeep ZankatNo ratings yet

- Journal 9 PDFDocument45 pagesJournal 9 PDFRuzengulalebih ZEta's-ListikNo ratings yet

- PREDICTION OF COMPRESSIVE STRENGTH OF CONCRETE WITH AGRICULTURAL WASTE AND NATURAL FIBRE 2024Document5 pagesPREDICTION OF COMPRESSIVE STRENGTH OF CONCRETE WITH AGRICULTURAL WASTE AND NATURAL FIBRE 2024Nagaraja M LNo ratings yet

- Experimental Investigation On Concrete With Partial Replacement of Fine Aggregate by Marble Dust PowderDocument7 pagesExperimental Investigation On Concrete With Partial Replacement of Fine Aggregate by Marble Dust PowderDas TadankiNo ratings yet

- Settlement and Bearing Capacity of Geogrid-Reinforced Sand Over Collapsible SoilDocument14 pagesSettlement and Bearing Capacity of Geogrid-Reinforced Sand Over Collapsible Soiljavad khosraviNo ratings yet

- Efficacy of Class C Fly Ash As A Stabilizer For Marginal Residual SoilDocument8 pagesEfficacy of Class C Fly Ash As A Stabilizer For Marginal Residual SoilmakiNo ratings yet

- Studies On Soil Stabilization by Using Bagasse AshDocument6 pagesStudies On Soil Stabilization by Using Bagasse AshArjun KumarNo ratings yet

- Durability of Lime Stabilized Earth Blocks: A Guettala, H. Houari, B. Mezghiche AND R. ChebiliDocument6 pagesDurability of Lime Stabilized Earth Blocks: A Guettala, H. Houari, B. Mezghiche AND R. ChebilihburitiNo ratings yet

- Ground Granulated Blast Furnace Slag (GGBS) : Effect of Particle Size and Dosage On Compressive Strength With Microstructural Analysis of ConcreteDocument8 pagesGround Granulated Blast Furnace Slag (GGBS) : Effect of Particle Size and Dosage On Compressive Strength With Microstructural Analysis of ConcreteIJRASETPublicationsNo ratings yet

- Experimental Investigation of Heave Control Technique of Expansive Soil Using Micro Piles and Geotextile LayersDocument9 pagesExperimental Investigation of Heave Control Technique of Expansive Soil Using Micro Piles and Geotextile LayersAnandNo ratings yet

- Enhancing The Index and Engineering Properties of Urban Fills by Stabilizing With Cement, Lime and Bagasse AshDocument13 pagesEnhancing The Index and Engineering Properties of Urban Fills by Stabilizing With Cement, Lime and Bagasse Ashjyothi ramaswamyNo ratings yet

- Cement Matecconf Icsbe2019 04011Document8 pagesCement Matecconf Icsbe2019 04011Hhowtobe YounesNo ratings yet

- Investigation On Sustainable Concrete Using M-Sand and Rice Husk AshDocument4 pagesInvestigation On Sustainable Concrete Using M-Sand and Rice Husk AshjyothiNo ratings yet

- Correlation Between Particle Fines and Laboratory CBR ValuesDocument7 pagesCorrelation Between Particle Fines and Laboratory CBR ValuesMasood AhmedNo ratings yet

- How RHA Reduces Shrinkage of Problem SoilDocument19 pagesHow RHA Reduces Shrinkage of Problem Soilhamisu dahiruNo ratings yet

- 11 - Chapter 3Document16 pages11 - Chapter 3city cyberNo ratings yet

- Engineering Properties of Batu Pahat Soft Clay Stabilized With Lime, Cement and Bentonite For Subgrade in Road ConstructionDocument46 pagesEngineering Properties of Batu Pahat Soft Clay Stabilized With Lime, Cement and Bentonite For Subgrade in Road ConstructionHawaiiChongNo ratings yet

- 10.1201 9781003323020-147 ChapterpdfDocument8 pages10.1201 9781003323020-147 ChapterpdfFarjallah Al-AssãadNo ratings yet

- IJCIET_08_04_196Document9 pagesIJCIET_08_04_196GOKULKATHIR.H II YEAR CIVILNo ratings yet

- Assessment of Potential of Marble Slurry As A Mineral Admixture in ConcreteDocument14 pagesAssessment of Potential of Marble Slurry As A Mineral Admixture in ConcreteEditor IJTSRDNo ratings yet

- Effect Polypropylene of Fiber On Drying ShrinkageDocument12 pagesEffect Polypropylene of Fiber On Drying ShrinkageHusain Masood ChandharNo ratings yet

- Review File fp-852 5466495740Document6 pagesReview File fp-852 5466495740ahmadNo ratings yet

- Effect of Rice Husk Ash On Lime StabilizationDocument20 pagesEffect of Rice Husk Ash On Lime Stabilizationmyself_07101100% (1)

- 2 11 1619677415 2 11 1618558824 Ijcseierdjun20214Document6 pages2 11 1619677415 2 11 1618558824 Ijcseierdjun20214TJPRC PublicationsNo ratings yet

- By-Vishva R. Patel (120773106044)Document16 pagesBy-Vishva R. Patel (120773106044)ShriNo ratings yet

- Ordinary and Encased Stone Columns at Two Different Relative DensitiesDocument12 pagesOrdinary and Encased Stone Columns at Two Different Relative DensitiesTiến Bách PhạmNo ratings yet

- AN EXPERIMENTAL INVESTIGATION ON THE PERFORMANCE OF BACTERIAL CONCRETE S. N. Priyom1, M. Islam2, and S. Islam3Document7 pagesAN EXPERIMENTAL INVESTIGATION ON THE PERFORMANCE OF BACTERIAL CONCRETE S. N. Priyom1, M. Islam2, and S. Islam3GR DesignsNo ratings yet

- Effect of MMT on bearing capacity of stabilized soilDocument6 pagesEffect of MMT on bearing capacity of stabilized soilLinh GeotechniqueNo ratings yet

- Influence of Milled Waste Glass As Partial Cement Replacement On Durability of Recycled Aggregate Concrete in Sulfate EnvironmentDocument7 pagesInfluence of Milled Waste Glass As Partial Cement Replacement On Durability of Recycled Aggregate Concrete in Sulfate EnvironmentGhislainNo ratings yet

- 153 Ijmperdfeb2018153Document10 pages153 Ijmperdfeb2018153TJPRC PublicationsNo ratings yet

- Paper862782 27861 PDFDocument5 pagesPaper862782 27861 PDFHarshali BhatNo ratings yet

- Ijciet 08 02 035 PDFDocument10 pagesIjciet 08 02 035 PDFIAEME PublicationNo ratings yet

- Soil stabilization using marble dustDocument2 pagesSoil stabilization using marble dustABDIRAHMANNo ratings yet

- Paper 274Document9 pagesPaper 274FikeduNo ratings yet

- Influence of CDW Recycled Aggregate On Drying Shrinkage of MortarDocument5 pagesInfluence of CDW Recycled Aggregate On Drying Shrinkage of MortarJotica SuárezNo ratings yet

- Materials Today: Proceedings: K. Naveen Kumar, D.S. Vijayan, R. Divahar, R. Abirami, C. NivethaDocument5 pagesMaterials Today: Proceedings: K. Naveen Kumar, D.S. Vijayan, R. Divahar, R. Abirami, C. NivethaAnandha SuthanNo ratings yet

- The Effect of Recycled Aggregates On Cre PDFDocument6 pagesThe Effect of Recycled Aggregates On Cre PDFPablo Peña TorresNo ratings yet

- The Effect of Cohesive Soil Depth On Consolidation Coefficient and Compression IndexDocument16 pagesThe Effect of Cohesive Soil Depth On Consolidation Coefficient and Compression IndexMahmoud AtiaNo ratings yet

- Experimental Investigation On Partially Replacement of Cement, Coarse Aggregate by Corn Cob Ash and Steel SlagDocument6 pagesExperimental Investigation On Partially Replacement of Cement, Coarse Aggregate by Corn Cob Ash and Steel SlagIJIRSTNo ratings yet

- Effect of Quarry Dust As Partial Replacement of Sand in ConcreteDocument9 pagesEffect of Quarry Dust As Partial Replacement of Sand in ConcreteSuman VarmaNo ratings yet

- Study On Behaviour of Soil Stabilization With Rice Husk CementDocument15 pagesStudy On Behaviour of Soil Stabilization With Rice Husk Cementvikas chawlaNo ratings yet

- Improving The Performance of Bituminous Concrete Mix by Waste PlasticDocument6 pagesImproving The Performance of Bituminous Concrete Mix by Waste PlasticAfi KhanNo ratings yet

- Performance of Porous Asphalt Affected by Aging ProcessDocument11 pagesPerformance of Porous Asphalt Affected by Aging ProcessDao Phuc LamNo ratings yet

- Effect of Fly AshDocument7 pagesEffect of Fly AshHenryNo ratings yet

- Glass Beads For Use in Pavement Marking PaintsDocument6 pagesGlass Beads For Use in Pavement Marking PaintsSudip MukhopadhyayNo ratings yet

- ASTM D 2171 - 01 (Standard Test Method For Viscosity of Asphalts by Vacuum Capillary Viscometer)Document8 pagesASTM D 2171 - 01 (Standard Test Method For Viscosity of Asphalts by Vacuum Capillary Viscometer)Sudip MukhopadhyayNo ratings yet

- Methodology For Bitumen MasticDocument6 pagesMethodology For Bitumen MasticSudip MukhopadhyayNo ratings yet

- 3.IJPRT-D-19-000046rev (Extraction and Recovery of Asphalt Binder)Document13 pages3.IJPRT-D-19-000046rev (Extraction and Recovery of Asphalt Binder)Sudip MukhopadhyayNo ratings yet

- Adv PART TIME DOCTOR 4.5Document4 pagesAdv PART TIME DOCTOR 4.5Sudip MukhopadhyayNo ratings yet

- 1698curriculum - Vitaé - Atanu PramanikkDocument3 pages1698curriculum - Vitaé - Atanu PramanikkSudip MukhopadhyayNo ratings yet

- Website Advt - No.02 of 2021Document6 pagesWebsite Advt - No.02 of 2021Sudip MukhopadhyayNo ratings yet

- TLE Masonry Nc-Ii: Quarter 1 - Module 2: Lay-Out/establish Brick/block StructureDocument25 pagesTLE Masonry Nc-Ii: Quarter 1 - Module 2: Lay-Out/establish Brick/block StructureKevin John100% (2)

- Tall or Highrise BuildingsDocument35 pagesTall or Highrise Buildingscopy catsNo ratings yet

- U.C.05-HQ-TRE-021 Civil and Structural Design Specification - OnshoreDocument33 pagesU.C.05-HQ-TRE-021 Civil and Structural Design Specification - OnshoreLumy NastaseNo ratings yet

- Types of Dressing & Polishing of Artificial Stones: Building Materials and Construction Assignment OnDocument9 pagesTypes of Dressing & Polishing of Artificial Stones: Building Materials and Construction Assignment OnKasper ProductionsNo ratings yet

- Punchlist Report Phase 2Document3 pagesPunchlist Report Phase 2LouJanisLaudeNo ratings yet

- Operations Management: Unit IiiDocument24 pagesOperations Management: Unit IiiTariq RehmaniNo ratings yet

- Ctoe Case Study: New Balance Athletic Shoe IncDocument12 pagesCtoe Case Study: New Balance Athletic Shoe IncSakshi ShardaNo ratings yet

- Energy saving in buildings using green materialsDocument18 pagesEnergy saving in buildings using green materialsindian royalNo ratings yet

- Procurement Tracking ChartDocument5 pagesProcurement Tracking ChartjayNo ratings yet

- APA - Load-Span Tables Sheathing Panels (2001)Document4 pagesAPA - Load-Span Tables Sheathing Panels (2001)LJD211No ratings yet

- Cold Formed Steel Channel Section DesignDocument62 pagesCold Formed Steel Channel Section DesignNishan GajurelNo ratings yet

- Rectification 4 MH Concrete and Asphalt 2Document4 pagesRectification 4 MH Concrete and Asphalt 2mahesh gowdaNo ratings yet

- Plumbing BOQDocument13 pagesPlumbing BOQPavan GowdaNo ratings yet

- Personal Summary: Sudimara Barat, Ciledug, Tangerang Banten 15151 0823-111-01-333/0858-1021-7814Document2 pagesPersonal Summary: Sudimara Barat, Ciledug, Tangerang Banten 15151 0823-111-01-333/0858-1021-7814heri ahmadiNo ratings yet

- 4239-AA-DC-21U50RN005-IS00 - TCM Check 021122Document1 page4239-AA-DC-21U50RN005-IS00 - TCM Check 021122amitNo ratings yet

- General Logistics ProcedureDocument15 pagesGeneral Logistics Procedurederil100% (1)

- Phoenix Mumbai - Case StudyDocument15 pagesPhoenix Mumbai - Case StudySathya MurthiNo ratings yet

- Prestressed Load Balancing MethodDocument6 pagesPrestressed Load Balancing MethodJay D MercadoNo ratings yet

- The Platina commercial space investment opportunityDocument10 pagesThe Platina commercial space investment opportunityaman3327No ratings yet

- Form release agents, cures, sealers and moreDocument2 pagesForm release agents, cures, sealers and moreMNo ratings yet

- Specification 302 Earthworks PDFDocument50 pagesSpecification 302 Earthworks PDFalejandraoy9No ratings yet

- C4M Aluminium Shuttering Works - Mivan FormworkDocument1 pageC4M Aluminium Shuttering Works - Mivan FormworkAashini Enid ErnestinaNo ratings yet

- Design Calculation of Typical Cantilever RC SlabsDocument14 pagesDesign Calculation of Typical Cantilever RC SlabsAgus CnsNo ratings yet

- Interior Design: Japanese InteriorsDocument11 pagesInterior Design: Japanese InteriorsNishith ReddyNo ratings yet

- BoQ Model For ReservoirDocument41 pagesBoQ Model For ReservoirPo RaksmeyNo ratings yet

- Gangajamuna Rural Municipality: Phulkharka, Dhading Abstract of CostDocument5 pagesGangajamuna Rural Municipality: Phulkharka, Dhading Abstract of CostSujan LamichhaneNo ratings yet

- Foam Concrete PresentationDocument27 pagesFoam Concrete PresentationMuhammad FarooqNo ratings yet

- StructureMag DCA62012 StructuralSpecifications 1704Document4 pagesStructureMag DCA62012 StructuralSpecifications 1704PrateekPokharelNo ratings yet

- Ambo University Hachalu Hundessa Campus: School of Civil and Environmental EngineeringDocument22 pagesAmbo University Hachalu Hundessa Campus: School of Civil and Environmental EngineeringTarekegnNo ratings yet

- Karachi Building Control Authority: Public NoticeDocument2 pagesKarachi Building Control Authority: Public NoticeAbdul Wahab KhanNo ratings yet