Professional Documents

Culture Documents

2010-2020 Nissan March Micra - Front Axle

Uploaded by

Juan Antonio Ochoa Padron0 ratings0% found this document useful (0 votes)

34 views28 pageseje delantero nissan march

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenteje delantero nissan march

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

34 views28 pages2010-2020 Nissan March Micra - Front Axle

Uploaded by

Juan Antonio Ochoa Padroneje delantero nissan march

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 28

TRANSMISSION & DRIVELINE

scoron FAX

FRONT AXLE

CONTENTS

PRECAUTION Removal and Installation see

Disassembly and Assembly oa

PRECAUTIONS Inspection sae VB

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- FRONT DRIVE SHAFT BOOT ..

‘SIONER" ssesse se 2 Exploded View

Precautions for Drive Sha 2

WHEEL SIDE

Precautions for Whe! Hub and Knuckla 2 WHEEL SIDE : Removal and Installation se IB

PREPARATION TRANSAXLE SIDE

PREPARATION 3 TRANSAXLE SIDE ‘Removal and istaaton 18

Special Sorvce Tos "3 Inspection wns senna

Commercial Service Tools ‘4 FRONT DRIVE SHAFT ..

SYMPTOM DIAGNOSIS ed i

Removal and Installation .

NOISE, VIBRATION AND HARSHNESS:

+ WHEEL SIDE

(NVH) TROUBLESHOOTING IDE: Dis fh oe

NVH Troubleshooting Chart WHEEL SIDE : Disassembly and Assembly 2

TRANSAXLE SIDE

PERIODIC MAINTENANCE .. TRANSAXLE SIDE: Disassomby ané Assombiy..29

Inspection o. 26

FRONT WHEEL HUB AND KNUCKLE

Inspection ed

FRONT DRIVE SHAFT

Inspection.

REMOVAL AND INSTALLATION

SERVICE DATA AND SPECIFICATIONS

(SDs)

SERVICE DATA AND SPECIFICATIONS

(SDS)

Wheel Bearing 8

FRONT WHEEL HUB AND KNUCKLE 9 Drive Shaft 8

Exploded View 8

Revision: October 2016 FAX-1 2016 Micra

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" soo

‘The Supplemental Restraint System such as “AIR BAG" and “SEAT BELT PRE-TENSIONER’, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

+ To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, it is recommended that all mainte-

nance and repair be med by an authorized NISSAN/INFINITI dealer.

+ Improper repair, including incorrect removal and installation of the SRS, can lead to personal injury

‘caused by unintentional activation of the system. For removal of Spiral Cable and Ait Bag Module,

see the SR section.

+ Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

+ When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

Ignition ON of engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

+ When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery or batteries, and wait at least three minutes before performing any service.

Precautions for Drive Shaft roe emacs e869

Observe the following precautions when disassembling and assembling drive shatt.

Do not disassemble joint sub-assembly because it is non-overhaul parts.

Perform work in a location which is as dust-free as possible.

Clean the parts, before disassembling and assembling,

Prevent the entry of foreign objects during disassembly of the service location.

Reassemble disassembled parts carefully in the correct order. If work is interrupted, a olean cover must be

placed over parts.

Use paper shop cloths. Fabric shop cloths must not be used because of the danger of lint adhering to parts.

Clean disassembled parts (except for rubber parts) with kerosene which shall be removed by blowing with

air or wiping with paper waste.

Precautions for Wheel Hub and Knuckle rom commevamete

Observe the following precautions when assembling wheel hub and knuckle.

+ Perform work in a location which is as dust-free as possible.

+ Use paper shop cloths. Fabric shop cloths must not be used because of the danger of lint adhering to pars.

+ Many of wheel hub, steering knuckle, wheel bearing, and wheel hub lock nut is dropped, it must not be used.

+ Always check that the tools used for press-fit work of wheel hub and wheel bearing have no wear and defor-

mation so that a pressure can be applied vertically.

Revision: October 2016 FAX-2 2016 Micra

PREPARATION

< PREPARATION >

PREPARATION

PREPARATION

Special Service Tools seooumaacis

‘The actual shape ofthe tools may cfr from those ilustrated here,

“Tool numer Description

(TachMate No)

ool name

i«va0704000 Removing and Instaling whee! hub lock nut

(=) a: 85 mm (3.35 in) id

Hub lock nut wrench bb: 65 mm (2.56 in)

‘8738710000 Removing whee! hub

Cy aa: 30 mm (1.18 in) dia.

rit bb: 23 mm (0.91 in) dia.

‘3790081000 Removing wie! bearing inner race (outer)

oe)

Puller

‘8735321000 + Flemoving wheel bearing

C=) + Instaling wheel hub

Dri aa: 49 mm (1.93 In) dia.

S bb: 41 mm (1.61 in) dia.

‘3798271000 Instaling wheel beating

C=) a: 72 mm (2.83 In) dia.

rit bb: 63 mm (2.48 in) dla,

‘5739061000 Instaling wheel hub

C=) aa: 38 mm (1.50 in) dia,

Dri bi: 28.5 mm (1.122 in) dia

Revision: October 2016 FAX-3, 2016 Micra

PREPARATION

< PREPARATION >

"Tool number Desorption

(Techttate No.)

Tool name

Kv40107300 Instaling boot band

wst75t)

Boot band crimping tool

KVv40107500 Flemoving drive shatt

c— )

Drive shaft attachment

oe

v38107800 Intaling drive shaft

c=) ‘a: 32 mm (1.26 in) i

Difforental side ol seal protector

Commercial Service Tools ey

Tootname Description

Drive shat puller Flomoving drive shaft joint sub assembly

‘Siding harver Removing dive shat

x

aw

Bal int remover Femoving hub bot

Revision: October 2016 FAX-4 2016 Micra

PREPARATION

< PREPARATION >

Tool name Description

Dai * Instaling wheel bearing

+ Instaling splash guard

‘a: 68 mm (2.68 in) dia.

Dai Installing splash guard

2:95 mm (3.74 in) dia.

id

Power tool Loosening nuts, screws and bolts

Revision: October 2016 FAX-5, 2016 Micra

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SYMPTOM DIAGNOSIS >

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

Use chart below to nd the cause ofthe symptom. It necessary, repair or replace these pats.

¥

Reterence efi lala Hh

o ql

5

g z

2 so 8

Possible cause and SUSPECTED PARTS 3 e582 |

5 $2 P64 ge

g 52ie2 g5 8

4 Se E ER guile &

5 PEPE Ee slg E

a Eecs & Ce 6/5 o

Dave [Noise x ebeLe el x

‘SHAFT ‘Shake x xx x

Noise ep [expe

Shake =D» x[xixfel x

Symetom

Front | Vibration =eleleL el lett

AXLE ‘Shimmy x x x

shudder x ell

Por ualy rie or haning x[» x

hppieabe

Revision: October 2016

FAX-6 2016 Micra

FRONT WHEEL HUB AND KNUCKLE

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

FRONT WHEEL HUB AND KNUCKLE

Inspection seooumaacis

COMPONENT PART

Check that the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are normal,

WHEEL BEARING

Check the following items, and replace the part if necessary.

+ Move wheel hub and wheel bearing in the axial direction by hand. Check there is no looseness of wheel

bearing.

Axial end play + Refer to FAX-28, "Wheel Bearing”,

+ Rotate wheel hub and wheel bearing and check there is no unusual noise or other irregular conditions. If

there is any of irregular conditions, replace wheel bearing.

Revision: October 2016 FAX-7 2016 Micra

FRONT DRIVE SHAFT

< PERIODIC MAINTENANCE >

FRONT DRIVE SHAFT

Inspection

Check the following items, and replace the part if necessary.

+ Check drive shaft mounting point and joint for looseness and other damage,

CAUTION:

Replace entire drive shaft assembly when noise or vibration occurs from drive shaft.

+ Check boot for cracks and other damage.

Revision: October 2016 FAX-8 2016 Micra

FRONT WHEEL HUB AND KNUCKLE

< REMOVAL AND INSTALLATION >

REMOVAL AND INSTALLATION

FRONT WHEEL HUB AND KNUCKLE

Exploded View soos

‘SEC. 440-440

5,2

SN

>) PP

00

/

1. Steering knuckle 2 Splash guard 3. Wheel beating

4 Snap rng 5. Hub bot 6. Wheel hub

7. Dise rotor 8. Whoo! hub lock nut 8. Cotter pin

Removal and Installation scorn 21621

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-7. "Removal and installation".

2. Remove wheel sensor from steering knuckle. Refer to BRO-139, "FRONT WHEEL SENSOR : Removal

‘and Installation”.

CAUTION:

Do not pull on wheel sensor harness.

Remove lock plate from strut assembly. Refer to ol

4. Remove caliper assembly. Hang caliper assembly not t0 interfere with work. Refer to BR:40, “BRAKE

s

CALIPER ASSEMBLY : Removal and install

CAUTION:

Do not depress brake pedal while brake caliper is removed.

Revision: October 2016 FAX-9, 2016 Micra

FRONT WHEEL HUB AND KNUCKLE

5, Remove disc rotor.

CAUTION:

* Put matching marks (A) on the wheel hub and the disc

rotor before removing the disc rotor.

+ Donot drop

6. Remove cotter pin, and then loosen wheel hub lock nut, using

Too! (A).

Tool number (A): KV40104000( — )

7. Patch wheel hub lock nut with a piece of wood. Hammer the

‘wood to disengage wheel hub from drive shaft

CAUTION:

+ Do not place drive shaft joint at an extrem

careful not to overextend slide joint.

not allow drive shaft to hang down without support for

joint sub-assembly, shaft and the other parts.

NoTt

Use suitable puller, if whee! hub and drive shaft cannot be sepa-

rated even after performing the above procedure.

8, Remove wheel hub lock nut.

9, Remove steering outer socket from steering knuckle. Refer to

‘ST-15, "Removal and Installation’.

ingle. Also be

10. Remove steering knuckle from strut assembly. Refer to FSU-9, "Removal and Installation".

11. Suspend the drive shaft with suitable wire.

12. Remove steering knuckle from transverse link.

13. Remove hub bolts (1) from whee! hub, using suitable tool (A).

CAUTION:

+ Remove hub bolt only when necessary.

+ Do not hammer the hub bolt to avoid Impact to the wheel

bearing.

+ Pull out the hub bolt in a direction perpendicular to the

wheel hub.

14. Perform inspection after removal. Refer to FAX-13, "Inspectios

INSTALLATION

Installation is in the reverse order of the removal.

CAUTION:

+ During the installation, do not damage the wheel bearing seal by shock. If shocked, replace wheel

bearing with a new one.

Revision: October 2016 FAX-10

2016 Micra

FRONT WHEEL HUB AND KNUCKLE

< REMOVAL AND INSTALLATION >

* Do not allow paint to adhere to the wheel bearing seal.

+ Check each mounting surface for water and foreign matter. If there is any water or foreign matter,

clean the mounting surface.

Place a washer (A) as shown to install the hub bolts (1) by using

‘he tightening force of the nut (B).

CAUTION:

* Check that there is no clearance between wheel hub, and

hub bolt.

+ Do not reuse hub bolts.

Do not reuse steering knuckle and transverse link fixing nut.

Clean the matching surface of wheel hub lock nut and wheel hub.

CAUTION:

Do not apply lubricating oil to these matching surface.

Clean the matching surface of drive shaft, wheel hub, and wheel

bearing. And then apply paste [service parts (440037S000)] to sur-

face (A) of joint sub-assembly of drive shat.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assembly il

of drive shaft, OL (i

Amount paste 1.0 3.0.g (0.04 - 0.10 02) S34

+ Tighten the wheel hub lock nut to the specified torque. —)

CAUTION: =

+ Since the drive shaft is assembled by press- = osm

tightening torque range for the wheel hub lock nut.

+ Be sure to use torque wrench to tighten the wheel hub lock nut. Do not use a power tool.

+ Do not reuse wheel hub lock nut.

Align the matching marks that have been made during removal when reusing the disc rotor.

Perform the final tightening of each of parts under unladen conditions, which were removed when removing

Wheel hub and steering knuckle.

When installing a cotter pin, securely bend the basal portion to prevent rattles,

CAUTION:

Do not reuse cotter pin.

+ Perform inspection after installation, Refer to FAX-13, "Inspection",

Disassembly and Assembly soouaat

DISASSEMBLY

1. Remove wheel hub using Tool.

Tool number: $T33710000( — )

2. Remove splash guard from steering knuckle.

Revision: October 2016 FAX-11 2016 Micra

FRONT WHEEL HUB AND KNUCKLE

3. Remove wheel bearing inner race (outer side) from wheel hub

using Tools,

397 oan

Tool number: ST33710000( —

)

Tool number :$T30031000( — ) -

4, Remove snap ring from steering knuckle using suitable tool.

CAUTION:

Do not damage steering knuckle,

5. Remove wheel bearing from steering knuckle using Too}.

Tool number: ST35321000( — )

ASSEMBLY

1. Install whee! bearing to steering knuckle, using Tool (A) and suit

able tool (B).

Z.

Tool number (A) :ST35271000( — ) J aL °

CAUTION: 2 ©

+ Do not reuse wheel bearing. AZ

+ Do not apply a cleaning agent or anticorrosive to the

mounting surface of the wheel bearing of steering

knuckle.

+ Set steering knuckle and wheel bearing horizontally and

insert them vertically.

load must be applied to the wheel bearing

and the steering knuckle

+ Do not apply press-fit load to the wheel bearing inner race, the seals (C and D). Ifa press-fit load

is applied, the wheel bearing must be replaced with a new one.

+ Wheel bearing press-fit load must be 49 KN (5,000 kg, 11,015 Ib).

2. Install snap ring to steering knuckle.

CAUTION:

+ Do not damage the wheel bearing seal.

+ The allowance of all around the snap ring must be equal.

Revision: October 2016 FAX-12 2016 Micra

FRONT WHEEL HUB AND KNUCKLE

3. Press splash guard (1) with suitable tools (A and 8) all the way

to the steering knuckle,

CAUTION:

Do not reuse splash guard.

4, Install wheel hub, using Tools (A and B).

Tool number (A): ST33061000( — )

(8): ST35321000( — )

CAUTION:

* Do not apply lubricating oil to the press-fit surface of the

wheel hub bearing.

+ Set wheel hub and wheel bearing horizontally and insert

them vertically.

+ The press-fit load must be applied to the wheel hub and

the whee! beari

+ Do not apply press-fit load to the steering knuckle and the wheel bearing, the seal. Ifa press-fit

load is applied, the wheel bearing must be replaced with a new one.

+ Apply a press-fit load of 49 kN (5,000 kg, 11,015 Ib) and maintain the loaded state for 30 seconds.

+ If the inserted wheel hub is removed again, the wheel bearing must be replaced with a new one.

5. Perform inspection after assembly. Refer to FAX-13, "Inspection".

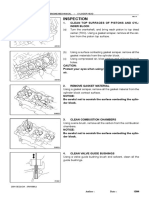

Inspection soon)

INSPECTION AFTER REMOVAL

Check the following items, and replace the part if necessary.

* Check components for deformation, cracks, and other damage.

* Check boots of transverse link and steering outer socket ball joint for breakage, axial end play, and swing

torque. Refer to FSU-10, "Inspection" and ST-16, "inspection".

INSPECTION AFTER DISASSEMBLY

Wheel Hub

* Check whee! hub for cracks (with magnetic exploration or dye testing). Replace if necessary.

‘Steering Knuckle

* Check steering knuckle for deformation, cracks, and other damage. Replace if any non-standard conditions

are found,

‘Snap Rings

* Check snap ring for wear or cracks, Replace if necessary.

INSPECTION AFTER ASSEMBLY

Check wheel bearing rotating torque as per the following instructions.

NOTE:

The adequacy of turning torque can be judged from a measurement value by a spring balancer.

1. For a proper fit of the bearing, turn the wheel hub both clockwise and counterclockwise, respectively, 10

times or more with a press-fit load of 34,300 to 49,000 N (3,500 to 4,998 kg, 7,710 to 11,015 Ib) applied.

Revision: October 2016 FAX-13 2016 Micra

FRONT WHEEL HUB AND KNUCKLE

2. Set a spring balance on strut mounting hole (upper). Measure

rotating torque at an rpm of 8 - 12 rpm.

Rotating torque: Refer to EAX-28, "Wheel Bearing".

Spring balance: Refer to FAX-28, "Wheel Bearing".

measurement

+ If the turning torque cannot be obtained by the above method,

measure the torque, according to the instructions below.

+ Install drive shaft and tighten the hub lock nut to the specified

torque. Rotate the wheel hub to fit property.

Set a spring balancer to the hub bolt and measure turning torque

at turning speeds of 8 to 12 rpm.

Rotating torque 11,90 Nem (0.19 kg-m, 16.82 in-Ib) or less

Spring balance measurement —_—: 38.0 N (3.87 kg, 8.54 Ib) or less

INSPECTION AFTER INSTALLATION

Check the wheel alignment. Refer to FSU-7, "Inspection".

Revision: October 2016 FAX-14

2016 Micra

FRONT DRIVE SHAFT BOOT

< REMOVAL AND INSTALLATION >

FRONT DRIVE SHAFT BOOT

Exploded View

LH

10.

a

RH

SEC. 391

Circular cip

Snap ring

Boot

Dynamic damper

Wheo! side

2. Dust shield 3.

5. Spider assembly 6

Shaft

11. Circular ip 12.

Fill NISSAN Genuine grease or equivalent.

Housing

Boot band

Damper band

Joint sub-assombly

SEC. 391

Joint suo-assembly

Boot

Dynamic damper

Housing

Revision: October 2016

Circular ep 3

5. Shaft 6.

8. Spider assembly 8

11. Dust shield 12.

FAX-15,

Boot band

Damper band

Snap ring

Circular lip

2016 Micra

FRONT DRIVE SHAFT BOOT

<2 Weel side

EES Fl NISSAN Genuine grease or equivalent

WHEEL SIDE

WHEEL SIDE : Removal and Installation wrote emacs

REMOVAL,

1, Remove wheel and tire using power tool. Refer to WT-7, "Removal and Installation’.

2. Remove wheel sensor from steering knuckle. Refer to BRC-139, "FRONT WHEEL SENSOR : Removal

CAUTION

Do not pull on wheel sensor harness.

3, Remove lock plate from strut assembly. Refer to FSU-9, "Removal and Installation".

4, Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-40, "BRAKE

CALIPER ASSEMBLY : Removal and Installation’.

CAUTION:

Do not depress brake pedal while brake caliper is removed.

5, Remove disc rotor. Refer to FAX-9, "Removal and Installation",

Remove cotter pin, and then loosen wheel hub lock nut. Refer to FAX-9, "Removal and installation.

7. Patch whee! hub lock nut with a piece of wood. Hammer the wood to disengage wheel hub from drive

shaft.

CAUTION:

+ Do not place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

+ Do not allow drive shaft to hang down without support for joint sub-assembly, shaft and the

other parts.

NOTE:

Use suitable pull, if wheel hub and drive shaft cannot be separated even after performing the above pro-

cedure.

8, Remove wheel hub lock nut.

9, Remove strut assembly from steering knuckle, Refer to " .

10, Remove drive shaft from wheel hub.

11, Remove boot bands, and then remove boot from joint subassembly.

12. Screw suitable tool (A) into joint sub-assembly screw part to a

length of 30 mm (1.18 in) or more. Support drive shaft with one

hand and pull out joint sub-assembly from shatt.

CAUTION:

+ Align drive shaft puller and drive shaft and remove them

by pulling firmly and uniformly.

+ If joint sub-assembly cannot be pulled out, try after

removing drive shaft from vehicle. Refer to FAX-21

“WHEEL SIDE : Disassembly and Assembly”.

13. Remove circular clip from shaft \~

14. Remove boot from shaft.

INSTALLATION

1. Clean the old grease on joint sub-assembly with paper waste.

2, Fill serration slot joint sub-assembly with NISSAN genuine grease or equivalent until the serration slot and

ball groove become full to the brim.

CAUTION:

After applying grease, use a paper waste to wipe off old grease that has oozed out.

3. Install boot and boot bands to shaft

CAUTION:

+ Wrap serration on shaft with tape to protect the boot from damage.

+ Do not reuse boot and boot band.

4, Remove the tape wrapped around the serration on shaft

Revision: October 2016 FAX-16 2016 Micra

FRONT DRIVE SHAFT BOOT

'5. Position the circular clip on groove at the shaft edge.

CAUTION:

Do not reuse circular clip.

NOTE:

Drive joint inserter is recommended when installing circular clip,

6. Align both center axles of the shaft edge and joint sub-assembly. Then assemble shaft with joint sub-

assembly holding circular clip.

7. Install joint sub-assembly (1) to shaft using plastic hammer.

CAUTION:

Confirm that joint sub-assembly is correctly engaged while

rotating drive shaft.

8. Apply the specified amount of grease into the boot inside from

large diameter side of boot,

Grease amount _: Refer to FAX-28, "Drive Shaft".

9. Install the boot securely into grooves (indicated by “*" marks) as

shown.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on the shaft or joint sub-assembly, boot may

be removed. Remove all grease from the boot mounting

surface.

10. To prevent the deformation of the boot, adjust the boot installa-

tion length (L) to the specified value shown below by inserting

the suitable tool into inside of the boot from the large diameter S

side of the boot and discharging the inside ai. —

(Ll) : Refer to FAX-28, "Drive Shaft".

CAUTION:

+ If the boot installation length exceeds the standard, it may cause breakage of the boot.

+ Be careful not to touch the inside of the boot with a tip of tool.

11, Secure the large and small ends of the boot with boot bands

using Too! (A).

Tool number (A): KV40107300 (J-51751)

CAUTION:

+ Do not reuse boot band.

+ Secure boot band so that dimension (M) meets th

fication as shown.

(M):1.0- 4.0 mm (0.039 - 0.157 in)

12, Secure joint sub-assembly and shaft, and then check that they

are in the correct position when rotating boot. Reinstall them

using boot bands when boot installation positions become incor-

rect, M

CAUTION:

Do not reuse boot band.

Revision: October 2016 FAX-17 2016 Micra

FRONT DRIVE SHAFT BOOT

< REMOVAL AND INSTALLATION >

73. Clean the matching surface of wheel hub lock nut and wheel hub.

CAUTION:

Do not apply lubricating oil to these matching surface.

14. Clean the matching surface of drive shaft, wheel hub, and wheel

bearing. And then apply paste [service parts (440037S000)] to

surface (A) of joint sub-assembly of drive shaft.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assem-

bly of drive shaft.

Amount paste —_—: 1.0- 3.0 (0.04-0.10 02)

15. Insert drive shaft to wheel hub, and then temporarily tighten

‘wheel hub lock nut

CAUTION:

+ Do not reuse wheel hub lock nut.

+ During the installation, do not damage the wheel bearing seal by shock. If shocked, replace

wheel bearing with a new one.

+ Do not allow paint to adhere to the wheel bearing seal.

+ Check each mounting surface for water and foreign matter, If there is any water or foreign mat-

ter, clean the mounting surface.

+ Be sure to use torque wrench to tighten the wheel hub lock nut. Do not use a power tool.

16. Install strut assembly to steering knuckle. Refer to FSU-9, "Removal and installation’

17. Install dise rotor.

18. Install caliper assembly to steering knuckle. Refer to "BRAKE CALIPER ASSEMBLY : Removal

Do not depress brake pedal while brake caliper is removed.

19. Install lock plate to strut assembly. Refer to BR-26, "FRONT : Removal and Installation’.

20. Install wheel sensor and sensor harness. Refer to BRO-139, "FRONT WHEEL SENSOR : Removal and

Installation’.

Use the following torque for tightening the wheel hub lock nut.

Tightening torque _: Refer to FAX-9, "Exploded View".

CAUTION:

+ Be sure to use torque wrench to tighten the wheel hub lock nut. Do not use a power tool.

+ Do not reuse wheel hub lock nut.

22. When installing a cotter pin, securely bend the basal portion to prevent rattles.

CAUTION:

Do not reuse cotter pin.

23. Install wheel and tire. Refer to WT-7. "Removal and Installation’.

24. Perform inspection after installation. Refer to FAX-18, "Inspection’.

TRANSAXLE SIDE

TRANSAXLE SIDE : Removal and Installation roe emacs ee8

21

Remove boot after drive shaft is removed from the vehicle.

+ For drive shatt removal and installation, refer to FAX-20, "Removal and Installation’.

+ For drive shatt disassembly and assembly, refer to FAX-23, "TRANSAXLE SIDE : Disassembly and Assem-

bly".

Inspection roe cinc meer

INSPECTION AFTER INSTALLATION

Check the wheel alignment. Refer to FSU-7, "Inspection".

Revision: October 2016 FAX-18 2016 Micra

FRONT DRIVE SHAFT

< REMOVAL AND INSTALLATION >

FRONT DRIVE SHAFT

Exploded View nwovoorencscaiees

LH

SEC. 391

1. Giroular ip 2. Dust shield 3. Housing

4. Snap ring 5. Spider assembly 6. Boot band

7. Boot 8. Shaft 8. Damper band

10. Dynamic damper 11. Circular ip 12, Joint sub-assembly

<2 Whee! side

Fill NISSAN Genuine grease or equivalent.

RH

SEC. 391

1. doint suo-assembly 2 Cireular clip 3. Boot band

4. Boot 5. Shaft 6. Damper band

7. Dynamic damper 8. Spider assembly 9. Snap ring

10. Housing 11. Dust shield 12, Circular ip

Revision: October 2016 FAX-19 2016 Micra

FRONT DRIVE SHAFT

<2 Weel side

EES Fl NISSAN Genuine grease or equivalent

Removal and Installation wrooceronemiter

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-7, "Removal and installation’.

2, Remove wheel sensor from steering knuckle. Refer to BRC-139, "FRONT WHEEL SENSOR : Removal

and Installation",

CAUTION:

Do not pull on wheel sensor harness,

3, Remove lock plate from strut assembly. Refer to FSU-9, "Removal and installation’.

4, Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-40, "BRAKE

CALIPER ASSEMBLY : Removal and Installation’.

CAUTION:

Do not depress brake pedal while brake caliper is removed.

5, Remove disc rotor.

Remove cotter pin, and then loosen wheel hub lock nut. Refer to FAX-9, "Removal and installation.

7. Patch whee! hub lock nut with a piece of wood. Hammer the wood to disengage wheel hub from drive

shaft.

CAUTION:

+ Do not place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

+ Do not allow drive shaft to hang down without support for joint sub-assembly, shaft and the

other parts.

NOTE:

Use suitable pull, if wheel hub and drive shaft cannot be separated even after performing the above pro-

cedure.

8, Remove wheel hub lock nut.

9, Remove strut assembly from steering knuckle, Refer to " i.

10. Remove drive shatt from wheel hub.

11. Use Tool (A) and a suitable tool (B) while inserting tip of the drive

shaft attachment between shaft and transaxle assembly, and

then remove drive shaft trom transaxle assembly.

Tool number (A): KV40107500( — )

CAUTION:

+ Do not place drive shaft joint at an extreme angle when

removing drive shaft. Also be careful not to overextend

slide joint.

+ Confirm that the circular clip Is attached to the drive shaft.

12. Perform inspection after removal. Refer to FAX-26, “Inspection”. Sent

INSTALLATION

Note the following, and install in the reverse order of removal.

Transaxle Side

+ Always replace differential side oil seal with new one when installing drive shaft.

~ MIT: Refer to TM-19, "Removal and Installation".

- ATT: Refer to TM-287, "Removal and Installation’.

Revision: October 2016 FAX-20 2016 Micra

FRONT DRIVE SHAFT

< REMOVAL AND INSTALLATION >

* Place Too! (A) onto transaxle assembly to prevent damage to the

oll seal while inserting drive shaft. Slide rive shatt sliding joint and

tap with a hammer to install securely.

Tool number (A): KV38107900( — )

CAUTION:

Check that circular clip is completely engaged.

tallation, do not damage the wheel bearing seal by shock. If shocked, replace wheel

bearing with a new one.

+ Do not allow paint to adhere to the wheel bearing seal.

+ Check each mounting surface for water and foreign matter. If there is any water or foreign matter,

clean the mounting surface.

+ Clean the matching surface of wheel hub lock nut and wheel hub.

CAUTION:

Do not apply lubricating oil to these matching surface.

+ Clean the matching surface of drive shaft, wheel hub, and wheel

bearing. And then apply paste [service parts (440037S000)] to sur-

face (A) of joint sub-assembly of drive shaft.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assembly

of drive shaft.

Amount paste .0 - 3.0 g (0.04 0.10 02)

+ Use the following torque for tightening the wheel hub lock nut.

Tightening torque _: Refer to FAX-9, "Exploded View". aca

CAUTION:

+ Be sure to use torque wrench to tighten the wheel hub lock nut. Do not use a power tool.

+ Do not reuse wheel hub lock nut.

Perform the final tightening of each of parts under unladen conditions, which were removed when removing

whee! hub and steering knuckle

When installing a cotter pin, securely bend the basal portion to prevent rattles,

CAUTION:

Do not reuse cotter pin.

+ Perform inspection after installation. Refer to FAX:26, "Inspection!

WHEEL SIDE

WHEEL SIDE : Disassembly and Assembly ro erect a699

DISASSEMBLY

1. Fix shaft with a vise.

‘CAUTION:

Protect shaft when fixing with a vise using aluminum or copper plates.

2. Remove boot bands, and then remove boot from joint sub-assembly.

Revision: October 2016 FAX-21 2016 Micra

FRONT DRIVE SHAFT

3. Screw drive shaft puller (A) (commercial service tool) into joint

sub-assembly screw part to a length of 90 mm (1.18 in) or more,

Support drive shaft with one hand and pull out joint sub-assem-

bly trom shatt.

CAUTION:

+ Align drive shaft puller and drive shaft and remove them

by pulling firmly and uniformly.

+ If joint sub-assembly cannot be removed after five or

more unsuccessful attempts, replace shaft and joint sub

assembly as a set.

4, Remove circular clip from shatt.

5, Remove boot from shaft.

6. Perform inspection after disassembly. Refer to FAX-26. "Inspection".

ASSEMBLY

1. Clean the old grease on joint sub-assembly with paper waste.

2. Fill serration slot joint sub-assembly (1) with NISSAN genuine

grease or equivalent until the serration slot and ball groove

become full to the brim.

CAUTION:

After applying grease, use a paper waste to wipe off old

grease that has oozed out.

3, Install boot and boot bands to shaft,

CAUTION:

+ Wrap serration on shaft with tape (A) to protect the boot

from damage.

+ Do not reuse boot and boot band.

4, Remove the tape wrapped around the serration on shaft.

5. Position the circular clip (1) on groove at the shaft edge.

CAUTION:

Do not reuse circular clip.

NoTt

Drive joint inserter is recommended when installing circular clip.

6. Align both center axles of the shatt edge and joint sub-assembly.

Then assemble shaft with joint sub-assembly holding circular

clip.

Revision: October 2016 FAX-22

®

Prom

2016 Micra

FRONT DRIVE SHAFT

< REMOVAL AND INSTALLATION >

7.

10.

1"

12

Install joint sub-assembly to shaft using plastic hammer.

CAUTION:

~ Check circular clip is properly positioned on groove of the

joint sub-assembly.

+ Confirm that joint sub-assembly is correctly engaged

while rotating drive shaft.

Apply the specified amount of grease into the boot inside from

large diameter side of boot,

Grease amount + Refer to FAX-28, "Drive Shaft".

Install the boot securely into grooves (indicated by “** marks) as

shown,

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on the shaft or joint sub-assembly, boot may

be removed. Remove all grease from the boot mounting

surface,

‘To prevent the deformation of the boot, adjust the boot installa-

tion length (L) to the specified value shown below by inserting

the suitable tool into inside of the boot from the large diameter

side of the boot and discharging the inside ai.

(Ll): Refer to FAX-28, "Drive Shaft".

CAUTION:

+ Ifthe boot installation length exceeds the standard, it may cause breakage of the boot.

+ Be careful not to touch the inside of the boot with a tip of tool.

‘Secure the large and small ends of the boot with boot bands

using Too! (A).

Tool number: KV40107300 (J-51751)

CAUTION:

+ Do not reuse boot bands.

+ Secure boot band so that dimension (M) meets the

fication as shown.

(M): 1.04.0 mm (0.039 - 0.157 in)

Secure joint sub-assembly and shaft, and then check that they

are in the correct position when rotating boot. Reinstall them

using boot bands when boot installation positions become incor-

rect,

CAUTION:

Do not reuse boot bands.

TRANSAXLE SIDE

TRANSAXLE SIDE : Disassembly and Assembly

DISASSEMBLY

1

Fix shaft with a vise.

Revision: October 2016 FAX-23

2016 Micra

FRONT DRIVE SHAFT

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vist

2, Remove boot bands, and then remove boot from housing.

3, Put matching marks on housing and shaft, and then pull out housing from shaft.

CAUTION:

Use paint or an equivalent for matching marks. Do not scratch the surfaces.

4, Put matching marks (A) on the spider assembly and shaft.

CAUTION:

Use paint or an equivalent for matching marks. Do not

scratch the surfaces.

5, Remove snap ring (1), and then remove spider assembly from

shaft.

6. Remove boot from shaft.

7. Remove dust shield from housing.

8, Remove citcular clip from housing.

9, Clean old grease on housing with paper towels.

10. Remove damper bands, then remove dynamic damper from

shaft.

11. Perform inspection after disassembly. Refer to FAX-26, "Inspec:

tion".

ASSEMBLY

1. Install dynamic damper, follow the procedure described below.

a. Install dynamic damper to shaft.

b. Secure dynamic damper with boot bands in the following speci-

fied position (A) when installing.

CAUTION:

Do not reuse boot bands.

(A): Refer to FAX-28, "Drive Shaft",

2, Install new boot and boot bands to shaft.

CAUTION:

+ Wrap serration on shaft with tape (A) to protect boot from

damage.

+ Do not reuse boot and boot bands.

8, Remove the tape wrapped around the serration on shaft.

Revision: October 2016 FAX-24

2016 Micra

FRONT DRIVE SHAFT

< REMOVAL AND INSTALLATION >

4. To install the spider assembly (1), align it with the matching

‘marks (A) on the shaft (2) during the removal, and direct the ser-

ration mounting surface (B) to the shaft.

5. Secure spider assembly onto shaft with snap ring (1)

CAUTION:

Do not reuse snap ring.

6. Apply the appropriate amount of grease to spider assembly and

sliding surface.

7. Assemble the housing onto spider assembly, and apply the bal-

ance of the specified amount grease.

Grease amount + Refer to FAX-28, "Drive Shaft".

8. Align matching marks put during the removal of housing,

9. Install boot securely into grooves (indicated by “” marks) as

shown.

CAUTION:

If grease adheres to the boot mounting surface (with “*”

mark) on shaft or housing, boot may be removed. Remove

all grease from the surface.

10. To prevent the deformation of the boot, adjust the boot installa

tion length to the value shown below (L} by inserting the suitable

tool into the inside of boot from the large diameter side of boot

and discharging inside air.

(L)_ + Refer to FAX:28, "Drive Shaft",

CAUTION:

.—__1___]*

+ If the boot installation length exceeds the standard, it may cause breakage of the boot.

+ Be careful not to touch the

11. Install large and smaller boot bands securely.

CAUTION:

Do not reuse boot bands.

For tow profile type band

Put boot band in the groove on drive shaft boot. Then fit

awis (4) into holes to temporary installation.

NOTE:

For the large diameter side, fit projection (A) and guide slit

(8) at frst.

Revision: October 2016 FAX-25

je of the boot with the tip of tool.

2016 Micra

FRONT DRIVE SHAFT

2. Pinch projection on the band with suitable pliers to tighten |—

band,

3. Insert the tip of band into the lower part of pawl (marked

with dotted circle) as shown.

For crimping type band

+ Secure the boot with boot bands using Too! (A).

Tool number (A): KV40107300 (J-51751)

CAUTION:

‘Secure boot band so that dimension (A) meets the specifi-

cation as shown.

(A) :7.0 mm (0.276 in) or less.

42. Secure housing and shaft, and then check that they are in the

correct position when rotating boot. Reinstall them using boot

bands when boot installation positions become incorrect.

CAUTION:

Do not reuse boot bands.

13. Install dust shield, a

CAUTION:

Do not reuse dust shield.

414. Install circular clip to housing.

CAUTIOI

Do not reuse circular clip.

Inspection osama

INSPECTION AFTER REMOVAL

Check the following items, and replace the parti necessary.

+ Move joint up/down, leftright, and in the axial directions. Check for motion that is not smooth and for signif-

cant looseness.

+ Check boot for cracks, damage, and leakage of grease.

INSPECTION AFTER DISASSEMBLY

Check the following items, and replace the part if necessary.

Shaft

Check shaft for runout, cracks, or other damage.

Dynamic Damper

Check damper for cracks or wear.

Joint Sub-Assembly (Wheel Side)

Revision: October 2016 FAX-26 2016 Micra

FRONT DRIVE SHAFT

‘Check the following:

+ Joint sub-assembly for rough rotation and excessive axial looseness.

+ The inside of the joint sub-assembly for entry of foreign material.

+ Joint sub-assembly for compression scars, cracks, and fractures inside of joint sub-assembly.

Replace joint sub-assembly if there are any non-standard conditions of components.

Housing and spider assembly (Transaxle Side)

Replace housing and spider assembly if there is scratching or wear of housing roller contact surface or spider

roller contact surface,

NOTE:

Housing and spider assembly are used in a set.

INSPECTION AFTER INSTALLATION ana

Check the wheel alignment. Refer to FSU-7, "Inspection’

Revision: October 2016 FAX-27 2016 Micra

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Bearing

Tom Sadana

Taal ond pay TS (0.002 rs

Aang tous 1.8m (18m, 17 vores

Spring balance measurement 12.7 N (140 2.0 barons

Drive Shaft son

HRI6DE

Sard

tom

wr | wr

Wheol ade 30= 1009 17-955

Grease quanity

Tanaal i 1927-1487 9 (668-5240) | 141.1187. 9498-85402

Wheel ce 136.8 mem 6.39 125.5 mm (35

ita

Boots instalieg lenght Transaxle side 145.5 mm (6.73 in) 154.0 mm (6.06 in)

- Le sise 267 ~ 243 mm (959-957 n)

Dimorslon of dynamic damper

" per Right side 454 — 460 mm (17.87 — 18.11 in)

*: For measuring position, refer to FAX-21, "WHEEL SIDE : Disassembly and Assembly” (Wheel side), FAX-

23, "TRANSAXLE SIDE : Disassembly and Assembly" (Transaxle side).

Revision: October 2016

FAX-28

2016 Micra

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Engine Controls and Fuel (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairP0507Document4 pagesEngine Controls and Fuel (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairP0507Juan Antonio Ochoa PadronNo ratings yet

- 6T30 - 6T40 - 6T45 - Automatic TransmissionDocument6 pages6T30 - 6T40 - 6T45 - Automatic TransmissionJuan Antonio Ochoa PadronNo ratings yet

- Ignition System, Knock Sensor (Powertrain Management) - ALLDATA RepairDocument1 pageIgnition System, Knock Sensor (Powertrain Management) - ALLDATA RepairJuan Antonio Ochoa PadronNo ratings yet

- P0336 (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairDocument3 pagesP0336 (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairJuan Antonio Ochoa PadronNo ratings yet

- Ubicacion RelayDocument1 pageUbicacion RelayJuan Antonio Ochoa PadronNo ratings yet

- DatalineDocument1 pageDatalineJuan Antonio Ochoa PadronNo ratings yet

- Starting - Charging - Starting Circuit (Starting and Charging) - ALLDATA RepairDocument2 pagesStarting - Charging - Starting Circuit (Starting and Charging) - ALLDATA RepairJuan Antonio Ochoa PadronNo ratings yet

- Fuse Panel (Fuse) - ALLDATA RepairDocument1 pageFuse Panel (Fuse) - ALLDATA RepairJuan Antonio Ochoa PadronNo ratings yet

- Anti-Theft (Antitheft and Alarm Systems) - ALLDATA RepairDocument1 pageAnti-Theft (Antitheft and Alarm Systems) - ALLDATA RepairJuan Antonio Ochoa PadronNo ratings yet

- Modulo DisDocument1 pageModulo DisJuan Antonio Ochoa PadronNo ratings yet

- TERECMDocument2 pagesTERECMJuan Antonio Ochoa PadronNo ratings yet

- INSTDocument13 pagesINSTJuan Antonio Ochoa PadronNo ratings yet

- 2010-2020 Nissan March Micra - LAN SystemDocument68 pages2010-2020 Nissan March Micra - LAN SystemJuan Antonio Ochoa PadronNo ratings yet

- Camshaft GearDocument10 pagesCamshaft GearJuan Antonio Ochoa PadronNo ratings yet

- DiagramaDocument4 pagesDiagramaJuan Antonio Ochoa PadronNo ratings yet

- TIS - Scion 2006 Xa RepairDocument5 pagesTIS - Scion 2006 Xa RepairJuan Antonio Ochoa PadronNo ratings yet

- DTC P0100 Mass or Volume Air Flow Circuit DTC P0102 Mass or Volume Air Flow Circuit Low Input DTC P0103 Mass or Volume Air Flow Circuit High InputDocument8 pagesDTC P0100 Mass or Volume Air Flow Circuit DTC P0102 Mass or Volume Air Flow Circuit Low Input DTC P0103 Mass or Volume Air Flow Circuit High InputJuan Antonio Ochoa PadronNo ratings yet

- Reglaje de ValvulasDocument15 pagesReglaje de ValvulasJuan Antonio Ochoa PadronNo ratings yet